Acrylic structural adhesives are versatile and used in many industries due to their fast-paced technology. In this blog article, we will discuss the new developments and uses of ZDS Chemical’s acrylic adhesives.

Technological Advancements

Acrylic structural adhesives have improved a lot in recent years. They work better and can be used in more ways. Some notable developments include:

Improved Bonding Strength

Manufacturers are constantly striving to enhance the bonding strength of acrylic structural adhesives. New formulas have been created through research, making stronger bonds even in tough conditions.

Quick Curing Formulas

Time plays a crucial role in many industries, and adhesive manufacturers have taken note of this demand. The newest acrylic glues dry quickly, saving time and keeping a strong hold.

Increased Temperature Resistance

Acrylic structural adhesives now have increased temperature resistance for extreme environments in industries. These advanced formulations ensure durability and stability even in high-temperature applications.

Innovative Application Cases

The versatility of acrylic structural adhesives has led to their adoption in a wide range of industries. Let’s explore some innovative application cases where these adhesives have proven their effectiveness:

Automotive Industry

Acrylic structural adhesives are extensively used in automotive assembly processes. These adhesives are great for joining different parts, like panels and trim, making them strong and light.

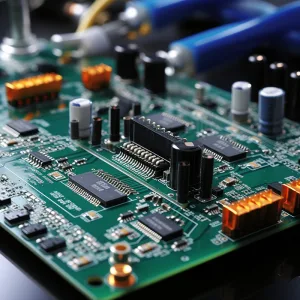

Electronics

Acrylic structural adhesives are important in making small electronic devices due to miniaturization. Their strong ability to stick well helps fragile parts bond securely, making electronic devices more reliable and efficient.

Construction Sector

Acrylic adhesives are used in construction for bonding architectural panels and composite materials. They are reliable. These adhesives enable seamless joining of diverse materials while ensuring long-lasting structural stability.

Industry Trends

Acrylic structural adhesives change and get used in different ways due to industry trends. Here are some noteworthy industry trends:

Sustainability

The glue industry is developing eco-friendly formulas because people are more concerned about the environment. More and more environmentally friendly manufacturers now use acrylic adhesives. These adhesives emit fewer harmful gases and are also easier to recycle.

Customization

Industries require adhesive solutions tailored to their specific needs. To meet different needs, adhesive makers now offer custom acrylic adhesives. These can bond different materials, cure at different speeds, and be used in special ways.

Digitalization

Digital technologies like IoT sensors are changing the adhesive industry. These clever glues can monitor bond quality, temperature, and more, making repairs easier and products better.

The latest improvements in glue have created new opportunities in different fields. These adhesives are valuable in many uses because they bond well, dry fast, and resist high temperatures. ZDS Chemical stays up-to-date on industry trends, like sustainability and customization. They provide innovative adhesive solutions to meet customer demands.