In the fast-growing energy storage sector, Adhesive for Energy Storage Battery Pack. These special lithium-ion battery adhesives help safely build battery cells. They also aid in managing heat well and keeping the structure strong. At ZDS™, we know what battery manufacturers need. That’s why we have a wide range of adhesive solutions that fit their tough requirements.

Key Takeaways

- ZDS™ offers specialized adhesives for energy storage battery packs.

- Our lithium-ion battery adhesives ensure safe assembly and efficient thermal management.

- Our solutions include thermal interface adhesives, electrolyte-resistant adhesives, and high-temperature resistant adhesives.

- Our conductive and dielectric adhesives provide electrical connectivity and insulation.

- Our adhesive technology for cooling plates optimizes thermal management.

- We offer structural bonding solutions and a range of adhesives and sealants for battery pack applications.

The Role of Adhesives in Battery Pack Manufacturing

In the fast-moving electric vehicle (EV) scene, adhesives are key. They help make high-quality battery packs. When factories move from using nails and screws to adhesives, they find many benefits. Production speeds up, and the batteries work better.

Ensuring Safety and Reliability

Battery cells need to be put together safely and well for EVs to work right. Adhesives make sure different parts stick and don’t cause issues like fires or breaking down. This structural bonding makes sure the batteries can handle being moved around and used without falling apart.

Enhancing Thermal Management

Keeping the right temperature is vital for a battery’s life and performance. Adhesives help move heat away from the cells to keep them cool. These special adhesives move heat well, stopping the battery from getting too hot, which can ruin it.

Improving Structural Integrity

Battery packs need to stay strong against tough weather and use. Adhesives that are strong keep everything together. This makes the batteries last longer and makes the cars lighter and more efficient.

| Adhesive Type | Application | Benefits |

|---|---|---|

| Acrylic-based | Battery cell potting | Environmental resistance, thermal conductivity |

| Epoxy-based | Structural bonding | High strength, chemical resistance |

| Urethane-based | Sealing and encapsulation | Flexibility, impact resistance |

| Silicone-based | Thermal interface materials | High thermal conductivity, vibration resistance |

Using the right adhesives helps battery packs perform better and last longer. In the electric vehicle world, they’re a big deal for safety and reliability.

Types of Adhesives for Battery Packs

At ZDS™, we get the tough work battery pack makers do with lithium-ion batteries. That’s why we have a full line of special adhesives just for them. These adhesives are made for the detailed needs of the energy storage field.

Thermally Conductive Adhesives

Good thermal management is key to keep batteries working well for a long time. Our thermally conductive adhesives move heat smoothly from battery cells to the cooling system. This helps prevent problems like overheating. They are made to be great at conducting heat, sticking strong, and lasting a long time.

Electrolyte-Resistant Adhesives

The liquid in batteries, called electrolytes, can eat away at normal adhesives. This can weaken the whole battery pack. Our electrolyte-resistant adhesives can handle these tough liquids. They make sure your battery stays strong and bonds last a long time. They’re tough on chemicals but still great at sticking and bending without breaking.

High-Temperature Resistant Adhesives

When batteries run, they can get very hot. This tests the adhesives with high temperatures. Our high-temperature resistant adhesives don’t mind the heat. They keep strong and hold well, even in really hot places. This makes sure they stay reliable and last a long time.

battery pack adhesive

At ZDS™, we create high-performance battery pack adhesives. They are made to fit the energy storage industry’s needs precisely. Our adhesives offer strong bonding, good thermal conductivity, and resistance to chemicals. They ensure your battery pack works well.

Looking for adhesives for battery module bonding or battery cell potting? Or maybe thermal interface applications or structural bonding? We have what you need. Our selection includes electrolyte-resistant and high-temperature resistant formulas. We also offer conductive and dielectric adhesives, perfect for your battery pack projects.

Our advanced adhesive technology ensures strong bonds, good heat dissipation, and durability. This guarantees your battery packs last and perform well.

Thermal management is key at ZDS™ for battery packs. Our thermally conductive adhesives help the cells cool properly. They transfer heat to the cooling plate, stopping them from getting too hot. Also, our thermal adhesives connect cooling plates to battery modules. This helps the heat disperse and maintains the right temperatures.

- Battery Module Bonding Adhesives

- Cell Potting Compounds

- Thermal Interface Materials

- Electrolyte-Resistant Adhesives

- High-Temperature Resistant Adhesives

- Conductive and Dielectric Adhesives

Choose ZDS™ for a wide selection of adhesives and sealants for battery packs. We ensure top performance and trustworthiness for all your products.

Selecting the Right Adhesive for Your Application

Choosing the right adhesive for your battery pack is key. It helps the pack work well and last a long time. You need to look at several things to pick the best adhesive for your application.

Factors to Consider

The place your battery pack will be used matters a lot. If it faces high or low temperatures, lots of moisture, shakes, or harsh chemicals, you need the right adhesive. This makes sure your batteries stay together even in tough conditions.

Environmental Conditions

Things like very hot or cold places, wetness, and shakes can weaken the adhesive. If your battery pack will be in a tough environment, you might need a special adhesive. Look for ones that are high-temperature resistant or electrolyte-resistant adhesives.

Performance Requirements

Think about how your battery pack needs to perform. Does it need to pass heat well, keep electricity in, or hold its shape under pressure? These are important to check so your adhesive does what your battery pack needs.

| Adhesive Type | Key Benefits | Typical Applications |

|---|---|---|

| Thermally Conductive | Excellent heat transfer properties | Battery module bonding, cooling plate attachment |

| Dielectric | Electrical insulation | Safety-critical components |

| Conductive | Reliable electrical connectivity | Electrical interconnects |

| Structural | High bond strength and durability | Battery pack assembly, structural bonding |

Considering where and how your battery pack will be used is crucial. By looking at both the environment and what your battery pack needs, you can choose the perfect adhesive. This ensures your battery pack works well, is dependable, and lasts a long time.

Adhesive Application Techniques

Getting the best bond and performance in battery pack making needs careful adhesive work. ZDS™ helps with various ways to apply adhesive and how to make it harden properly. This way, you get the right glue job every time for your battery pack adhesive demands.

Dispensing Methods

We have many ways to put adhesives on, meeting all sorts of making needs. You can choose from doing it by hand, partly by machine, or fully by machine. We match the right tools for your battery module bonding or battery cell potting jobs.

- Manual dispensing: Great for making just a few or trying new things, this way gives you control and freedom.

- Semi-automated dispensing: This method is a step towards more efficiency, helping you do more without losing touch.

- Fully automated dispensing: If you’re doing a lot, fully automated tools make sure things are always done the right way, saving time and materials.

Curing Processes

Curing, which makes the glue harden, is key for it to work well and last. ZDS™ guides you to the best way to do this, depending on your glue and how you’re making things.

- Heat curing: When speed and strong bonds are a must, heat curing does the job.

- Room temperature curing: For easy, flexible use without needing heat, curing at room temp is a good choice.

- UV curing: Fast and uses less energy, UV curing works well for certain glue types.

Our team works closely with you to find the right way to apply and cure your glue. We consider your adhesive technology, how things need to stick together, and how you make it all come together.

With our help on adhesive jobs, make sure your cooling plates, sticks, and other key parts in battery packs work great.

Adhesive Solutions from ZDS™

At ZDS™, we provide a wide range of advanced adhesive solutions for the energy storage industry. Our product portfolio features thermally conductive adhesives, electrolyte-resistant formulations, and more. These are perfect for battery pack and may other crucial applications.

Our Innovative Offerings

We know the challenges that battery pack makers face. Our adhesive technology meets these demands head-on. It is designed for everything from battery module bonding to thermal interface adhesives. So, your battery pack will perform better and last longer.

1. The square cell is bonded to the cell structure

The steel or aluminum casing of prismatic cells, or their surface coatings, or the self-adhesion and mutual adhesion of the PET film on the cell surface. Read more about battery Core adhesives: Square Energy Storage Battery Core Adhesive Solution

|

Type

|

General Polyurethane Structural Adhesive for Cells

|

High Thermal Conductivity Polyurethane Structural Adhesive

|

Medium-High Thermal Conductivity Polyurethane Structural Adhesive

|

Medium-Low Thermal Conductivity Polyurethane Structural Adhesive

|

|---|---|---|---|---|

|

Model

|

ZDS-PU828

|

ZDS-PU925

|

ZDS-PU926

|

ZDS-PU936

|

|

Mixed Color

|

Green

|

Gray-Black

|

Green

|

Gray-Black

|

|

Volume Ratio A:B

|

1:1

|

1:1

|

1:1

|

1:1

|

|

Working Time (min)

|

30

|

30

|

45

|

35

|

|

Initial Curing Time (min)

|

120

|

180

|

240

|

180

|

|

Shear Strength (Mpa)

|

12

|

7.0

|

9.0

|

9.0

|

|

Operating Temperature (°C)

|

~60~120

|

~60~120

|

~60~120

|

~60~120

|

|

Thermal Conductivity (W/m.k)

|

/

|

2

|

1.2

|

0.8

|

|

Packaging Form

|

400ml Dual Cartridge

|

400ml Dual Cartridge

|

400ml Dual Cartridge |

400ml Dual Cartridge

|

2. Temporary Adhesive for Cylindrical Cell Bonding

The metal casing or coating of cylindrical cells, along with the self-adhesion or mutual adhesion of the PET film on the cell surface.

| Type | Quick-drying Adhesive |

|---|---|

| Model | ZDS460 |

| Characteristics | Instant drying, low whitening, fast curing, no white smoke. |

| Packaging Form | 20g per tube, 50g per tube |

3. Voltage Sensor Solder Joint Protective Adhesive

Used for protecting and reinforcing the solder joints of voltage sensors to prevent breakage, loosening, oxidation, and moisture.

Type: Thermal Conductive Silicone

| Model | ZDS8716 | ZDS708 |

|---|---|---|

| Characteristics | Thermal conductive silicone, white, thermal conductivity 1.6 W/m.k | Thermal conductive silicone, white, thermal conductivity 1.0 W/m.k, UL94 V-0 |

| Packaging Form | 300ml per tube | 100g per tube, 300ml per tube |

4. Encapsulation Adhesive for FPC to Nickel Sheet Solder Joint, NTC Temperature Sensor, and Wiring Terminals

Used for protecting and reinforcing the solder joints of voltage sensors to prevent breakage, loosening, oxidation, and moisture.

Type: UV Adhesive

| Model | WC-23091601 | ZDSYA23052901 | ZDSYA23101601C6 |

|---|---|---|---|

| Appearance | Light yellow liquid | Slightly yellow turbid liquid | Slightly blue transparent liquid |

| Viscosity (cps) | 15000~20000 | 12272 | 5000-7000 (20 rpm) |

| Hardness (Shore D) | 75D | 76-80D | 22-26D |

| Surface Drying | Surface dry | Surface dry | Non-surface dry |

| Elongation at Break (%) | 110 | / | 300 |

| Positioning Time (s) | 2-4 | 20 | 2-4 |

| Curing Energy (mj/cm²) | 500 | 880 | 500 |

| Curing Time (s) | 15-30 | 30-60 | 10-20 |

| Temperature Range | -20-100℃ | -30-80℃ | -30-100℃ |

| Characteristics | Good adhesion, excellent high and low temperature resistance, good toughness | Flame retardant, low odor, non-corrosive to copper, aluminum, PVC, PP, and silicone materials, fast curing | Flame retardant, low odor, non-corrosive to copper, aluminum, PVC, PP, and silicone materials, fast curing |

| Packaging Form | 1000ml per bottle, 50ml per bottle | 1000ml per bottle, 50ml per bottle | 1000ml per bottle, 50ml per bottle |

5. Adhesive for Battery Safety Valve Bonding

Used for bonding and sealing the safety valve on the battery.

Type: Acrylic Structural Adhesive

| Model | ZDS14167 |

|---|---|

| Characteristics | Acrylic structural adhesive, 10:1 usage ratio, room temperature curing, easy to apply, strong adhesion, impact-resistant, good toughness. |

| Color | Milky white/Blue |

| Volume Ratio A:B | 10:1 |

| Working Time (min) | 15 |

| Initial Curing Time | 20 |

| Shear Strength (Mpa) | 25 |

| Operating Temperature (°C) | -50 ~ 150 |

| Packaging Form | 50ml per tube, 490ml per tube |

6. Thermal Conductive Adhesive for Bonding Cells to Box Side Panels/Partitions

Used for bonding and thermal conduction between battery cells and the box side panels.

Type: Thermal Conductive Silicone

| Model | ZDS8716 | ZDS708 |

|---|---|---|

| Characteristics | Thermal conductive silicone, white, thermal conductivity 1.6 W/m.k | Thermal conductive silicone, white, thermal conductivity 1.0 W/m.k, UL94 V-0 |

| Packaging Form | 300ml per tube | 100g per tube, 300ml per tube |

7. Thermal Conductive Adhesive for Bonding Cells to Box Base Plate (Some with Liquid Cooling Plate)

Used for bonding or thermal conduction between battery cells and the box base plate (some of which also serve as liquid cooling plates).

Type: Medium-High Thermal Conductivity Polyurethane Structural Adhesive

| Model | ZDS-PU926 |

|---|---|

| Mixed Color | Green |

| Volume Ratio A:B | 1:1 |

| Working Time (min) | 45 |

| Initial Curing Time | 240 |

| Shear Strength (Mpa) | 9 |

| Operating Temperature (°C) | ~60~120 |

| Thermal Conductivity (W/m.k) | 1.2 |

| Packaging Form | 400ml dual cartridge |

8. Thermal Conductive and Flame Retardant Potting and Filling Adhesive

Used for potting or filling gaps between battery cells, or between cells and the box, providing thermal conductivity, flame retardancy, and protection against shock and water.

Type: Thermal Conductive Silicone

| Model | To be determined | To be determined |

|---|---|---|

| Characteristics | Potting silicone, 1:1 ratio, thermal conductivity 0.6~0.9 W/m.k, low density 1.3, UL94 V-0 | Thermal conductive gel, 1:1 ratio, thermal conductivity 2 W/m.k, UL94 V-0, Shore 00 45 |

| Packaging Form | 20kg/set | 20kg/set |

9. Conductive Adhesive for Aluminum Foil and Copper Tabs of Battery Cells

Enhances the electrical conductivity and reliability between aluminum foil and copper tabs.

Type: Thermal Conductive Silicone

| Model | To be determined | To be determined |

|---|---|---|

| Characteristics | Silicone, light brown, silver-coated copper, high conductivity, room temperature curing | Thermal conductive gel, 1:1 ratio, thermal conductivity 2 W/m.k, UL94 V-0, Shore 00 45 |

| Packaging Form | 20kg/set | 20kg/set |

Customized Formulations

Every application is different, and we get that. That’s why we also create customized formulations just for you. Our team, made up of skilled chemists and engineers, will design what you need. This makes your battery pack work even better.

Looking for thermal management or something like cooling plate bonding? What about special adhesives for lithium-ion batteries? ZDS™ is here for you. We have the knowledge and the tools to craft the perfect solution for you.

Lithium-ion Battery Adhesives

Lithium-ion batteries bring unique challenges for adhesive use. At ZDS™, we’ve met these challenges head on. We’ve crafted special adhesives made for the tough demands of making lithium-ion batteries.

Addressing Unique Challenges

Our adhesives for lithium-ion batteries beat the odds. They resist damage from the battery’s fluid, stand up to high heat, and spread heat well. This makes bonding strong and keeps the battery the right temperature. No matter the job – bonding battery pieces, sealing them tight, or holding structures in place – our adhesives are ready. They make lithium-ion batteries work better and last longer.

| Adhesive Type | Key Features | Applications |

|---|---|---|

| Electrolyte-Resistant Adhesives | Withstand exposure to harsh battery electrolytes, preventing degradation and ensuring long-term performance. | Battery module bonding, cell potting, structural bonding |

| High-Temperature Resistant Adhesives | Maintain bond integrity and stability at elevated temperatures generated during battery operation. | Thermal interface applications, cooling plate attachment |

| Thermally Conductive Adhesives | Facilitate efficient heat transfer from battery cells to cooling systems, enabling optimal thermal management. | Battery module bonding, cooling plate attachment, thermal interface material (TIM) |

We’ve carefully designed our adhesives and sealants. They exclusively cater to the needs of making lithium-ion batteries. They’re known to bond well, manage heat effectively, and offer long-term quality in tough settings.

Battery Module Bonding

At ZDS™, bonding battery modules is key to making lithium-ion packs. This step is vital for the cells to work together well. Through innovation, we’ve created strong adhesives for this job.

Our battery pack adhesives are top-notch. They keep the cells together, handle heat well, and last long. For all bonding needs, our products are up for the challenge.

The ZDS™ ThermoLock™ Adhesive is one standout. It’s perfect for thermal tasks in battery module bonding. This unique mix ensures heat moves out fast and bonds tight.

| Product | Key Features | Applications |

|---|---|---|

| ZDS™ ThermoLock™ Adhesive |

|

|

| ZDS™ ElectroShield™ Adhesive |

|

|

We also have special thermal interface adhesives. Plus, we offer electrolyte-resistant and high-temperature resistant adhesives. For example, our ZDS™ ElectroShield™ Adhesive is great for sticking to different materials, keeping out battery liquids, and staying strong in changing temps.

We at ZDS™ keep striving to make better adhesives. These help store energy safely and efficiently.

Thermal Interface Adhesives

ZDS™ knows how important it is to manage heat well for batteries to work their best and last a long time. That’s why we have thermal interface adhesives that help the heat move from the batteries to the cooling system.

Ensuring Efficient Heat Transfer

Our thermally conductive adhesives are top-notch at moving heat, keeping things cool and not letting things get too hot. They can handle high temperatures and tough conditions in battery pack applications, which means they stick well for a long time.

Our thermal interface adhesives fit many uses, including battery module bonding and cooling plate attachment. They are great for whatever you may need to keep your electronics cool (thermal management).

When the connection between the batteries and the cooling system is just right, our thermal adhesives make everything work better. This makes your batteries last longer and your devices do more. ZDS™’s adhesives meet the special needs of energy storage, making battery packs work reliably and efficiently.

If you need adhesives that can handle high heat, work with certain chemicals, or stick things together strong, we can help. Our experts are here to customize solutions just for you.

Conductive and Dielectric Adhesives

ZDS™ values the need for reliable electrical connections and insulation in batteries.

Our conductive adhesives ensure strong bonds and good electrical flow. Meanwhile, dielectric adhesives provide top-notch insulation for safety-focused uses.

Conductive adhesives meet tough battery conditions like heat and chemicals. They ensure solid electrical connections between parts.

Dielectric adhesives prevent short circuits, keeping the battery safe. They work well in all conditions, promising durability and performance.

Our adhesive technology is perfect for both electrical connections and safety insulation. It’s reliable and high-performing.

We excel in creating structural bonding solutions just for you, using our adhesive know-how. Our chemists and engineers adapt formulas for the best bonds and durability.

| Adhesive Type | Key Features | Applications |

|---|---|---|

| Conductive Adhesives |

|

|

| Dielectric Adhesives |

|

|

ZDS™ dedicates itself to cutting-edge adhesive solutions for the energy sector. Our goal is to meet the specific needs of battery adhesive applications. We promise effective performance, good thermal handling, and enduring strength.

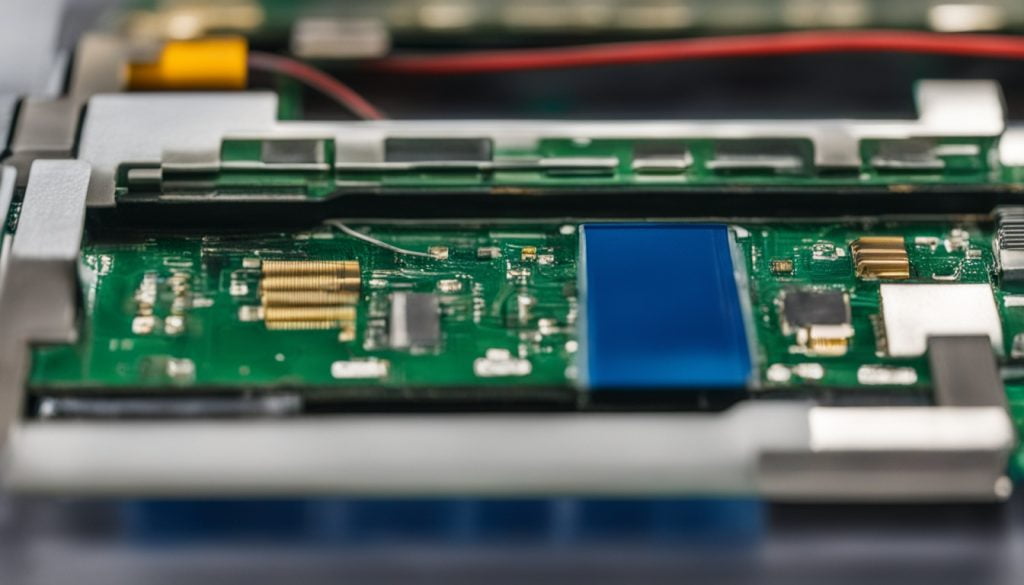

Adhesive Technology for Cooling Plates

The need for top-notch battery packs is growing fast. To make them work well and last long, good thermal management is key. ZDS™ has created a special adhesive technology for joining cooling plates and battery modules.

Optimizing Thermal Management

Our thermal adhesives are made for a strong bond, high thermal conductivity, and they stand up to tough battery pack conditions. By making the battery cells and cooling system work together better, it boosts thermal management. This helps the battery life last longer and improves how the system works.

The global market for adhesives and sealants was worth USD 62.63 billion in 2021. It shows how important these materials are in many fields, including energy storage. The market is expected to jump to $92.29 billion by 2029. This growth is due to the rising need for advanced adhesive technology in new uses.

Robust and Reliable Bonding

Our thermal adhesives for cooling plates are tough enough for battery pack use. They handle high heat, shaking, and chemicals. This strong bond between cooling plates and battery modules keeps thermal management steady over the system’s life.

| Adhesive Property | Benefit |

|---|---|

| High Thermal Conductivity | Facilitates efficient heat transfer from battery cells to cooling system |

| Superior Bonding Strength | Ensures reliable and durable adhesion between cooling plates and battery modules |

| Environmental Resistance | Withstands harsh operating conditions, including high temperatures and chemical exposure |

Using our adhesive technology for cooling plates means your battery pack will handle heat well and last longer. Our team is here to give you exactly what you need, so you can lead the way in the changing energy storage sector.

Conclusion

At ZDS™, we’re dedicated to making the best adhesives for the energy storage sector. We offer cutting-edge products for making battery packs, like thermally conductive adhesives and those that resist electrolytes. Our lineup also includes adhesives that can handle high temperatures and solutions for cooling plates.

These products are specially made for attaching lithium-ion components, bonding battery cells, and handling the heat in batteries. By working with us, you can use top-notch adhesive technology. Plus, you’ll get formulas made just for your needs and expert advice. Our solutions make sure your batteries work well, stick together properly, and manage heat efficiently.

Choosing us means you’ll have the best adhesive solutions for your battery packs. We’re focused on being innovative and meeting your satisfaction. Trust us to be your partner in the future of adhesives for energy storage.

FAQ

What role do adhesives play in battery pack manufacturing?

Adhesives are key in making lithium-ion battery cells safe and reliable. They help with efficient heat control and keep the structure strong. Adhesives stop dangers, help the heat flow out, and make battery packs last longer.

What types of adhesives are used for battery packs?

There are several types of adhesives for making battery packs. Some make sure heat moves well, some resist chemicals, and some handle high temperatures. Each does a specific job.

How do thermal interface adhesives contribute to battery pack performance?

Thermal interface adhesives are important for keeping battery cells cool. They help the cooling system take away heat. This keeps the battery working well for a longer time.

What factors should be considered when selecting an adhesive for battery pack applications?

When picking an adhesive, think about where it will be used and how hot it might get. Also, its resistance to chemicals, need for good heat flow, how well it helps keep electricity in, and how strong it makes things can matter a lot.

What adhesive application techniques are used in battery pack manufacturing?

Using adhesives correctly is crucial. We know how to apply them with various tools. This includes doing it by hand, with less human help, or using machines. We also know the best ways to make them harden, whether by heat, at room temperature, or with UV light.

Can adhesives be customized for specific battery pack applications?

Yes, we can make an adhesive just for your battery needs. Our experts will work with you to design a formula that works best for you. This helps improve how your battery pack works.

How do your adhesive solutions address the unique challenges of lithium-ion battery manufacturing?

Our adhesives are made to be great for lithium-ion batteries. They’re very good at resisting chemicals, staying strong in high heat, and letting heat move. This makes them perfect for keeping everything together in batteries and making them last longer.

What adhesive solutions do you offer for battery module bonding?

We have a line of adhesives that are perfect for gluing battery parts together. They are very strong, let heat move well, and hold up against the environment. So, your battery’s parts will stay together well and last a long time.

How do your adhesive solutions contribute to effective thermal management in battery packs?

Our adhesives for heat control are just what battery packs need. They make sure heat flows out well and keep the temperature right. This makes the battery management better and help the battery stay strong for a longer time.