Looking for the best adhesive for metal bonding? ZDS™ is your go-to brand. Our range of metal glues is perfect for both industrial and DIY projects. We focus on what’s important – bond strength, curing time, material compatibility, and resistance to the elements. This ensures your metal bonds are both strong and lasting.

Choosing the right metal to metal adhesive is important. Take two-part epoxies, for example. They are made of resin and hardener that must be mixed just right. You want a formula with strong tensile and shear strengths. And don’t forget about curing time. Some adhesives cure fast, while others take longer.

It’s essential to match the adhesive to your materials for the best bond. Also, think about the environment your project will face. Whether you need resistance to heat, moisture, or chemicals, choose an epoxy that can handle it. Our adhesives are designed to excel in any situation, surpassing your expectations every time.

Key Takeaways

- ZDS™ offers a range of top metal bonding adhesives, suitable for both industrial and DIY projects.

- Two-part epoxy adhesives require precise mixing for a strong bond.

- High tensile and shear strengths are critical for durable metal bonds.

- Curing times vary; choose accordingly for your project’s timeline.

- Ensure surface compatibility and environmental resistance for optimal performance.

Understanding the Basics of Metal Adhesives

When you’re bonding metal, knowing the differences between adhesives is key. Whether you’re making something, fixing stuff, or using them in big projects, the metal adhesive you choose affects how well parts stick together.

Types of Metal Adhesives

Different metal adhesives are made for various tasks. Here are the ones you’ll see a lot:

- Epoxies: Made of resin and hardener, epoxies create very strong bonds. They’re perfect for tough jobs.

- Silicone Adhesives: They can handle extreme temperatures, from very cold to very hot. This makes them great for harsh conditions.

- Acrylic Adhesives: These cure quickly at room temp and are really strong. They work well on metals like aluminum and steel.

- Anaerobic Adhesives: They cure without oxygen, making them good for sealing metal parts that screw together.

- Cyanoacrylates: Also known as super glue, they work fast with an activator for tricky surfaces.

Common Applications

Metal adhesives are crucial in many fields because they’re strong and versatile. They’re used in car repairs, building stuff, electronics, and even space crafts. For example, glues that bond metal are handy in fixing cars. The strongest epoxies are vital for aerospace, where bonds must handle lots of stress. Choosing the right glue for the job ensures a strong, lasting fix.

Knowing each adhesive’s special features and their uses helps us choose wisely for our projects. For more on gluing metals effectively, see this detailed guide on metal gluing.

The Importance of Bond Strength in Metal Adhesives

The importance of bond strength in metal adhesives is huge. It determines how well the adhesive performs. This strength ensures the bond can handle loads and stand up to different stresses.

Factors Affecting Bond Strength

Many factors affect the bond strength of metal adhesives. One key factor is the adhesive’s chemical makeup. High-quality formulas from ZDS™ offer better strength and reliability. Another important factor is how well the surface is prepared; a good prep leads to a stronger bond. Lastly, the way you apply it—like using the right pressure or spreading it evenly—affects strength too.

- Adhesive Composition: The chemical makeup ensures optimal performance.

- Surface Preparation: Thorough cleaning and roughening before application enhance bonding.

- Application Process: Correct techniques increase the bond’s integrity.

Testing Bond Sternces:

To test the bond strength of metal adhesives, we look at tensile and shear strength. These tests tell us if the adhesive can handle different forces. By doing these tests, we make sure we offer the most durable metal adhesive options. ZDS™ is proud to offer adhesives that pass these tough tests, assuring great performance under various conditions.

Choosing the best adhesive for metal is crucial for long-lasting, reliable results. Knowing and testing the bond strength leads to success in projects.

Best Adhesive for Metal: Key Features to Look For

When you need to glue metal surfaces, look for key features. These include curing time, metal compatibility, and how well they hold up against weather. These factors ensure your project turns out great.

Curing Time

Curing time matters when choosing a glue for metal. Quick-setting adhesives like epoxy can bond in just five minutes. They’re perfect for fast repairs and DIY projects.

Using adhesives can make things quicker and cheaper. They cut down on assembly steps. They are a great alternative to more traditional methods like welding or using screws.

Compatibility with Various Metals

It’s important to pick a glue that works well with different metals. Metals such as aluminum, brass, copper, and steel all react differently with various adhesives. For example, super glue works well with brass and copper.

Aluminum needs special glues like anaerobic, epoxy, or acrylic for a strong bond. These also protect against rust.

Environmental Resistance

Glues must stand up to different environments to last. A good metal adhesive should handle changes in temperature and moisture. This quality keeps it strong over time.

They offer better protection from rust compared to welding. Some, like polyurethanes, also resist water and UV light. This makes them reliable in various conditions.

Top Metal Adhesive Options on the Market

Exploring metal bonding solutions reveals ZDS™ leads with diverse adhesive products. These options have grown popular as they outdo traditional fastening and welding in efficiency and cost.

- Epoxy Adhesives: Known for their strong bond, epoxy adhesives come in one and two-part systems. They provide dependable bonding across various uses.

- Acrylic Adhesives: Available in surface-activated and bead-on-bead types, these adhesives excel in metal-to-metal bonding. They adapt well to differing project demands.

- Cyanoacrylate Glue: Also called super glue, cyanoacrylate is favored for its quick setting time. It’s particularly good for fast metal bonding.

- Anaerobic Adhesives: Great for locking threads and making gaskets, these adhesives work without air and bond metal strongly.

- MS Polymers and UV Curable Systems: Offering clear, solid bonds, these adhesives serve well in various industrial scenarios.

For better understanding, here’s a lab-tested summary of some adhesives with their performance metrics:

| Adhesive Type | Peel Strength (kgf) | Shear Strength (kgf) | Tensile Stress (kgf) |

|---|---|---|---|

| 78 | 85 | 90 | |

| Epoxy System | 72 | 80 | 85 |

| Acrylic Adhesive | 68 | 75 | 80 |

Selecting metal adhesives helps us match specific project needs. ZDS™ provides a range of high-quality products for strong metal bonding. For both industry and personal projects, these adhesives ensure lasting, dependable results.

Choosing the Right Adhesive for Specific Metal Types

Choosing the perfect glue for different metals is key to a strong bond. At ZDS™, we have special glues for steel, aluminum, and copper. They match the metals’ needs perfectly.

Adhesive for Steel

Steel is strong and resists rust, which makes it widely used. But, bolts and screws can corrode and get loose. Using a top-notch adhesive stops corrosion and spreads out stress. ZDS™ glues for steel keep its best qualities and give a solid bond.

Adhesive for Aluminum

Aluminum is light and bends easily, so it’s great when you need to cut weight. But, it can rust if not handled right. The right glue keeps its lightness and fights rust. Our glue for aluminum is strong and makes assembling things easier, saving money.

Adhesive for Copper

Copper is great for carrying electricity and being shaped. The best glue supports these traits and sticks well. ZDS™ has glues just for copper, boosting both electrical flow and strength. Our solutions work well for sticking rubber to metal or metal to metal.

Glues are getting more popular than old bonding ways in many fields. They’re cheaper and make assembly quicker by cutting steps. ZDS™ is leading the change in metal bonding with better and lasting solutions.

Adhesive Applications: Metal to Wood, Plastic, and Rubber

ZDS™ offers top-notch adhesives for different materials. These adhesives work well for bonding metal to wood, plastic, and rubber. They handle various expansion rates and surface energies.

Metal to Wood Adhesive

Our metal to wood adhesives work great for the porous nature of wood. They’re perfect for both large-scale and at-home projects. These products create a strong bond between metal and wood, despite their different expansion rates.

Metal to Plastic Adhesive

Bonding metal to plastic presents unique challenges. Our specially designed adhesive makes a strong and durable connection. It’s perfect for use in cars, electronics, and more, where it’s important for things to stay together.

Rubber to Metal Adhesive

Attaching rubber to metal is about balancing flexibility with strength. Our ZDS™ adhesive does just that. It is especially useful in cars, machines, and places with lots of movement.

Using Epoxy Adhesives for Metal Bonding

Epoxy adhesives are a top choice for metal bonding. They’re known for their strength and long-lasting durabilty. They’re used in various industries for their superb bonding qualities and ability to withstand tough environments.

Advantages of Epoxy Adhesives

Epoxy adhesives are great for bonding metal thanks to their high strengths. For example, the XXX can handle about 492.7 kgf. The XXX can manage up to 478.46 kgf. These facts show why many see epoxy as the strongest metal epoxy.

Epoxy adhesives can resist chemicals and heat, too. This trait makes them a solid choice for harsh or hot conditions. They’re also flexible, so the things they bond can move without breaking the bond. This flexibility lessens the risk of the bond breaking under pressure.

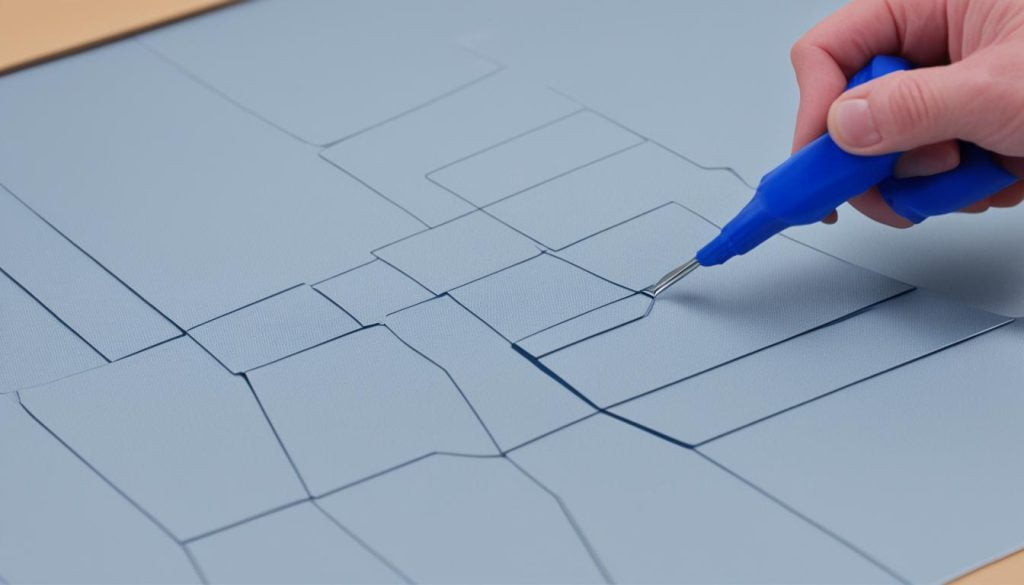

How to Apply Epoxy Adhesives

It’s key to apply epoxy adhesives the right way for top results. Here’s how to do it best:

- Surface Preparation: The metal surfaces must be clean, dry, and free of dirt. Making the surfaces rough can also help the adhesive stick better.

- Mixing: Be sure to mix the adhesive as recommended. This ensures the mix is correct and will work best.

- Application: Spread the mixed adhesive evenly on the metal. Using the right tools helps get a smooth and even coat.

- Curing: Give the adhesive enough time to set, as the maker suggests. Proper curing makes the bond much stronger.

The right application makes the adhesive work better and last longer. Epoxy adhesives from ZDS™ are designed to handle the tough demands of metal bonding. This makes them an excellent choice for metal projects.

Looking at some top epoxies can show why they’re so liked and effective:

| Product | Average Bond Strength (kgf) |

|---|---|

| AAA | 492.7 |

| BBB | 478.46 |

| CCC | 432.32 |

| DDD | 416.51 |

By choosing top-notch epoxies from ZDS™ for your metal bonding needs, you ensure your projects are strong and durable.

Expert Tips for Achieaching Optimal Adhesion

Achieving the best stickiness requires looking into several key factors. These include preparing surfaces right, applying methods accurately, and following safety steps. We make sure you get the most out of your metal glue, helping it last longer and work better.

Surface Preparation

Getting a surface ready is key for a strong bond with metal glue. It’s important to clean off oils, dirt, and any rust from metals like aluminum. We suggest using the correct cleaners to make the glue stick better. Making the surface a bit rough, like by sanding, also helps by giving the glue more to hold onto.

Application Techniques

How you put on the glue matters a lot for a strong connection. It’s best to spread the glue thinly and evenly to avoid bubbles or weak spots. For certain jobs, like locking threads or sealing, special glues work best. It’s also crucial to let the glue dry as the maker says, for the strongest hold.

Safety Precautions

Safety first when using strong metal glues. Wear gloves and goggles to protect your skin and eyes. Making sure the room is well-ventilated keeps you safe from bad fumes. Following these safety steps is good for us and makes sure the glue job is done right.

With these professional tips, you can get the most out of your glue for metal, ensuring great results every time.

Conclusion

Choosing the right glue for metal is key for strong and long-lasting results. At ZDS™, we have a detailed guide and top-quality adhesives for different needs. Whether you’re a hobbyist or a pro, our selection offers the best choices for bonding metal.

Each type of adhesive has its own use and benefits. Epoxy adhesives are great for steel, aluminum, and copper, needing time to set. Quick to dry, cyanoacrylate adhesives are perfect for speedy repairs, but can’t handle much weight. For items that move or get knocked around, polyurethane adhesives are best thanks to their flexibility and tough bond.

For the best bond, it’s crucial to clean and sand the surfaces first. Applying the glue correctly and letting it cure at the right temperature also matters. Thanks to our experience and diverse adhesive options, ZDS™ stands for quality. Working with us means successful metal projects, backed by the right knowledge and materials.

FAQ

What are the different types of metal adhesives?

Metal adhesives include epoxies, polyurethanes, and cyanoacrylates. Each type is unique. For example, some are strong, others are flexible, or quick to cure.

What are some common applications for metal adhesives?

They are used in automotive repairs, construction, and consumer electronics. This is because they bond metal well due to their strength and versatility.

What factors affect the bond strength of metal adhesives?

Bond strength depends on the adhesive’s makeup, surface prep, and how it’s applied. Testing for tensile and shear strength is key for the best performance.

How is bond strength tested for metal adhesives?

We test bond strength with tensile and shear strength tests. These tests check if the adhesive can handle loads and stress, making sure the bond lasts.

Why is curing time important when selecting metal adhesives?

Curing time matters because it shows how fast an adhesive sets and hardens. Quick curing can speed up projects or be crucial for urgent tasks.

How do I choose the right adhesive for different metal types?

The right adhesive matches the metal’s features. For steel, it should boost strength and resist rust. For aluminum, it should be flexible and light.

Can metal adhesives bond metal to other materials like wood, plastic, and rubber?

Yes, metal adhesives can join metal to wood, plastic, and rubber. They are made to handle different expansion rates and surfaces for a strong bond.

Why are epoxy adhesives preferred for metal bonding?

Epoxy adhesives offer great bond strength and resist chemicals and heat. They ensure a strong, lasting bond for heavy-duty use.

How should I prepare the surface for optimal adhesion when using metal adhesives?

Get the surface ready by cleaning it well and roughening it up. This makes for better bonding and strength.

What safety precautions should I take when using metal adhesives?

Always wear gloves and goggles, and work in a well-ventilated area. These steps prevent health problems and make for a safer work space.