ZDS™ epoxy resin delivers unmatched performance for construction, art, and industrial needs. Its durable, high-gloss finish and resistance to chemicals, water, and UV rays make it perfect for any project. From creating stunning resin art to heavy-duty industrial coatings, ZDS™ epoxy resin is your reliable choice. With easy application, a long-lasting finish, and exceptional versatility, ZDS™ ensures professional-grade results every time. Ideal for floors, countertops, and marine use. Choose ZDS™ epoxy resin for unparalleled quality and performance.

What is Epoxy Resin?

Epoxy resin is a versatile, synthetic material known for its exceptional adhesive properties, durability, and resistance to chemicals and environmental factors. Commonly used in construction, art, and industrial applications, it is formed by mixing resin and hardener to create a strong, durable polymer.

Key Properties of Epoxy Resin

Durability

Long-lasting and resistant to wear.

Adhesive Strength

Bonds with various materials, including wood, metal, and plastic.

Waterproofing

Suitable for marine and outdoor applications.

Chemical Resistance

Can withstand harsh chemicals and solvents.

Types of Epoxy Resin and Their Uses

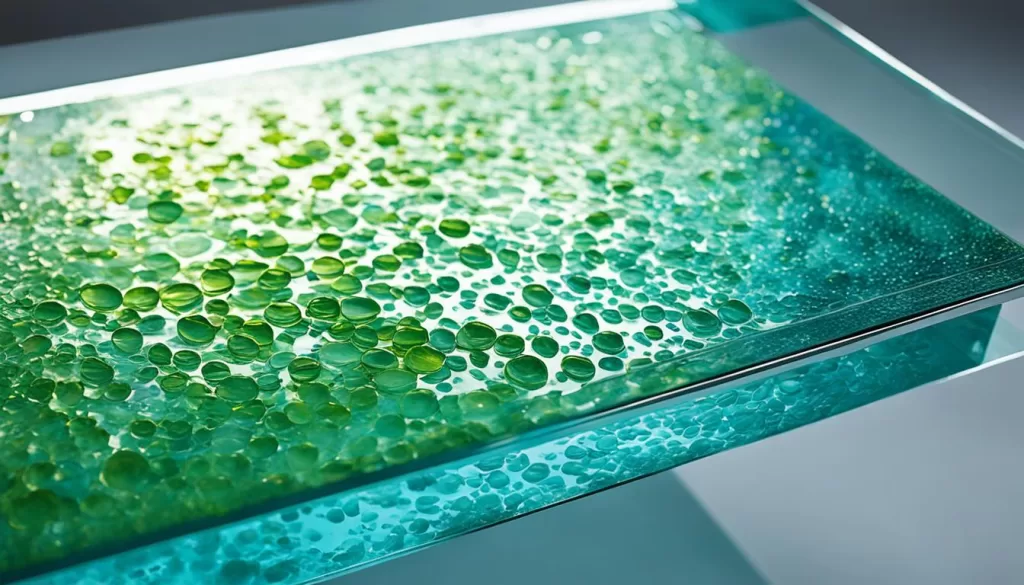

Clear Epoxy Resin

Ideal for art projects and creating transparent finishes.

UV-Resistant Epoxy Resin

Best for outdoor applications to prevent yellowing.

High-Temperature Epoxy Resin

Used in environments requiring heat resistance.

Marine Epoxy Resin

Designed for boats, docks, and other water-exposed structures.

Applications of Epoxy Resin in Industries

Construction

Flooring, countertops, and adhesives.

Automotive

Coatings and structural adhesives.

Aerospace

Lightweight, durable parts.

Electronics

Insulators and protective coatings.

Benefits of Using Epoxy Resin

- Exceptional finish for aesthetics and functionality.

- Provides high mechanical strength.

- Offers excellent resistance to corrosion and impact.

Epoxy Resin for Art and DIY Projects

Epoxy resin is a favorite among artists for creating resin art, jewelry, and decorative objects. Its clear, glossy finish enhances the appearance of pigments, glitter, and other additives.

How to Use Epoxy Resin Safely

- Protective Gear: Use gloves, masks, and goggles.

- Ventilation: Work in a well-ventilated space to avoid fumes.

- Mixing Ratio: Follow manufacturer instructions for precise curing.

Caring for Epoxy Resin Products

- Clean with mild soap and water.

- Avoid abrasive cleaners to prevent scratches.

- Reapply coatings to maintain durability in outdoor applications.

Choosing the Right Epoxy Resin for Your Needs

- Assess the specific requirements of your project.

- Check for certifications like non-toxicity and UV resistance.

- Opt for ZDS™ epoxy resin for its superior quality and versatility.

Why Choose ZDS™ Epoxy Resin?

ZDS™ offers industry-leading epoxy resin solutions tailored for diverse applications. With a commitment to quality and customer satisfaction, our products are ideal for both professional and DIY projects.