When we delve into construction, electronics, or even simple repairs, adhesives play a crucial role. Have you ever pondered the adhesive bonding process? If you view glue as merely a sticky substance, get ready for a deep dive into the world of understanding adhesive properties. We’ll explore how modern adhesives are redefining traditional fastening methods, capable of holding even massive structures like cars firmly in place.

Adhesives have evolved from simple household items to sophisticated materials, essential in various industries such as automotive and electronics. The key to their strength lies in the molecular bonding science. Join us as we delve into the “sticky science” behind these remarkable materials.

Key Takeaways

- Discover the science behind the adhesive bonding process which is robust enough for industrial use.

- Gain insights into understanding adhesive properties that contribute to their strength and versatility.

- Learn about the technological advancements that have transformed adhesives from household items to industrial marvels.

- Understand the environmental and efficiency benefits of modern adhesives in various industries.

- Explore the reasons why adhesives have become a go-to solution for durable and reliable bonds in demanding applications.

Uncovering the Mystery: How Does Adhesive Work?

The fundamental concept of adhesives is intriguing, focusing on their ability to bond with surfaces upon contact. To grasp how does the adhesive works, one must first understand the surface interaction. Upon application, the adhesive must wet the surface effectively. This wetting process is vital as it ensures the adhesive spreads uniformly, enhancing bonding potential.

Adhesive strength factors are deeply rooted in this initial contact. The adhesive’s viscosity and the surface’s smoothness significantly impact the bonding process. Exploring adhesive options and techniques for glass art can provide insight into this process.

| Surface Type | Adhesive Type | Application Technique |

|---|---|---|

| Glass | Silicone Caulk | Thin, Even Spread |

| Metal | Epoxy | Surface Roughening |

| Wood | PVA Glue | Clamping after Application |

After wetting the surface, the adhesive cures or hardens, transitioning from a liquid to a solid state. In this phase, adhesive molecules either entangle or chemically bond with the surface, forming a microscopic attachment. This transformation is crucial for understanding how does the adhesive works to create lasting bonds.

- Chemical Bonding: Creates strong, durable bonds suitable for high-stress applications.

- Physical Bonding: More reversible, suitable for applications needing frequent repositioning or removal.

The effectiveness and durability of an adhesive joint are influenced by external adhesive strength factors like humidity, temperature, and chemical presence. These factors can either speed up or slow down the curing process, potentially impacting the adhesive strength.

By considering these factors when selecting and applying adhesives, practitioners can achieve more reliable and effective bonds across various materials.

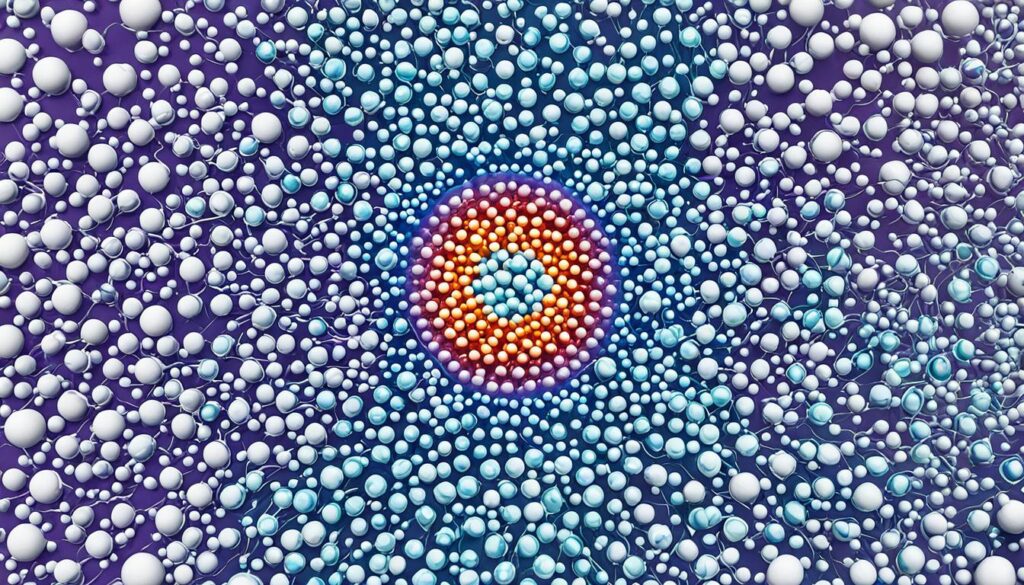

The Chemistry Behind Adhesion: Bonding on a Molecular Level

Exploring the molecular intricacies of adhesion reveals how materials bond through advanced chemical and physical processes. This science involves a complex interaction of forces and the strategic use of various types of adhesives. These factors determine the success of the adhesive bonding process.

The Role of Adhesive Polymers

Adhesive polymers are key in bonding technologies. Their large, chain-like molecules interact with the surface atoms of the substrates, forming strong molecular networks. This flexibility and strength ensure effective load distribution across the bond area, enhancing the bond’s durability and strength.

Van der Waals Forces in Action

Van der Waals forces are a type of physical adhesion, involving the attraction between molecules near each other. Though weak individually, their combined effect is significant in densely packed molecular structures. This directly impacts the performance of adhesives at the molecular level.

Chemical vs. Physical Adhesion

It’s crucial to understand the difference between chemical and physical adhesion for selecting the right adhesive. Chemical adhesion forms strong, permanent covalent bonds. In contrast, physical adhesion relies on mechanical interlocking and weaker van der Waals forces.

| Type of Adhesion | Binding Mechanism | Common Applications |

|---|---|---|

| Chemical Adhesion | Covalent Bonds | Structural bonding in automotive and aerospace industries |

| Physical Adhesion | Mechanical Locking, Van der Waals Forces | Labeling, temporary attachments in consumer products |

For designing industrial products or enhancing manufacturing processes, understanding both chemical and physical adhesion is crucial. This knowledge helps in selecting the correct types of adhesives. It significantly impacts the success of the adhesive bonding process.

Exploring Different Adhesive Strength Factors

Exploring the realm of adhesives reveals several key factors that significantly impact their bonding effectiveness. A deeper understanding adhesive properties can greatly enhance application results across various sectors.

Surface Energy and Adhesion

Surface energy is crucial for adhesive bond strength. High surface energy facilitates better wetting, allowing adhesives to form strong bonds. Polyurethane adhesives from ZDS™ stand out, thanks to their formulation that optimizes surface compatibility and boosts adhesive strength factors.

Temperature and Humidity Effects

Temperature and humidity are vital environmental factors that influence adhesive performance. Their impact can either improve or diminish adhesive strength factors, depending on the material and application. Grasping how these elements interact with adhesives helps avoid bonding failures and ensures durability.

| Condition | Effect on Adhesive Performance |

|---|---|

| High Temperature | May speed up curing but weaken bond |

| Low Temperature | Can slow down curing and reduce tackiness |

| High Humidity | Increases curing time, potential for weaker bonds |

| Low Humidity | Favors quicker handling strength |

By examining these adhesive strength factors, professionals can make better-informed decisions. This optimizes adhesive use across different conditions and materials, improving the reliability of adhesive applications.

Types of Adhesives: A Look at Variety and Uses

The world of adhesives is vast, offering a wide range of options tailored for specific applications. Each type of adhesive comes with its own set of characteristics. Knowing the types of adhesives and their adhesive application methods can greatly improve your projects. This knowledge is essential for construction, crafts, or industrial settings.

Natural adhesives, such as animal glues and plant-based starches, contrast with synthetic ones like epoxies and silicones. Each type has its own set of benefits and challenges. It’s vital to choose the right adhesive for your project to ensure it lasts and works effectively.

| Adhesive Type | Common Uses | Application Methods |

|---|---|---|

| Polyvinyl Acetate (PVA) | Woodworking, paper projects | Brush, roller, squeeze bottle |

| Epoxy Resins | Metal bonding, structural adhesives for construction | Manual mixing and application with spatula or syringe |

| Acrylic Adhesives | Automotive parts, aerospace applications | Automated dispensing systems for industrial use |

| Silicone Adhesives | Electronics sealing, high-temperature applications | Cartridge and caulk gun application |

| Urethane Adhesives | Flooring installation, panel bonding | Trowel applied, especially for large surfaces |

The choice of adhesive depends on the materials being bonded, the environment, and the bond strength needed. Proper adhesive application methods are crucial for the best results. Each adhesive type may require a specific method, like spray, brush, or precision dispensing.

Understanding these details ensures strong, lasting bonds and avoids common mistakes from incorrect adhesive use or application. As the adhesive industry advances, staying updated with new products and techniques is vital for both professionals and hobbyists.

Understanding Adhesive Properties and Selection Criteria

To excel in adhesive applications, one must deeply understand adhesive properties. Knowing how these properties affect adhesive bonding optimizes the selection and application process. This ensures strong, durable bonds. Adhesive bonding best practices rely heavily on the adhesive’s inherent characteristics.

Choosing the right adhesive demands a thorough analysis of factors like tack, cure time, and elasticity. These elements are crucial for adhesive performance. Selecting the correct adhesive is like finding the right key for a lock, ensuring perfect compatibility and functionality.

Tack, Cure Time, and Elasticity

The initial stickiness or ‘tack’ of an adhesive is key to the bond strength at first contact. The ‘cure time’, or the time it takes for the adhesive to fully set, is also crucial. It affects project timelines and efficiency. Lastly, ‘elasticity’ is the adhesive’s ability to stretch and return to its original state. This is essential for maintaining bond integrity under stress or thermal changes.

Choosing the Right Adhesive for the Job

For adhesive applications to succeed, one needs expertise in understanding adhesive properties and making an informed choice of adhesive type. Environmental exposure, substrate materials, and bond longevity must match the adhesive’s properties. With this knowledge, professionals can apply adhesive bonding best practices for reliable results.

Adhesive Application Methods: Tips and Techniques

Mastering adhesive application methods is essential for creating strong, lasting bonds in any adhesive bonding process. Whether you’re a seasoned professional or a DIY novice, grasping the best techniques for applying adhesives can greatly affect your project’s success.

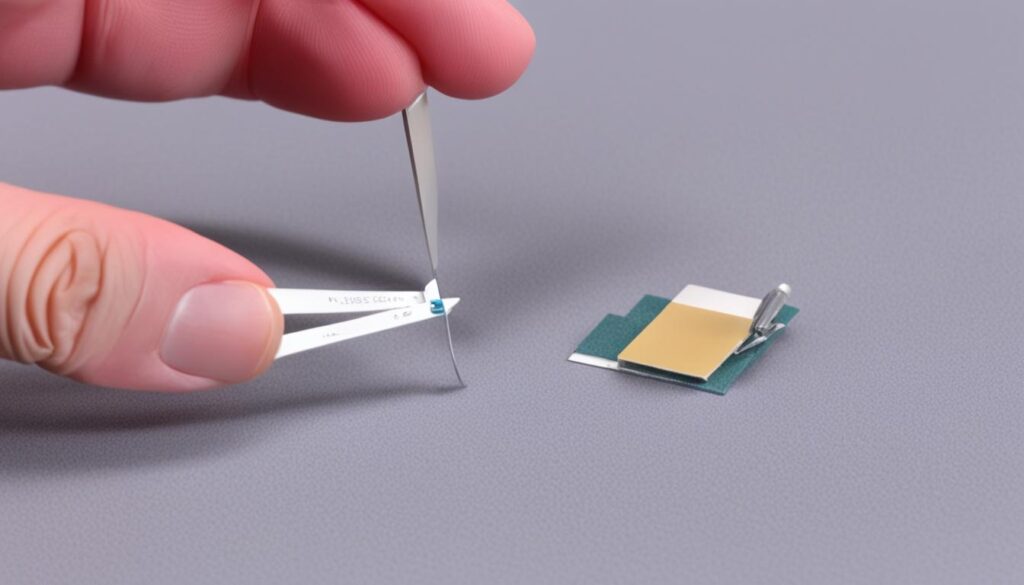

Surface Preparation for Optimal Bonding

Surface preparation is crucial before applying any adhesive. Ensuring surfaces are clean, dry, and roughened allows adhesives to bond effectively, enhancing bond strength. Common preparation steps include sanding, solvent cleaning, and applying primers, depending on the materials at hand.

Application Process for Different Adhesive Forms

Application techniques differ significantly across various adhesive forms, including liquids, tapes, films, and pastes. Here’s a breakdown of typical application strategies:

- Liquid Adhesives: Often applied with brushes or rollers, ideal for covering large areas uniformly.

- Adhesive Tapes: Requires careful placement and pressure to ensure complete contact with the surface.

- Adhesive Films: Typically used with heat to activate the adhesive layer, ensuring a firm bond upon cooling.

- Paste Adhesives: Commonly applied using a spatula or a syringe for precision work, particularly in smaller or intricate areas.

| Adhesive Form | Application Tool | Typical Use |

|---|---|---|

| Liquid | Brush, Roller | Surface Coating |

| Tape | Manual pressure | Quick Patches |

| Film | Heat press | Industrial Bonding |

| Paste | Syringe, Spatula | Precision Detailing |

Each adhesive type and application method has its unique strengths, making it crucial to select the right adhesive application methods for specific tasks. By following these guidelines, the adhesive bonding process becomes more dependable and successful.

The Adhesive Bonding Process: Step by Step

The adhesive bonding process involves a detailed sequence of steps. These steps ensure a strong, lasting bond between materials. This guide simplifies the understanding of how various types of adhesives transform from a liquid to a solid state. This transformation forms reliable bonds across diverse applications.

First, the surface where the adhesive will be applied must be thoroughly cleaned. Dirt, oil, or other contaminants can significantly reduce the bond strength. After cleaning, the adhesive is prepared for application, chosen for its compatibility with the materials and conditions.

- Surface Preparation: Ensuring all surfaces are clean, dry, and properly roughened if necessary.

- Adhesive Application: Even application of the adhesive to avoid air bubbles and ensure complete coverage.

- Joining Materials: Carefully positioning and pressing materials together to maximize contact with the adhesive.

- Curing Process: Allowing sufficient time for the adhesive to set and achieve full bond strength according to manufacturer’s instructions.

This detailed explanation demystifies the adhesive bonding process. It also underscores the importance of selecting the right types of adhesives for successful outcomes.

| Type of Adhesive | Application Technique | Setting Time |

|---|---|---|

| Epoxy | Apply with a spatula or mixer | 24 hours |

| Acrylic | Brush or roller application | 20 minutes |

| Silicone | Cartridge or tube dispensing | 6-12 hours |

Each type of adhesive has unique properties and curing times. These are essential for project-specific requirements. They ensure the bond’s efficacy and longevity.

Adhesive Bonding Best Practices: Ensuring Strong, Durable Bonds

Choosing the right adhesive is just the beginning in achieving a strong bond. It’s equally important to focus on application techniques and curing processes. By delving into adhesive properties and adhering to established best practices, both manufacturers and DIY enthusiasts can guarantee the durability and strength of their bonds.

Guidelines for Effective Adhesive Use

Understanding adhesive properties is key to selecting the right adhesive for any project. The process starts with surface preparation, which involves cleaning and, if needed, roughening the surfaces to boost bond strength. It’s essential to apply the adhesive evenly and in the correct amount. Too much or too little adhesive can result in weak bonds.

- Choose the correct type of adhesive (e.g., epoxy, silicone, acrylic) based on the materials involved and the environmental conditions it must endure.

- Apply adhesive to a clean, dry surface to prevent bond failures due to contaminants or moisture.

- Follow the manufacturer’s guidelines for application methods and amounts to enhance bond strength and curing time.

The Importance of Proper Clamping and Curing

Clamping and curing are vital in the adhesive bonding process. Proper clamping ensures the adhesive stays in close contact with each surface until it fully cures.

- Use appropriate clamping techniques to apply uniform pressure across the bond, preventing distortion and fostering a stronger bond.

- Allow adequate curing time as advised by the adhesive manufacturer, which can differ based on the adhesive type and environmental conditions.

Adhering to these best practices maximizes the adhesive’s effectiveness, leading to more reliable and lasting bonds. Thus, understanding adhesive properties not only aids in selecting the right adhesive but also ensures optimal utilization of its capabilities.

The Intricacies of Adhesive Curing Process

The adhesive curing process is crucial for achieving the best strength and efficiency in various applications. This section explores the complex mechanisms behind curing. It shows how time and temperature significantly affect bonding outcomes, following adhesive bonding best practices.

Understanding Cure Mechanisms

Cure mechanisms in adhesives involve chemical reactions that turn a liquid into a solid. This solid state enables strong adhesion to substrates. The type of chemical composition in the adhesive determines these mechanisms. Some adhesives cure with heat or light, while others cure at room temperature with moisture or time.

The Role of Time and Temperature in Curing

Time and temperature are key in the adhesive curing process. Optimizing these factors leads to faster curing and better adhesive bonds. Higher temperatures speed up curing but can cause premature curing, affecting the adhesive’s ability to spread evenly. On the other hand, low temperatures may result in a weak bond.

Adjusting time and temperature according to adhesive bonding best practices helps avoid these problems. This ensures a strong and durable bond. Achieving the right balance between time and temperature requires precise control. Advanced adhesive formulations and curing technologies can help, depending on the materials and intended use.

- Ensuring accurate temperature control

- Monitoring time constraints

- Adhering to recommended practices for each adhesive type

Mastering and controlling these curing dynamics is vital for manufacturers and professionals. They depend on effective adhesive solutions in their products and operations.

Adhesive Failure Analysis: Why Bonds Break Down

Understanding why adhesive bonds fail is key to improving the adhesive bonding process and avoiding future failures. By identifying common causes and diagnosing issues, experts can create more effective and reliable adhesive applications.

Adhesive failures can be classified into several types, each caused by different factors in the bonding environment or process. Let’s explore these failures and the crucial role of adhesive failure analysis in fixing them:

- Cohesive Failure: This type occurs within the adhesive layer, indicating either an improper curing process or a formulation problem.

- Adhesive Failure: This involves the bond breaking at the adhesive-substrate interface. It can stem from poor surface preparation or the wrong adhesive choice.

- Interfacial Failure: Like adhesive failure, but it happens at a molecular level where the adhesive and substrate don’t bond well.

During adhesive failure analysis, it’s found that solving these problems requires a deep understanding of the adhesive bonding process. This process is heavily influenced by external factors like temperature and humidity.

To effectively analyze a failed bond, professionals follow a step-by-step approach:

- Collect detailed information about the adhesive, surface preparation methods, and environmental conditions during application.

- Use microscopy to examine the failed interfaces and pinpoint the specific failure mode.

- Perform mechanical tests to evaluate the adhesive’s strengths and weaknesses under various conditions.

By learning from each failure, improvements can be made in materials, application techniques, and environmental controls. This leads to stronger, more dependable adhesive bonds.

Conclusion

In this detailed look at adhesives, we’ve explored the complex science behind how the adhesive works. We’ve examined the chemistry and physics that drive this essential technology in our everyday lives. Starting with the molecular level, we discussed the factors influencing adhesive strength. We then covered the wide range of adhesives available and the essential steps for their proper use to create strong bonds.

Understanding adhesive properties is key to choosing the right adhesive for a particular task. By grasping the importance of properties like tack, cure time, and elasticity, along with the adhesive bonding process, readers can make better choices. We also highlighted crucial practices, from preparing surfaces to curing, which are essential for lasting adhesion.

To sum up, adhesives are crucial in various settings, from industrial use to home projects and innovative breakthroughs. It’s our aim that this article has not just taught but also sparked a deeper interest in adhesive technology. With this knowledge, you’re now ready to approach projects with confidence, ensuring a strong bond that keeps everything together.

FAQ

How do adhesives work to bond surfaces together?

Adhesives bond surfaces by adhering to them, creating a strong connection. This process involves wetting the surface, forming a bond, and curing to strengthen the connection. The bond can be chemical, physical, or a mix of both.

What are the main factors that contribute to an adhesive’s strength?

The strength of an adhesive bond depends on several factors. These include the surface energy of the materials, the adhesive’s chemical makeup, temperature, humidity, and bonding pressure. Understanding these factors aids in selecting the right adhesive for specific needs.

How does surface preparation affect the strength of the adhesive bond?

Surface preparation is crucial for strong bonding. It ensures surfaces are clean and roughened, increasing adhesion. Proper preparation significantly enhances the bond’s durability and strength.

Can temperature and humidity affect adhesive performance?

Yes, temperature and humidity impact adhesive performance. High temperatures can speed up curing or weaken bonds. Low temperatures may slow curing. High humidity can reduce adhesion by adding moisture or changing the adhesive’s viscosity.

What are some common types of adhesives and their uses?

Common adhesives include PVA glue for woodworking, cyanoacrylates for quick fixes, epoxies for durable bonds, silicone for flexibility, and hot-melt for packaging. Each adhesive has unique properties for specific tasks.

What should I consider when selecting an adhesive for a project?

When choosing an adhesive, consider the materials, environmental conditions, bond strength, flexibility, cure time, and application method. Matching the adhesive to the project’s needs ensures optimal performance.

What are the best practices for applying adhesives to ensure a strong bond?

For a strong bond, prepare surfaces well, apply the right amount of adhesive, and use suitable tools. Apply pressure as needed, respect the open and cure times, and follow the manufacturer’s instructions. Proper application is crucial for a strong bond.

How does the curing process affect the adhesive bond?

Curing solidifies the adhesive and maximizes bond strength. Time, temperature, and environment influence the process. Cure methods vary among adhesives, including evaporation, chemical reactions, or cooling. Proper curing is vital for a durable bond.

What are some reasons adhesive bonds fail, and how can failure be avoided?

Bonds fail due to poor surface prep, wrong adhesive choice, incorrect application, inadequate curing, and environmental stress. To prevent failure, follow the manufacturer’s guidelines, ensure proper surface prep, select the right adhesive, and allow enough curing time.