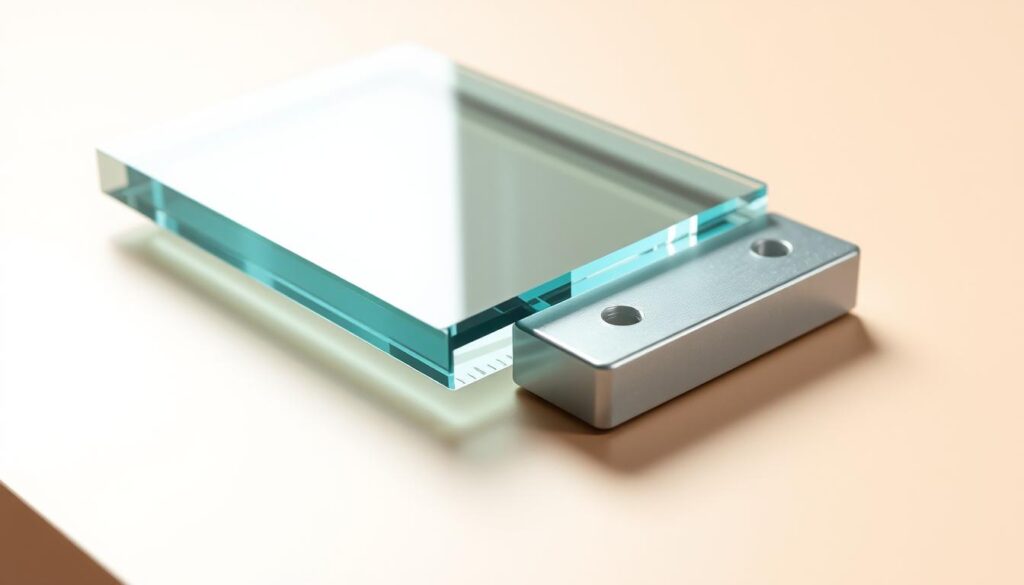

At ZDS™, we specialize in top-notch glue solutions for glass to metal. Our adhesives are made to be strong and last long. They bond glass and metal well. We’re known for quality and performance. Both professionals and DIY fans use our glue for their projects.

Key Takeaways

- ZDS™ specializes in innovative glass to metal glue solutions.

- Our adhesives are designed for high strength and durability.

- We offer a range of products suitable for both professionals and DIY enthusiasts.

- Focus on quality and performance has made ZDS™ a trusted name in the industry.

- Reliability for various glass and metal projects is our priority.

Introduction to Glass to Metal Gluing

Learning how to glue glass to metal is crucial for strong and pretty outcomes. It’s key in cars, industries, and homes where both strength and looks are essential.

Why is Gluing Glass to Metal Important?

Gluing glass to metal is vital in many fields. It creates a sturdy connection without hurting the materials. The top choice glue ensures a clean look and strong performance. It matters in everything from detailed art to complex machines.

Challenges Faced in Glass to Metal Adhesion

Finding a powerful bond without damaging the glass is tough. Glass and metal expand at different rates, causing cracks or breaks. Plus, weather like heat or moisture can weaken the bond. ZDS™ tackles these problems with innovative adhesives that work well under many conditions, making their product very dependable.

Types of Glue for Glass to Metal Applications

Choosing the right glue is key for a strong bond between glass and metal. We’ll look at three main glues: epoxy adhesives, silicone-based glues, and UV-curing adhesives. Each type has unique traits for different needs.

Epoxy Adhesives

Epoxy adhesives are strong and resist chemicals well. They create long-lasting bonds perfect for tough projects. They’re great for needs that require staying power and stability.

Silicone-based Glues

Silicone-based glues are flexible and can handle heat and weather. They work best where there might be movement or temperature changes. Their flexibility helps them absorb shocks without breaking the bond.

UV-Curing Adhesives

UV-curing adhesives set fast when exposed to ultraviolet light. They are perfect for projects that need quick assembly. These adhesives speed up work by allowing immediate handling.

Picking the right adhesive depends on what your project needs, like strength, flexibility, and how fast it needs to set. Knowing about epoxy, silicone-based, and UV-curing adhesives can help you choose the best one for glass to metal jobs.

Choosing the Right Glue for Sticking Metal to Glass

Choosing the right metal to glass adhesive is important. You must consider various factors to make sure the bond lasts.

Factors to Consider

When you want to glue metal to glass, think about bond strength, curing time, and how thick the glue is. The glue needs to make a strong and lasting link between metal and glass.

Environmental Conditions

The environmental conditions where you use the adhesive matter a lot. Temperature changes, moisture, and sunlight can affect the bond. It’s key to choose an adhesive that can deal with these issues.

Best Glue for Glass to Metal: ZDS™ Recommendations

ZDS™ adhesives are top picks for bonding glass to metal. They blend special features to satisfy both experts and everyday users.

Product Features

Key traits of ZDS™ adhesives ensure top-notch glass to metal joining:

- Superior Bond Strength: Guarantees durable sticking.

- Temperature Resistance: Stays strong in different temperatures.

- Durability: Holds up against wear and tear.

Comparative Analysis with Competitors

Comparing ZDS™ with others proves they’re the best choice for glass and metal:

| Feature | ZDS™ Adhesives | Competitors |

|---|---|---|

| Bond Strength | High | Medium |

| Temperature Resistance | Excellent | Average |

| Durability | Superior | Good |

ZDS™ adhesives top the list after thorough analysis. They excel over competitors, offering stellar performance and value for both professional and personal projects. Count on ZDS™ for reliable and efficient bonding solutions.

How to Use Glue for Glass to Metal Applications

When you’re using glue to stick metal to glass, being precise and careful is key. Let’s walk you through how to do this right with our detailed step-by-step guide. We’ll also share important safety tips to keep in mind.

Step-by-Step Guide

- Surface Preparation: Clean both glass and metal well to remove dirt or grease. Use a proper cleaner and let it dry completely.

- Adhesive Application: Apply a small, even layer of the adhesive on the metal. Don’t use too much glue; it can weaken the bond.

- Positioning: Gently place the glass on the glued metal. Make sure it’s aligned right to avoid shifting that can weaken the bond.

- Clamping: Press the glued pieces together with a clamp or a weight. Let it set according to the glue manufacturer’s instructions.

- Curing: Let the glue cure fully. Check the glue’s package for specific curing times, as they can vary.

Safety Tips

- Wear gloves and eyewear to protect yourself from the glue.

- Work in a well-aired area to avoid breathing in fumes.

- Follow the glue manufacturer’s instructions and safety warnings.

- Keep the glue to stick metal to glass out of reach of kids and pets.

By carefully following our step-by-step guide and sticking to vital safety tips, you can achieve a strong and lasting bond between metal and glass.

Advantages of High Strength Glass and Metal Adhesive

One huge plus of strong glass and metal adhesive is its lasting power. It’s made to handle tough situations well, which makes it great for both work and home use. ZDS™ products, for example, keep their strength in different climates.

Also, these adhesives look good when applied. They allow for a smooth and tidy look. This means the places where materials are joined aren’t easy to spot. ZDS™ adhesives keep the connection area almost hidden.

These adhesives are made to last through all kinds of weather. They stay strong against heat, chemicals, and water. So, they’re crucial whether you’re fixing something at home, working on big machinery, or being creative.

| Advantage | ZDS™ Adhesive | Competitors |

|---|---|---|

| Durability | High | Moderate |

| Visibility of Bond Line | Minimal | Moderate |

| Environmental Resistance | Excellent | Good |

In summary, strong glass and metal adhesives have many key benefits. They keep things together strongly and look good doing it. For projects that need to meet high standards, going with a trusted name like ZDS™ is your best bet.

Customer Testimonials for ZDS™ Glass Metal Adhesives

We are very proud of our high customer satisfaction. Many customer testimonials show our adhesives work well for bonding glass to metal. This is true across many industries.

“ZDS™ adhesives were a game-changer for our manufacturing process. The bond strength and durability surpassed our expectations!” – Automotive Industry Client

“Using ZDS™ products for our art installations has been a seamless experience. The glue’s transparency and adhesion quality are unmatched.” – Art & Craft Professional

| Testimonial | Industry | Rating |

|---|---|---|

| “The best adhesive for glass to metal we’ve ever used.” – Industrial Client | Industrial | ⭐⭐⭐⭐⭐ |

| “Highly recommend ZDS™ adhesives for delicate home repairs.” – Home Repair User | Home Repairs | ⭐⭐⭐⭐⭐ |

The positive customer testimonials show how good ZDS™ products are. Our adhesives deliver perfect results, from big projects to small repairs at home. Find out why ZDS™ is the top choice for attaching glass to metal. Read more ZDS™ adhesives reviews from happy customers.

Common Applications of Glass to Metal Glue

Using glue for glass and metal brings many practical and artistic uses. It’s key for both tough industrial glue applications and detailed home repairs adhesive tasks. This glue firmly connects both materials together.

Industrial Use

In industries, glue for glass and metal is a must. It’s used to bond parts in machinery and cars. It stands up to a lot of wear and tear. Thus, it makes industrial items last longer and work better.

| Application | Benefit |

|---|---|

| Automotive components | Enhanced durability |

| Machinery | Increased reliability |

| Architectural elements | Strong aesthetic and functional bonds |

Home Repairs

This home repairs adhesive is crucial for fixing things. It mends broken glass and secures metal elements. These glues can handle both small and big fixes at home with ease.

Art and Crafts

In arts and crafts, glue for glass and metal unlocks creative potential. Artists use it for detailed work, combining materials without losing integrity. It ensures artistic pieces stay beautiful and whole.

Maintenance and Longevity of Glass to Metal Bonding

To make sure the glass metal bond stays strong, focus on adhesive maintenance matters a lot. Pick the right adhesive, apply it correctly, and take great care after it’s set. This way, the bond will last much longer.

Proper Adhesive Selection: Choose the right adhesive by asking experts for advice. We ensure our ZDS™ products are top quality.

Correct Application: To get the strongest possible glass metal bond, follow a careful process. Always stick to what the maker suggests.

Post-Curing Care: After the bond sets, check it regularly and maintain it well. This stops the bond from getting weaker over time.

| Adhesive Maintenance Tips | Benefits |

|---|---|

| Regular Inspections | Finds issues early |

| Proper Cleaning | Keeps chemicals from damaging it |

| Optimal Storage Conditions | Keeps the adhesive in good shape |

Using these steps not only makes the bond stronger at the start but also keeps it tough longer. ZDS™ makes sure taking care of your glass to metal bonds is easy.

Conclusion

Our ZDS™ adhesive solutions stand out as the top choice for bonding glass to metal. We’ve explored a wide range of glues, including epoxy, silicone, and UV-curing types. Each one has been carefully reviewed to ensure you get the best.

When selecting an adhesive, we help you weigh all important factors. This ensures that you make an informed choice. Our recommended products shine for their strength and reliability, outperforming others on the market. We also guide you on how to use them safely and effectively.

Our adhesives are versatile, suitable for many needs ranging from industrial to DIY projects. We share tips on keeping your bonds strong for longer. ZDS™ is committed to top-notch adhesive solutions and customer happiness, making us a leader in the field.

FAQ

What is the best glue for glass to metal?

ZDS™ adhesives are top-notch for bonding glass to metal. They are made especially to be strong and long-lasting.

Why is gluing glass to metal important?

It’s key in industries like auto and home appliances. It offers both function and beauty.

What challenges are faced in glass to metal adhesion?

The main issues are getting a strong bond without breaking the glass. Also, dealing with different expansion rates and making it last under all weather.

What types of glue are suitable for glass to metal applications?

Epoxy adhesives, silicone-based glues, and UV-curing adhesives are great choices. Each has special features for different needs.

What factors should be considered when choosing glue for sticking metal to glass?

Think about how strong the bond needs to be, how fast it sets, and the glue’s thickness. Environmental factors like temperature changes and humidity matter too.

What are the features of ZDS™ adhesives for glass to metal applications?

ZDS™ adhesives offer super strength and can handle temperature changes well. They are also very durable.

How do ZDS™ adhesives compare to competitors?

ZDS™ adhesives are better than others, offering stronger bonds and more value. They are preferred for both professional and personal projects.

How should glue for glass to metal be applied?

Start by preparing the surface, then apply the glue. Clamp them together. ZDS™ has a guide to help you get the best bond.

What safety tips should be followed when using glue for glass to metal?

Always wear safety gear and make sure the area is well-ventilated. Follow the directions closely to stay safe.

What are the advantages of high-strength glass and metal adhesives?

They’re perfect for tough situations, keep bonds strong in various conditions, and the bond looks good because it’s barely noticeable.

Are there any customer testimonials for ZDS™ glass metal adhesives?

Yes, many customers have shared positive reviews. They say ZDS™ adhesives work great for glass to metal jobs.

What are common applications of glass to metal glue?

It’s used in industry, home fixes, and crafts. ZDS™ glues make glass and metal stick together well.

How can the longevity of glass to metal bonding be maintained?

To keep the bond strong over time, pick the right adhesive. Apply it correctly and do regular upkeep as ZDS™ recommends.