Welcome to our guide on Industrial Polyurethane Potting Compounds. At ZDS™, we aim to show how these materials boost manufacturing and engineering. We offer insights on choosing, using, and the perks of top-notch chemical-resistant potting compounds. Our main focus is on polyurethane materials, key for protecting electronic and mechanical parts in tough industrial settings.

In this guide, you’ll learn how our potting compounds stand up to tough conditions. This makes your projects last longer and work better. We’re all about quality and new ideas, helping both pros and DIY fans with industrial potting stuff.

Want to know more about these important materials? Check out our thermal conductivity potting solutions. They show how vital they are in many uses.

Key Takeaways

- Industrial polyurethane potting compounds are key for protecting electronic parts.

- They have high chemical resistance and last long.

- Using them right is key for the best results.

- There are options for different industrial needs.

- Knowing what potting materials do helps pick the right one for your project.

Introduction to Industrial Potting Compounds

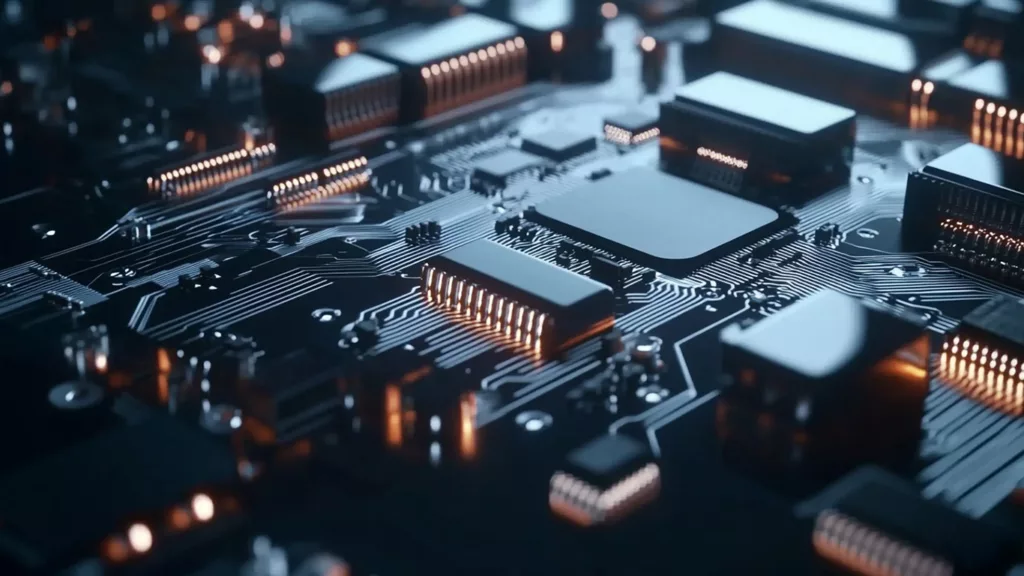

Industrial potting compounds protect and cover electronic parts. They do many things, like insulate and keep moisture out. Polyurethane is a top choice because it works really well.

Polyurethane is used in many fields, like aerospace and medicine. It’s great because it can handle tough chemicals. Choosing the right polyurethane potting material helps meet standards and makes systems work better.

What is a Polyurethane Potting Material?

Polyurethane potting materials are special compounds made from polymers. They are designed to protect electronic parts. These materials mix polyol and isocyanate to create a strong, flexible resin. This makes them great for many uses.

Definition and Properties

Let’s look at what makes polyurethane potting materials so useful:

- Thermal Stability: They can handle high temperatures, keeping components safe.

- Chemical Resistance: They fight off corrosion and damage, perfect for tough places.

- Mechanical Strength: They’re strong against physical harm, like shocks and vibrations.

Applications in Various Industries

Polyurethane potting material is used in many fields:

- Electronics: It’s great for covering circuit boards, sensors, and LEDs.

- Automotive: It shields important parts like headlights and control units from moisture and shakes.

- Aerospace: It offers top-notch protection for avionics and instruments in planes.

This shows how important it is to know about polyurethane potting material. Choosing the right one can make systems and devices work better and last longer.

Benefits of Using Chemical-Resistant Potting Compounds

Chemical-resistant potting compounds bring many benefits to different uses. They are tough and protect against harsh conditions. This makes them a top choice for many industries. Let’s dive into why these compounds are so valuable.

Durability and Longevity

One big plus of chemical-resistant potting compounds is their long-lasting nature. This means the parts they cover can last longer. Here are some key benefits:

- Extended Lifespan: They keep parts safe from damage over time.

- Cost-Effectiveness: They save money by needing less repair and replacement.

- Enhanced Performance: They keep electrical and thermal properties stable, improving function.

Protection Against Harsh Environments

These compounds are made to handle extreme conditions. They offer vital protection for reliable work. They stand up well against:

- Corrosive Chemicals: They block damage from harsh solvents and acids.

- Moisture and Humidity: They stop water from getting in, which can cause failures and lower efficiency.

- Thermal Fluctuations: They keep performance steady, even with changing temperatures.

Choosing a chemical-resistant polyurethane potting compound means your projects will work well, even in tough conditions. Their durability and protective qualities highlight the importance of picking the right industrial potting compound.

Understanding Industrial Grade Potting Compounds

Industrial grade potting compounds meet the tough needs of many industries. They have key traits that make electronic parts work better and last longer. These include:

- Higher Performance Specifications: These compounds meet strict industry standards. They perform well in tough settings.

- Tailored Formulations: They come in different viscosities and cure times. This lets manufacturers pick the right one for their needs.

- Versatile Use Cases: These compounds work well in many situations. They help make important parts more reliable.

Choosing the right polyurethane potting sealant is key to a system’s durability. Knowing about these features helps manufacturers pick the best materials. This ensures their products work well for a long time.

| Feature | Description | Benefit |

|---|---|---|

| Performance Specifications | Conforms to industry standards | Ensures reliability in critical applications |

| Custom Formulations | Various viscosities and cure times | Meets specific project requirements |

| Application Flexibility | Suitable for diverse operating environments | Boosts reliability across multiple use cases |

Key Characteristics of Polyurethane Potting Sealants

Polyurethane potting sealants are known for their important traits. These traits make them reliable and effective for electronic parts. They are flexible and stick well, meeting the needs of many industries.

Flexibility and Adhesion

One key feature of polyurethane potting sealants is their flexibility. This lets them handle shock and movement well. Here are some important points:

- Adhesion: Sticks well to different surfaces, staying strong under stress.

- Thermal Expansion: Changes with temperature without cracking, keeping circuits safe.

Moisture Resistance

Keeping electronics dry is vital, and polyurethane sealants do a great job. They solve many problems:

- Barrier Formation: Makes a waterproof seal to keep moisture out.

- Condensation Protection: Stops damage from moisture buildup, keeping electronics working right.

| Characteristic | Benefit | Application |

|---|---|---|

| Flexibility | Absorbs shock and accommodates movement | Electrical circuits in variable environments |

| Adhesion | Strong bond to various substrates | Encapsulation and potting of components |

| Moisture Resistance | Protects from humidity and condensation | Use in humid or wet environments |

Types of Chemical-Resistant Polyurethane Potting Compound for Industrial Use

Chemical-resistant polyurethane potting compounds are used in many industries. They come in standard and specialty types. Each type has its own benefits for different challenges, making the right choice important.

Standard vs. Specialty Formulations

Standard formulas protect against common industrial conditions well. They work great for most places with usual moisture and temperature changes. But, specialty formulas are made for tougher environments.

- Extreme temperatures

- High chemical exposure

- Moisture-rich conditions

It’s key to pick the right formula for your needs. This ensures the compound lasts and works well in your application.

Comparative Analysis of Brands

Comparing different industrial potting compounds is important. Many brands stand out with special features:

| Brand | Key Features |

|---|---|

| Brand A | Known for moisture-resistant formulations |

| Brand B | Specialized products with superior thermal stability |

Knowing the differences helps you make better choices. This leads to better results in industrial settings.

Application Methods for Industrial Polyurethane Potting Compound

Getting the right application methods for industrial potting compounds is key to success. The setup and preparation of the area and materials are very important. They help make the potting process work better. Following the right steps ensures strong bonding and lasting results.

Preparation and Setup

Before you start with polyurethane potting compounds, you need to prepare well. Here are some important steps:

- Surface Cleaning: Make sure all surfaces are clean to help the compound stick well.

- Temperature Control: Keep the temperature right for both the environment and materials. This helps the compound stick better.

Application Techniques

There are different ways to apply polyurethane potting compound, each for different needs. Knowing these methods is important for doing it right:

- Pour Method: Great for covering big parts, it spreads the material evenly.

- Injection Method: Perfect for small, detailed parts, it lets you place the material exactly where you want it.

Choosing the right method makes the compound last longer and work better. This is important for many industrial uses.

| Technique | Best For | Advantages |

|---|---|---|

| Pour Method | Larger components | Even distribution, simple application |

| Injection Method | Intricate electronic parts | Precision control, minimal waste |

Choosing the Right Polyurethane Potting Material

Choosing the right polyurethane potting material is key for top performance in many uses. Knowing the factors in selecting polyurethane potting material is vital. It affects how well electronic parts and other industrial items work.

Factors to Consider

When picking the right potting material, several key points are important:

- Environmental Conditions: Look at moisture, temperature changes, and chemical risks for good protection.

- Application Specifics: Think about the size and shape of parts, and any special challenges they might have.

Recommendations for Different Applications

For the best results, pick the best polyurethane potting compound for applications based on what you need:

| Application | Recommended Compound | Key Features |

|---|---|---|

| Electronics | Moisture-resistant formulations | Excellent adhesion and electrical insulation |

| Automotive | Chemical-resistant options | Can handle various car fluids and environmental stressors |

Knowing these tips helps experts choose the best materials for each job. This makes their systems more reliable and efficient. For more info on these materials and their uses, check out our guide on electrical potting solutions.

Best Practices for Using Industrial Potting Compound

Using industrial potting compounds right means knowing how to store them and keeping safe. Learning the best ways to store these compounds and following safety rules can make them last longer and work better.

Shelf Life and Storage Tips

Storing and handling industrial potting compounds correctly can really boost their performance. Here are some key tips:

- Cool, Dry Environment: Keep them in a room temperature spot, away from sunlight to keep them stable.

- Containers: Use tight containers to stop air and moisture from getting in, keeping the compound good.

Safety Precautions

When you’re working with chemical-resistant potting compounds, safety is the top priority. Here are some important steps to follow:

- Personal Protective Equipment (PPE): Wear gloves, safety glasses, and masks to protect yourself from harmful chemicals.

- Ventilation: Make sure your workspace has good air flow when using these materials to avoid breathing in harmful fumes.

Case Studies of Successful Applications

Looking at real examples shows how well chemical-resistant polyurethane potting compounds work. These stories show how different industries use them to get better results and dependability.

Industry-Specific Examples

Different fields have found special benefits in using polyurethane potting compounds. Here are some examples:

- Aerospace: Using these compounds to cover sensitive parts has made things work better and last longer. This is key for keeping things running smoothly.

- Medical Devices: It’s important to protect important parts to make sure devices work well, even when they’re being sterilized.

Client Testimonials and Experiences

What clients say shows the real benefits of using polyurethane potting compounds:

“Switching to polyurethane potting compounds has made our products more reliable and cut down our repair costs a lot.”

These comments show how investing in good potting solutions can make products last longer.

Future Trends in Polyurethane Potting Compounds

The world of polyurethane potting compounds is changing fast. People are now more aware of the need for eco-friendly materials. This means companies are looking for ways to make products that are good for the planet without sacrificing quality.

There’s also a big push towards smart materials. New tech lets us make potting compounds with sensors inside. These smart compounds can check how well they’re working in real time. This makes things run more smoothly in many areas.

Keeping up with these trends can help companies stay ahead. It lets them offer better products and stay competitive. By exploring these new ideas, businesses can get ready for what’s next.

| Trend | Description | Impact on Industry |

|---|---|---|

| Eco-Friendly Materials | Materials designed to reduce environmental impact. | Increased demand for sustainable practices and compliance with regulations. |

| Smart Materials | Potting compounds with sensors for real-time monitoring. | Improved operational efficiency and data collection for performance optimization. |

| Enhanced Performance | Focus on compounds that provide superior durability and resistance. | Better longevity of components, leading to reduced maintenance costs. |

Conclusion

Understanding industrial polyurethane potting compounds is key to protecting industrial parts well. This guide has covered their properties, uses, and best practices. It shows how they offer many benefits.

At ZDS™, we want to help both manufacturers and DIY fans make smart choices about potting materials. We aim to give you the knowledge you need. This fits with our goal of providing top-notch products and new solutions.

We’re dedicated to solving industry challenges with quality and expertise. Working together, we can make critical components more reliable and effective. Your use of these materials is vital for success in tough settings.

FAQ

What is a chemical-resistant polyurethane potting compound?

It’s a special material for protecting electronic parts. It keeps them safe from harsh chemicals, moisture, and extreme temperatures. This ensures they last longer and work well in tough conditions.

How do I choose the right industrial potting compound for my application?

Think about the environment it will be in. Consider the temperature and moisture levels. Also, think about the size and shape of the parts and what you need the compound to do.

What are the key benefits of using polyurethane potting materials?

They are very durable and protect well against harsh conditions. This means parts last longer and need less maintenance. It also saves money by reducing the need for frequent replacements.

Can I use polyurethane potting sealant in outdoor applications?

Yes, you can use it outside. It’s good at keeping moisture out and protecting against chemicals. This makes sure the parts work well in different weather.

What are some common applications for industrial-grade potting compounds?

They’re used in many places. In electronics for circuit boards and sensors. Also in cars for protection against moisture and shaking. And in planes for keeping avionics safe.

How should I store polyurethane potting compounds to ensure their effectiveness?

Keep them in a cool, dry place away from sunlight. Use airtight containers to stop moisture and contamination. This keeps them working well.

What safety precautions should be taken when using potting compounds?

Always wear protective gear like gloves and masks. Work in a place with good air flow. Follow the safety instructions on the packaging.

Are there eco-friendly options for industrial potting compounds?

Yes, there’s a growing need for green options. Companies are making products that are better for the environment but work just as well.

What application techniques are recommended for polyurethane potting compounds?

Use the pour method for big parts to spread it evenly. For small, detailed parts, use injection. This gives you more control.

How does moisture resistance impact the performance of potting compounds?

It’s very important. Moisture can cause corrosion and damage. Good potting compounds block moisture, keeping parts safe and working right.