Manufacturing processes are becoming increasingly competitive, and every company seeks to stay ahead by improving operational efficiency and reducing costs. In particular, adhesive materials, which are often used in a variety of manufacturing processes, can represent a significant portion of production expenses. Whether in automotive, construction, electronics, or packaging, manufacturers are always looking for ways to reduce costs while maintaining high-quality standards. This article will explore practical and strategic cost-saving solutions for manufacturers using adhesives, helping businesses streamline their production and achieve better profit margins.

Understanding the Importance of Adhesives in Manufacturing

Adhesives are an essential part of the modern manufacturing landscape. From joining components to providing a reliable bond for different materials, adhesives are used in countless applications across multiple industries. However, the cost of adhesives can sometimes be overlooked as an area for cost savings. Many manufacturers tend to focus primarily on raw materials and labor, but adhesives are a critical component that can impact both quality and expenses.

The challenge is finding a balance between reducing adhesive costs and ensuring the quality of the final product. High-quality adhesives might come at a premium price, but their durability, performance, and suitability to specific applications often make them worthwhile. The goal, therefore, is to find cost-effective solutions that do not compromise the desired outcome.

Strategic Procurement to Lower Adhesive Costs

One of the first steps in reducing adhesive costs is optimizing the procurement process. This involves selecting the right suppliers, negotiating better contracts, and ensuring that adhesive purchases are made at the best possible price without sacrificing quality.

Supplier Selection and Negotiation

Manufacturers should take the time to evaluate potential suppliers carefully. Building a long-term relationship with reliable suppliers who offer competitive pricing can lead to substantial savings. Negotiating favorable terms and seeking bulk purchasing options can also be beneficial.

Bulk Purchasing

Buying adhesives in bulk can be a significant cost-saving measure. Manufacturers often find that purchasing adhesives in larger quantities allows them to take advantage of discounts, resulting in a lower per-unit cost. Additionally, buying in bulk ensures that materials are readily available, which can reduce delays and improve production efficiency.

Choosing the Right Adhesive for the Job

Selecting the right adhesive is not just about finding the cheapest option. The right adhesive choice depends on the materials being bonded, the environmental conditions the product will be exposed to, and the required bond strength. Using an adhesive that is too strong or too weak for the application can lead to unnecessary costs.

Customizing Adhesive Formulas for Efficiency

Some manufacturers invest in developing custom adhesive formulations that meet their specific requirements. Custom adhesives can often be tailored to optimize bonding efficiency and reduce waste. In this case, the initial cost might be higher, but over time, the savings from reduced wastage and more efficient production processes can more than make up for it.

Implementing Adhesive Usage Best Practices

Another effective way to reduce adhesive costs is to adopt best practices in adhesive usage. A surprising amount of waste can be generated if adhesives are not applied correctly or if the equipment is not set up for optimal usage.

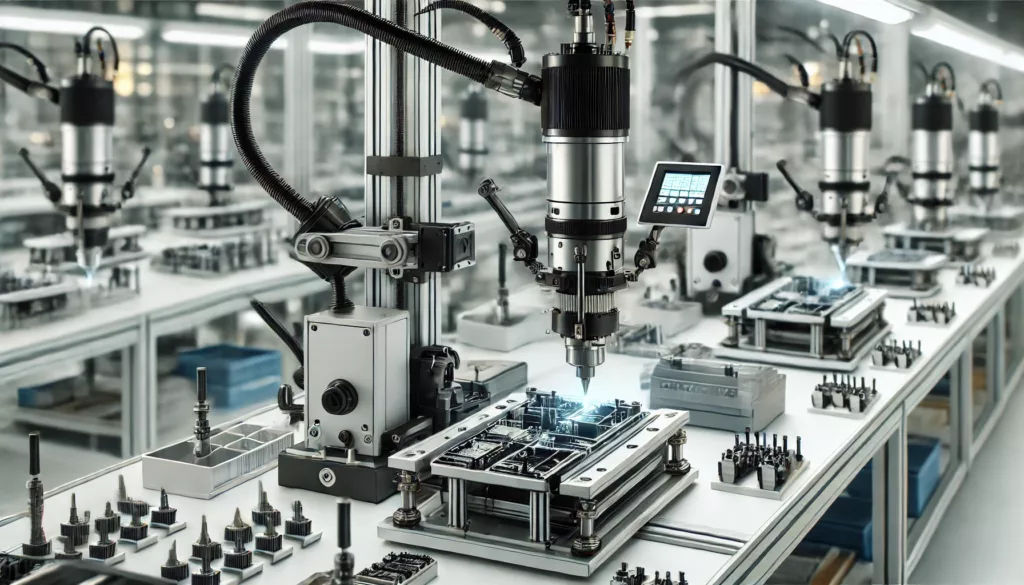

Reducing Adhesive Waste through Precision Application

Adhesive waste is a major cost factor in manufacturing. Over-application or unnecessary use of adhesives leads to wastage, which ultimately increases production costs. By using more precise dispensing systems such as automatic applicators or robots, manufacturers can significantly reduce excess adhesive application.

Training Employees on Proper Adhesive Handling

Employee training plays a crucial role in reducing adhesive waste. Proper handling and application of adhesives ensure that the materials are used efficiently. Whether in assembly or packaging processes, workers must be trained to understand the properties of adhesives and apply them in the correct quantities.

Automating Adhesive Application Processes

Automation can also reduce adhesive consumption. Automated adhesive dispensers can apply precise amounts of adhesive, eliminating the risk of human error and wastage. These machines are especially beneficial for high-volume operations, where even small reductions in adhesive use can lead to significant savings over time.

Optimizing Adhesive Storage and Shelf Life

Another often-overlooked area is the storage and handling of adhesives. Improper storage can reduce the effectiveness and shelf life of adhesives, leading to more frequent purchases and increased costs.

Proper Adhesive Storage Conditions

Adhesives must be stored according to the manufacturer’s guidelines to maintain their quality. Storing adhesives in ideal temperature and humidity conditions can prevent them from curing or becoming ineffective before use. By ensuring proper storage, manufacturers can avoid having to discard expired adhesives, which directly impacts the bottom line.

Investing in Bulk Packaging

Another way to save on adhesive costs is by switching to bulk packaging. While smaller packages may be easier to handle and store, larger containers reduce the per-unit cost of adhesives. Additionally, bulk packaging often uses less plastic or cardboard, which helps reduce overall packaging costs.

Exploring Alternative Adhesives

In some cases, switching to alternative adhesives can result in cost savings. Manufacturers should continuously explore different types of adhesives to determine if a less expensive option could serve the same purpose. For example, hot melt adhesives might be cheaper and faster to apply than traditional liquid adhesives in certain industries.

Sustainable and Green Adhesives for Cost Efficiency

The trend toward sustainability is also gaining momentum in manufacturing, and this can lead to cost savings as well. Many “green” adhesives, which are made from renewable or recycled materials, are now being produced. While these adhesives were once considered more expensive, advances in technology have made them a viable option for manufacturers looking to reduce environmental impact without incurring high costs.

Reduce Downtime with Faster Curing Adhesives

Some adhesives require long curing times, which can slow down production. By opting for faster-curing adhesives, manufacturers can reduce the amount of time it takes for products to move through the production line, thus increasing throughput and reducing labor costs associated with extended curing times.

Leveraging Technology to Track Adhesive Usage

Tracking and monitoring adhesive usage through advanced software or ERP systems can help manufacturers identify patterns of waste and inefficiency. With this data, businesses can make more informed decisions on how to optimize their adhesive usage and reduce costs.

Cost-Saving Solutions Beyond Adhesives

While adhesives are a critical part of the manufacturing process, they should not be viewed in isolation. Broader cost-saving initiatives that affect the entire production process can contribute to overall savings in adhesive use.

Improving Operational Efficiency

Streamlining other parts of the production process can indirectly reduce adhesive costs. By increasing overall efficiency, manufacturers can reduce the time and materials wasted during production. Improved machine efficiency, better workflow management, and streamlined labor processes all contribute to lower overall production costs.

Lean Manufacturing Practices

Incorporating lean manufacturing principles into the production process can lead to significant cost reductions. By focusing on eliminating waste, improving quality control, and reducing inventory levels, manufacturers can improve their bottom line and reduce costs in adhesive consumption.

Collaborating with Suppliers for Joint Cost-Saving Initiatives

Collaborating with adhesive suppliers on cost-saving initiatives can provide mutual benefits. Suppliers are often willing to work with manufacturers to find ways to optimize adhesive usage or introduce innovative products that can cut costs. Joint development of new adhesive solutions that align with the manufacturer’s needs can yield long-term benefits.

Case Study: A Real-World Example of Adhesive Cost Savings

Consider a manufacturer in the automotive industry that specializes in assembling vehicle components. By transitioning from manual adhesive application to automated robotic dispensers, they reduced adhesive wastage by 30%. Additionally, by consolidating orders and negotiating bulk pricing with suppliers, they achieved a 15% reduction in adhesive purchasing costs. Combined with the use of faster-curing adhesives, the company realized a significant improvement in production speed and a reduction in costs.

Conclusion

Cost-saving solutions for manufacturers in the adhesive sector require a multi-faceted approach. From optimizing procurement processes to reducing waste through precision application, every step in the adhesive usage cycle presents an opportunity for savings. By taking a proactive approach to adhesive selection, storage, application, and overall production efficiency, manufacturers can achieve significant cost reductions without compromising product quality. This, in turn, ensures that manufacturers remain competitive in an increasingly cost-sensitive market. With the right strategies in place, the adhesive costs that once seemed like a necessary expense can be transformed into an area of opportunity.

FAQs

What are the main cost-saving strategies for manufacturers using adhesives?

The main strategies include optimizing adhesive procurement, reducing waste through precision application, automating adhesive dispensing, and selecting cost-effective adhesives that meet the specific needs of the application.

How can manufacturers reduce adhesive waste?

Manufacturers can reduce adhesive waste by implementing automated dispensing systems, training employees on proper adhesive handling, and using precise application methods to avoid overuse.

Are there sustainable adhesives that can help reduce costs?

Yes, many sustainable adhesives made from renewable materials are available. These can often reduce production costs in the long run by improving efficiency and offering lower environmental impact.

Can bulk adhesive purchasing reduce costs?

Yes, buying adhesives in bulk allows manufacturers to take advantage of discounts, lower per-unit costs, and ensure that adhesives are always available when needed, reducing production delays.

What role does adhesive curing time play in cost savings?

Faster-curing adhesives can reduce downtime and improve production efficiency, leading to savings in both labor and overall operational costs.

How can manufacturers evaluate the right adhesive for their processes?

Manufacturers should evaluate adhesives based on their specific application needs, including material compatibility, bond strength requirements, environmental conditions, and cost-effectiveness.