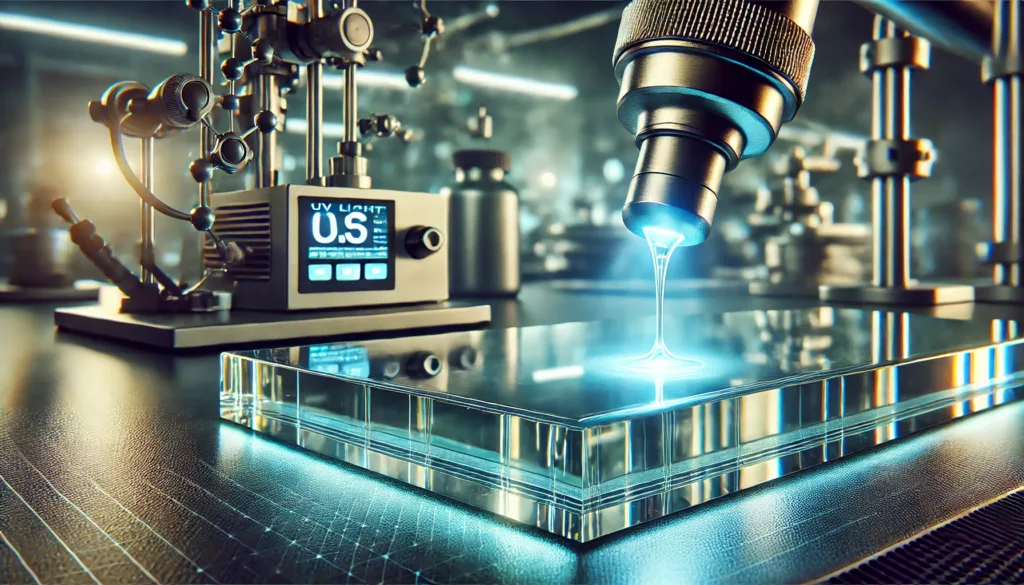

UV light adhesives, also known as UV-curing adhesives, are an innovative solution for achieving strong, durable bonds in various industries. These adhesives use ultraviolet (UV) light to initiate a chemical reaction that cures the adhesive, creating a solid bond. From electronics to medical devices, UV adhesives offer rapid curing, precision, and reliability, making them a preferred choice for complex bonding applications.

Understanding UV Light Adhesives

UV light adhesives are a unique type of bonding material that relies on a photochemical process. When exposed to UV light of a specific wavelength, the adhesive undergoes a transformation from a liquid to a solid state. This transformation is achieved through a polymerization reaction driven by photoinitiators—compounds in the adhesive that absorb UV light and generate reactive species.

What Makes UV Light Adhesives Unique?

Rapid Curing Process

One of the most striking features of UV adhesives is their speed. Traditional adhesives may take hours or days to cure fully. UV light adhesives, however, can cure in seconds or minutes, saving significant time in manufacturing and assembly processes.

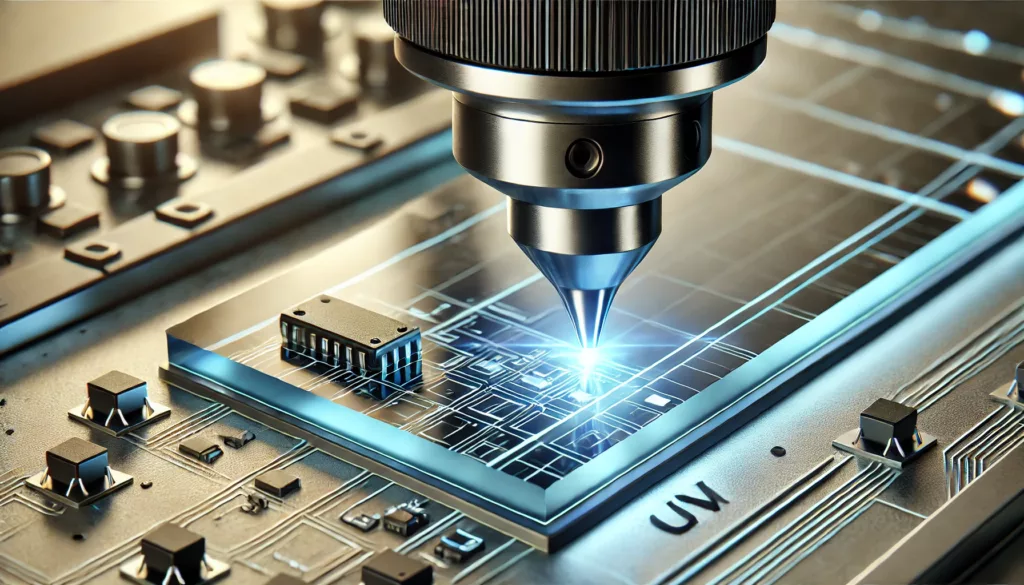

Precision Bonding

Because UV adhesives cure only when exposed to UV light, they allow precise application and curing. This controlled process is especially beneficial in applications requiring meticulous detail, such as bonding miniature components in electronics.

Strong and Durable Bonds

The chemical reaction triggered by UV light creates bonds that are both strong and durable. These adhesives can resist extreme temperatures, moisture, and chemical exposure, ensuring long-lasting performance.

How Do UV Light Adhesives Work?

To understand their functionality, let’s break down the process into key steps:

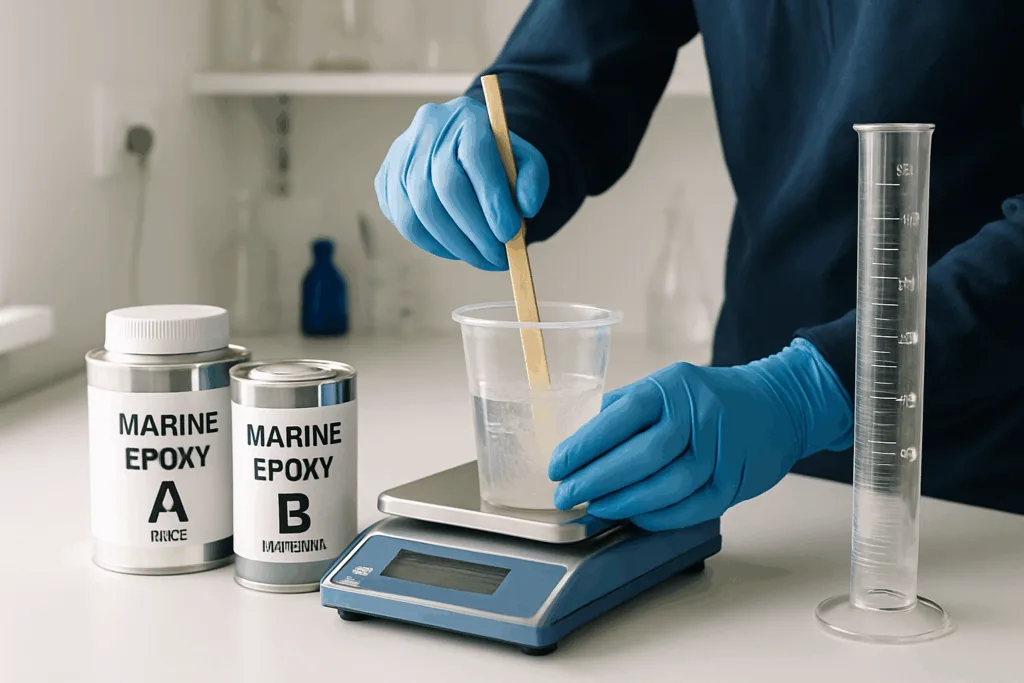

1. Application of Adhesive

The adhesive is applied to the surface(s) to be bonded. This step requires attention to detail to ensure even coverage.

2. Alignment of Components

Before curing, the components to be bonded must be properly aligned. The adhesive remains in liquid form, allowing adjustments.

3. Exposure to UV Light

Once everything is in position, the adhesive is exposed to UV light. The wavelength and intensity of the light depend on the adhesive formulation.

4. Initiation of Polymerization

The photoinitiators absorb the UV light, generating reactive species that initiate polymerization—a chemical reaction that transforms the adhesive into a solid.

5. Full Curing

Within seconds to minutes, the adhesive hardens, creating a robust bond. Post-curing may be necessary for some applications to enhance bond strength further.

Applications of UV Light Adhesives

UV light adhesives have a wide range of applications across various industries:

Electronics

Used for assembling circuit boards, attaching components, and sealing sensitive electronics.

Medical Devices

Ideal for bonding medical equipment, including catheters and syringes, due to their biocompatibility and precision.

Automotive

Provides reliable bonding for glass, plastics, and other components in car manufacturing.

Optics

Ensures clear and strong bonds for lenses, screens, and optical fibers without affecting clarity.

Advantages of UV Light Adhesives

Time-Efficient

UV adhesives drastically reduce production time due to their rapid curing process.

Eco-Friendly

Many formulations are solvent-free, reducing environmental impact.

Enhanced Control

Manufacturers have complete control over the curing process, ensuring accuracy.

Versatility

UV adhesives bond a wide range of materials, including plastics, glass, and metals.

Challenges in Using UV Light Adhesives

While UV adhesives offer numerous advantages, there are a few challenges to consider:

Light Accessibility

The adhesive must be exposed to UV light, which can be challenging for opaque or shaded areas.

Special Equipment

The process requires UV light sources, which may involve an upfront investment.

Material Compatibility

Not all materials are suitable for UV adhesives, requiring thorough testing beforehand.

Innovations in UV Light Adhesives

The field of UV adhesives is continually evolving with advancements like:

- Hybrid Adhesives: Combining UV curing with thermal or moisture curing for enhanced flexibility.

- LED UV Systems: Energy-efficient and safer alternatives to traditional UV lamps.

- Customized Formulations: Adhesives tailored for specific industrial needs.

How to Choose the Right UV Light Adhesive

Consider the Substrate

Different materials require specific adhesive formulations for optimal bonding.

Evaluate Bond Strength

Determine the required bond strength based on the application.

Assess Curing Conditions

Ensure that the adhesive can be cured effectively in the intended environment.

Check Environmental Resistance

Choose adhesives that can withstand the operational environment, such as high temperatures or exposure to chemicals.

FAQs

What materials can UV light adhesives bond?

UV adhesives can bond a variety of materials, including plastics, glass, metals, and ceramics.

Do UV adhesives work on opaque surfaces?

No, UV adhesives require exposure to UV light, so they are not suitable for opaque surfaces.

How long does it take for UV adhesives to cure?

Curing typically takes a few seconds to a few minutes, depending on the adhesive and UV light intensity.

Are UV adhesives environmentally friendly?

Yes, many UV adhesives are solvent-free, making them eco-friendly compared to traditional adhesives.

Can UV adhesives handle extreme temperatures?

Yes, they are designed to withstand high and low temperatures, as well as moisture and chemicals.

Is special equipment needed to use UV adhesives?

Yes, a UV light source is required for the curing process.

Conclusion

UV light adhesives represent a cutting-edge solution for bonding challenges in modern industries. With their rapid curing times, precision application, and robust performance, they have become indispensable in manufacturing, electronics, medical devices, and more. While they require specific conditions for optimal use, their advantages far outweigh the limitations, making them a versatile and reliable choice for bonding needs. As technology advances, UV adhesives are poised to offer even greater efficiency and adaptability in the future.