In modern manufacturing and engineering, the debate between structural adhesives and mechanical fasteners has evolved into a strategic decision about performance, aesthetics, and long-term reliability. As industries seek lighter, stronger, and more efficient assemblies, structural adhesives are rising to the forefront.

ZDS™ is a trusted adhesive manufacturer providing innovative bonding solutions, supporting industries worldwide with high-performance adhesives designed for structural integrity, speed, and durability.

Let’s explore the top five benefits of structural adhesives over mechanical fasteners, and why engineers and designers are making the shift.

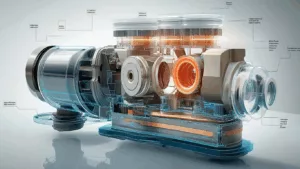

1. Improved Stress Distribution

Unlike bolts or rivets that create concentrated stress points, structural adhesives distribute loads evenly across bonded surfaces. This uniform stress dispersion reduces the risk of localized material failure and enhances the overall mechanical strength of the joint.

Key Takeaway:

- Minimized stress concentration enhances fatigue resistance.

- Ideal for composite and lightweight materials.

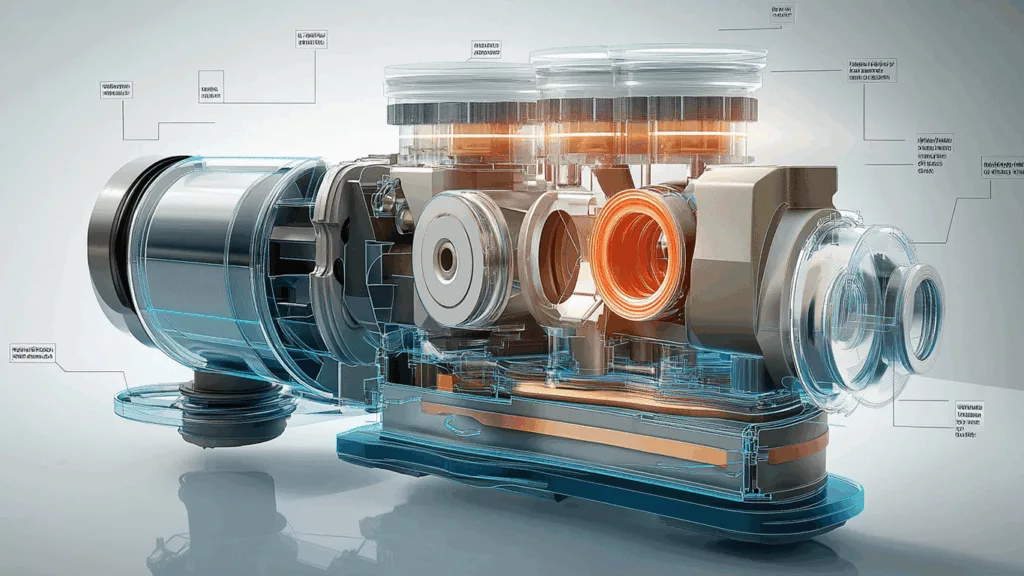

2. Lightweight Assembly Without Compromising Strength

In sectors like automotive, aerospace, and electronics, reducing weight is critical. Structural adhesives eliminate the need for heavy mechanical fasteners, contributing to lighter assemblies while maintaining or even increasing strength.

Structural Bonding Advantages:

- Eliminates added weight from nuts, bolts, or welds.

- Enables design flexibility with thinner materials.

3. Enhanced Aesthetics and Streamlined Design

Mechanical fasteners can disrupt surface continuity and appearance. Adhesive bonding allows for seamless, smooth finishes, which are especially important in consumer products, electronics, and automotive interiors.

Benefits Include:

- No visible screws or holes.

- Better aerodynamic profiles in automotive and aerospace designs.

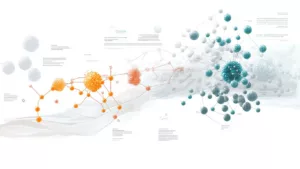

4. Corrosion Resistance and Durability

Fasteners can create crevices where moisture and contaminants gather, leading to galvanic corrosion—especially in mixed-metal joints. Adhesives seal joints completely, preventing environmental ingress and improving long-term performance.

Industrial Adhesive Benefits:

- Improved resistance to water, chemicals, and UV exposure.

- Maintains structural integrity in harsh conditions.

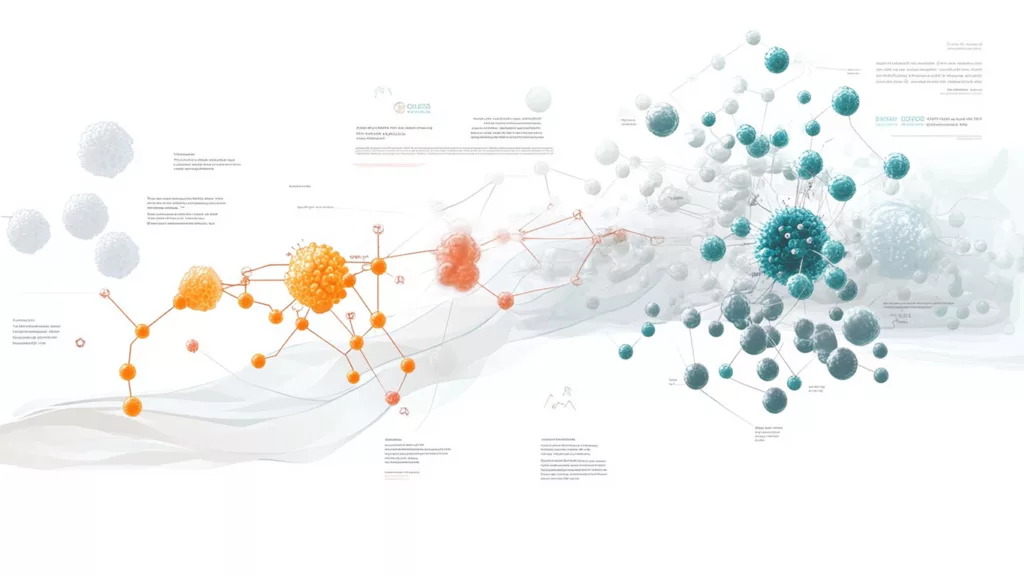

5. Faster and More Cost-Effective Manufacturing

Structural adhesives reduce assembly time by eliminating drilling, tapping, or welding steps. They can also bond dissimilar materials—like metal to plastic—without additional hardware or tools, streamlining production lines.

Efficiency Gains:

- Lower labor costs and fewer parts.

- Compatible with automation and robotic dispensing systems.

FAQs

Q1: Are structural adhesives as strong as mechanical fasteners?

Yes, in many applications, adhesives offer comparable or superior strength—especially when bonding large or dissimilar surfaces.

Q2: Can adhesives replace fasteners in all applications?

While adhesives are versatile, high-impact or removable joints may still benefit from mechanical fasteners or hybrid bonding methods.

Q3: What materials can structural adhesives bond?

Adhesives can bond metals, plastics, composites, glass, and more—making them ideal for multi-material assemblies.

Final Call to Action

As design demands evolve, structural adhesives offer a smarter, cleaner, and more efficient alternative to traditional fasteners. Whether you’re in aerospace, electronics, or automotive manufacturing, leveraging the benefits of structural bonding can transform your production process.

Partner with ZDS™ to explore cutting-edge adhesive solutions tailored to your industry needs. Our expertise and innovation ensure your assemblies are built to last—without compromise.