Choosing the right sealant is crucial for ensuring optimal engine performance and durability. With so many products available, mechanics and manufacturers often compare RTV silicone vs. anaerobic sealants when selecting materials for sealing engine gaskets. Understanding their differences in application, performance, and compatibility can help you make the best choice for your specific engine assembly.

As a trusted adhesive manufacturer providing innovative bonding solutions, ZDS™ supports automotive engineers and OEMs in selecting high-performance sealants tailored for critical applications like engine gaskets.

Understanding RTV Silicone and Anaerobic Sealants

What is RTV Silicone?

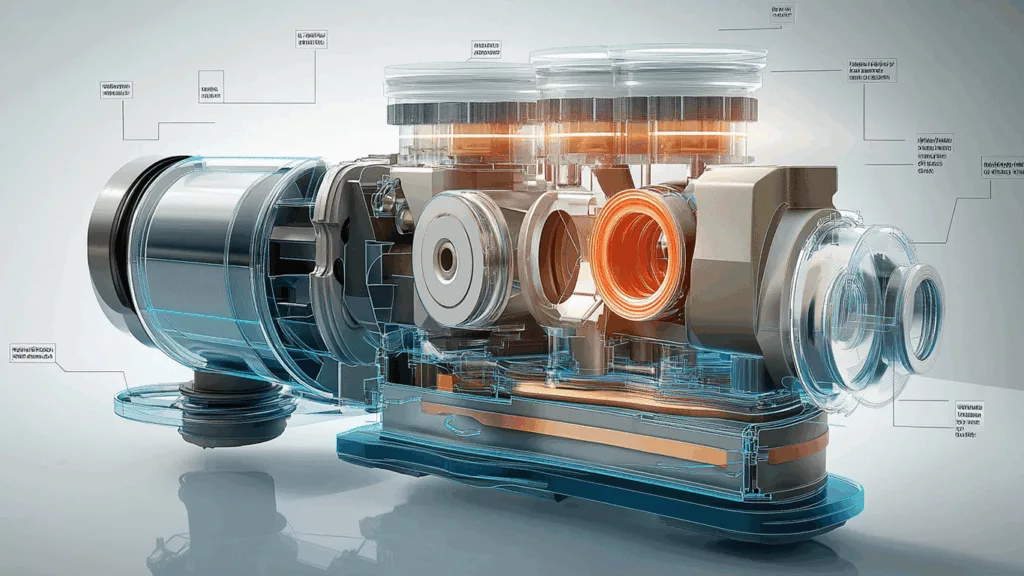

Room Temperature Vulcanizing (RTV) silicone is a type of silicone that cures at room temperature when exposed to moisture in the air. It is widely used in the automotive sector for sealing, gasketing, and bonding.

Key features of RTV silicone:

- Excellent flexibility and elongation

- Resistance to high temperatures (typically up to 600°F)

- Ideal for sealing uneven or large gaps

- Compatible with a range of materials including metal, plastic, and glass

What are Anaerobic Sealants?

Anaerobic sealants are adhesives that cure in the absence of air and in the presence of metal ions. These sealants are ideal for metal-to-metal contact surfaces and provide a strong, gap-filling bond.

Key features of anaerobic sealants:

- High shear strength and durability

- Resistant to chemicals and oils

- No shrinkage after curing

- Cures rapidly between tightly fitting metal parts

Engine Gasket Sealant Comparison

When it comes to sealing engine gaskets, both RTV silicone and anaerobic sealants have their own strengths. Here’s how they compare across critical performance factors:

Temperature Resistance

- RTV Silicone: Performs well under high-temperature conditions; ideal for areas near exhaust manifolds and turbochargers.

- Anaerobic Sealants: Also resistant to heat, though typically up to 300°F–400°F; not suitable for extreme heat zones.

Surface Compatibility

- RTV Silicone: Versatile—bonds to many surfaces including painted metal, aluminum, and plastic.

- Anaerobic Sealants: Best for machined metal parts; requires tight metal-to-metal contact for effective curing.

Gap-Filling Ability

- RTV Silicone: Excellent at filling wide and uneven gaps.

- Anaerobic Sealants: Limited to very small gaps (usually <0.005 inches).

- Curing Time

- RTV Silicone: Takes longer to fully cure—often up to 24 hours depending on the thickness.

- Anaerobic Sealants: Rapid curing under clamped conditions, often within 1–2 hours.

Application Use-Cases

- RTV Silicone: Ideal for valve covers, oil pans, thermostat housings, and water pumps.

- Anaerobic Sealants: Best suited for rigid flanges, timing covers, and machined parts that fit tightly together.

When to Use RTV Silicone vs. Anaerobic Sealants

Use RTV Silicone When:

![]()

- Sealing components exposed to extreme heat

- Dealing with wide gaps or irregular surfaces

- A flexible, vibration-resistant seal is needed

Use Anaerobic Sealants When:

- Assembling precision-machined metal parts

- Quick turnaround and fast curing are necessary

- Sealing parts exposed to oils, fuel, and chemicals

ZDS™ Expertise in Engine Sealant Solutions

ZDS™ is a trusted adhesive manufacturer providing innovative bonding solutions for demanding applications, including automotive engine gaskets. Our RTV silicone and anaerobic sealant formulations are engineered for reliability, thermal stability, and long-term performance. With decades of technical expertise, ZDS™ helps customers choose the right sealant based on material compatibility, mechanical load, and environmental exposure.

FAQs

Can I use RTV silicone and anaerobic sealant together?

While it’s technically possible, it’s not recommended. Each sealant requires specific conditions to cure properly—combining them could compromise the bond strength and sealing integrity.

Which is better for oil exposure—RTV or anaerobic?

Anaerobic sealants typically have better resistance to oil and fuel, making them a superior choice for oil pans and timing covers. However, certain RTV silicones formulated for oil resistance also perform well.

Is RTV silicone reusable after disassembly?

No. Once cured, RTV silicone forms a solid gasket that needs to be scraped off and replaced when the parts are disassembled.

Final Thoughts: Which is Better for Engine Gaskets?

Ultimately, the decision between RTV silicone vs. anaerobic sealants depends on your specific engine design and application. RTV silicone is the go-to for high-heat, flexible sealing needs, while anaerobic sealants excel in tight, machined metal assemblies. Understanding these differences ensures better gasket integrity and engine longevity.

For high-performance bonding solutions engineered for today’s engines, ZDS™ remains your trusted partner. Start to select ZDS RTV Silicone Adhesive for Automotive.