Acrylic Structural Adhesive

ZDS™ Structural Adhesives: Strengthening Your Creations with Precision and Durability.

At ZDS™, we aim to make sure every project you work on reaches its best potential. Our top-quality structural adhesives bring strength and resilience. In today’s fast-paced world, precision and durability are key. That’s why our epoxy and melt adhesives are perfect for the job.

Our adhesives are designed to tackle the toughest bonding challenges. They work well with metals, plastics, and composites. ZDS™ is here to improve the strength and performance of your projects. Learn how our products can change your bonding solutions by visiting our detailed product page.

Item | Value |

Place of Origin | China |

Guangdong | |

Main Raw Material | Structural acrylic adhesives |

Brand Name | ZDSpoxy |

Key Takeaways

- ZDS™ Structural Adhesives are engineered for unparalleled precision.

- Our adhesives offer superior durability for long-lasting projects.

- Versatile applications make ZDS™ products suitable for various industries.

- ZDS™ technology ensures high-performance bonding in extreme conditions.

- Excellence in adhesion quality sets ZDS™ apart from the competition.

Introduction

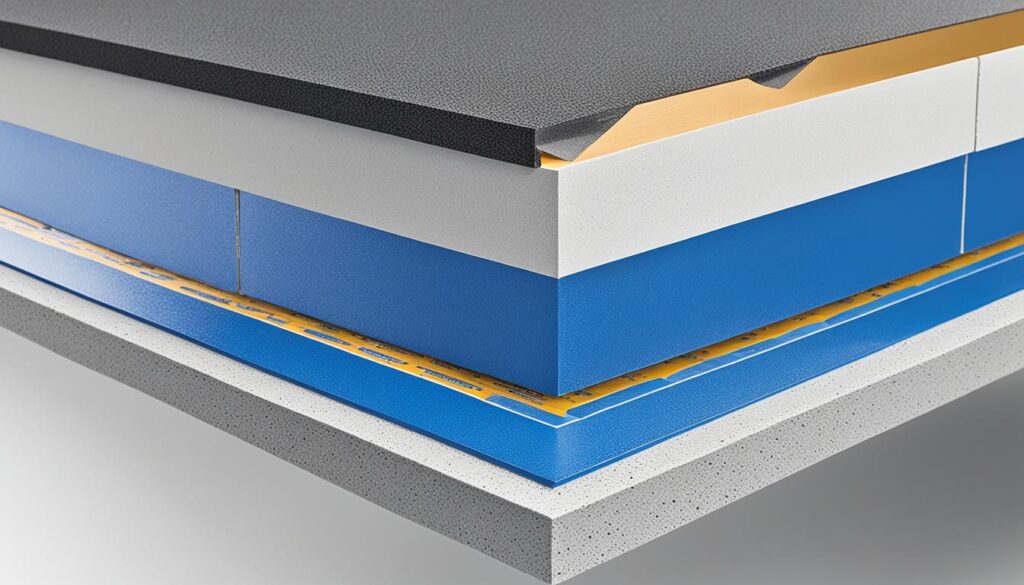

Traditional methods like screws, bolts, and rivets are often used for fastening materials. But ZDS™ structural adhesives offer a new way that has many benefits. They provide strength, making sure our creations stay strong and reliable.

These adhesives are more than just glue. They are special chemicals designed for strength and durability. ZDS™ acrylic glue are perfect for many applications, making them key in modern making and building.

Unlike screws that can weaken materials, adhesives spread loads evenly. This makes the bond stronger and lasts longer. Let’s explore the big benefits and applications of ZDS™ adhesives:

- Automotive assemblies

- Aerospace components

- Construction and infrastructure

- Woodworking projects

ZDS™ adhesives are versatile and reliable for many applications. They’re great for everything from car frames to big projects. Our adhesives make every bond strong and long-lasting.

Using ZDS™ adhesives changes how you build, offering strength and reliability. They avoid the problems of old fastening ways.

Why Choose ZDS™ Structural Adhesives?

ZDS™ structural adhesives are top-notch for their precision, durability, and wide use. They are perfect for many applications.

Unparalleled Precision

ZDS™ is all about top precision in adhesives. We make sure every adhesive works flawlessly, keeping your designs perfect. Whether you’re in aerospace, building things, or making consumer goods, our high standards mean great results.

Superior Durability

Durability is key for our adhesives. ZDS™ products last long, handling wear, chemicals, and stress well. They make sure your projects look great and last long.

Versatile Applications

ZDS™ adhesives are super versatile. They work for many industries, from aerospace to making everyday products. With ZDS™, you know our solutions will meet your project’s tough demands.

Introduction to ZDS™ Structural Adhesive

ZDS™ is a top choice for bonding solutions with its advanced acrylic glue. It uses the latest in adhesive tech, making it a leader in the automotive, woodworking, and metal sectors. Our epoxy-based solutions offer top-notch bonding across a variety of materials and uses.

| Attribute | Details |

|---|---|

| Type | Metal bonding |

| Feature | Low odor |

| Model | ZDS450 |

| Color A/B | Blue/light green |

| Volume ratio A:B | 1:1 |

| Pot life /Min | 3 |

| Initial solidification time /Min | 10 |

| Full solidification time /H | 12 |

| Shear strength (carbon steel) Mpa | 22 |

| Temperature range ℃ | -50~120 |

| Packaging | 50ml/400ml |

| Shelf life | 9-12 months |

| Attribute | Details |

|---|---|

| Type | Metal bonding |

| Feature | General bonding |

| Model | ZDS456 |

| Color A/B | Blue/red |

| Volume ratio A:B | 1:1 |

| Pot life /Min | 3 |

| Initial solidification time /Min | 30 |

| Full solidification time /H | 12 |

| Shear strength (carbon steel) Mpa | 25 |

| Temperature range ℃ | -50~120 |

| Packaging | 50ml/400ml |

| Shelf life | 9-12 months |

| Attribute | Details |

|---|---|

| Type | Metal bonding |

| Feature | Low odor/flame retardant |

| Model | ZDS470 |

| Color A/B | Blue/White |

| Volume ratio A:B | 1:1 |

| Pot life /Min | 5 |

| Initial solidification time /Min | 30 |

| Full solidification time /H | 24 |

| Shear strength (carbon steel) Mpa | 18 |

| Temperature range ℃ | -50~120 |

| Packaging | 50ml/400ml |

| Shelf life | 9-12 months |

| Attribute | Details |

|---|---|

| Type | Metal bonding |

| Feature | Long Pot life |

| Model | ZDS805 |

| Color A/B | Light green/light red |

| Volume ratio A:B | 1:1 |

| Pot life /Min | 15 |

| Initial solidification time /Min | 30 |

| Full solidification time /H | 24 |

| Shear strength (carbon steel) Mpa | 25 |

| Temperature range ℃ | -50~120 |

| Packaging | 50ml/400ml |

| Shelf life | 9-12 months |

| Attribute | Details |

|---|---|

| Type | Metal bonding |

| Feature | High temperature resistance |

| Model | ZDS332 |

| Color A/B | Clear |

| Volume ratio A:B | —— |

| Pot life /Min | 120 |

| Initial solidification time /Min | 3 |

| Full solidification time /H | 20min @ 130 ℃ |

| Shear strength (carbon steel) Mpa | 18 |

| Temperature range ℃ | -50~180 |

| Packaging | 1kg |

| Shelf life | 9-12 months |

| Attribute | Details |

|---|---|

| Type | Composite material bonding |

| Feature | General bonding |

| Model | ZDS14167 |

| Color A/B | Creamy white/blue |

| Volume ratio A:B | 10:1 |

| Pot life /Min | 10 |

| Initial solidification time /Min | 15 |

| Full solidification time /H | 12 |

| Shear strength (carbon steel) Mpa | 25 |

| Temperature range ℃ | -50~150 |

| Packaging | 50ml/490ml |

| Shelf life | 9-12 months |

Applications in Woodworking

In woodworking, the right adhesive can greatly improve the quality and durability of the final product. ZDS™ Structural Adhesives offer advanced solutions that boost the strength and longevity of woodworking projects.

Strength in Every Bond

Woodworking projects need adhesives that offer unmatched strength and reliability. ZDS™ Structural Adhesives are made to provide top-notch bonding strength. This ensures the stability of wood structures. They are used in various woodworking tasks, like cabinetry and furniture making, and outperform traditional wood glues.

These adhesives are crucial in tasks like finger jointing and face gluing. A strong and lasting bond is key in these areas.

Long-lasting Adhesion

The bond’s durability is as crucial as its initial strength. ZDS™ Structural Adhesives are made for lasting adhesion, ensuring wood products stay intact over time. They are widely used in architectural woodworking and I-Beam construction, where reliability is crucial.

Using ZDS™ adhesives in cross-laminated timber (CLT) shows their ability to keep bonds strong in complex structures.

There’s a growing trend towards using engineered wood, like CLT, in sustainable building projects. Henkel’s LOCTITE® HB X Purbond adhesive is a non-formaldehyde option that makes bonding efficient and safe for the environment. Its success in CLT applications highlights the importance of advanced adhesives in modern woodworking.

Metal Bonding Capabilities

ZDS™ Structural Adhesives lead the way in metal bonding with unmatched performance and reliability. They create strong, lasting bonds for various applications, especially in the automotive industry.

Optimal Performance

Our adhesives are top-notch for bonding metals. They’re perfect for automotive parts or industrial metal structures. ZDS™ structural bonding solutions are versatile and precise, fitting many uses.

Heat and Weather Resistance

Our adhesives can handle high temperatures and harsh weather. This is key for metal structures in tough conditions, like in cars or outdoors. With ZDS™ Adhesives, you get bonds that last, no matter the environment.

Automotive Uses of ZDS™ Structural Adhesives

The automotive industry is always changing, making strong and reliable bonds more important than ever. ZDS™ structural adhesives are key in this area. They make vehicle assembly and auto body repair better.

Common Applications in the Automotive Industry

ZDS™ adhesives are used in many ways in car making. They bond body panels, frame parts, and lightweight materials together. This makes cars perform better. Let’s look at some of these uses:

- Auto body repairs

- Assembly of frame components

- Bonding body panels

- Integrating lightweight materials for enhanced performance

Studies show that using ZDS™ adhesives makes cars stronger and safer. For instance:

| Application | Benefit | Example |

|---|---|---|

| Body Panel Bonding | Increased durability and reduced weight | Ford F-150 |

| Frame Component Assembly | Enhancedstructural integrity | Chevrolet Silverado |

| Lightweight Materials Integration | Improved fuel efficiency | Tesla Model 3 |

As we keep innovating in the automotive world, the importance of structural adhesives will grow. They will help make cars better and make customers happier.

Importance of High-Strength Bonds

High-strength bonds are key for the durability and performance of structures. They play a crucial role in keeping load-bearing parts strong in many industries.

Load-Bearing Applications

Adhesives for load-bearing parts must be very strong and stable. High-strength adhesives make sure these parts can handle big loads and stresses safely. This is vital in building bridges, buildings, or heavy machinery.

Critical Structural Components

Using high-strength adhesives in important parts makes them last longer and be more resilient. ZDS™ Structural Adhesives create strong bonds that can handle tough conditions. They are perfect for projects that need top performance, like infrastructure or aerospace engineering.

ZDS™ adhesives show their strength in many projects. For example, they’ve made infrastructure projects last longer and be more reliable.

| Industry | Application | Benefits |

|---|---|---|

| Construction | Bridge Joints | Enhanced Durability |

| Aerospace | Fuselage Assembly | Improved Safety |

| Automotive | Chassis Bonding | Increased Load Capacity |

How ZDS™ Adhesives Enhance Safety

In the world of product design and use, adhesives play a key role. At ZDS™, we make sure our adhesives boost safety, especially in cars. Our advanced epoxy makes bonds stronger and more reliable, leading to safer results.

Stronger bonds keep parts together securely, lowering the chance of failure in tough situations. In cars, our adhesives join parts that face extreme conditions and stress. This makes cars safer by reducing weak spots.

- Automotive Safety: Our epoxy adhesive makes cars more durable and stable, keeping passengers and drivers safe.

- Construction Applications: Our products help build stronger structures that can handle tough weather and heavy loads.

- Consumer Products: Better durability in everyday items means safer and longer-lasting use.

ZDS™ adhesives are tested rigorously. They meet and beat safety standards and rules. This ensures they stay safe and work well over time.

| Product | Application | Safety Impact |

|---|---|---|

| ZDS™ Epoxy | Automotive Frame | Enhanced crash protection |

| ZDS™ Structural Adhesive | Building Reinforcement | Increased structural integrity |

| ZDS™ High-Strength Adhesive | Consumer Electronics | Improved product durability |

Structural Adhesives: An Investment in Quality

Choosing high-quality structural adhesives like ZDS™ is a smart move for your projects. These adhesives offer more than just immediate benefits. They provide cost efficiency and long-term advantages for many industries.

Cost Efficiency

ZDS™ structural adhesives bring big cost efficiency benefits. They often cut down on material and labor costs. This means less waste and faster production, saving you money.

This makes them a smart investment for businesses looking to save on their budgets.

Long-Term Benefits

Using top-notch structural adhesives also has long-term perks. They make products last longer, reducing the need for frequent repairs or replacements. This means your components and products will work better for a longer time.

This shows why adding ZDS™ adhesives to your process is key. It leads to better quality and lower costs over time.

Choosing ZDS™ structural adhesives means investing in quality and efficiency. You get strong, cost-effective solutions that last.

Choosing the Best Structural Adhesive for Your Needs

Choosing the best structural adhesive is key to a successful project. ZDS™ offers adhesives for many materials, like wood, metal, or mixed materials.

Know what you need for your project to pick the right epoxy or adhesive. Here’s how to make a smart choice:

- Material Compatibility: Think about the materials you’re working with. ZDS™ adhesives work well with metal to metal, wood to wood, and different materials together.

- Curing Time: Quick-curing adhesives are great for fast projects. Slow-curing ones provide stronger bonds for complex tasks.

- Bond Strength: For heavy-duty or important applications, choose adhesives with high tensile strength.

- Operating Environment: Consider the conditions your adhesive will face, like temperature, moisture, and chemical exposure. ZDS™ has products for tough conditions.

Here’s a look at some popular ZDS™ adhesives:

| Product | Best For | Curing Time | Strength | Adaptability |

|---|---|---|---|---|

| ZDS™ Epoxy-100 | Metal Applications | 15 Minutes | High | Resistant to Heat |

| ZDS™ Wood-Bond | Wood Adhesion | 30 Minutes | Medium | Waterproof |

| ZDS™ Flexi-Bond | Mixed Materials | 45 Minutes | Very High | Flexible Use |

For the best results with ZDS™ adhesives, follow these tips:

- Surface Preparation: Clean and dry surfaces improve bond strength. Use the right cleaners to get rid of dirt.

- Mixing and Application: Mix as the maker says. Apply evenly to prevent weak spots.

- Curing Environment: Keep the temperature right and don’t disturb the bond while it cures.

By knowing these tips and comparing products, you can pick the best structural adhesive for your project.

Conclusion

We’ve taken a deep dive into ZDS™ Structural Adhesives and their many benefits. These adhesives are known for their strength and versatility. They are essential in many fields, like woodworking, metal bonding, and the automotive industry.

Choosing the right adhesive is key for safety and efficiency. ZDS™ is known for its reliable solutions. It meets the specific needs of each project, ensuring strong and lasting bonds.

Looking ahead, we aim to improve bonding technologies and set new standards. ZDS™ leads the way with its expertise and customer focus. Together, we’re building a safer, stronger, and more innovative world.

FAQ

What makes ZDS™ Structural Adhesives stand out?

ZDS™ Structural Adhesives are known for their strong bonds and precise application. They improve the strength and performance of bonded parts in many industries.

Are ZDS™ Structural Adhesives suitable for use on wood and metal?

Yes, they are! Our adhesives work well on wood, metal, and more. They’re great for automotive parts or woodworking projects, offering strong and lasting bonds.

What types of applications are ZDS™ Structural Adhesives best suited for?

ZDS™ Structural Adhesives are perfect for many uses. This includes automotive repairs, metal bonding, woodworking, and cabinetry. They’re the go-to for projects needing strong, durable adhesives.

How do ZDS™ Structural Adhesives improve safety in automotive applications?

They provide strong and lasting bonds, making vehicles safer. This ensures critical parts stay securely attached, enhancing vehicle safety and occupant protection.

Do ZDS™ Structural Adhesives resist extreme temperatures and weather conditions?

Yes, they can handle high temperatures and harsh weather. This makes them ideal for tough environments in cars and industrial settings.

What are the benefits of using structural adhesives over traditional fastening methods?

Structural adhesives offer better stress distribution, less weight, and nicer looks. They also resist wear, chemicals, and the elements, making them a better choice.

How does ZDS™ ensure the quality and reliability of their adhesives?

ZDS™ tests our products thoroughly and follows strict safety rules. We aim for customer satisfaction by offering adhesives that meet or beat industry standards.

Can ZDS™ Structural Adhesives be used for load-bearing applications?

Yes, our strong adhesives are made for load-bearing tasks. They provide essential connections in things like construction and infrastructure projects.

What long-term benefits do ZDS™ Structural Adhesives offer?

Using ZDS™ adhesives can save money, cut down on maintenance, and make components last longer. They’re a smart choice for boosting product performance.

How can I choose the best ZDS™ Structural Adhesive for my project?

Choose based on your project’s materials and needs. Think about curing time, bond strength, and the environment it will be in. Our team can help find the right adhesive for you.