Our company focuses on making new energy vehicles (NEVs) more sustainable and efficient. We do this with our Adhesive Solutions for New energy vehicle. Our top-notch adhesives for electric vehicles (EVs) not only reach the high standards of the industry. They also push forward in how cars are designed and put together. Our ZDS™ adhesive products make NEVs better for the environment. They also improve the cars’ performance and how long they last.

Electric vehicle adhesives do more than just hold parts together. They are key to making the car strong and less harmful to the planet. Our adhesives help make cars lighter, safer, and last longer. This makes them crucial for the future of making cars. As more and more electric cars are made, it’s important to know how these green bonding solutions can make cars cheaper and more eco-friendly to make.

Key Takeaways

- Essential for improving durability and sustainability of NEVs.

- High-performance adhesives play a crucial role in reducing vehicle weight and enhancing safety.

- Our ZDS™ products offer optimal performance, supporting extended lifespans for NEV components.

- Adhesive solutions contribute significantly to cost-efficiency and eco-friendliness in the electric vehicle sector.

- Continued innovation and adaptation of adhesives ensure compatibility with evolving automotive technologies.

Introduction to Adhesive Solutions for New Energy Vehicles

In the world of Adhesive for New energy vehicle are key. They play a big role in making these cars. With these advanced adhesives, NEVs get better in many ways. They become stronger and can be designed in new ways.

Benefits of Adhesive Solutions in NEVs

We are working hard to make NEVs better with top adhesive solutions. These adhesives help solve many problems car makers face. They bond different materials together. This makes cars lighter and more efficient.

- Improving the strength and lasting power of important joints

- Making cars with better design, sleek and aerodynamic

- Keeping performance up in different weather by being more stable

Adhesive solutions also make building NEVs easier. They simplify how cars are put together. This method gets rid of some older ways to join parts. It makes the car-making process faster. It also makes the cars lighter. Lighter cars perform better and use less energy.

The benefits of adhesives in NEVs change the game. They lead to cars that are more innovative and eco-friendly. This not only helps the planet. It also gives us cars that are better and more reliable.

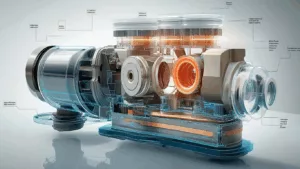

The Role of Adhesives in Electric Vehicle Manufacturing

In electric vehicle production, adhesives are key. They ensure these vehicles are durable, efficient, and safe. This matches the industry’s goal for innovative, high-performance vehicles.

Key Applications of Adhesives in EVs

Adhesives change how electric vehicles are made. They are crucial for assembling batteries and the car’s structure. An average electric vehicle needs about eight pounds of adhesives and sealants for the battery and motor, says Industrial Market Insight.

For the car’s framework, adhesives replace old-style fasteners. This lowers the vehicle’s weight and boosts manufacturing efficiency. It helps make the car lighter and stronger, which is key for safety.

Adhesives are also important for interior and exterior elements. They improve cabin comfort and how well the car moves through air. This also helps the car use less energy and makes it quieter.

Discover more about the transformative role of adhesives in electric vehicle manufacturing

By 2040, EV sales might be 58% of all car sales. So, it’s vital to understand adhesives’ roles in EVs. With an expected 500 million passenger EVs on the road by then, adhesives will stay essential in car design and assembly.

We aim to make our adhesive technologies even better. We want to support the creation of more sustainable, efficient, and high-performing electric vehicles. This goal is shared across the industry as we aim for a greener, more advanced automotive future.

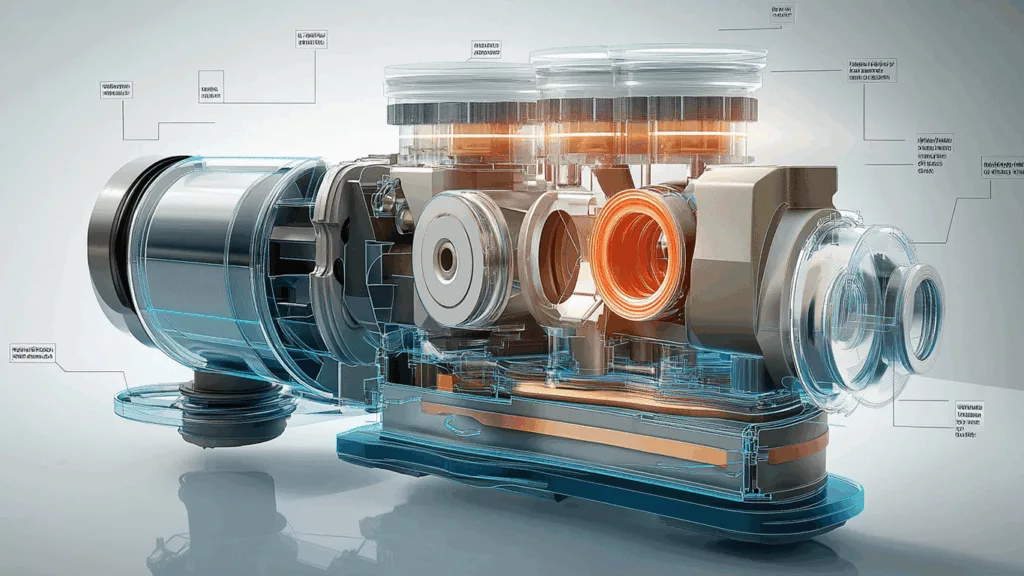

Application of ZDS™ products in new energy vehicles

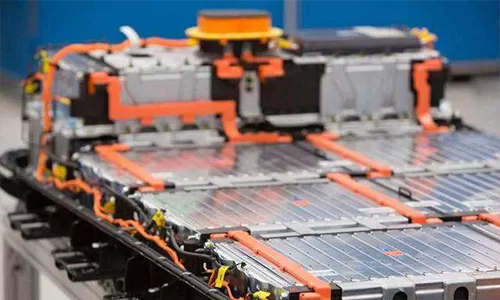

Battery pack Base Adhesive Bonding

Function: Secures the base of the battery cell at both ends, effectively mitigating vibration pressure to maintain stable battery operation; Epoxy Adhesive ZDS-169AB: Medium to high viscosity, extended working time, offering high strength and good hardness; Acrylic Structural Adhesive ZDS-14167: Medium viscosity, with impact resistance that exceeds that of epoxy resins, and features excellent heat and moisture resistance.

Battery Potting Compound

Function: Fills the gaps within the battery module, providing thermal conductivity, flame retardance, moisture-proofing, and shock absorption; Epoxy Potting Compound ZDS-168AB: Has a high thermal conductivity coefficient and offers good insulation, compressive strength, and strong adhesion; Silicone Adhesive ZDS-903 (Black): Provides excellent insulation, adhesion, and resistance to moisture, shocks, corona, and leakage.

Battery Foam Adhesive

Function: Enhances battery safety and service life through moisture-proof sealing; Polyurethane Foam Soft Gel ZDS-206-2-5: Expands three times in volume, anti-vibration, has good elasticity, insulating and sealing capabilities, and is resistant to aging; used for fixed filling; Polyurethane Foam Hard Gel ZDS-216-11: Offers superior insulation, good sealability, high thermal properties, and vibration resistance.

Internal Circuit Board Component Protection Adhesive

Silicone Adhesive ZDS-708: Exhibits outstanding bonding performance and excellent resistance to thermal cycling upon curing; Conformal Coating ZDS-620C: Creates a dense protective film after UV exposure, protecting various electronic components and solder joints.

Wireless Charging Coil Bonding and Potting Adhesive

Potting Compound ZDS-168AB-3Z: Features a high thermal conductivity coefficient along with good insulation, compressive resistance, and strong adhesive properties; Sealant: Delivers exemplary bonding performance with excellent thermal cycling resistance once cured; Low-Temperature Curing Adhesive ZDS-720-T: Used for securing and insulating electronic parts against moisture, making electronic components and PCB substrates waterproof.

Touchscreen Bonding

UV Adhesive ZDS-1601: Highly transparent post-curing, does not turn white or fog up, and provides high strength; Quick-Dry Adhesive ZDS-460: Offers reliable bonding performance specifically for touchscreens, rapid positioning without blushing; Epoxy Adhesive ZDS-702AB: Cures at room temperature, cures rapidly, is highly robust, suitable for bonding temperature-sensitive devices.

Electronic Device Component Circuit Board Potting

Epoxy Potting Compound ZDS-300-1: High thermal conductivity coefficient, with excellent insulation, compression strength, and strong adhesive qualities; Conformal Coating ZDS-620C: Forms a compact protective film after UV irradiation, safeguarding various electronic components and solder junctions.

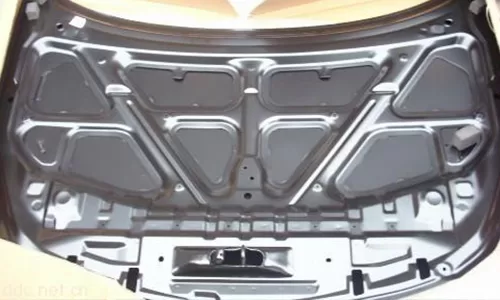

Enclosure or Housing Sealing

Quick-Dry Adhesive ZDS-480: Highly flexible, applied for its excellent aging-resistant properties in external enclosures and housings; Polyurethane Structural Adhesive ZDS-8719: Provides good adhesive efficiency for enclosure or housing materials, yielding a tough adhesive film upon curing, resistant to impact and shearing forces; Epoxy Adhesive ZDS-169AB: Medium to high viscosity, high bonding strength, and good hardness post-curing, fatigue-resistant.

Automotive Radar System Bonding and Sealing

Sealant: Superior bonding performance with remarkable cold and heat alternation resistance after curing; Fast-Drying ZDS-460: Bonds well to a variety of plastics and metals, employed for sealing and bonding radar casings and PINs; Epoxy Adhesive ZDS-169AB: High viscosity, suitable for metal and plastic bonding, fulfilling the sealing and bonding requisites of radar systems.

Electric Motor Magnet Bonding

Epoxy Adhesive ZDS-282AB: Medium to high viscosity, long work time, high strength, and resistance to fatigue; Epoxy Structural Adhesive ZDS-169AB: Prominent bonding effects between same or different metals, shock-resistant, and exceptional heat tolerance.

Thread Locking

Anaerobic Adhesive ZDS-727: Rapid positioning, in-depth curing; Quick-Dry Adhesive ZDS-0040: Instant adhesive designed for high-strength binding required between various metals.

End Cap Surface Sealing

Sealant: High viscosity, high-temperature endurance, waterproof sealing; Epoxy Adhesive: Medium to high viscosity, achieving high bond strength and good hardness after curing, fatigue-resistant.

Advancements in Automotive Bonding Solutions

The move to electric vehicles (EVs) has pushed for better manufacturing methods. This has led to significant advancements in adhesive solutions. Automotive bonding solutions at the cutting edge offer not just innovation. They also meet the tough safety and performance standards that new vehicles need.

Innovative Adhesive Technologies for EVs

We are dedicated to innovative adhesive technologies. Our work has brought forth advanced adhesives that boost the making and final quality of cars. These adhesives spread out load and resist stress. This is vital for the light materials used in EVs. Adding such tech makes vehicles lighter and sturdier over time.

Meeting Safety and Performance Standards with Advanced Adhesives

Reaching the safety and performance standards of this industry is our top priority. Our advanced adhesives are key to this goal. They can handle high heat and environmental pressures. This is important for the battery packs and motors in electric cars. Our adhesives go beyond what’s needed, ensuring safety is always first.

| Feature | Benefit | Application in EVs |

|---|---|---|

| Thermal Resistance | Ensures stability in high-temperature environments | Battery enclosures |

| Load Distribution | Improves vehicle integrity and longevity | Structural bonding |

| Environmental Resistance | Protects against weather and chemical corrosion | Exterior joints |

Case Studies: ZDS™ Adhesives at Work

We’re excited to share some case studies and success stories. They show how our ZDS adhesives are doing great in the car industry. These examples highlight our products’ strength and how they help in making better car bonds.

Benchmarking Performance: ZDS™ in Real-World Applications

Looking closely at different uses, ZDS adhesives prove to be strong under tough conditions. For electric vehicle batteries, our adhesives last long and resist heat well. This adds safety and life to the vehicles.

Client Success Stories with ZDS™ Automotive Bonding Solutions

A top car maker used ZDS adhesives to make their electric vehicle’s frame lighter. This cut the frame’s weight by 20%, boosting the car’s efficiency and power. Here’s their feedback:

We have seen big improvements in how we make cars and their performance with ZDS adhesives. They went beyond what we needed for car bonding.

Below is a table comparing how ZDS adhesives perform in car uses against others:

| Parameter | ZDS Adhesives | Other Adhesives |

|---|---|---|

| Durability | High | Medium |

| Thermal Resistance | Excellent | Adequate |

| Environmental Impact | Low | High |

| Application Ease | Very Easy | Moderately Easy |

Our ZDS adhesives are changing the game from battery bonding to making cars lighter and greener. The stories and feedback from our clients show our leadership in adhesive tech. They highlight our products’ outstanding real-world performance.

Trends and Future Outlook for EV Adhesive Solutions

We are diving into the exciting world of electric vehicles (EVs). Let’s focus on the trends in adhesive technology shaping this field. Adhesives are vital for putting EVs together and making them last. They help the vehicles perform better and last longer.

Emerging Trends in Adhesive Technology for New Energy Vehicles

The future of EV adhesive solutions is all about being green and efficient. There’s a move towards bio-based adhesives. These are great for the planet and work better too, like drying faster and being stronger in the heat. This change is part of bigger improvements in adhesive technology. It aims to make bonds stronger and EVs more durable.

Preparing for the Future: ZDS™’s Commitment to Innovation

ZDS™ is all about innovation. We’re always making our adhesive solutions better for the EV market. Our research and development focus on creating products that are safe, perform well, and lead the market.

We keep an eye on trends in adhesive technology. ZDS™ is ready to be a leader in next-gen adhesives for electric vehicles. We work with partners and research continuously to stay ahead. Our goal is to give our clients the best and most reliable products.

ZDS™ is focused on the future, exploring emerging trends in adhesive technology. We are looking into nanomaterials and electrically conductive adhesives, key for EV batteries. Our passion for innovation drives us to offer more than just adhesives. We provide full bonding solutions to enhance the automotive industry.

Conclusion

We’ve talked a lot about how choosing the right adhesives for New Energy Vehicles (NEVs) is really important. By picking adhesives that perform well, are good for the planet, and last a long time, we show we care about making NEVs better. ZDS™ plays a big role in making these top-notch adhesives.

ZDS™ adhesives are key for building modern cars. They’re used in many ways, like sticking batteries together and putting car bodies together. These adhesives do more than just stick parts together; they make cars stronger and last longer.

Looking ahead, special adhesives will become even more important in car tech. We want to end by saying ZDS™ is all in on creating new and eco-friendly adhesives. As cars change, our adhesives will too, keeping us leading in glue tech for NEVs. This means better cars for the planet.

FAQ

What are adhesive solutions for New Energy Vehicles (NEVs)?

Adhesive solutions for NEVs are special bonding products made for electric vehicle production. These adhesives help make parts of NEVs stronger, last longer, and work better.

Why are adhesive solutions important in NEV applications?

Adhesive solutions are key for NEVs because they help make cars lighter. This means cars can go farther without using more power. Adhesives also make cars stronger by spreading stress over a larger area. Plus, they allow for more creative car designs and make cars quieter and smoother to ride in.

What are the key benefits of using adhesive solutions in NEVs?

Using adhesives in NEVs brings many benefits. They help make cars lighter and stronger. They also offer better design options. This means cars last longer even in tough weather and are quieter, more comfortable, and use energy better by keeping air out.

How do adhesives contribute to the manufacturing of Electric Vehicles (EVs)?

Adhesives are vital in making EVs by joining different parts together. They keep battery parts secure and protect them. Adhesives join metal and composite parts, making the car body stronger. They are also used for inside parts, giving a neat finish.

What are some innovative adhesive technologies for EVs?

There are new adhesive technologies for EVs that are very strong and durable. Some adhesives cure quickly to save time in production. Others are better for the environment and can stand up to heat and chemicals. These technologies work well with both heavy and light materials.

How do advanced adhesives meet safety and performance standards in EV manufacturing?

Advanced adhesives meet strict safety and performance rules in making EVs. They are tested to make sure they are safe in crashes. These adhesives can handle impact, shaking, and wear well. This helps make EVs safer and perform better.

Can you provide examples of ZDS™ adhesive solutions in real-world applications?

Yes, ZDS™ adhesives have been used effectively in the car industry. For instance, our adhesives keep battery parts in EVs stable and safe. Our products have helped make cars lighter. They’ve also been used to seal parts tightly against moisture, dust, and noise.

Are there any client success stories with ZDS™ automotive bonding solutions?

Indeed, many clients have benefitted from using ZDS™ adhesives. They’ve made manufacturing faster and cheaper and enhanced their products. Our adhesives have led to higher production, better durability, and lower warranty costs. These successes show how reliable and valuable ZDS™ adhesives are in the car industry.

What are the emerging trends in adhesive technology for New Energy Vehicles?

New trends in adhesive technology for NEVs focus on being eco-friendly. This includes bio-based adhesives and those with less harmful emissions. Quicker curing times are also important for better production. There’s a push for adhesives that work with a wide range of materials, including lighter ones. Being able to withstand extreme conditions is also essential.

How is ZDS™ committed to innovation in adhesive solutions for the NEV industry?

ZDS™ focuses on innovating adhesive solutions for the NEV market. We invest in creating advanced, eco-friendly adhesives. Our aim is to improve the quality and life of electric vehicles. We work with partners and join industry events to stay ahead in NEV adhesive technology.