Introduction

Adhesives play a crucial role in industries ranging from automotive and aerospace to construction and electronics. Selecting the right industrial adhesive glue can enhance product durability, improve efficiency, and reduce production costs. But with so many options available—epoxy, polyurethane, cyanoacrylate, and more—how do you determine the best adhesive for your specific needs?

This guide explores different adhesive types, their applications, and the best industrial glue for various materials and industries.

What is Industrial Adhesive Glue?

Industrial adhesive glue is a high-strength bonding agent used to join materials like metal, plastic, wood, and glass. Unlike standard household glue, these adhesives are designed to withstand extreme conditions such as heat, moisture, and heavy loads.

Industrial adhesives offer advantages over mechanical fasteners like screws or welding, including weight reduction, improved aesthetics, and even stress distribution across bonded surfaces.

Why Industrial Adhesives Are Essential in Manufacturing?

Modern manufacturing relies on industrial adhesive glue for various reasons:

- Stronger Bonds– Adhesives distribute stress evenly, preventing weak points.

- Lightweight Construction– Reduces material weight compared to bolts and rivets.

- Seamless Finish– Eliminates the need for visible fasteners.

- Improved Durability– Many adhesives resist chemicals, heat, and moisture.

- Cost-Effectiveness– Reduces labor costs associated with mechanical fasteners.

From automotive assembly to electronics manufacturing, industrial adhesives offer unmatched efficiency and strength.

Types of Industrial Adhesive Glue

Choosing the right industrial adhesive glue depends on factors like material compatibility, environmental resistance, and application method. Let’s explore the most common types:

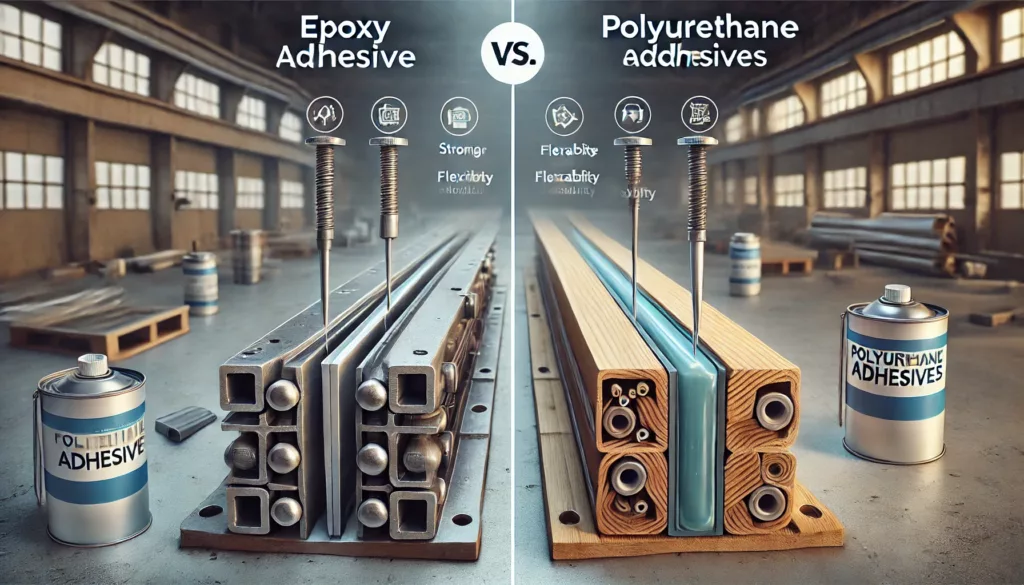

Epoxy Adhesives: Strong and Durable Bonds

Epoxy adhesives are two-part systems (resin and hardener) known for their incredible strength and chemical resistance. They are widely used in:

- Aerospace and automotive– Ideal for metal bonding.

- Construction– Used for structural applications.

- Electronics– Provides insulation and protection.

Pros: High strength, excellent chemical resistance, long-lasting.

Cons: Longer curing time, may require surface preparation.

Polyurethane Adhesives: Flexibility and Strength

Polyurethane adhesives are known for their flexibility, making them ideal for materials that expand and contract, such as:

- Woodworking– Used in furniture making.

- Automotive– Bonds rubber and plastic components.

- Marine industry– Water-resistant applications.

Pros: Flexible, impact-resistant, and waterproof.

Cons: Sensitive to moisture during curing.

Cyanoacrylate Adhesives: Instant Bonding Power

Commonly known as “super glue,” cyanoacrylate adhesives create instant bonds in small-scale applications:

- Electronics– Fixing circuit boards and sensors.

- Medical devices– Used in surgical glues.

- Household repairs– Quick fixes for plastic and metal.

Pros: Fast-setting, easy to use.

Cons: Brittle, not suitable for high temperatures.

Silicone Adhesives: Heat and Moisture Resistance

Silicone adhesives remain flexible even under extreme heat and moisture exposure. They are best for:

- Automotive gaskets

- Glass and ceramic bonding

- Sealing applications

Pros: Heat-resistant, waterproof.

Cons: Longer curing time, not as strong as epoxy.

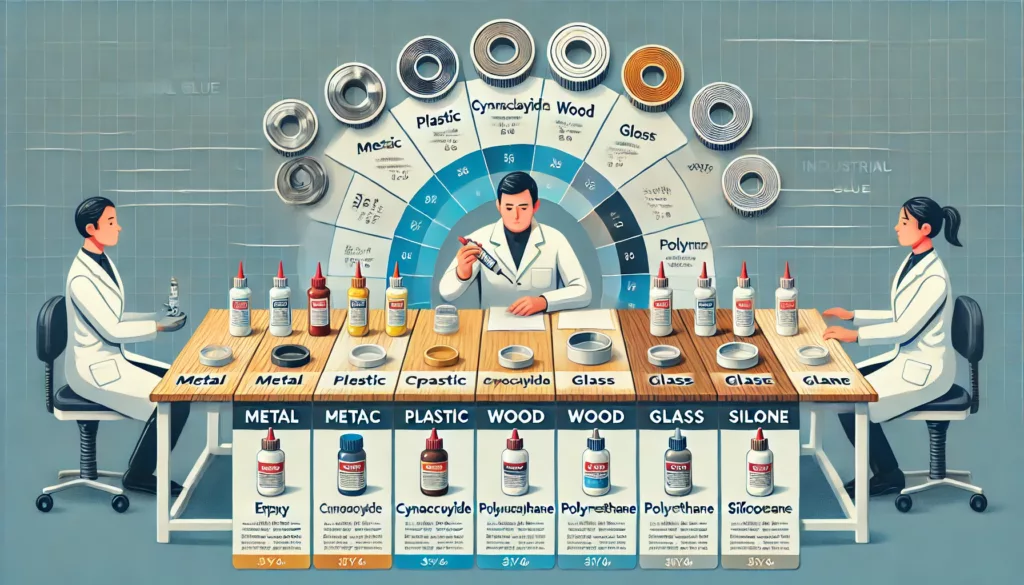

Best Industrial Glue for Different Materials

Finding the best industrial glue depends on the material you need to bond:

| Material | Best Adhesive Type |

| Metal | Epoxy, polyurethane |

| Plastic | Cyanoacrylate, acrylic |

| Wood | Polyurethane, hot melt |

| Glass | Silicone, UV-curing adhesives |

| Fabric & Leather | Water-based adhesives |

Best Practices for Applying Industrial Adhesives

![]()

To ensure a strong and lasting bond, follow these best practices:

- Surface Preparation– Clean and dry surfaces for optimal adhesion.

- Correct Application– Apply adhesive evenly and use proper curing methods.

- Curing Time– Allow sufficient time for the adhesive to set fully.

FAQs About Industrial Adhesive Glue

What is the strongest industrial adhesive glue?

Epoxy adhesives are considered the strongest due to their durability and resistance to heat and chemicals.

Which industrial adhesive works best for metal bonding?

For metal surfaces, epoxy and polyurethane adhesives provide the best strength and durability.

Is industrial adhesive glue waterproof?

Yes, many industrial adhesives, such as polyurethane and silicone, are waterproof.

Can industrial adhesives replace welding?

In some applications, high-strength adhesives can replace welding, offering a cleaner and lightweight alternative.

How long does industrial adhesive take to cure?

Curing time varies from a few seconds (cyanoacrylate) to several hours (epoxy and polyurethane).

Conclusion

Selecting the right industrial adhesive glue depends on the material, application, and required durability. From epoxy to polyurethane and cyanoacrylate, each adhesive type serves a unique purpose in manufacturing, construction, and beyond. By understanding the different options, industries can achieve stronger, more efficient, and cost-effective bonding solutions.