Introduction: Managing Heat in Modern Electronics

As electronic devices become faster, smaller, and more powerful, thermal management has become one of the most critical design challenges. Whether it’s a smartphone, electric vehicle, LED lighting system, or industrial server, excess heat can lead to component degradation, performance issues, and system failure.

That’s where adhesives for electronics thermal management materials come in. These specially engineered adhesives do more than just bond—they enable efficient heat dissipation, structural stability, and long-term reliability across a wide range of electronic systems.

In this post, we’ll explore how advanced adhesive technologies help manufacturers improve thermal performance and ensure electronic safety and durability.

What Are Thermal Management Materials?

Thermal management materials are designed to control heat flow within electronic devices. Common examples include:

- Heat sinks

- Thermal interface materials (TIMs)

- Gap fillers

- Thermal pads and gels

- Phase change materials (PCMs)

To integrate these materials into a system, specialized thermally conductive adhesives are used to bond and secure components while ensuring optimal thermal transfer.

Functions of Adhesives in Thermal Management

Thermally conductive adhesives perform several key functions:

- Efficient heat transfer from heat-generating components to heat sinks or housings

- Mechanical bonding to eliminate screws or clips, saving space and weight

- Vibration and shock resistance to protect sensitive electronics

- Electrical insulation to prevent short circuits (in non-conductive variants)

- Gap filling for irregular surfaces or uneven interfaces

Key Types of Thermal Adhesives for Electronics

![]()

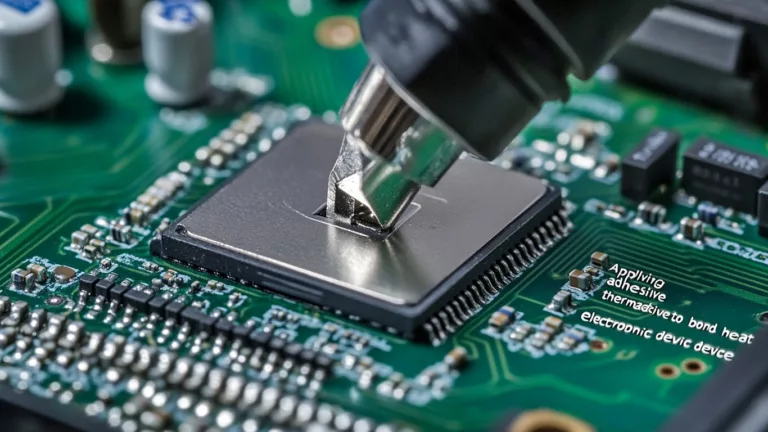

1. Thermally Conductive Epoxy Adhesives

High-strength, permanent bonding with heat dissipation

These two-part adhesives are ideal for bonding heat sinks to power devices, LEDs, and IC packages.

Applications:

- Power supplies and converters

- CPU and GPU bonding

- LED modules

Benefits:

- High thermal conductivity (1–3 W/m·K)

- Long-term mechanical integrity

- Chemical and moisture resistance

2. Thermally Conductive Silicone Adhesives

Flexible bonding for temperature-sensitive electronics

Silicones are preferred where vibration damping, flexibility, or high-temperature operation is required.

Applications:

- Automotive electronics

- Consumer electronics

- Display modules and PCBs

Benefits:

- Excellent thermal cycling resistance

- Operating range from -60°C to +250°C

- Electrically insulating and thermally conductive options

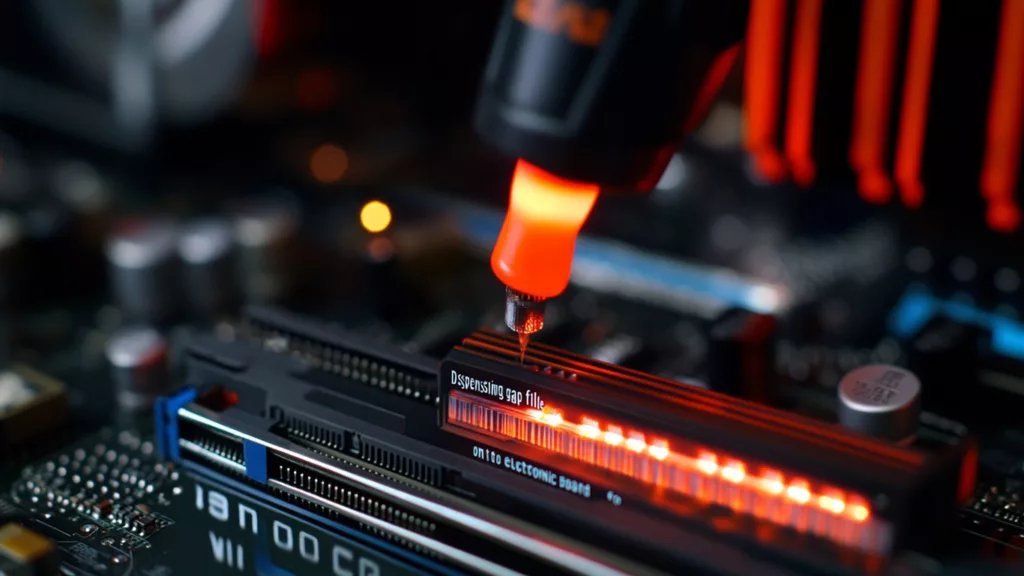

3. Thermal Gap Fillers and Pastes

Non-adhesive thermal interface materials with adhesive variants

These materials conform to irregular surfaces, minimizing thermal resistance at interfaces.

Applications:

- EV battery packs

- LED backlighting systems

- Embedded processors and chipsets

Benefits:

- Soft and conformable

- Low thermal impedance

- Optional adhesive-backed versions available

ZDS™ Adhesive Solutions for Thermal Management

At ZDS™, we provide custom and off-the-shelf adhesive solutions specifically formulated for electronics thermal management. Whether you’re bonding heat sinks, protecting sensitive components, or optimizing heat transfer in confined designs, we offer adhesives engineered to deliver:

✔️ High Thermal Conductivity

From 0.8 to 3.5 W/m·K, our adhesives ensure efficient heat transfer between critical components and dissipation structures.

✔️ Electrical Insulation

For applications where thermal transfer must be paired with high dielectric strength.

✔️ Long-Term Stability

Designed to withstand thermal cycling, mechanical stress, and chemical exposure over the product’s lifecycle.

✔️ Compatibility with Assembly Lines

Options available for screen printing, automated dispensing, and jetting systems.

Applications Across Industries

| Industry | Application | Thermal Adhesive Role |

| Automotive (EVs) | Battery packs, inverters, control units | Heat dissipation + vibration damping |

| Consumer Electronics | Smartphones, tablets, wearables | Bonding TIMs + thermal insulation |

| Telecom & Servers | CPUs, GPUs, power modules | High-conductivity bonding |

| Industrial Controls | Power relays, drives, PLCs | Heat management and bonding |

| LED Lighting | COB and SMD LED modules | Bonding to heat sinks or housings |

Selecting the Right Thermal Adhesive

When choosing an adhesive for electronics thermal management, consider the following:

✅ Thermal Conductivity Requirement

Is your application high-power or low-heat? Choose based on W/m·K ratings.

✅ Electrical Insulation vs. Conductivity

Ensure compatibility with your circuit’s needs.

✅ Bond Line Thickness & Gap Filling

For uneven surfaces or large gaps, use gap fillers or soft silicone pastes.

✅ Processing Requirements

Select between one-part or two-part systems, cure times, and application methods.

✅ Environmental Resistance

Consider exposure to moisture, solvents, UV, and mechanical stress.

Need assistance? Our ZDS™ engineering team will help you run tests and select the right adhesive for your thermal challenges.

ZDS™ Quality You Can Trust

All our thermal adhesives undergo rigorous testing for:

- 🔥 Thermal conductivity and thermal impedance

- 💧 Moisture resistance and aging

- 🧪 Dielectric strength and breakdown voltage

- 📉 Low shrinkage and low outgassing

- 🧲 Mechanical adhesion and peel strength

We are committed to providing RoHS-compliant, REACH-certified, and environmentally conscious adhesive solutions.

Conclusion: Smarter Thermal Solutions for Next-Gen Electronics

In today’s electronics, thermal performance equals product performance. With ZDS™ adhesives for electronics thermal management materials, you get cutting-edge bonding solutions that enhance heat dissipation, extend component life, and improve system efficiency.

Whether you’re building electric vehicles, compact smartphones, or industrial-grade automation systems, ZDS™ delivers engineered thermal adhesive solutions to keep your tech cool and dependable.

✅ Partner with ZDS™ for Advanced Thermal Adhesives

🔗 Contact ZDS™ for thermal adhesive consultation

📦 Request samples for testing in your electronics designs

📩 Subscribe for product updates and thermal application insights

📘 Learn more about ZDS™ thermal interface adhesives