Adhesives for the intelligent manufacturing industry

Leading Adhesives for Intelligent Manufacturing

High-performance industrial adhesives are changing how we make things in today’s smart factories. They are key for making manufacturing better and more efficient. Companies like ZDS™ are making adhesives that work well in the tough conditions of modern factories.

These adhesives are all about precision, reliability, and strength. They help make sure parts stick together right, which is crucial in making things like machines and electronics. We’ll look into how these adhesives help with making things better and stronger in smart factories.

Key Takeaways

- The increasing demand for intelligent production adhesives in smart factory solutions.

- High-performance industrial adhesives offered by ZDS™ are essential for advanced manufacturing processes.

- These adhesives are designed for exceptional precision, reliability, and durability.

- Advanced adhesive solutions address the unique challenges of intelligent manufacturing industries.

- Superior bonding capabilities enable seamless integration within smart factories.

Introduction to Intelligent Manufacturing

Intelligent manufacturing is changing how we make things. It combines advanced automation, data sharing, and cyber-physical systems. This approach boosts productivity, efficiency, and flexibility, helping companies adapt to the fast-changing global market.

Overview of Intelligent Manufacturing

It uses the latest tech like the Internet of Things (IoT), big data, and artificial intelligence (AI). These technologies make production more efficient and adaptable. They keep an eye on and fine-tune the process as it happens, cutting down on waste and downtime.

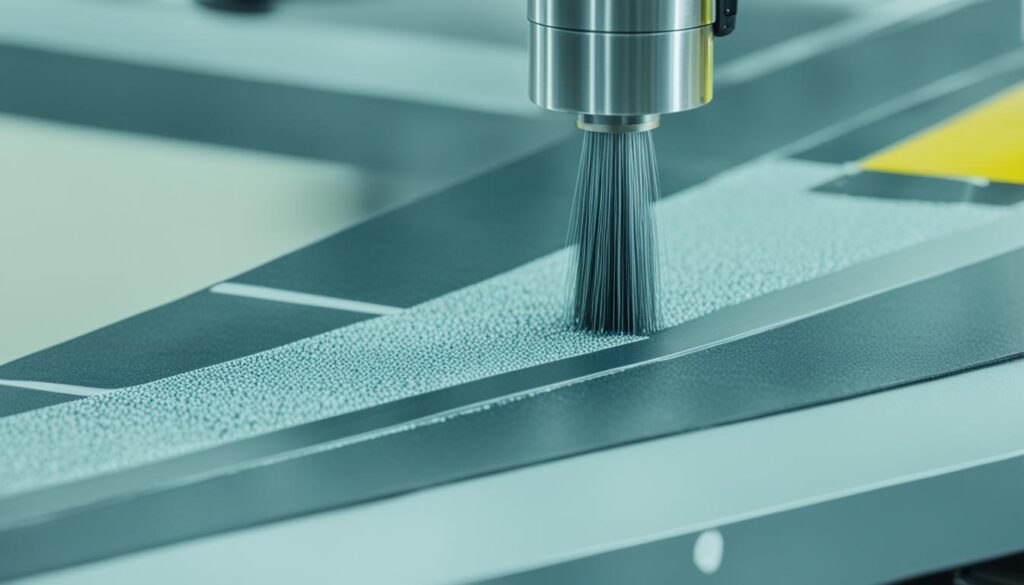

The Role of Adhesives in Smart Factories

Adhesives are key in smart factories for putting complex parts together. Innovative adhesives for smart factories create strong, lasting bonds. These bonds are crucial for the strength and function of modern products, from electronics to lightweight materials.

Why Choose ZDS™ Adhesives?

ZDS™ adhesives bring big benefits to manufacturers. They’re made for digital manufacturing, offering top-notch performance and reliability. With ZDS™, you get digital manufacturing adhesives that meet the tough demands of smart manufacturing. This means smoother, more efficient production.

| Feature | Benefit |

|---|---|

| High Precision | Ensures accurate component alignment |

| Strong Bonding | Enhances structural integrity |

| Durability | Prolongs the lifespan of products |

| Versatility | Suitable for various applications |

Key Applications of Adhesives

Adhesives are key in smart manufacturing. They help with sensor integration and make robotics work better. They keep parts together and make sure complex systems don’t fall apart.

Sensors and Transducers

Adhesives are vital for attaching sensors and transducers. These parts are crucial for automation and getting feedback. With sensor integration, they work more reliably and accurately. This means they give the right data for controlling and monitoring processes.

AMR and AGV Robots

Adhesives are essential for AMR (Autonomous Mobile Robots) and AGV (Automated Guided Vehicles). They help these robots move smoothly and work well. By securing parts, adhesives make AGV robot assembly easier and improve smart manufacturing.

Industrial Digital Manufacturing Processes

In digital manufacturing, adhesives are a must for making and putting together advanced parts. They add precision and reliability, which is key for digital manufacturing systems. Using adhesives makes production smooth and strong.

| Application | Benefits |

|---|---|

| Sensor Integration | Improves reliability and data accuracy |

| AMR and AGV Robots | Enhances maneuverability and operational stability |

| Digital Manufacturing | Ensures efficiency and structural integrity |

Adhesives for the Intelligent Manufacturing Industry

The need for new adhesives in smart manufacturing is growing fast. We’re looking at adhesives for Industry 4.0 that can handle today’s tough manufacturing needs. These adhesives help make production better and more reliable.

At ZDS™, we know the challenges of smart manufacturing. Our solutions are designed with precision for these challenges. Our next-generation manufacturing adhesives are made for top bonding strength, staying strong under heat, and keeping stable in chemicals.

Using these advanced adhesives makes sure high-tech devices and complex parts stay together well. It also helps meet Industry 4.0 goals. By using the latest adhesive tech, we make production lines more efficient and reliable, helping the industry grow.

“Integrating industry 4.0 adhesives into our production has revolutionized our capabilities. The future of manufacturing is now.”

Adding ZDS™ adhesives to smart manufacturing has big benefits. It means better performance, longer-lasting parts, and smoother production. We’re always innovating to keep our next-generation manufacturing adhesives leading in industry progress.

Adhesives for Sensor Integration

In smart manufacturing, sensors are key for precision and efficiency. The right adhesives are vital for these sensors to work well. We’ll look at the types of sensors and how to apply adhesives best.

Types of Sensors in Smart Manufacturing

Smart manufacturing uses many sensors. Some of the most common are:

- Temperature Sensor: These sensors keep an eye on temperature in real-time. They help keep production at the right level.

- Pressure Sensor: These sensors check and control pressure levels. They make sure things are safe and run smoothly.

- Micropressure Sensor: For very precise pressure detection, these sensors are a must. They give accurate readings in tiny pressure changes.

Application Methods and Techniques

How and when you apply adhesives is crucial for smart manufacturing. Here are some key steps:

- Surface Preparation: Make sure surfaces are clean and dry for a strong bond.

- Adhesive Selection: Pick the right adhesive for the sensor and its needs.

- Application Process: Apply adhesive evenly to prevent air bubbles and ensure the sensor works well.

- Curing: Let the adhesive cure properly for the best bond strength and sensor reliability.

By using these steps, manufacturers can make their sensor systems more efficient and sensitive. This leads to better performance in smart manufacturing settings.

Requirements for Smart Manufacturing Adhesives

Exploring smart manufacturing adhesives shows us what they need to do well. They must bond strongly and work with many materials. We’ll look at these key points and see how ZDS™ meets these needs.

Adhesive Performance Criteria

Adhesives for smart manufacturing have to hit certain marks:

- High Bonding Strength: This keeps assemblies strong under stress.

- Thermal Cycle Resistance: They must not break down when heated or cooled many times.

- Material Compatibility: They need to stick well to metals, plastics, and composites used in smart manufacturing.

- Durability: They should last a long time in tough conditions, like with chemicals and wear.

ZDS™ Solutions for Superior Bonding

ZDS™ leads in making adhesives for precise needs. Our products go beyond what’s expected. Here’s what makes ZDS™ adhesives special:

- Enhanced Adhesion: Our adhesives bond strongly, offering great strength and reliability.

- Thermal Endurance: They handle extreme temperatures well, lasting longer.

- Versatility: Our adhesives work with many materials, making them flexible for different uses.

- Sustainable Performance: ZDS™ adhesives are made for long use, supporting sustainable production and reducing downtime.

Using ZDS™ adhesives in manufacturing means your work will run smoothly and efficiently. With these high precision adhesives, the future of smart manufacturing looks bright.

Innovation in Adhesive Solutions

ZDS™ adhesive solutions are all about constant innovation. They lead the way to more efficient and green production. By using adhesive technology innovation, they make things work better and last longer.

Next-Generation Manufacturing Adhesives

Our new adhesives are super strong, flexible, and easy to use. They meet the needs of today’s manufacturing, bonding different materials and surfaces well.

ZDS™ adhesives are perfect for industries looking for top performance. They bring together the best bonding tech for smoother manufacturing.

Developments in Digital Manufacturing Adhesives

In digital manufacturing, adhesive technology innovation is key. Our adhesives are made for precise use and top performance. This is vital in high-tech settings where every detail counts.

This tech helps make products more complex and reliable.

Innovative Adhesives for Autonomous Mobile Robots

Autonomous mobile robots (AMRs) get a big boost from our adhesives. ZDS™ offers strong, flexible bonds that can handle the tough demands of AMRs.

We’re always pushing the limits of adhesive tech. Our goal is to help digital manufacturing and autonomous tech advance. We want our clients to lead in a tough market.

Features of Advanced Manufacturing Adhesives

At ZDS™, we create adhesives for the tough needs of smart factories. They are very strong and flexible, perfect for modern manufacturing. They can handle tough conditions better than old adhesives.

Here are the main features of ZDS™ adhesives:

- High Durability: They can take a lot of stress and last a long time.

- Flexibility: They move with parts that change shape or size due to heat.

- Environmental Resistance: They stand up to moisture, heat, and chemicals, making them great for many uses.

Our adhesives work well for many things, like putting sensors together or making robots. They are key to making smart manufacturing work better.

| Criteria | ZDS™ Advanced Adhesives | Conventional Adhesives |

|---|---|---|

| Durability | High | Moderate |

| Flexibility | Excellent | Low |

| Environmental Resistance | Superior | Basic |

Using ZDS™ adhesives means your smart manufacturing projects will work well and last long. We focus on making the best adhesives for industry needs. We lead in providing top-notch bonding solutions.

Robot Production and Adhesive Applications

Making robots, like AMR robots and AGV systems, needs precision and reliable adhesives. These adhesives help the robots work well in many manufacturing settings. They meet the important needs for performance and lasting use.

AMR, AGV, and Industrial Robots

The creation of autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) has changed how we make things. These smart robots use top-quality adhesives to keep their parts together. From putting things together to checking them, these robots need adhesives that create a strong bond. Our suggested adhesives, ZDS™, are a top choice for this.

Ensuring Performance and Durability

For robot production, picking the right adhesives is key for good performance and lasting use. These adhesives are crucial for putting things together, sealing, and keeping things strong. How adhesives are applied affects how well robots work, including AMR robots and other advanced systems.

Working with ZDS™, we ensure the adhesives we use are up to the tough demands of automation. Whether it’s for simple tasks or complex ones, the right adhesive brings unmatched strength and lasting performance. This is key to keeping AMR robots and other industrial robots running well.

Impact of Industry 4.0 on Adhesive Technology

Industry 4.0 has brought big changes to many areas, including adhesive technology. These changes are making production more efficient and effective. They also call for more integration and innovation in adhesives.

Integration with Smart Manufacturing Systems

Adhesive technology must work well with smart manufacturing system integration for Industry 4.0. This means making adhesives that support more data exchange, automation, and optimization in connected production setups. Companies like ZDS™ are leading the way, making sure their adhesives meet the needs of modern manufacturing.

These adhesives for Industry 4.0 have big benefits like better performance and more sustainable production. Reports show that companies like Henkel are playing a big role in this change. They highlight the importance of new tech in making adhesives better.

Advancements in Material Science

Material science is key to making Industry 4.0 adhesives better. New adhesive types are being made that are strong, efficient, and fit the needs of high-tech and automated industries. Thanks to new research, these innovations are making adhesives essential for smart manufacturing.

ZDS™ and other leaders are investing in research to create new solutions. These solutions help integrate smart manufacturing systems, setting new standards in adhesive technology.

| Features | Benefits |

|---|---|

| Enhanced Data Exchange | Streamlined Production Processes |

| Automation Integration | Increased Efficiency |

| Material Science Innovations | Superior Adhesive Performance |

Case Studies: Successful Applications

We’re going to look at how ZDS™ adhesives work in real smart factories. These examples show how ZDS™ adhesives have changed manufacturing for the better. They prove their power and flexibility in making big improvements.

Real-World Examples of ZDS™ Adhesives in Action

A top car maker used ZDS™ adhesives in their smart factory. They put ZDS™ adhesives to work for attaching sensors and transducers. This made their production line more precise and quick to respond.

Another example is an electronics company. They used ZDS™ adhesives to build autonomous mobile robots (AMR). These adhesives made the robots stronger and more durable over time.

Benefits and Outcomes

ZDS™ adhesives bring many advantages to smart factories. They bond strongly, making things last longer and cutting down on repair costs. They can be used in many ways, like attaching sensors or putting together robots.

Using ZDS™ adhesives also makes production smoother. This means factories work better and faster. Companies see a big jump in how well they operate, showing the value of top-notch adhesives in making things.

| Application | Industry | Benefits |

|---|---|---|

| Sensor Integration | Automotive | Enhanced precision, increased responsiveness |

| Robot Assembly | Electronics | Improved durability, reduced maintenance costs |

| Component Bonding | Aerospace | Streamlined processes, higher efficiency |

Conclusion

ZDS™ adhesives for intelligent manufacturing lead the way in the industry. They are reliable and meet the complex needs of today’s smart factories. We’ve shown how ZDS™ adhesives excel with their strong bonding, versatility, and innovative features.

Our journey into adhesives shows how vital they are for automation. They support everything from sensor integration to the work of Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs). Choosing ZDS™ adhesives gives manufacturers an edge, boosting performance and durability in many areas.

As Industry 4.0 advances, our products prove their worth. ZDS™ adhesive excellence is more than a promise; it’s a proven fact through successful results. We’re committed to leading in innovation, helping intelligent manufacturing succeed.

FAQ

What are intelligent production adhesives?

Intelligent production adhesives are special glues made for the tough conditions of smart factories. They help bond materials together strongly for advanced manufacturing.

Why are adhesives important in smart factories?

Adhesives are key in smart factories for putting complex parts together with precision and strength. They help parts work together well, making them reliable and long-lasting.

What benefits do ZDS™ adhesives offer for intelligent manufacturing?

ZDS™ adhesives bring new technology to digital manufacturing. They bond strongly, resist heat and chemicals, and are perfect for smart factories.

How are adhesives used in the production of AMR and AGV robots?

Adhesives hold parts together in AMR (Autonomous Mobile Robots) and AGV (Automated Guided Vehicles). This helps them move well and work efficiently in smart factories.

What types of sensors rely on adhesives in smart manufacturing?

Temperature, pressure, and micropressure sensors in smart manufacturing use adhesives. This ensures they work accurately and reliably.

What performance criteria must adhesives meet in intelligent manufacturing?

Smart manufacturing adhesives need to bond strongly, handle heat well, and work with many materials. This ensures top bonding performance.

How does ZDS™ innovate in adhesive technology?

ZDS™ is always improving its manufacturing adhesives. It focuses on digital manufacturing and solutions for autonomous mobile robots.

What are the key features of advanced manufacturing adhesives by ZDS™?

ZDS™ adhesives are durable, flexible, and resist the environment. They’re great for smart manufacturing tasks.

Why are adhesives crucial in the production of AMR, AGV, and industrial robots?

Adhesives keep AMR, AGV, and industrial robots working well. They help these systems perform well in different manufacturing settings.

How has Industry 4.0 impacted adhesive technology?

Industry 4.0 has made adhesive technology better. It focuses on working with smart manufacturing systems and improving materials for automated production.

Can you provide examples of successful applications of ZDS™ adhesives?

Case studies show how ZDS™ adhesives work well in real smart factories. They highlight their top performance and flexibility in smart manufacturing.