Welcome to our comprehensive guide on advanced thermosetting resins for aerospace applications. In this article, we will explore the critical role these resins play in the aerospace industry and the various types of resins used. From aerospace coatings to aerospace composites, these advanced materials offer exceptional strength, durability, and heat resistance, making them perfect for demanding aerospace environments.

Key Takeaways:

- Advanced thermosetting resins are essential in aerospace applications due to their exceptional properties.

- Epoxy resins, thermosetting polymers, and high-performance resins are commonly used in the aerospace industry.

- These resins provide strength, durability, and heat resistance in demanding aerospace environments.

- Aerospace coatings and aerospace composites are some of the key applications for advanced thermosetting resins.

- Continuous advancements in resin technology ensure improved performance and environmental sustainability.

Understanding Advanced Thermosetting Resins

When it comes to aerospace applications, advanced thermosetting resins are at the forefront of innovation and performance. These materials, consisting of thermosetting polymers, offer extraordinary strength, durability, and resistance to extreme conditions, making them ideal for aerospace environments.

One of the defining characteristics of advanced thermosetting resins is their unique composition and the process they undergo called cross-linking. This process involves the formation of a three-dimensional network of chemical bonds, resulting in a rigid and heat-resistant structure. This cross-linking mechanism enhances the overall properties of the resin and contributes to its exceptional performance.

Advanced thermosetting resins provide various advantages that make them the preferred choice in aerospace applications:

- High-temperature resistance: These resins can withstand elevated temperatures commonly experienced in aerospace environments, ensuring the integrity and reliability of critical components.

- Excellent chemical resistance: Aerospace resins are highly resistant to corrosive substances, including fuels, hydraulic fluids, and other harsh chemicals, making them well-suited for demanding aerospace conditions.

- Superior mechanical properties: Advanced thermosetting resins offer exceptional mechanical strength and stiffness, contributing to the structural integrity and load-bearing capabilities of aerospace components.

By utilizing these resins in aerospace applications, engineers can design lighter and more efficient structures without compromising on performance or safety. Whether it’s for aircraft panels, interior components, or structural elements, advanced thermosetting resins provide the necessary strength and reliability required in the aerospace industry.

“The exceptional characteristics of advanced thermosetting resins make them indispensable in aerospace applications. Their ability to withstand high temperatures and resist chemicals ensures the longevity and reliability of aerospace components.” – Aerospace Engineer

| Advantages of Advanced Thermosetting Resins | Description |

|---|---|

| High-temperature resistance | Can withstand elevated temperatures commonly experienced in aerospace environments |

| Excellent chemical resistance | Highly resistant to corrosive substances, including fuels and hydraulic fluids |

| Superior mechanical properties | Exceptional strength and stiffness, contributing to structural integrity |

Next:

In the next section, we will explore the diverse applications of these advanced thermosetting resins within the aerospace industry. From aerospace coatings to aerospace composites, these resins provide crucial solutions for enhancing performance and ensuring safety in aviation.

Applications of Advanced Thermosetting Resins in Aerospace

When it comes to the aerospace industry, advanced thermosetting resins find numerous applications, adding strength, durability, and reliability to various components and structures. Let’s explore some key areas where these resins play a vital role.

Aerospace Coatings

Aerospace coatings are crucial for protecting aircraft surfaces from the harsh realities of the sky. Advanced thermosetting resins, such as industrial epoxy resins, form a significant part of these coatings. They provide a durable barrier against corrosion, UV radiation, and extreme weather conditions, ensuring the longevity and aesthetics of the aircraft.

Aerospace Composites

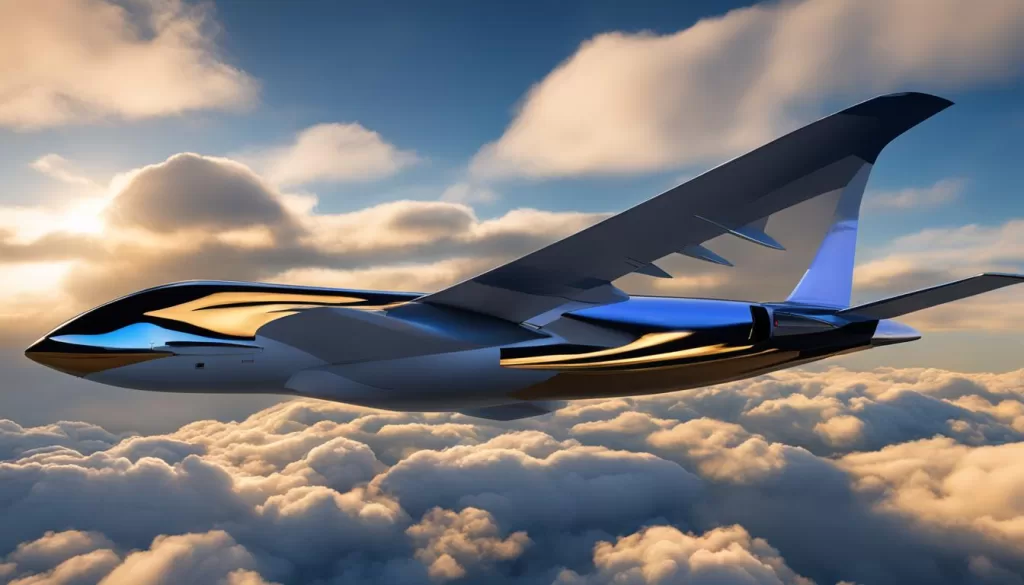

Aerospace composites, known for their lightweight properties and high strength-to-weight ratios, heavily rely on advanced thermosetting resins. By impregnating the reinforcing fibers—such as carbon or glass—with these resins, aerospace engineers produce strong and rigid composites. These composites contribute to the overall structural integrity of various aircraft components, including wings, fuselages, and interior panels.

Let’s take a closer look at the benefits offered by advanced resins and high-performance resins in these applications:

- Enhanced strength and durability: Aerospace coatings and composites reinforced with advanced thermosetting resins offer superior strength and durability, ensuring the structural integrity and safety of the aircraft in demanding operational conditions.

- Excellent chemical resistance: Resistant to a wide range of chemicals, these resins protect the aircraft from harmful substances that can degrade its performance and compromise safety.

- Temperature resistance: Advanced thermosetting resins exhibit high-temperature stability, enabling them to withstand the extreme heat generated during flight operations.

- Lightweight properties: By using these resins in aerospace composites, engineers can significantly reduce the weight of aircraft components without sacrificing strength, contributing to fuel efficiency and lower operating costs.

The applications of advanced thermosetting resins in aerospace coatings and composites are essential for ensuring the reliability, performance, and safety of modern aircraft. The continuous advancement in resin technology allows the aerospace industry to push the boundaries of engineering and deliver next-generation aircraft that meet the ever-increasing demands of the industry.

| Advantages of Advanced Thermosetting Resins in Aerospace Applications | Aerospace Coatings | Aerospace Composites |

|---|---|---|

| Strength and Durability | Increase resistance against corrosion, UV radiation, and extreme weather conditions. | Provide structural integrity and rigidity to various components. |

| Chemical Resistance | Protect aircraft surfaces from chemicals that can degrade performance. | Shield composite materials from chemical damage. |

| Temperature Resistance | Withstand high temperatures generated during flight operations. | Retain structural stability at elevated temperatures. |

| Lightweight Properties | N/A | Reduce weight without compromising strength, enhancing fuel efficiency. |

Advancements in Aerospace Resin Technology

In the ever-evolving aerospace industry, staying at the forefront of technological advancements is crucial. This includes embracing the latest developments in resin technology to enhance the performance, longevity, and environmental sustainability of aerospace materials. Let’s explore the exciting advancements in advanced resins and thermosetting materials that have revolutionized the aerospace sector.

One significant area of advancement is in the formulation of advanced resins. Researchers and engineers have been tirelessly working to develop resins that exhibit enhanced properties such as improved strength, durability, and heat resistance. These advancements have resulted in resins that can withstand the extreme conditions experienced in aerospace applications, ensuring the safety and reliability of aircraft.

Moreover, manufacturing processes have also seen significant advancements. Techniques such as advanced composite molding and additive manufacturing have been employed to produce aerospace components with increased precision and reduced production time. These innovative manufacturing methods enable the creation of complex geometries and lightweight structures, further optimizing the overall performance of aircraft.

The Role of Environmental Sustainability

Complementing the advancements in resin formulation and manufacturing processes, aerospace companies are increasingly prioritizing environmental sustainability. With growing concerns over carbon emissions and environmental impact, the aerospace industry has been actively working towards developing resins with reduced ecological footprints.

One notable example is the introduction of bio-based resins, derived from renewable resources such as plant oils and agricultural waste. These bio-based resins offer comparable mechanical properties to their conventional counterparts while significantly reducing dependence on fossil fuels. By adopting such environmentally friendly resins, aerospace companies can contribute to the global effort for a more sustainable future.

Overall, the advancements in aerospace resin technology are enabling the industry to push boundaries and achieve unprecedented levels of performance and reliability. By harnessing the power of advanced resins and thermosetting materials, aerospace companies can continue to innovate and excel in a highly competitive landscape.

| Advancements in Aerospace Resin Technology | Benefits |

|---|---|

| Formulation of advanced resins | – Enhanced strength, durability, and heat resistance – Improved safety and reliability of aircraft |

| Advanced manufacturing processes | – Precise production of complex geometries – Lightweight structures for improved performance |

| Focus on environmental sustainability | – Introduction of bio-based resins – Reduced ecological footprint |

Challenges and Solutions in Aerospace Resin Applications

Working with advanced thermosetting resins in aerospace applications presents unique challenges for engineers and manufacturers. Understanding the specific properties and handling requirements of epoxy resins, aerospace resins, and thermosetting polymers is crucial to ensure optimal performance and reliability.

Handling and Application Challenges

- Precise Mixing: Achieving the ideal resin-to-hardener ratio is essential for proper curing and maximizing resin performance. Inaccurate measurements or insufficient mixing can result in inadequate bonding or compromised mechanical properties.

- Viscosity Control: Aerospace resins often have high viscosities, making them challenging to handle and apply. Specialized equipment and techniques are required to ensure uniform coverage and prevent any voids or air entrapment.

- Controlled Curing: The curing process of thermosetting resins is time-dependent and requires specific temperature and humidity conditions. Maintaining precise curing parameters is vital to avoid incomplete curing or resin degradation.

Overcoming these challenges necessitates innovative solutions to optimize the use of advanced thermosetting resins in aerospace applications. By addressing these issues, we can unlock the full potential of these materials and ensure the structural integrity and safety of aerospace components.

Solutions for Optimization

- Precision Mixing Systems: Automated equipment and advanced software can ensure accurate resin-to-hardener ratios and consistent mixing. This eliminates human error and ensures reliable bond formation.

- Viscosity Modifiers: Adding viscosity-modifying agents to resins can enhance flow properties, making them easier to handle and apply. These modifiers reduce tap and settle time, improving overall processability.

- Controlling Curing Parameters: State-of-the-art curing ovens and environmental control systems provide precise temperature and humidity control during the curing process. This ensures uniform resin consolidation and complete cross-linking.

Implementing these solutions leads to improved resin application and component performance in aerospace applications. By optimizing handling, application, and curing processes, we can enhance the strength, durability, and reliability of advanced thermosetting resins in the aerospace industry.

Quality control measures and testing protocols are also critical to ensure the highest standard of resin application and component performance. Regular inspections, non-destructive testing, and extensive qualification procedures enable the identification and correction of any potential issues before they impact the final product.

“Using advanced thermosetting resins in aerospace applications requires overcoming challenges in handling, applying, and curing processes. Precise mixing, viscosity control, and managing curing parameters are crucial for optimal resin performance.”

By addressing these challenges and utilizing innovative solutions, we can unlock the full potential of epoxy resins, aerospace resins, and thermosetting polymers in the aerospace industry. These materials pave the way for enhanced structural integrity, efficiency, and safety in aircraft manufacturing and maintenance.

Next: Conclusion

Conclusion

In conclusion, advanced thermosetting resins are invaluable in the aerospace industry, revolutionizing safety and performance. These aerospace resins, derived from thermosetting materials, offer exceptional durability, strength, and chemical resistance. Whether utilized in aerospace coatings, composites, or other applications, these advanced resins are vital in enhancing the reliability and efficiency of aircraft.

By embracing advancements in resin technology, aerospace companies can continuously push the boundaries of aerospace engineering. Innovations in advanced resins and thermosetting materials have led to improved formulations and manufacturing processes. These advancements not only enhance the overall performance and longevity of aerospace components but also contribute to environmental sustainability.

Despite the numerous benefits, challenges arise when working with epoxy resins, aerospace resins, and thermosetting polymers. However, by employing optimized handling processes, quality control measures, and testing protocols, these challenges can be overcome, ensuring the highest standard of resin application and component performance.

In summary, advanced thermosetting resins are driving progress in the aerospace industry. Through ongoing research, development, and application of these materials, aerospace companies can achieve new heights in safety, reliability, and efficiency, solidifying their commitment to innovation and excellence.

FAQ

What are advanced thermosetting resins?

Advanced thermosetting resins are a type of material used in aerospace applications due to their exceptional strength, durability, and heat resistance. They undergo a process called cross-linking, which gives them their unique properties.

What types of resins are commonly used in aerospace?

Epoxy resins, thermosetting polymers, and high-performance resins are some of the commonly used types of resins in the aerospace industry. These materials provide excellent chemical resistance, withstand high temperatures, and exhibit superior mechanical properties.

What are the applications of advanced thermosetting resins in aerospace?

Advanced thermosetting resins find applications in aerospace coatings, which protect aircraft surfaces from corrosion, UV radiation, and extreme weather conditions. They are also used in aerospace composites to provide structural integrity and lightweight properties. Additionally, advanced resins and high-performance resins enhance the overall performance and safety of aerospace components.

What advancements have been made in aerospace resin technology?

Recent advancements in aerospace resin technology include new formulations and manufacturing processes that improve the performance, longevity, and environmental sustainability of advanced resins and thermosetting materials. Staying updated with these developments allows aerospace companies to utilize the most cutting-edge materials available.

What challenges are faced in aerospace resin applications and how can they be addressed?

Engineers and manufacturers face challenges when working with advanced thermosetting resins in aerospace applications. Specific properties and handling requirements of epoxy resins, aerospace resins, and thermosetting polymers need to be considered. Solutions for optimizing their use include implementing quality control measures, testing protocols, and ensuring the highest standard of resin application and component performance.

What role do advanced thermosetting resins play in the aerospace industry?

Advanced thermosetting resins elevate safety and performance in the aerospace industry. Whether used in coatings, composites, or other applications, they offer exceptional durability, strength, and chemical resistance. By embracing advancements in resin technology and addressing challenges in their application, aerospace companies can enhance the reliability and efficiency of aircraft.