We’re going to look at how advanced adhesives help make sensors in factories. Adhesives are key in making different kinds of sensors work well. They help sensors perform better, last longer, and innovate in fields like cars and medical devices.

Adhesive technology has changed a lot and affects how sensors are made. We’ll share insights to show how important adhesive for sensors are. These solutions are key for sensors to work well and last long in many industries. They make sensors stronger and more stable in heat, which is vital for making sensors.

Key Takeaways

- Adhesives are crucial in the production of various types of sensors.

- They enhance the performance and reliability of sensors in applications ranging from automotive to medical devices.

- Advanced adhesive technologies have a significant impact on sensor manufacturing processes.

- Sensor adhesive solutions play a pivotal role in improving mechanical strength and thermal stability.

- These developments contribute to the innovation and longevity of sensors in multiple industrial sectors.

- The discussion sets the stage for a comprehensive exploration of sensor adhesives.

Introduction to Sensor Adhesives

Using the right adhesives is key to making sensors work well. These adhesives keep sensor parts together and safe in different conditions. Knowing how to pick the best adhesives can make sensors last longer and work better.

Importance of Adhesives in Sensor Manufacturing

Adhesives are vital in making sensors. They help put together sensor modules, like MEMS temperature sensors. These adhesives need to bond strongly and protect against the environment. Epoxy and silicone adhesives are great for keeping sensors working well in extreme temperatures and keeping electrical signals safe.

Choosing the right adhesive can make sensors last longer and work better.

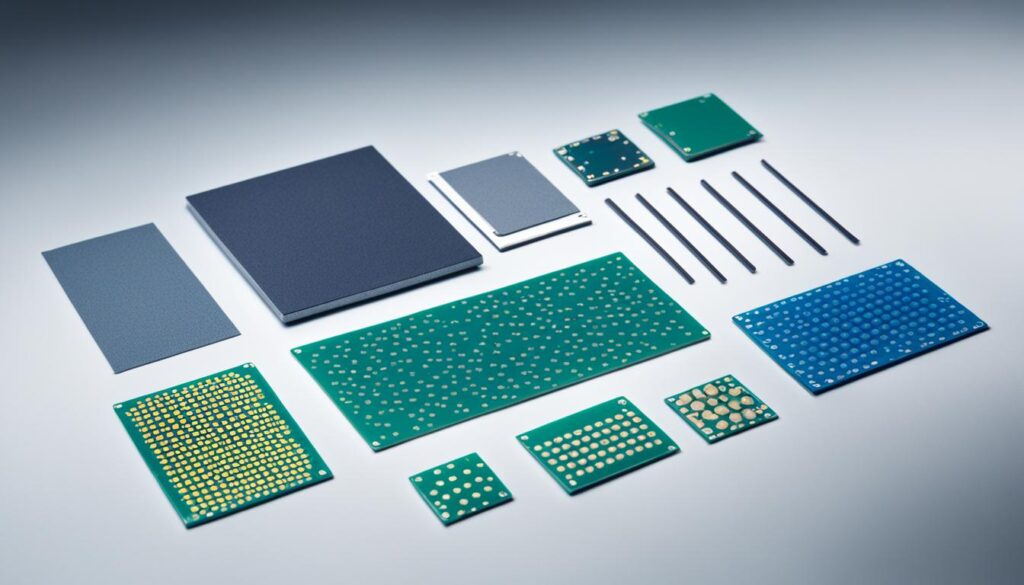

Common Types of Adhesives Used

There are several adhesives used for sensors, each with its own benefits:

- Epoxies: These are strong and stick well, perfect for tough environments.

- Silicones: They’re flexible and stay stable in extreme temperatures.

- Acrylics: These offer good adhesion and flexibility, ideal for fast applications.

Each adhesive has its own strengths, suited for different needs. For more information on these adhesives, check out this in-depth resource.

Adhesive for Sensors: Key Properties

Choosing the top adhesive for sensor application is crucial. We must look at several key properties. These ensure the adhesive works well and lasts long in different conditions. Let’s explore these important features and why they matter for sensors.

Viscosity and Flow

The viscosity of an adhesive is key. It must flow well and fill gaps between the sensor and its base. This is vital for the sensor’s precise placement and stability. It also boosts the adhesive mechanical properties.

Temperature Resistance

Adhesives for thermal management are essential in changing temperatures. They must keep working well without losing strength.

Electrical Conductivity

Electrical conductivity is crucial for many sensors. Conductive adhesives let electrical signals pass smoothly. The best adhesive balances electrical performance with other important traits. This makes it a key part of the top adhesive for sensor application.

Knowing these properties helps us pick and use adhesives wisely. This ensures they work well and reliably in sensor applications.

Top Adhesive for Sensor Application

Choosing the best adhesive for sensors is key for top performance and long life. We look at top adhesives made for sensors, focusing on ones that lead the industry. Working with leaders like 3M, Henkel, and Dow Corning, we’ve found high-performance sensor adhesives that are trusted globally.

These reliable adhesives for sensor technology are made to handle different sensor needs. They resist the elements and bond strongly. Here are some top adhesives known for their quality:

| Brand | Product Name | Key Features |

|---|---|---|

| 3M | Scotch-Weld | High strength, temperature resistance, and fast curing |

| Henkel | LOCTITE 4902 | Flexibility, impact resistance, and wide material compatibility |

| Dow Corning | Silicone Adhesive 734 | Excellent adhesion to metals and plastics, and outstanding environmental durability |

| ZDS™ | Silicone Adhesive ZDS1607 | High performance, versatility, and reliability |

These products show what high-performance sensor adhesives should be like. They offer quick curing and long-lasting strength. As sensor technology advances, these adhesives will keep ensuring sensors work well for a long time.

Choosing the Best Adhesive for Sensors

Choosing the right adhesive for sensors is a big deal. It’s important to make sure the adhesive works well with different materials. It also needs to form a strong bond that can handle stress and environmental changes.

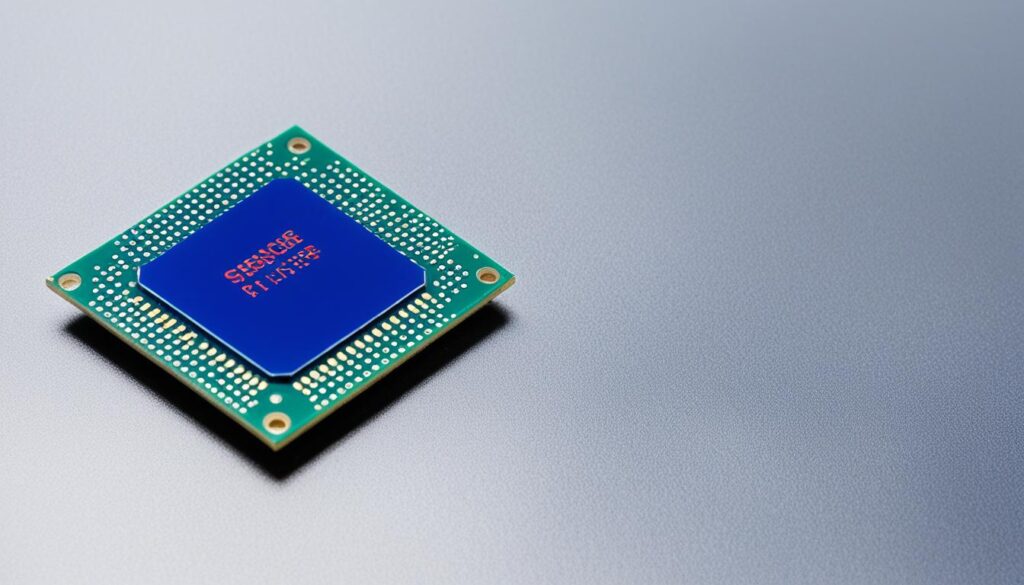

Compatibility with Sensor Materials

Adhesives must work well with materials like plastics, metals, and ceramics. They need to stick to these without harming the sensor’s function. Picking the right adhesive material helps avoid problems like corrosion or damage over time.

Mechanical Strength and Durability

The adhesive’s strength and durability are key. A durable adhesive solution should keep its bond under stress from heat, vibrations, and impacts. This ensures the adhesive lasts long, even in tough conditions.

| Material | Compatible Adhesives | Benefits |

|---|---|---|

| Plastics | Acrylics, Epoxies | High flexibility, strong bond |

| Metals | Epoxies, Polyurethanes | High mechanical strength, corrosion resistance |

| Ceramics | Silicone Adhesives | Resistant to high temperatures, excellent adhesion |

Sensor Bonding Agent: Critical Considerations

Choosing the right sensor bonding agents is key. We must look closely at curing time and methods. These affect how fast and well we make products. By improving how we cure adhesives, we can make our production faster and more reliable.

Curing Time and Techniques

Knowing how to cure sensors right is vital for their performance. Adhesives cure in different ways—some need heat, others UV light, and some just time. Getting this right helps avoid weak bonds and makes sensors last longer.

Here is a comparison of common curing methods:

| Curing Method | Advantages | Disadvantages |

|---|---|---|

| Thermal Curing | Strong bond strength, widely applicable | Energy-intensive, longer process time |

| UV Curing | Rapid curing, low energy consumption | Requires UV-transparent materials, limited depth |

| Room Temperature Curing | Convenient, energy-efficient | Longer curing time, potential for incomplete cure |

Environmental Considerations

Using eco-friendly sensor adhesives is now more important than ever. Choosing adhesives that are good for the planet helps us follow the law and supports a healthier Earth.

What’s around us affects which adhesives we pick. Making sure we cure adhesives right and protect the environment takes careful thought. Using adhesives that are good for the planet means we make better products and help the environment.

Innovations in Sensor Adhesive Solutions

The world of adhesives is changing fast, keeping up with sensor technology advancements. New adhesives like nanocomposite and bio-based ones are changing how we use sensors. These adhesives perform better, last longer, and are friendlier to the environment.

Nanocomposite materials are a big step forward in adhesive tech. They use nanoparticles to boost strength, stability, and conductivity. This makes them perfect for modern sensors. With these materials, we can make adhesives that work great in many conditions.

Bio-based adhesives are another big deal. They use natural resources instead of oil, making them better for the planet. As we need greener materials for sensors, bio-based adhesives are a great choice for companies wanting to be eco-friendly.

Using these new adhesives helps the environment and improves sensor technology. By adding innovative adhesives to our products, we can make sensors better and more reliable.

ZDS1607

| Attribute | Details |

|---|---|

| Type | Silicone |

| Model | ZDS1607 |

| Features | Potting silicone, 1:1 ratio, thermal conductivity 0.6~0.9, low density 1.3, UL94V0 |

| Packaging Form | 20kg per set |

ZDS5112-7-3

| Attribute | Details |

|---|---|

| Type | Polyurethane Potting Compound |

| Model | ZDS5112-7-3 |

| Features | Polyurethane potting compound, weight ratio 30:100, elastic, excellent waterproof and insulation properties. |

| Packaging Form | 25kg per bucket |

ZDS5050ab

| Attribute | Details |

|---|---|

| Type | Epoxy Resin Potting Compound |

| Model | ZDS5050ab |

| Features | Epoxy resin, weight ratio 5:1, black, cures at room temperature, temperature resistance -40 to 150°C. |

| Packaging Form | 25kg per bucket |

Adding new adhesives to sensors makes them work better and supports sustainable, high-performance tech. These changes help sensors meet today’s needs and open doors for future breakthroughs.

Sensor Attachment Adhesive: Methods and Techniques

Getting the adhesive right is key for a sensor’s success. This part talks about how to apply sensor adhesives well. It covers cleaning the surface and testing after applying the adhesive.

Surface Preparation

Starting with a clean surface is crucial for a strong bond. Clean the sensor and the surface it will stick to well. Use isopropyl alcohol or other cleaners to get rid of dirt. Making the surface a bit rough helps the adhesive stick better.

Application Techniques

There are different ways to apply adhesive, depending on what you need. You can use manual, automated, or silk screen printing methods. Automated robotic dispensing is great for putting the right amount of adhesive on every time. It cuts down on mistakes and makes making more products faster.

Post-Application Testing

After applying and drying the adhesive, test it to make sure it’s strong and lasts. You’ll test how well it sticks, how it handles heat and shaking, and more. These tests check if the adhesive works well and spot any problems early.

In short, making sure the surface is clean, applying adhesive carefully, and testing it well is key. Doing these steps right makes sure the adhesive sticks well and works as it should.

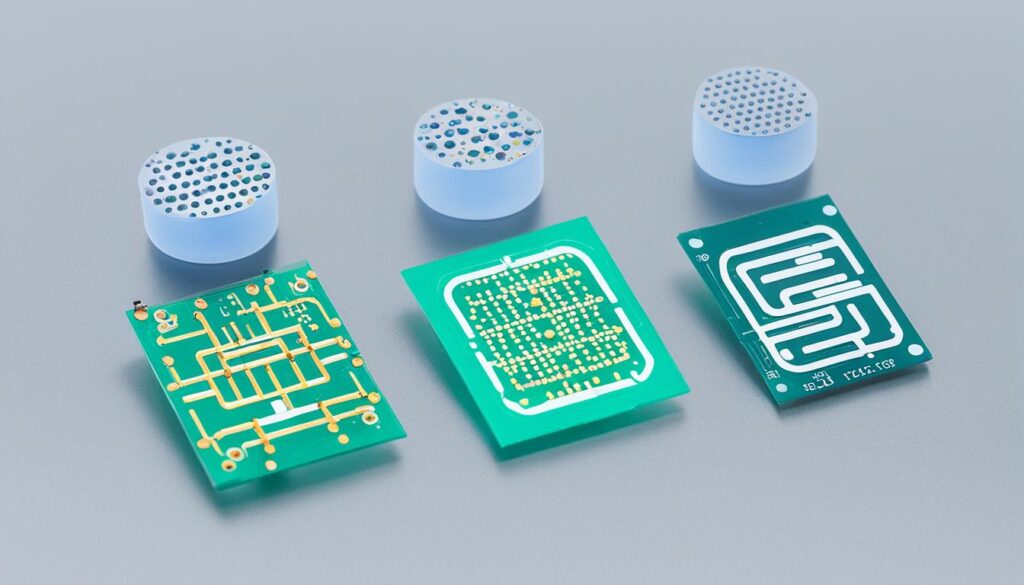

Sensor Potting Adhesive: Ensuring Longevity

Using a sensor potting compound is key to making sensors last longer and work well. This special glue wraps around sensitive parts, keeping them safe from things like moisture, dust, and extreme heat. It makes sensors more durable, helping them work better and last longer in many uses.

Benefits of Potting

There are many good things about using a sensor potting compound:

- Protection from Environmental Factors: These resins keep sensors safe from dust, moisture, and chemicals.

- Enhanced Mechanical Strength: Adding a layer of strength helps prevent damage.

- Electrical Insulation: These adhesives stop short circuits and other electrical problems.

- Improved Reliability: They reduce the effects of the environment, making sensors work more consistently.

How to Apply Potting Adhesive

Here’s how to apply sensor potting compound right:

- Prepare the Sensor: Clean and dry the sensor housing. Remove any dirt that could stop the glue from sticking.

- Mix the Potting Compound: Mix the adhesive parts together as the maker says to.

- Apply the Adhesive: Put the glue over the sensor parts, making sure it covers everything without air bubbles.

- Cure the Compound: Let the glue dry as the instructions say, at the right temperature and time.

- Inspect the Finish: After it’s dry, check the sensor to make sure the glue is even and covers everything well.

Following these steps will help sensors last longer and stay safe from the environment. Using top-quality potting adhesives also makes sensors more durable and reliable over time.

Sensor Sealing Glue: Protecting Against Elements

In the world of sensor technology, keeping sensors safe and working well is key. This makes sensor adhesive sealing very important. Advanced adhesives help protect sensors from moisture, dust, and chemicals.

Choosing the right glue is a big deal. It helps sensors stay safe from the outside world. The best glue keeps the inside parts safe and working right, even in tough places like cars, factories, or on ships.

A top-notch sensor protection adhesive keeps sensors working well for a long time. It’s important to pick the right glue for your needs. Here’s a quick guide to help you:

| Attribute | Importance | Recommendation |

|---|---|---|

| Moisture Resistance | High | Silicone-based adhesive |

| Dust Protection | Medium | Epoxy resin adhesive |

| Chemical Resistance | High | Polyurethane adhesive |

| Temperature Stability | Critical | Acrylic adhesive |

Choosing the right sensor adhesive sealing is complex but important. It’s crucial to pick adhesives that fit your needs and offer strong environmental resistance. Making smart choices helps make our sensors last longer and work better, keeping them safe from the elements.

Conclusion

Choosing the right adhesive for sensors is key to their optimal performance and reliability. We’ve looked into the different adhesives available and their features. This helps manufacturers make their sensor systems better and last longer.

Understanding the importance of viscosity, temperature resistance, and electrical conductivity is crucial. These factors are key to making strong sensor adhesives.

Advances in sensor adhesives show how science and industry work together. These new solutions solve current problems and open doors for future innovations. By thinking about things like material compatibility and environmental impact, manufacturers can make better sensors.

Adhesives are very important in making sensors work well. As technology advances, adhesives will keep playing a big role. We hope our readers use these tips to improve their sensor manufacturing. This will help their products perform better and last longer.

FAQ

What are sensor adhesives and why are they important in sensor manufacturing?

Sensor adhesives are special glues used to stick sensors to different surfaces. They make sure the assembly works well and lasts long. This is key for sensors used in cars and medical devices.

What are the common types of adhesives used in sensor manufacturing?

Sensors often use adhesives like epoxies, silicones, and acrylics. Each type is chosen for its special properties. For example, some are great at handling chemicals or bending without breaking.

What properties should we consider when selecting an adhesive for sensors?

When picking an adhesive, think about its flow, how it handles heat, and if it conducts electricity. These things make sure the adhesive works well with the sensor’s needs.

What are some top adhesives recommended for sensor applications?

Top adhesives for sensors come from companies like Henkel, 3M, and Dow. They’re known for sticking things together really well and lasting a long time. They also work well with many sensor materials.

How do we ensure compatibility between sensor materials and adhesives?

To make sure the sensor and adhesive work well together, look at their material properties. Things like how they expand when heated, resist chemicals, and stick together are important. Testing and talking to adhesive makers can help too.

What are critical considerations for using sensor bonding agents?

Important things to think about include how long the adhesive takes to dry and how it reacts to the environment. Choose adhesives that fit your production speed and meet safety rules. Also, think about how they affect the planet.

What are recent innovations in sensor adhesive solutions?

New advances include nanocomposite and bio-based adhesives. These are better for the planet and work even better. They help sensors do their job better and are more eco-friendly.

What are effective methods and techniques for applying sensor attachment adhesives?

Good methods include cleaning the surface well, applying the adhesive carefully, and testing it afterwards. These steps help make a strong and lasting bond. This is key for the sensor to work well over time.

What is sensor potting adhesive and how does it benefit sensor longevity?

Sensor potting adhesive wraps around the sensor and its connections. It protects them from the outside world. This keeps the sensor safe from moisture, shaking, and other dangers, making it last longer.

How does sensor sealing glue protect sensors from environmental elements?

Sensor sealing glue keeps out moisture, dust, and harmful chemicals. It acts as a shield, letting the sensor work without interruption, even in tough conditions.