Ever wondered why modern cars are so tough and long-lasting? It’s all about the cutting-edge materials and tech used in making them. A key part of this is structural bonding adhesive. At ZDS™, we’re all about making adhesives that can handle the tough life of cars.

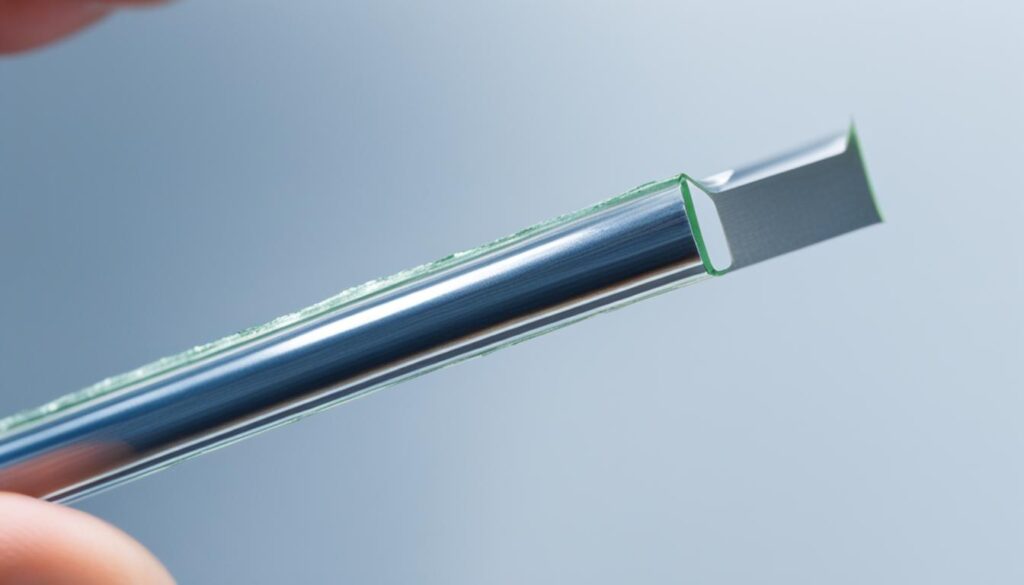

Our adhesive is key for sticking together materials like metals and composites in cars and fixing them up. We focus on making sure these bonds last a long time. So, what makes these adhesives so important for car safety and durability? Let’s dive into the world of structural bonding adhesives.

Key Takeaways

- Structural bonding adhesives are vital for the automotive industry.

- ZDS™ specializes in creating durable adhesives for various materials.

- Our adhesives ensure strong, lasting bonds under harsh conditions.

- Advanced bonding solutions contribute to vehicle safety and longevity.

- Understanding these adhesives enhances our appreciation of modern vehicles.

Introduction to Structural Bonding Adhesives

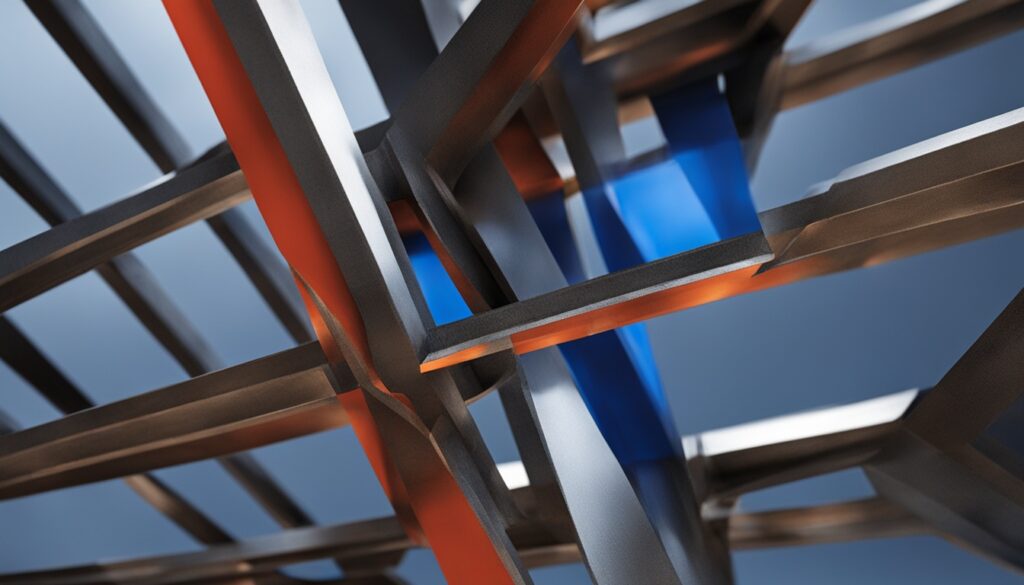

Structural bonding adhesives are key in modern manufacturing, especially in the automotive field. They offer strong, lasting bonds that can handle heavy loads and stresses. Let’s explore why these adhesives are vital for high-strength uses.

What Are Structural Bonding Adhesives?

A structural adhesive is a special glue for heavy-duty tasks. It’s made to create strong connections that can handle a lot of stress. Unlike regular adhesives, these are designed for situations where long-lasting strength is crucial. They are perfect for permanent bonds, keeping parts together securely over time.

Importance in Automotive Industry

In the car industry, structural adhesives are key for safety, performance, and efficiency. They help make cars lighter yet stronger, improving fuel efficiency and safety in crashes. Companies like General Motors and Ford use these adhesives to meet tough industry standards.

These adhesives also allow for more flexible designs. This lets engineers innovate without risking the car’s safety. Thanks to advances in structural adhesive technology, cars are getting safer and more efficient, meeting what consumers want today.

Why Choose High-Strength Adhesives?

High-strength adhesives have many benefits, making them key in many industries. They bond different materials well, handle high temperatures, and spread stress evenly. ZDS™’s adhesives are versatile and strong, fitting into aerospace, construction, and electronics sectors.

Advantages of High-Strength Adhesives

Choosing high-strength adhesives brings big advantages. They improve bonding, increase durability, and strengthen structures. These adhesives can stick materials like metal and composites together, lasting long even in tough conditions. They also help make constructions lighter by needing less material than traditional fasteners.

Applications in Different Industries

High-strength adhesives are used in many industries, showing their broad applications:

- Aerospace: They assemble parts that face high stress and extreme temperatures.

- Construction: They bond materials, making structures stable and long-lasting.

- Electronics: They connect delicate parts, making products last longer.

In the automotive world, high-strength adhesives, like a structural adhesive for metal, are vital. They form bonds that last through daily use. As industrial adhesives, they make assembly easier and products more reliable.

Types of Structural Adhesives

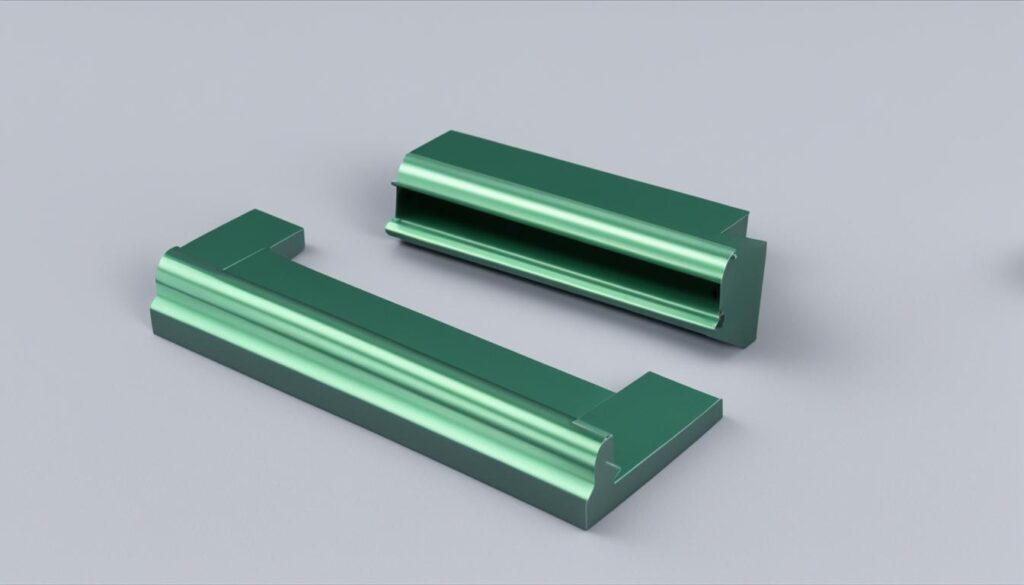

There are two main types of structural adhesives: epoxy and polyurethane. Each has special features that make them great for certain jobs. They are used in many places, from strong bonds to flexible ones.

Epoxy Adhesives

Epoxy adhesives are top picks for their strong bonds and lasting power. They can handle tough environments and heavy loads. Brands like ZDS™ make high-quality epoxy adhesives for many industrial needs.

Polyurethane Adhesives

Polyurethane adhesives are flexible and tough. They can take impacts and vibrations without breaking. This makes them perfect for jobs where things might move a bit. ZDS™ offers special polyurethane adhesives for different heavy-duty tasks.

| Type | Key Properties | Ideal Applications |

|---|---|---|

| Epoxy Adhesives | High strength, excellent durability, extreme environmental resistance | Heavy-duty applications, load-bearing structures |

| Polyurethane Adhesives | Flexibility, impact resistance, good resilience | Applications with moderate movement, environments with vibrations |

Epoxy Adhesive: A Popular Choice

Epoxy adhesive is a top pick for metal bonding in tough situations. It’s known for its strong bonds and resistance to chemicals. This makes it a key player in many industries.

Features of Epoxy Adhesive

Epoxy adhesive is known for its special mix of traits:

- High Strength: It bonds very strongly, keeping parts securely in place.

- Chemical Resistance: It stands up well to chemicals, which is important for many uses.

- Durability: It can handle tough conditions, making bonded materials last longer.

Benefits for Heavy-Duty Applications

Epoxy adhesive is a game-changer for heavy-duty tasks, like in the car industry. At ZDS™, we make epoxy adhesives for the tough demands of making and fixing cars. They help attach important parts securely, so they can handle the stress and weather.

If you need a strong adhesive for metal in harsh conditions, epoxy is a smart pick. It offers not just strength and long life, but also protection against chemicals and the elements. This makes it a must-have for modern car solutions.

Choosing the Right Auto Structural Bonding Adhesive

Choosing the right auto structural adhesive is key for lasting repairs and manufacturing. We must think about material match, cure time, and the bond needed for the job.

When picking a structural adhesive, knowing how it performs is vital. Things like UV resistance and chemical durability affect how long the bond lasts. We can’t just look at the price. While cost matters, a cheap option might not work well.

ZDS™ offers expert advice on finding the best adhesive for cars. They consider strength, flexibility, and thickness to match each application’s needs. Also, guides like this detailed guide can help us pick the right adhesive.

For repairs or making new parts, we have the perfect adhesive. By understanding each project’s needs and picking the right adhesive, we ensure top-quality results.

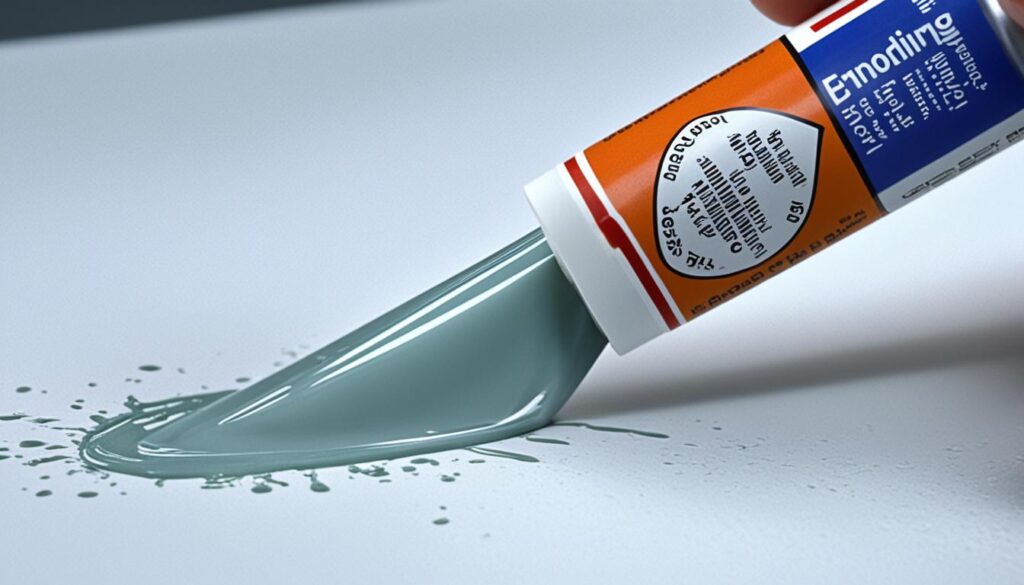

Tips for Using Adhesives for Metal in Automotive Repairs

Using adhesive for metal in car repairs makes sure the bond is strong and lasts long. By taking the right steps, we can make the most of the adhesive and get great results.

Surface Preparation

Getting the surface ready is key when using adhesive for metal. A clean surface means a stronger bond. Here’s how to prepare:

- Cleaning: Remove dirt, grease, or oil with a good cleaner.

- Sanding: Sand the surface lightly to make it rough for better sticking.

- Priming: Sometimes, a primer can make the bond even stronger.

Application Techniques

Applying adhesive for metal the right way is crucial. Here are some tips for the best results:

- Measure and mix the adhesive as the maker says.

- Put a thin, even layer of adhesive on the surfaces.

- Press the metal parts together firmly to avoid air pockets.

Always follow the maker’s advice for the best results. Our products, like ZDS™, have clear instructions for a professional finish every time.

The Role of Industrial Adhesives in Manufacturing

Industrial adhesives have changed how things are made, making assembly better and saving money. They fit right into current manufacturing setups, promising quality and reliability. It’s key for industry experts to grasp the wide role these adhesives play in making things.

Efficiency and Cost-Effectiveness

Using industrial adhesive makes putting things together faster and more reliable. For instance, adhesive for construction bonds parts quickly and well, cutting down on time and effort. This saves money for makers.

ZDS™’s adhesives create strong and lasting bonds, often replacing mechanical fasteners. These can be pricier and take more time to use.

Enhancing Product Durability

Industrial adhesive makes products last longer. It’s made to handle tough conditions, creating bonds that last. Adhesive for construction is especially tough, keeping structures strong over time.

This means products work better, customers are happier, and there’s less need for fixes and new products.

By using industrial adhesive, makers can set a high standard of quality and reliability. This sets a mark of excellence in their fields.

| Advantages | Impact |

|---|---|

| Streamlined Operations | Reduces assembly time, increasing the speed of production. |

| Cost-Effectiveness | Lower labor costs and reduced material waste. |

| Enhanced Durability | Longer-lasting products with higher performance standards. |

| Quality Assurance | Consistent bonding quality ensures product reliability and safety. |

Structural Bonding Adhesive: A Key to Strong Bonds

In today’s fast-paced world, having a dependable structural bonding adhesive is vital. These adhesives are key for many uses, from cars to home appliances. Our structural bonding adhesives are top-notch, ensuring strong, lasting bonds in every situation.

We focus on providing adhesives that keep bonded structures strong and resilient. Our products are tested hard to make sure they meet and often beat industry standards. They work well with metals, plastics, and ceramics, making them versatile for different bonding needs.

Our adhesives are made to handle tough conditions, offering great temperature resistance and durability. This is great for industries like car making and electrical gear, where things need to hold up under stress. We provide products that have been tested and proven to help our clients get the best results in their projects.

Our Hybrid Universal Bonders show our dedication. They combine the best of structural and instant adhesives for top performance and flexibility. This makes them a great pick for solving design and assembly challenges in many settings. Whether you’re in the car industry or working on home appliances, our adhesives are made to excel.

Conclusion

ZDS™ is proud to offer top-notch bonding adhesives for the automotive industry and more. Our adhesive makes strong bonds that last, no matter what. It’s all about reliability and performance.

We’re always pushing the limits of adhesive technology. Our goal is to give our customers the best bonding solutions out there. We keep improving our products and methods to meet the changing needs of industries like automotive, manufacturing, and aerospace.

ZDS™ is all about quality and innovation. We aim to lead the industry with our adhesives. We invite our clients to use our expertise and advanced technology for their projects. This ensures their work is durable and efficient.

FAQ

What are structural bonding adhesives?

Structural bonding adhesives are made for permanent bonds that need to be strong and last a long time. They can handle a lot of weight, making them key for building and fixing things.

Why are structural bonding adhesives important in the automotive industry?

In cars, these adhesives are vital for putting parts together and fixing them. They stick materials like metals and composites together well, keeping cars safe and strong even in tough conditions.

What are the advantages of high-strength adhesives?

High-strength adhesives are great because they can stick different materials together. They also work well in extreme heat or cold and spread stress out evenly. This makes them useful in many fields like aerospace, building, and electronics.

What types of structural adhesives does ZDS™ offer?

ZDS™ makes epoxy and polyurethane adhesives for structures. Each kind has special features for different uses, giving the best results in many places.

What features make epoxy adhesives a popular choice?

Epoxy adhesives are loved for their strong bonds and resistance to chemicals. They’re perfect for tough jobs, like in cars, where they keep important parts together safely through stress and weather.

How do I choose the right auto structural bonding adhesive?

Picking the right adhesive means knowing what your project needs. ZDS™ experts can guide you to the best adhesive for your car repair or making cars, ensuring it lasts a long time and works well.

What tips can you offer for using adhesives for metal in automotive repairs?

For metal repairs, clean and prime the surface well, and apply the adhesive carefully. Our products come with clear instructions for a strong and lasting bond.

How do industrial adhesives enhance manufacturing processes?

Industrial adhesives make putting things together faster and cheaper, making products last longer. ZDS™ adhesives fit easily into current manufacturing, ensuring quality and reliability.

Why is structural bonding adhesive key to strong bonds?

A strong bond is crucial in all uses. ZDS™ offers adhesives that are very strong and reliable. We test our products a lot to keep up the highest quality and performance.