Automotive Adhesives: The Future of Vehicle Assembly and Repair

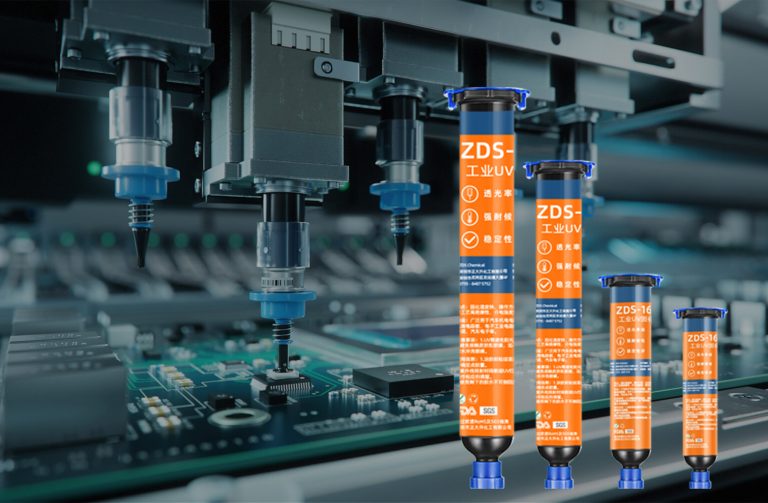

In today’s advanced automotive industry, the use of adhesives has revolutionized vehicle assembly and repair processes. At ZDS™, we’re at the forefront as a manufacturer and supplier of high-quality automotive adhesives that meet diverse needs. Understanding these adhesives’ applications, benefits, and technological advancements is crucial for anyone involved in automotive manufacturing or repair.

Automotive adhesives are integral to modern vehicles, offering solutions ranging from sealants to epoxy options, each serving specific purposes. In this comprehensive guide, we’ll explore the world of automotive adhesives, diving deep into their uses, advantages over traditional bonding methods

What Are Automotive Adhesives?

Automotive adhesives are specialized glues designed to bond various vehicle materials securely, including metals, plastics, and composites. These adhesives play a critical role in the structural integrity and performance of modern vehicles, offering improved safety, weight reduction, and enhanced aesthetic appeal.

Types of Automotive Adhesives

Epoxy Adhesives

Known for their strong bonding capabilities, especially on metal surfaces.

Acrylic Adhesives

Offer versatility and quick curing times.

Polyurethane Adhesives

Flexible and resistant to environmental factors like moisture and temperature changes.

Applications in the Automotive Industry

Automotive Parts Adhesive

Advantages Over Traditional Methods

Opting for automotive adhesives over conventional methods such as welding yields several benefits:

- Weight Reduction: Adhesives contribute to significant weight savings, improving fuel efficiency without compromising safety.

- Corrosion Resistance: By eliminating the need for metal fasteners, adhesives reduce potential rust points.

- Enhanced Aesthetics: Allow for smooth, clean lines and modern design elements with hidden joints.

- Improved Safety: Provide consistent performance and reliability, crucial for crash management systems.

Choosing the Right Automotive Adhesive

When selecting an adhesive, consider the following factors:

- Material Compatibility: Ensure the adhesive is suitable for the materials you’re bonding.

- Temperature Resistance: Choose adhesives that can withstand the operating temperature range of the vehicle.

- Curing Time: Consider production schedules and repair turnaround times.

- Environmental Impact: Opt for eco-friendly options that comply with regulatory standards.

How ZDS™ Meets Industry Standards

At ZDS™, we pride ourselves on producing top-tier automotive adhesives that not only meet but exceed industry standards. Our products are rigorously tested for performance, safety, and sustainability. We focus on delivering solutions that align with our customers’ evolving needs, ensuring reliability, efficiency, and innovation.

Experience and Expertise

Our team at ZDS™ comprises seasoned professionals with extensive experience in chemical engineering and materials science, ensuring that our adhesives meet the highest quality benchmarks.

Authoritativeness and Trustworthiness

We maintain transparent operations and adhere to international standards in manufacturing processes. Our commitment to quality assurance and customer service positions us as leaders in the automotive adhesive market.

Innovations in Automotive Adhesives

Heat-Resistant Solutions

As vehicles become more technologically advanced, the demand for heat-resistant adhesives grows. These adhesives are pivotal in engine compartments and other high-temperature areas, providing stability and durability.

Eco-Friendly Developments

With increasing environmental concerns, ZDS™ is dedicated to developing eco-friendly adhesives that minimize VOC emissions without sacrificing performance. These innovations support sustainability goals within the automotive sector.

Advanced Curing Technologies

New curing technologies, such as UV-curable adhesives, offer faster application times and reduced energy consumption, streamlining production processes while maintaining strong bonds.

Case Studies

Eco-Friendly Adhesives in Electric Vehicles

Electric vehicles (EVs) require lightweight and durable materials to maximize range and efficiency. Our eco-friendly adhesives have been successfully implemented in EV manufacturing, contributing to overall weight reduction and environmental impact reduction.

High-Performance Sports Cars

In collaboration with leading sports car manufacturers, ZDS™ adhesives have played a crucial role in achieving superior speed and agility through effective weight management and structural integrity.

Conclusion

The use of automotive adhesives is transforming the landscape of vehicle manufacturing and repair. At ZDS™, we are committed to providing high-quality adhesives that address current market demands while adhering to rigorous safety and environmental standards.

By choosing ZDS™, you partner with a company that values excellence and innovation. Our products empower manufacturers and repair professionals to deliver safer, more efficient vehicles to consumers worldwide.

For more information about our products and services, visit our website or contact our customer support team. Experience the future of automotive engineering with ZDS™ adhesives.

FAQ

What sets ZDS™ apart as a premium auto adhesive manufacturer?

ZDS™ stands out as a leading manufacturer of high-quality automotive adhesives. Our focus is on enhancing vehicle performance and safety. We offer a wide range of adhesives for various applications, ensuring strong and durable bonds. Our commitment to innovation and quality makes us a top choice in the automotive industry.

How does ZDS™ ensure the highest standard of their automotive adhesives?

Our approach involves rigorous research and development to advance adhesive technology. We engineer our adhesives for longevity, resistance to extreme temperatures, and robust bond strength. Through extensive testing in real-world scenarios, we ensure our products excel in multiple automotive applications.

Can ZDS™ adhesives be used on both glass and plastic automotive parts?

Yes, our adhesives are versatile and suitable for both glass and plastic components. For glass and windows, we offer adhesives that provide clear, resilient bonds under UV light and harsh weather. Our adhesives for plastic and trim combine flexibility with durability, ensuring a strong hold for both aesthetics and functionality in modern vehicles.

What types of ZDS™ adhesives are best suited for high-temperature environments?

Our advanced silicone adhesives are designed to handle high temperatures, making them ideal for engine compartments and exterior applications. These adhesives offer excellent weather resistance and are tailored for automotive parts exposed to heat.

How does ZDS™ maintain quality control during the manufacturing of their auto adhesives?

Quality control is central to our manufacturing process. We carefully select raw materials and implement thorough testing protocols for our products. Our commitment to quality ensures that every batch of ZDS™ auto adhesive meets our high standards of excellence.

What adhesive should I use for bonding metal parts in my car?

For bonding metal automotive components, ZDS™ offers a variety of adhesives tailored to this material. The choice depends on the bond’s requirements, such as part weight, environmental exposure, and strength needed. Our range includes epoxy and other specialized formulas for metal applications, ensuring a secure, lasting bond.

For automotive body work, what are the different types of adhesives available?

The variety of adhesives for vehicle body work is vast. ZDS™ provides a spectrum of solutions, including silicone, epoxy, and polyurethane-based adhesives, for various repair and maintenance tasks. Whether addressing cosmetic issues or requiring a strong structural bond, our lineup has an adhesive to meet your needs.

What makes ZDS™ the best choice for automotive structural adhesives?

Choosing the best automotive structural adhesive involves considering factors like material compatibility, load bearing, and environmental conditions. ZDS™ excels by offering a portfolio of adhesives that meet and often exceed these criteria. Our focus on professional-grade quality and superior performance makes us the top choice for structural bonding in the automotive industry.

Can I get expert advice on which ZDS™ adhesive to use for my vehicle's maintenance?

Yes, our team at ZDS™ is ready to provide expert advice tailored to your specific vehicle maintenance and repair needs. Whether you’re a DIY enthusiast or a seasoned mechanic, we can guide you through the selection process and recommend the perfect adhesive for your project, ensuring optimal results.