In the rapidly evolving automotive electronics industry, reliable adhesive solutions are crucial for ensuring the stability and durability of automotive electronic systems. As a specialized adhesive company, we are dedicated to providing a comprehensive range of automotive electronic adhesive solutions to meet the bonding and encapsulation needs of various automotive electronic components.

Key Takeaways

- High-performance automotive electronic adhesive solutions to meet modern vehicle requirements.

- Durability, thermal management, and electrical conductivity are core qualities.

- Reliable performance in harsh automotive environments.

- Specialized adhesives for bonding sensitive electronic components.

- Ensures robust thermal resistance for critical applications.

Introduction to Automotive Adhesives

Automotive adhesives are key in making vehicles. They bond parts strongly and efficiently, which is essential today. At ZDS, leading in adhesive technology is our aim. We have advanced products that meet the needs of modern manufacturing.

These adhesives have changed a lot over time. They must keep up with the complex needs of car electronics. ZDS‘s progress shows our dedication to top quality and new tech. We ensure electronic parts like sensors and screens work well together.

ZDS stands out as a top supplier of automotive adhesives. Our focus is on new ideas and making customers happy. We make adhesives that can handle tough conditions and keep up with car tech changes.

Let’s explore the different adhesives used in cars and their uses:

| Adhesive Type | Application |

|---|---|

| Epoxy Resins | Structural bonding of chassis and body components |

| Acrylic Adhesives | Bonding of lightweight materials and composite structures |

| Silicone Adhesives | Sealing and bonding of glass and other transparent elements |

| Polyurethane Adhesives | Fatigue-resistant bonding of panel assemblies |

| UV Cure Adhesives | Fast-setting bonding for sensitive electronic components |

We work with leading suppliers to bring high-quality adhesives to the market. This ensures sustainable and efficient car production. By advancing adhesive technology, we support the automotive industry with reliable and innovative solutions.

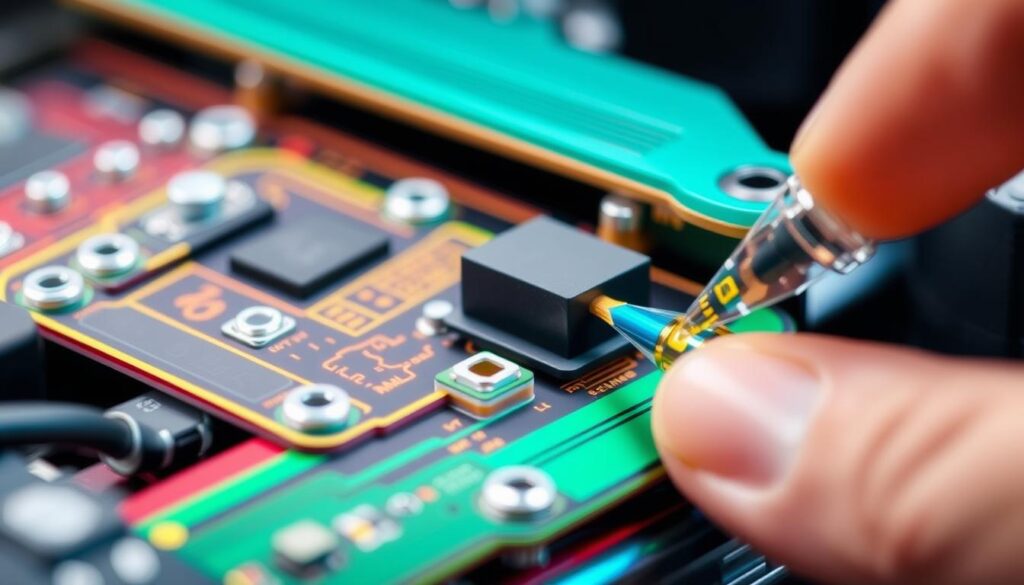

Understanding Automotive Electronic Bonding Solutions

Advanced bonding solutions are a must for automotive electronics. They handle diverse components and meet strict standards for durability, heat, and electricity. Let’s explore the key bonding solutions needed for various electronic components in cars.

1. Radio Platform Required Adhesives

Epoxy adhesives, PUR hot melt adhesives, or polyurethane adhesives.

Applications: Used to secure circuit boards, plastic housings, display screens, and other components, ensuring the stability and durability of the radio.

2. Smart Multimedia Host Required Adhesives

Two-component epoxy adhesives, UV adhesives.

Applications: Used to secure touch screens, circuit boards, speakers, and to create a strong connection between the display and the mainboard, providing lasting support for your smart multimedia host.

3. Smart LCD Instrument Panel Required Adhesives

Including acrylic adhesives, UV adhesives.

Applications: Used for securing the display screen to the backlight module and bonding various components within the instrument panel, ensuring clear display and accuracy of the instruments.

4. On-Board Terminal T-BOX Required Adhesives

Epoxy adhesives.

Applications: Used to secure circuit boards, antennas, housings, and ensure the communication stability and durability of the T-BOX.

5. HUD Auxiliary Information Display Required Adhesives

UV adhesives, acrylic adhesives.

Applications: Used to secure display screens, projection modules, and to create a strong connection between the HUD and the windshield.

6. 360 Panorama + ADAS + Radar Fusion Required Adhesives

Epoxy adhesives, UV adhesives.

Applications: Used to secure cameras, radar sensors, circuit boards, ensuring the accuracy and reliability of the system.

7. Dash Cam Required Adhesives

May include PUR hot melt adhesives, polyurethane adhesives.

Applications: Used to secure lenses, circuit boards, housings, ensuring stable performance and durability under various harsh road conditions.

8. On-Board USB Data Interface / USB Charging Box Required Adhesives

UV adhesives, acrylic adhesives.

Applications: Used to secure USB interfaces, circuit boards, housings, and create a strong connection between the interface and the mainboard.

Challenges in Automotive Electronic Adhesive Applications

Automotive electronic adhesives must tackle tough challenges due to their use in vehicles. They face extreme temperatures, vibrations, and harsh conditions. These adhesives need special formulas to keep performing well over time.

Thermal stability is a big concern for these adhesives. Electronics get really hot, and without the right adhesive, they could fail. High-temperature adhesives are made to stay strong in severe heat. They help keep electronics reliable.

Also, adhesives age faster because of tough car environments. Moisture, chemicals, and stress can weaken them. Our products are built to last in these conditions. They provide durability and a long life.

- Thermal Stability: Critical for maintaining adhesive integrity under high temperatures.

- Chemical Resilience: Necessary to prevent degradation from exposure to automotive fluids and gases.

- Mechanical Durability: Ensures adhesives withstand vibrations and physical stress from operational demands.

It’s crucial to overcome these challenges for electronic components’ longevity and reliability. By using our knowledge in automotive adhesives, we offer strong solutions. These can handle the tough conditions inside vehicles.

Innovations in Automotive Electronic Adhesive Technology

The field of automotive adhesive innovation is seeing big changes. This is because the industry needs adhesives that are reliable and perform well. At ZDS, our focus is on creating cutting-edge adhesive technology. This technology meets the complex needs of automotive electronics.

Recently, we’ve made big improvements. We’ve greatly shortened the time it takes for our performance automotive adhesives to cure. This means quicker production and less time spent manufacturing. Plus, these adhesives now have better electrical qualities. They offer top-notch conductivity and insulation for the electronic parts in modern vehicles.

We are also focusing on making our adhesives more eco-friendly. The newest ones we’ve developed perform well and are good for the environment. This shows our commitment to greener solutions in the industry.

| Innovation Aspect | Key Benefits |

|---|---|

| Reduced Cure Times | Enhances production efficiency |

| Improved Electrical Properties | Ensures superior conductivity and insulation |

| Eco-Friendly Formulations | Aligns with sustainability goals |

Our ongoing research and development are breaking new ground in automotive electronic applications. We’re making progress with cutting-edge adhesive technology. Our advancements are often ahead of industry standards.

We will keep improving our innovations. We want to make sure our performance automotive adhesives lead the industry. They will offer unmatched reliability and efficiency for the future’s vehicles.

Future Trends in Automotive Electronic Adhesives

The automotive adhesive industry is changing quickly. It’s moving towards smarter, more efficient solutions. The rise of electric and autonomous vehicles has greatly increased the importance of advanced adhesives.

Leading brands, like ZDS, are pushing this progress forward. They make sure their products meet the evolving demands of the automotive industry. These advanced adhesives are key to boosting vehicle performance, safety, and eco-friendliness.

The automotive adhesive market is being shaped by several major trends:

- Increased adoption of lightweight materials requiring specialized adhesives.

- Development of adhesives with superior bonding capabilities for electric vehicle batteries.

- Enhanced thermal management solutions through innovative adhesive formulations.

These trends are leading us to more sustainable adhesive solutions. Future automotive adhesives aim to lower environmental impact while still performing well.

Below is a comparison of the emerging trends in next-gen car adhesives, with their uses and advantages:

| Trend | Application | Benefit |

|---|---|---|

| Lightweight Materials | Body Panels | Improved Fuel Efficiency |

| Electric Vehicle Batteries | Battery Sealing | Enhanced Safety and Durability |

| Eco-Friendly Solutions | Interior Components | Reduced Environmental Impact |

As we embrace these trends, our focus on creating top-notch future automotive adhesives remains strong. By aligning with the needs of electric and autonomous vehicle production, we ensure our adhesives always lead the market.

Conclusion

ZDS is dedicated to premium automotive electronic adhesive solutions. These materials are key in boosting performance, safety, and reliability of vehicles.

Our adhesives give strong support, from radio platforms to dash cams. We use innovative technologies to keep every vehicle part securely in place, no matter the conditions.

We aim to be leaders in automotive adhesive solutions. Our focus is on improving continuously to surpass the automotive sector’s needs. Thanks for being with us, and we’re excited to keep offering top-notch solutions.

FAQ

What are automotive electronic adhesive solutions?

Automotive electronic adhesives, like those from ZDS, are special glues for cars. They include conductive and thermal adhesives. They bond parts together, conduct electricity, and manage heat in electronics.

How do automotive adhesives enhance vehicle electronics?

Automotive adhesives make vehicle electronics stay put and work well. They ensure durable bonds and handle heat and electricity well. Important for radios and smart devices in cars.

What bonding solutions do you offer for automotive electronic components?

We have various adhesives for car electronics, like UV and acrylic adhesives. We tailor them for specific needs, such as radio and smart display systems. They resist heat and the environment.

What challenges do automotive electronic adhesive applications face?

Automotive adhesives have to beat heat and tough conditions. Our high-temperature adhesives are made to last in these tough conditions. They keep electronics working long-term.

How is ZDS innovating in automotive adhesive technology?

ZDS is pushing forward with faster curing adhesives, better electrical features, and greener options. Our advanced technology sets the standard. It’s designed for top performance in car electronics.

What future trends do you see in the automotive adhesive industry?

The future is about smart tech and supporting electric and self-driving cars. We’re staying ahead with our adhesives. Planning for the next big thing in car tech.