Introduction

When it comes to fixing or assembling electronics, selecting the right adhesive is crucial. The best glue for electronics ensures not only that your components stay intact but also that they function as expected. Whether you’re repairing a smartphone, assembling a circuit board, or fixing a piece of plastic or metal housing, choosing the right adhesive can make all the difference. In this guide, we’ll explore the types of glues suitable for various electronic repairs, as well as tips for using them effectively.

What is Electronics Glue?

Electronics glue, sometimes called adhesive for electronics, is a specialized type of glue formulated to bond different materials used in electronics, such as metal, plastic, and ceramics. Unlike regular household glues, these adhesives are designed to withstand the heat, electrical conductivity, and wear and tear that electronic components often encounter. They provide durable, long-lasting bonds that don’t compromise the performance of the devices.

Types of Glue for Electronics

When it comes to electronics, there are several types of glues that can be used depending on the materials involved and the purpose of the repair. These include:

- Epoxy: Known for its strong bonding capabilities and resistance to heat, epoxy is commonly used for electronics repairs. It consists of two parts—resin and hardener—that must be mixed before use.

- Super Glue (Cyanoacrylate): A fast-drying adhesive, super glue is great for small, precise repairs but may not offer the long-term durability needed for more robust applications.

- Silicone Glue: Flexible and waterproof, silicone glue is ideal for sealing components or bonding surfaces that need some give.

- Conductive Adhesive: This glue is specifically designed to bond electronics while allowing the transfer of electrical current. It’s essential for repairing delicate components like circuit boards.

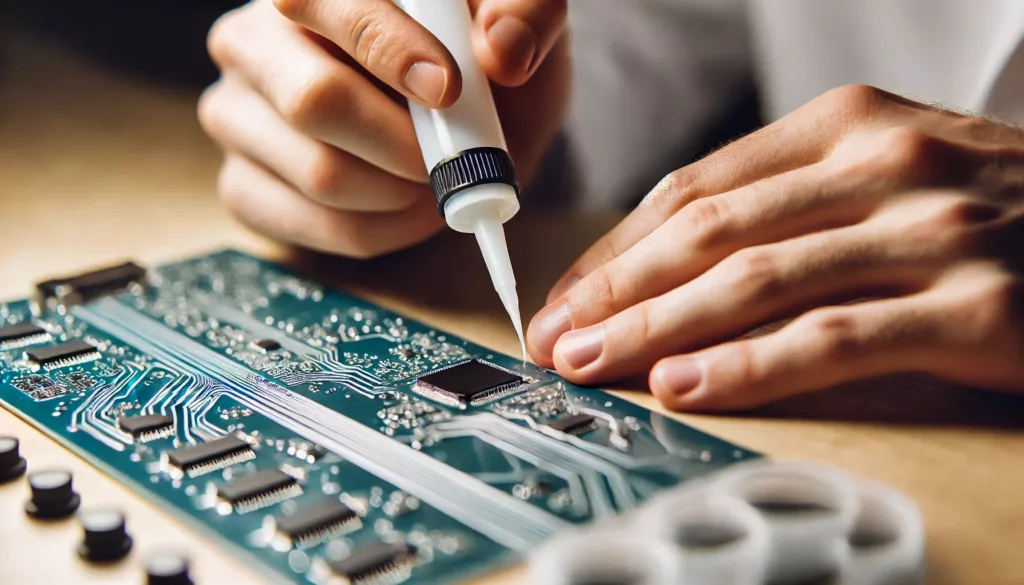

Best Glue for Circuit Boards

For those who work with printed circuit boards (PCBs), the glue you use is critical. You need an adhesive that can handle heat, vibration, and sometimes even moisture. Some of the best options for circuit board repairs include:

- Epoxy Resin Glue: This is one of the most reliable options for PCB repairs. It creates a very strong bond and can handle the temperatures and stresses typical in electronics.

- Conductive Adhesives: If you need to make connections between electrical components, conductive adhesives are necessary. These specialized glues contain particles that conduct electricity, enabling repairs without soldering.

- SMD (Surface-Mounted Device) Adhesive: These adhesives are specifically formulated for attaching surface-mount components to PCBs. They are non-conductive and come in various viscosities for different tasks.

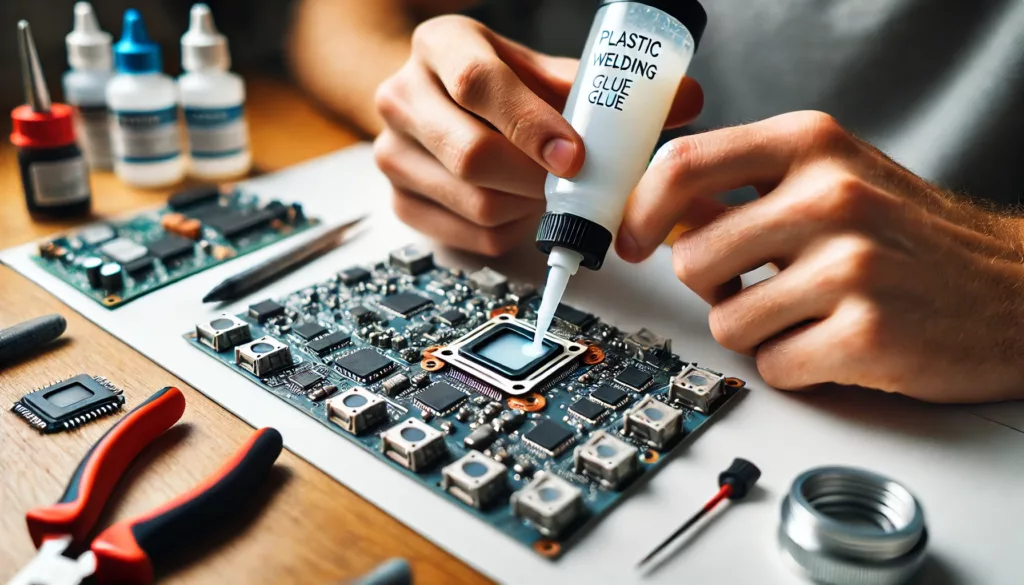

Best Glue for Plastic Electronics

Plastic is a common material in electronics, used in everything from phone housings to small gadgets. When bonding plastic parts in electronics, you want a glue that will create a strong, lasting bond without damaging the surface or affecting the function of the device.

- Plastic Welding Glue: This type of glue is perfect for plastic repairs. It works by creating a chemical bond that is stronger than traditional adhesives. Some brands even include a special activator to speed up the process.

- Super Glue: For small repairs, cyanoacrylate (super glue) can be effective for plastic electronics. It dries quickly and provides a firm hold.

- Epoxy: Epoxies can also be used for bonding plastics, especially when the bond needs to be resistant to heat or stress.

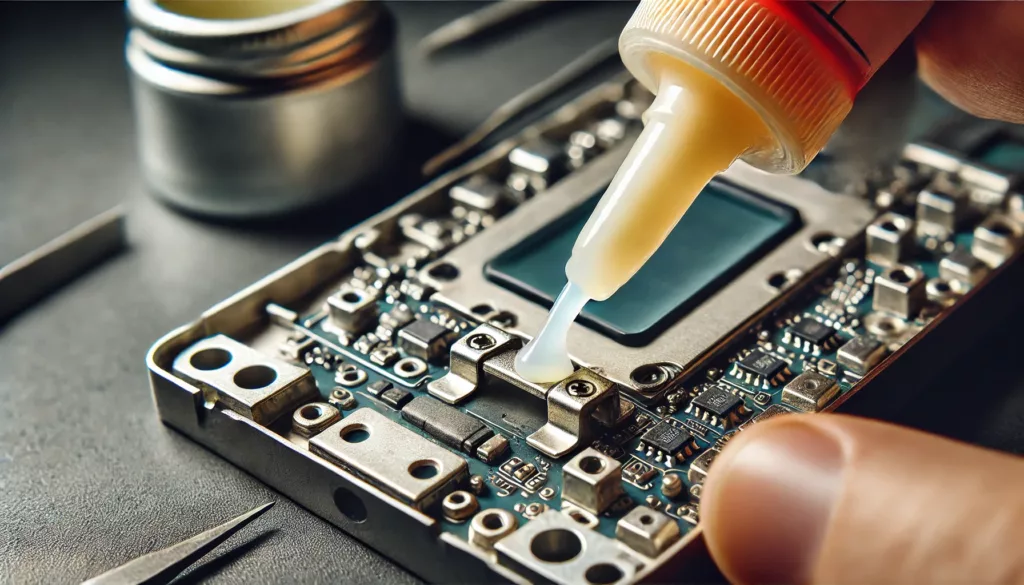

Best Glue for Metal Electronics

Metal components are commonly found in devices like computers, batteries, and larger electronics. Bonding metals in electronics requires an adhesive that can endure high temperatures, vibrations, and possibly exposure to moisture.

- Epoxy Resin: One of the most durable adhesives for metal, epoxy provides a strong and heat-resistant bond. It is perfect for heavy-duty applications in electronics.

- Cyanoacrylate (Super Glue): For smaller or more precise metal bonding, super glue is a good option. It works well for short-term fixes but might not be durable for high-stress or high-heat applications.

Best Glue for Screen Repairs

If you’ve ever cracked your phone or tablet screen, you know how important it is to have a strong adhesive to replace or fix the screen. The best adhesives for screen repairs need to be strong, flexible, and clear.

- UV Glue: This is one of the top choices for screen repairs. It is clear, so it won’t affect the appearance of the screen, and it can bond glass to metal or plastic effectively.

- Silicone Adhesive: Silicone provides flexibility, making it a great option for screen repairs where some give is needed.

Epoxy vs. Super Glue in Electronics

When choosing between epoxy and super glue, it’s essential to consider the needs of the project:

- Epoxy: Offers better heat resistance, long-lasting bonds, and is ideal for materials that experience high stress or require precision, such as circuit boards or metal components.

- Super Glue: Ideal for quick fixes, especially when working with small parts or plastics. However, it can be less durable under stress or in high-temperature environments.

Choosing the Right Adhesive for Different Applications

Selecting the right adhesive depends on the specific task at hand. Here’s a breakdown:

- For Circuit Boards: Conductive adhesives or epoxy are best.

- For Plastic Casings: Plastic welding glue or super glue work well.

- For Metal Components: Epoxy resin or super glue is recommended.

- For Screen Repairs: UV glue or silicone adhesive.

How to Use Electronics Glue Effectively

Applying electronics glue properly is key to ensuring the longevity and effectiveness of your repair. Follow these steps:

- Clean the Surfaces: Before applying glue, clean the surfaces of the components to remove any dust, oil, or residue.

- Apply the Glue: Use a fine applicator to apply a small amount of glue to one of the surfaces.

- Press the Parts Together: Align the parts carefully and press them together firmly.

- Allow for Proper Curing: Let the adhesive cure completely before testing the repaired device.

Factors to Consider When Choosing Electronics Glue

When selecting the best glue for your electronics project, consider:

- Strength: Choose an adhesive that offers enough strength to withstand stress, heat, and vibration.

- Curing Time: Some glues dry quickly, while others require hours. Choose one that fits your timeline.

- Heat Resistance: Electronics often generate heat, so opt for adhesives that can withstand high temperatures.

- Electrical Conductivity: For repairs involving electrical connections, make sure the glue is conductive.

Top Brands for Electronics Glue

Several reputable brands offer high-quality glues for electronics:

- Loctite: Known for its range of adhesives, including cyanoacrylate and epoxy glues for electronics.

- Gorilla Glue: Offers super glue and epoxy adhesives ideal for electronics repairs.

- 3M: Known for its precision and industrial-grade adhesives, 3M produces several glues suitable for electronics.

- ZDS™ : ZDS electronic adhesive series is suitable for production and repair.

Pros and Cons of Different Electronics Glues

Each type of glue has its benefits and limitations. Here’s a quick comparison:

- Epoxy: Strong and heat-resistant, but can be messy and requires mixing.

- Super Glue: Quick to apply and dries fast, but may not withstand high-stress conditions.

- Silicone: Flexible and waterproof, ideal for sealing, but not the best for structural repairs.

Environmental Considerations in Glue Selection

As more people seek eco-friendly options, choosing glues with minimal environmental impact is becoming important. Look for products labeled as non-toxic, solvent-free, or biodegradable to reduce your ecological footprint.

Troubleshooting Common Glue Problems in Electronics

Glue can sometimes cause issues like residue or uneven bonding. Here’s how to handle common problems:

- Excess Glue: Wipe off excess glue immediately with a clean cloth before it sets.

- Weak Bond: Ensure the surfaces are clean and properly aligned before applying glue.

Alternatives to Glue in Electronics

While glue is a common solution, some repairs might benefit from other methods like soldering, screws, or interlocking clips for certain components.

Cost-Effectiveness of Glue for Electronics Repairs

When selecting electronics glue, consider the cost per use. Premium glues like epoxies tend to be more expensive but may offer better durability, making them more cost-effective in the long run for frequent repairs.

Safety Precautions When Using Glue for Electronics

Always wear protective gloves when applying adhesives and work in a well-ventilated area. Avoid getting glue on your skin or in your eyes, as some glues can cause irritation.

FAQs

What is the best glue for circuit boards?

Epoxy resin and conductive adhesives are ideal for circuit boards. They offer strong bonds and can withstand the heat produced by electronics.

Can I use super glue for electronics?

Yes, super glue can be used for quick fixes, especially for small plastic or metal components, but it may not provide the heat resistance required for high-stress applications.

Is epoxy safe for electronics repairs?

Yes, epoxy is safe for most electronic repairs. It provides a strong, durable bond and can resist heat, making it ideal for circuit boards and metal components.

How long does it take for electronics glue to cure?

Curing time varies depending on the type of glue. Epoxies can take up to 24 hours, while super glue typically sets within minutes.

Can I use silicone glue for screen repairs?

Yes, silicone glue is flexible and waterproof, making it a good option for screen repairs, especially if the device is exposed to moisture.

Are there eco-friendly options for electronics glue?

Yes, there are eco-friendly glues available that are non-toxic and biodegradable, helping to reduce the environmental impact of your repairs.

Conclusion

Selecting the best glue for electronics depends on the materials you’re working with and the nature of the repair. Whether you need strong heat resistance, electrical conductivity, or quick bonding, there’s a glue suited for every task. By understanding your options and applying adhesives correctly, you can ensure that your electronics repairs are successful and long-lasting.