Ever wondered why some glue works great for one thing but not another? At ZDS™, we think picking the right glue is key. It’s not just about grabbing any glue you see. It’s about making smart choices for a strong and lasting bond. Our guide will cover everything you need to know, from the different types of adhesives to the best practices for your projects.

Key Takeaways

- Understanding the importance of selecting the right adhesive for each project is crucial.

- Learn about the various types of adhesives and their specific applications.

- Avoid common mistakes in adhesive choice to save time and avoid costly errors.

- Get insights on the best adhesive practices for optimal results.

- Discover essential safety tips for handling ZDS™ adhesives.

Why Choosing the Right Adhesive Matters

Picking the right adhesive is key to making bonds last longer and work better. The adhesive selection importance is huge, especially in fields needing precision and strength.

The Importance of Adhesive Selection

The right adhesive can greatly improve how well a product works. For example, ZDS™ UV light adhesives are great for electronics. They cure fast, bond precisely, and last a long time. They’re perfect for things like PCB assembly and display bonding. You can learn more on the ZDS™ website.

Picking the correct adhesive can mean the difference between a product that lasts or one that doesn’t. It ensures strong bonds, protects against the environment, and keeps products safe. Not paying attention to this choice can lead to project failures.

Common Mistakes in Adhesive Choice

Even with benefits, we can make mistakes with adhesives. A big mistake is not checking if the adhesive fits with the materials. It’s crucial to match the adhesive with the materials and their surroundings.

Other mistakes include skipping surface prep. Cleaning and priming surfaces well is key for a strong bond. Also, using too little or too much adhesive can lead to weak bonds or waste. Always follow the maker’s advice and get expert help for your specific needs.

Knowing how important the right adhesive choice is and avoiding common mistakes will lead to better project outcomes.

Understanding Different Adhesive Types

Choosing the right adhesive is key to a successful project. There are three main types: water-based, solvent-based, and hot melt adhesives. Each has its own benefits for different uses.

Water-Based Adhesives

Water-based adhesives are eco-friendly and simple to use. They’re great for projects focused on the environment. Made with natural or synthetic polymers in water, they’re safe and popular in packaging and paper industries.

The ZDS™ adhesives, known for their innovation, show how new adhesives help the environment.

Solvent-Based Adhesives

Solvent-based adhesives are known for their strong bonds. They use polymers in organic solvents and stick well to metals, plastics, and rubbers. But, they need careful use because they can release harmful fumes.

They’re a must-have in industries like automotive and construction where bonds need to last.

Hot Melt Adhesives

Hot melt adhesives dry fast and are very versatile. Applied hot, they cool to form a strong bond. Used in packaging, woodworking, and electronics, they’re all about speed and efficiency.

They don’t have solvents, which means less worry about harmful fumes. This makes them great for projects that care about the planet.

Choosing the right adhesive might seem hard, but knowing what each type offers helps. This way, you can pick the best one for your project.

Best Adhesives for Different Materials

Choosing the right adhesive for materials like wood, metal, and plastic is key. It ensures strong bonds, durability, and great performance. Let’s look at the top picks from ZDS™ for these materials.

Adhesives for Wood

Wood adhesives go deep into wood fibers for strong bonds that stand up to changes in size and shape. ZDS™ has top wood adhesives for furniture making, woodworking, and carpentry. They give great adhesion and last a long time.

Adhesives for Metal

Finding the right metal adhesive is tough because metals don’t soak up adhesives well. ZDS™ offers metal adhesives with high strength and can handle extreme heat or cold. They’re perfect for car repairs to metal crafting. These adhesives make sure metal parts stay together and last long.

Adhesives for Plastic

Plastics vary, and each needs a special adhesive for a strong bond. ZDS™ has plastic adhesives for different plastics like ABS, PVC, and polycarbonate. They’re great for both home and industrial uses.

For more info on the best adhesives for materials and ZDS™ products, visit their website.

Key Adhesive Properties to Consider

Choosing the right adhesive means knowing about adhesive properties. Look at bond strength, viscosity, and drying time to make sure it fits your project. These factors are key in many fields, from aerospace to medical. Let’s explore each one to help you pick the best adhesive.

Bond Strength

Bond strength is how well an adhesive holds two surfaces together. It’s crucial for safety and durability in many projects. Knowing what bond strength you need will help you pick the right adhesive. For more tips on choosing adhesives, see this guide at adhesive selection criteria.

Viscosity

Viscosity tells us how thick or thin an adhesive is. It affects how easily you can spread it on a surface. Thicker adhesives work well for vertical surfaces to prevent drips. Thinner adhesives are better for materials with pores.

Drying Time

Drying time is how long it takes for an adhesive to fully set. This is key for projects with tight deadlines or where you need to handle things quickly. Picking an adhesive with the right drying time makes your project go smoother and faster.

| Property | Description | Considerations |

|---|---|---|

| Bond Strength | Ability to hold surfaces together | Structural integrity, application environment |

| Viscosity | Thickness or resistance to flow | Application method, surface type |

| Drying Time | Time to set and achieve max strength | Project timelines, handling requirements |

Adhesive Strength Comparison

When comparing ZDS™ adhesives, we focus on key performance metrics. This helps us pick the right adhesive for different jobs. It gives us a clear view of each adhesive’s strengths.

We looked at tensile strength, shear strength, and peel strength to compare adhesives. Here’s how some popular ZDS™ adhesives stack up:

| Adhesive Type | Tensile Strength (psi) | Shear Strength (psi) | Peel Strength (piw) |

|---|---|---|---|

| Super Bond 100 | 4500 | 3200 | 20 |

| Ultra Grip 200 | 5200 | 4000 | 25 |

| Max Hold 300 | 6000 | 4500 | 30 |

| Ultimate Fix 400 | 7000 | 5000 | 35 |

The Ultimate Fix 400 leads in all areas, making it great for heavy-duty projects. It’s perfect when you need the strongest bond. Super Bond 100 is good for lighter tasks but still strong in tensile and shear strength.

Knowing these details helps us choose the right adhesive for our needs. This guide helps us pick the best adhesive, making our projects stronger and more reliable.

How to Apply Adhesives Correctly

Applying adhesives right is as important as picking the best type. By preparing surfaces well and using the right application methods, we can get a strong, lasting bond. This adhesive application guide will walk us through how to prepare surfaces and apply adhesives for the best results.

Surface Preparation

Getting the surface ready for adhesives is key to a good bond. We need to clean the surface to remove dirt, oils, and other things that could stop the adhesive from sticking. Here’s a simple way to do it:

- Clean the Surface: Use a solvent like isopropyl alcohol to clean the surface.

- Dry the Surface: Make sure the surface is dry before you go further.

- Sand if Necessary: For some materials, a little sanding can help the adhesive stick better. Don’t forget to clean off any dust.

- Priming: Some surfaces need a primer to help the adhesive bond better.

Application Techniques

Using the right ways to apply adhesives is key to getting the best results. Here are the main ways to apply:

- Spreading: Spread the adhesive evenly using a brush or applicator.

- Spot Application: For small, precise bonds, apply adhesive in dots or beads.

- Spray Application: This is best for large areas, making sure to cover evenly.

- Roller Application: Use a roller for big, flat surfaces to spread the adhesive well.

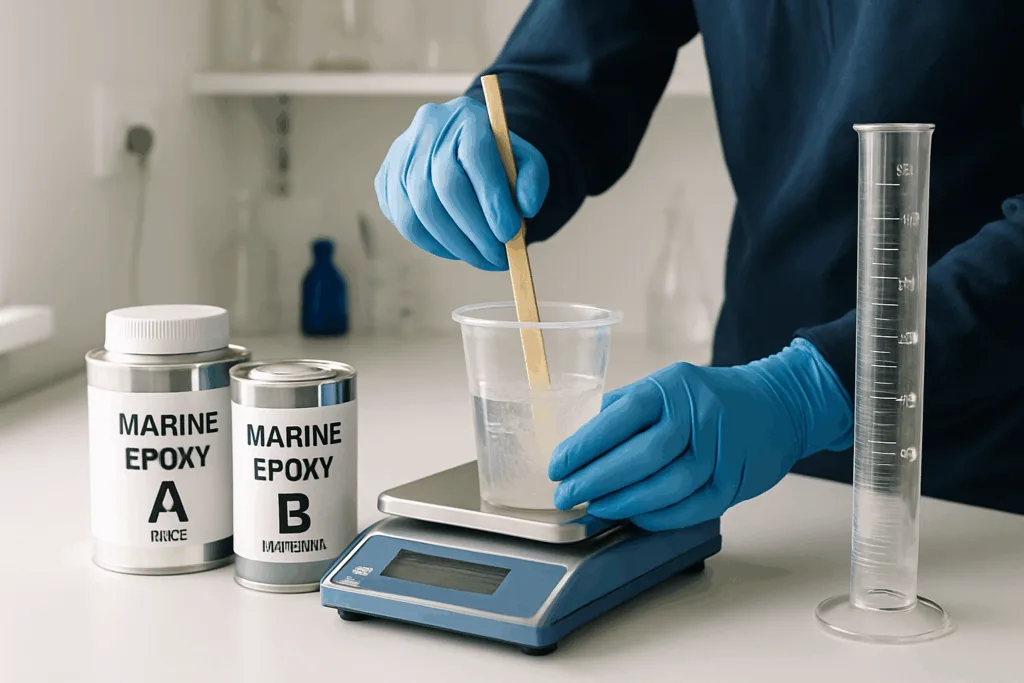

- Two-Component Mixing: Some adhesives need you to mix two parts together before applying. Always follow the instructions from the maker.

| Application Method | Best Use | Tools Required |

|---|---|---|

| Spreading | Flat Surfaces | Brush, Applicator |

| Spot Application | Small Areas | No Tools Required |

| Spray Application | Large Surfaces | Spray Gun |

| Roller Application | Large Flat Surfaces | Roller |

| Two-Component Mixing | Specialized Adhesives | Mixing Tools |

This detailed guide on applying adhesives covers both preparing surfaces and applying adhesives correctly. By following these steps, you can make sure your bonds are strong and reliable every time.

Common Applications for Various Adhesives

Adhesives have changed many industries with their versatility and efficiency. They are used in everything from small household projects to big industrial adhesive applications. Finding the right adhesive is key, whether you’re fixing a chair or building advanced electronics.

- Furniture Construction: Wood adhesives are crucial for making furniture last a long time. They create strong bonds that furniture can rely on.

- Automotive Assembly: In cars, adhesives help make them safer, lighter, and more efficient. They play a big role in how cars are put together.

- Electronic Device Manufacturing: For making tiny and delicate electronics, adhesives are a must. They ensure parts stay together securely and reliably.

| Application | Key Features | Optimal Adhesives |

|---|---|---|

| Furniture Construction | High Durability, Strong Bond | Wood Adhesives |

| Automotive Assembly | Lightweight, Safety | Structural Adhesives |

| Electronics | Precision, Reliability | Epoxy, Cyanoacrylate |

By picking the right adhesive uses for the job, we can make our projects better and more efficient. No matter the size of the project, choosing the right adhesive means better results and quality finishes.

Adhesives Selection Guide

In this section, we explore the key aspects of our adhesives selection guide. It helps you choose adhesives that fit your project’s needs. We look at important adhesive factors to consider for a strong bond every time.

How to Choose the Right Adhesive for Your Project

Finding the right adhesive for your project can seem tough. Our guide simplifies choosing adhesives by offering clear steps:

- Identify the materials you are bonding.

- Analyze environmental factors, such as temperature and humidity.

- Consider the mechanical stress the adhesive will face.

By following these steps, you can pick an adhesive that meets your needs.

Factors to Consider When Choosing Adhesives

When using our adhesives selection guide, remember these key points:

- Substrate Material: Some adhesives work best with certain materials like wood, metal, or plastic.

- Environmental Conditions: Think about if your project will face extreme temperatures, moisture, or UV light.

- Mechanical Stress: Check if the bonded materials will be under a lot of stress or vibration.

Keeping these adhesive factors in mind will help you make the best choices for your projects.

Safety Tips When Handling Adhesives

Working with adhesives requires safety first. It’s key to follow adhesive safety procedures to avoid accidents and health problems.

Personal Protective Equipment

Wearing PPE for adhesives is a must for your safety. This includes gloves, safety glasses, and protective clothing. Having the right PPE stops you from touching adhesives directly. This reduces the chance of burns, breathing problems, and skin irritation.

Ventilation and Workspace Setup

A good airflow is crucial for safe adhesive handling. It cuts down on the risks from breathing in adhesive fumes. Also, keep your workspace tidy by organizing your tools and materials. This makes it easier to get to what you need and keeps things safer.

| Safety Measure | Importance |

|---|---|

| Personal Protective Equipment (PPE) | Prevents direct contact with adhesives, preventing burns and skin irritation. |

| Ventilation | Reduces inhalation of harmful fumes, maintaining air quality. |

| Workspace Setup | Organizes tools and materials, minimizing clutter and enhancing safety. |

Maintaining Your Adhesive Supplies

Keeping your adhesives in top shape is key to their effectiveness and long life. By knowing how to store them right and understanding their shelf life, we can make sure they work well when we need them.

Storage Tips

Storing adhesives well is vital for keeping them strong and effective. Here are some tips for the best storage:

- Store adhesives in a cool, dry place away from direct sunlight.

- Keep the containers tightly sealed to prevent exposure to air and moisture.

- Label each container with the purchase date and expiration date to track usage.

Understanding Expiration Dates

How long an adhesive lasts affects its performance and trustworthiness. Knowing about expiration dates helps us keep adhesives in good shape:

- Check the manufacturer’s guidelines for each adhesive type to understand its shelf life.

- Use older adhesives first to minimize waste.

- Conduct a small test on a sample material to ensure the adhesive’s efficacy if it’s nearing expiration.

Frequently Asked Questions About Adhesives

Our customers often have many adhesive queries. We’ve put together a list of the most common adhesive FAQs. You’ll find answers on choosing the right adhesive and solving problems below.

A: Epoxy adhesives are super strong and last a long time. They work well with metal, wood, and some plastics.

Q: Can I use the same adhesive for different materials?

A: Not every adhesive fits all. Pick one made for the materials you’re working with. Check our guide for advice on different materials.

Q: How can I remove adhesive residue?

A: Removing adhesive residue can be hard. For most adhesives, use acetone or rubbing alcohol. Test it on a small area first to be safe.

Q: What is the difference between solvent-based and water-based adhesives?

A: Solvent-based adhesives give strong bonds and dry fast. Water-based adhesives are better for the planet and safer but might not work well in damp places.

Q: How should I store my adhesive supplies?

A: Keep adhesives in a cool, dry spot out of the sun. Make sure containers are closed tight to stop the adhesive from drying out or getting worse.

Q: Are there safety precautions I should take when handling adhesives?

A: Yes, always wear gloves and safety glasses. Make sure your area is well-ventilated to avoid breathing in fumes.

| Adhesive Type | Common Uses | Removal Method |

|---|---|---|

| Epoxy | Metal, Wood, Plastic | Acetone |

| Hot Melt | Cardboard, Fabric | Scraping, Heat |

| Cyanoacrylate (Super Glue) | Ceramics, Rubber | Acetone |

| Water-Based | Paper, Light Wood | Soap and Water |

We hope these answers to common adhesive queries help you in your projects. For more detailed info, keep reading our guide on picking the right adhesive.

Conclusion

Our guide has shown how important it is to pick the right adhesive for your projects. The right adhesive can make your work last longer and look better, whether it’s for work or home projects. Knowing what each adhesive can do helps you get the best results, like strong bonds and the right drying times.

Products like ZDS™ Cyanoacrylate offer great versatility and strong bonds on many materials. This is what the ZDS™ promise is all about: giving customers reliable adhesives for their needs. For more on ZDS™ Cyanoacrylate’s benefits and uses, check out our detailed guide. We want to give you the tools and knowledge you need for success.

We hope this guide has been helpful for your adhesive needs. At ZDS™, we’re all about giving you the best information and adhesives. We’re excited to help you with your projects, offering quality products and expert advice.

FAQ

What factors should I consider when selecting an adhesive?

When picking an adhesive, think about the material of the substrate, the environment it will be in (like temperature and humidity), how strong you need the bond to be, how long it needs to dry, and the application method. Our guide goes deep into these points to help you choose wisely.

How does the bond strength of different adhesives compare?

Different adhesives have different bond strengths. For instance, solvent-based adhesives usually have a stronger bond than water-based ones. Our guide gives you detailed info and charts to see how each adhesive stacks up in strength.

What are the best types of adhesives for wood projects?

For wood, go with PVA (polyvinyl acetate) adhesives or wood glues for a strong bond that’s also flexible. Epoxy adhesives work well with wood too, especially if it’s for outdoor use or where the bond will face a lot of stress.

Can I use the same adhesive for both metal and plastic?

It’s not a good idea to use the same adhesive on both metal and plastic. They have different adhesion properties and aren’t always compatible. For metal, choose a strong adhesive like epoxy or polyurethane. For plastic, use adhesives made for plastic, like cyanoacrylate (super glue) or plastic cements.

What is the proper way to prepare surfaces before applying adhesives?

Getting the surfaces ready is key for a strong bond. Clean them to remove dirt, oil, or debris. If needed, use a solvent like isopropyl alcohol. Make sure the surfaces are dry and roughen them if necessary to help the adhesive stick better.

How should I store my adhesives to maintain their efficacy?

Keep adhesives in a cool, dry spot, away from sunlight and extreme temperatures. Make sure the containers are closed well to stop contamination and drying out. Always check the expiration dates and use the adhesives as needed.

What are some safety tips when handling adhesives?

Always wear protective gear like gloves and safety goggles. Make sure your workspace is well-ventilated to avoid breathing in fumes. Follow the maker’s guidelines for safe use, and keep adhesives away from kids and pets.

What are the differences between water-based and solvent-based adhesives?

Water-based adhesives are better for the environment and have less smell, making them great for indoor projects. Solvent-based adhesives give stronger bonds and are good for tough jobs but need good ventilation because of their fumes.

Is there an adhesive application guide available?

Yes, our adhesive application guide gives you step-by-step instructions on applying different adhesives right. It covers preparing the surface, applying the adhesive, and best practices for a strong bond.