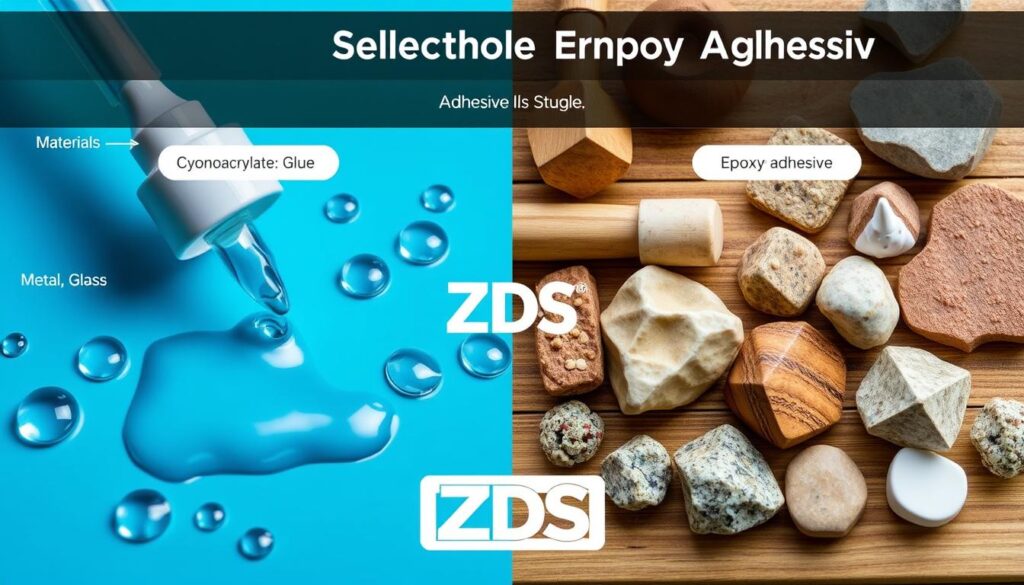

Comparing cyanoacrylate vs epoxy adhesives.

Choosing the right bonding solutions is key for various projects. Knowing the difference between cyanoacrylate and epoxy adhesives is essential. Each type has special qualities for different needs in the industrial adhesives world.

Our deep dive into adhesive comparison will explore their unique traits, strengths, and drawbacks. Understanding these details helps us pick the best option for our project needs.

Key Takeaways

- The importance of selecting the right adhesive for the job

- Cyanoacrylate adhesives offer fast bonding times

- Epoxy adhesives are known for their superior strength and versatility

- Material compatibility varies between cyanoacrylate and epoxy adhesives

- Curing times can differ significantly, impacting project timelines

- Cost and availability are factors to consider in adhesive selection

Introduction to Adhesives

Adhesives are crucial in many industries, like automotive, manufacturing, and healthcare. Thanks to adhesive technology improvements, we can now bond materials better, with specific solutions for different uses.

It’s vital to know the different adhesive types to get the best results. For example, cyanoacrylate adhesives are quick-setting glues perfect for small repairs. On the other hand, epoxy adhesives are known for their strong bond and durability, ideal for tougher jobs.

Adhesive technology has come a long way. Early on, people used natural stuff like tree sap for glue. Now, advanced adhesives like cyanoacrylate and epoxy let us join materials in new and lasting ways.

Understanding the nuances between these adhesives means looking closely at what makes them work well in various situations.

| Adhesive Type | Bonding Strength | Typical Uses |

|---|---|---|

| Cyanoacrylate | Moderate to High | Quick Repairs, Electronics |

| Epoxy | High | Construction, Heavy-duty Applications |

Understanding Cyanoacrylate Adhesive Properties

Cyanoacrylate adhesives are also called instant adhesives or super glue. They bond materials quickly and strongly. They’re essential in many projects for their speed, durability, but they have limits and best uses too.

Fast Bonding Time

These adhesives bond things together in seconds. That makes them perfect for quick fixes or emergencies. They work fast because they react to moisture in the air, which is great for many settings.

Strength and Durability

Super glue is both strong and durable. Once cured, it creates a tough bond. This works well for materials like metal, plastic, rubber, or glass. It’s chosen often for both home and industry needs.

Limitations and Uses

Yet, instant adhesives are not perfect. They don’t do well on porous surfaces and can break in harsh conditions. Knowing the best ways to use them increases their benefit. They’re good for minor fixes, plastic models, and some medical uses. To learn about choosing a dependable epoxy adhesive, you can click here.

Exploring Epoxy Adhesive Applications

The wide variety of epoxy uses shows the adhesive versatility. These structural adhesives are important in many fields. They are used in construction, cars, and electronics for their strong bond.

In construction, epoxy glues keep concrete, stone, and wood together. They make structures last a long time, which is great for builders and home owners. In the car industry, epoxies help stick metal and plastic together. This makes cars safer and last longer.

In electronics, epoxies keep parts in place and safe from heat and pressure. This makes gadgets work longer. ZDS™ offers special epoxy recipes for different industry needs.

Here is a table comparing epoxy uses in different fields:

| Industry | Epoxy Uses | Benefits |

|---|---|---|

| Construction | Bonding concrete, stone, and wood | Long-term structural integrity, reliable adhesion |

| Automotive | Bonding metal and plastic parts | Enhanced durability, improved safety |

| Electronics | Securing and insulating components | Mechanical strength, thermal stability |

The importance of adhesive versatility in industrial uses is growing. Knowing the wide range of epoxy uses helps companies choose what they need.

Cyanoacrylate vs Epoxy Bonding Strength

When we talk about adhesive performance, comparing cyanoacrylate to epoxy is key. These glues are known for their strength. Yet, they each shine best in different material bonding scenarios.

Comparative Analysis

Comparing cyanoacrylate to epoxy shows some clear differences. Cyanoacrylate, or super glue, bonds quickly. This fast action is great but not perfect for lasting under stress.

Epoxy, however, takes longer to set but offers superior durability and resistance. This makes it the better choice for projects needing strength over time.

Use Cases for Strong Bonds

Cyanoacrylate’s quick bond suits fast fixes and light repairs well. It’s great for jewelry, tiny electronic parts, and quick home fixes.

Epoxy is better for tougher jobs. It’s chosen in automotive, aerospace, and heavy industry where enduring strength matters most.

Material Compatibility

The types of materials they bond with set cyanoacrylate and epoxy apart. Cyanoacrylate is good with plastics, metals, and ceramics but can get brittle.

Epoxy is more flexible, working well with wood, metals, and some plastics. This gives it the edge in adhesive performance and lasting power.

Epoxy Adhesive Curing Time

Adhesive curing process knowledge is key for any project involving epoxy. The time it takes for epoxy to set can change based on temperature, humidity, and the specific epoxy type. Epoxy usually cures within a few hours to several days for the strongest bond.

ZDS™ experts suggest keeping an eye on temperature and humidity to speed up curing. By tweaking these, you can make the adhesive cure faster and maintain its strength.

Following the maker’s advice on epoxy setting time is critical for best performance. Changing the mix or using it in bad conditions might slow curing or weaken the bond.

Cyanoacrylate Adhesive Flexibility

Choosing the right adhesive means understanding its flexibility in different situations. Cyanoacrylate adhesives are strong in bonding. But what about their flexibility? Let’s explore how they perform in various environments.

Flexibility in Various Conditions

Evaluating cyanoacrylate uses includes looking at how they bend under different conditions. They face challenges like humidity and temperature changes. Versatile adhesives need to stay strong without breaking. Cyanoacrylates do offer some flexibility, helping in active settings. Yet, tough conditions might need special types to keep their stretch.

Appropriate Applications

The adhesive flexibility of cyanoacrylate is great for places with both still and moving stresses. In the car and plane industries, it’s important to keep bonds strong, even with shakes and temperature changes. Also, for fixing things at home or in hobbies, this flexibility means durable bonds as items shift over time.

| Application | Benefits of Cyanoacrylate |

|---|---|

| Automotive Repair | Maintains integrity under vibrations |

| Aerospace Components | Resists temperature fluctuations |

| Household Repairs | Strong bonds for various materials |

| Hobbyist Projects | Precision application with flexible hold |

Epoxy Adhesive Shelf Life

The shelf life of epoxy adhesives is crucial for their effectiveness over time. To keep epoxy working well, it’s important to know how to store it and its shelf life.

Keep epoxy adhesives in a cool, dry spot for best results. Heat can harm the adhesive, making it less effective. To protect your epoxy, avoid letting it get too hot or too cold.

Make sure the adhesive container is sealed tight. This stops moisture and dirt from spoiling the epoxy. By doing this, the epoxy stays ready to use, even if stored for a long time.

Choosing high-quality epoxies, like those from ZDS™, is crucial. Such products not only last longer but also work better in various conditions.

To make your epoxy adhesives last longer, follow these tips:

- Store in a place with controlled temperature.

- Keep the container closed when not using it.

- Avoid putting it in direct sunlight or wet places.

- Pick products known for their long-lasting quality.

It’s also good to know the manufacture date on the epoxy package. This date tells you how long the epoxy will work well. It helps make sure you don’t use epoxy that’s too old.

Following the right storage tips makes your epoxy last longer. It means you get the strongest, most reliable adhesive for all your projects. By knowing what affects epoxy shelf life, we choose the best products for our needs.

Cyanoacrylate Adhesive Uses in Everyday Life

Super glues, known as cyanoacrylate adhesives, are everywhere in our daily lives. They give quick fixes and strong connections. Let’s see how cyanoacrylate is used in different situations.

Household Repairs

Cyanoacrylate adhesives are often used for at-home repairs. They work great for fixing ceramics, plastics, and glass. These glues bond things quickly and are easy to use.

Whether it’s a broken vase or a leaky pipe, they offer fast and dependable solutions.

Hobbyist Projects

Hobbyists love cyanoacrylate for various crafts and DIY tasks. Model builders and miniaturists use it for its accuracy and strength. It’s perfect for putting together small, detailed pieces.

Woodworkers also use cyanoacrylate for quick woodworking project fixes.

Medical and Industrial Uses

Cyanoacrylate adhesives aren’t just for home use; they’re vital in both medicine and industry. Doctors use them for closing wounds and surgical cuts. This method is quick and doesn’t involve stitches.

In industry, these adhesives help assemble electronics, fix machinery, and with car repairs. They create bonds that are strong and lasting.

Epoxy Adhesive Chemical Resistance

Chemical-resistant adhesives are key for strong, lasting bonds, especially where conditions are tough. Epoxy adhesives are outstanding due to their chemical resistance in various places.

Epoxy adhesives are a top pick for projects exposed to harsh chemicals. They are stronger and more durable than PVA glue or cyanoacrylate, suited for industrial use.

Epoxy adhesives can handle chemicals well. They’re perfect for sectors needing durability and long life. For an insightful comparison, visit this overview on adhesives.

Industrial-grade adhesives, like ZDS™ epoxy, have top-notch chemical resistance. This is crucial for fighting off solvents, acids, and bases.

Epoxy stands out where other adhesives don’t due to its chemical-resistant traits. It ensures bonds stay strong, even with temperature changes and chemical exposure.

- Epoxy adhesives can take on a lot of chemical exposure.

- They excel in automotive, aerospace, and electronics due to their lasting strength.

- From building to the sea, epoxy’s versatility shines in many applications.

Selecting the right adhesive is vital for the best results in tough conditions. Rely on epoxy for outstanding performance and resilience.

Want to know how epoxy compares to other adhesives? Dive into more about epoxy vs. others and choose wisely for your projects.

Comparing Cyanoacrylate vs Epoxy Adhesives

Choosing the right adhesive is crucial for any project needing strong bonds. Adhesive selection guide helps identify the best glue. It considers the adhesives’ strengths and suitable uses.

Comparative Overview

Cyanoacrylate adhesives, known as super glue, cure quickly and form strong bonds fast. They are perfect for small, tight parts where speed is key. On the other hand, epoxy adhesives stand out for their durability and chemical resistance, making them ideal for tough environments.

Choosing the Right Adhesive for Your Project

Consider your project’s needs when choosing between cyanoacrylate and epoxy. Think about material compatibility, environment, and the strength of the bond needed. For indoor projects needing quick fixes, cyanoacrylate is great. For outdoor tasks or projects needing lasting bonds, go for epoxy.

Cost and Availability

The cost and availability of the adhesive can affect your choice. Cyanoacrylate is cost-effective for quick repairs. It’s available in many formulas for different materials. Epoxy, while more expensive, excels in demanding applications and is widely available.

| Feature | Cyanoacrylate | Epoxy |

|---|---|---|

| Bonding Speed | Fast | Moderate |

| Durability | Moderate | High |

| Chemical Resistance | Low | High |

| Cost | Low to Moderate | Moderate to High |

| Applications | Quick repairs, household uses | Heavy-duty, industrial uses |

Conclusion

We have looked at everything important about cyanoacrylate and epoxy adhesives. Making the right adhesive selection is crucial for project success. By knowing the fast bonding and strength of cyanoacrylate and the longevity of epoxy, we can choose the best adhesive for our needs.

Comparing these adhesives shows us their pros and cons. Cyanoacrylate works best for quick, strong joins. Epoxy is better for projects that need to last, especially against environmental factors. It’s important to think about curing time, shelf life, and how well they resist chemicals.

Working with top manufacturers like ZDS™ adhesives helps us use the best products and knowledge. The info in this article and tips from sources like ZDS™ can improve our project bonding solutions. By carefully choosing adhesives for our specific projects, we’ll see better results and quality.

FAQ

What is the main difference between cyanoacrylate and epoxy adhesives?

Cyanoacrylate adhesives, also called super glues, work quickly. They’re used for fast repairs. On the other hand, epoxy adhesives are stronger. They bond well with many materials in different industries.

What are the key properties of cyanoacrylate adhesives?

Cyanoacrylate adhesives bond instantly. They are strong and easy to use. But, they’re not as flexible and might not work on some plastics and glass.

Where can epoxy adhesives be used?

Epoxy adhesives are used in buildings, cars, and electronics. They bond strongly, resist chemicals, and handle tough conditions. They fit many kinds of projects.

How do cyanoacrylate and epoxy compare in bonding strength?

Epoxy adhesives create stronger and longer-lasting bonds than cyanoacrylate adhesives. Cyanoacrylate works well for quick and light bonding jobs.

What is the curing time for epoxy adhesives?

Epoxy adhesives take longer to cure than cyanoacrylate adhesives. Curing might take from minutes to hours. The right curing time is key for a strong bond.

How flexible are cyanoacrylate adhesives?

Cyanoacrylate adhesives are not very flexible. They may become brittle with time. While, epoxy adhesives have formulas for more flexibility.

What is the shelf life of epoxy adhesives?

Epoxy adhesives last between six months and two years with the right storage. Keep them in a cool, dry spot for longer life.

What are some common uses of cyanoacrylate adhesives in everyday life?

Cyanoacrylate adhesives fix things around the house, support hobbies, and help in medical and industrial uses. They are great for quick repairs of small items.

How chemically resistant are epoxy adhesives?

Epoxy adhesives resist chemicals well. This makes them great for tough industrial situations. They stay strong and reliable even around harsh chemicals.

Which adhesive should I choose for my project?

Choosing between cyanoacrylate and epoxy depends on your project. Use cyanoacrylate for speedy, light tasks. Epoxy is better for demanding, heavy-duty jobs.

What about the cost and availability of these adhesives?

Both types of adhesives are easy to find and come in many kinds. Epoxy adhesives might cost more, but they’re worth it for complex projects.