Automotive adhesives are key in making and fixing cars. They create strong bonds, are flexible, and resist heat and the environment. This guide will cover the different types of adhesives, how to use them, and their benefits. We’ll focus on ZDS™ products.

Understanding Different Types of Automotive Adhesives

Automotive adhesives are used in many ways in cars. They help keep the car safe and looking good. Let’s look at the main types:

Plastic Adhesives

Plastic adhesives stick different plastics together in cars. They are flexible to handle shocks and vibrations. Experts say they help prevent cracks in plastic parts.

Panel Bonding Adhesives

These adhesives are important for fixing cars after accidents. They keep big parts like car panels together. The 3M™ Panel Bonding Adhesive is known for its strong bonding.

3M.

Headliner Adhesives

Headliner adhesives stick headliners to car roofs. They must handle the car’s heat. ZDS™ headliner adhesive is heat-resistant and durable.

| Adhesive Type | Key Features | Applications |

|---|---|---|

| Plastic Adhesives | Flexible, strong bonds | Trim pieces, interior parts |

| Panel Bonding | High-strength, structural support | Exterior panels, body parts |

| Headliner Adhesives | Heat-resistant, long-lasting | Car roof linings |

Heat-Resistant Adhesives for High-Performance Applications

Headliner adhesives, like ZDS™, are key for car looks and function. They must handle heat and humidity to avoid sagging.

Benefits of Heat-Resistant Adhesives

These adhesives can handle high temperatures, over 190°F (88°C). They keep bonds strong over time. They also resist UV and humidity.

Use Case Example: ZDS™ Automotive Headliner Adhesive

ZDS™ headliner adhesive is made for tough conditions. It provides a strong, flexible bond that lasts.

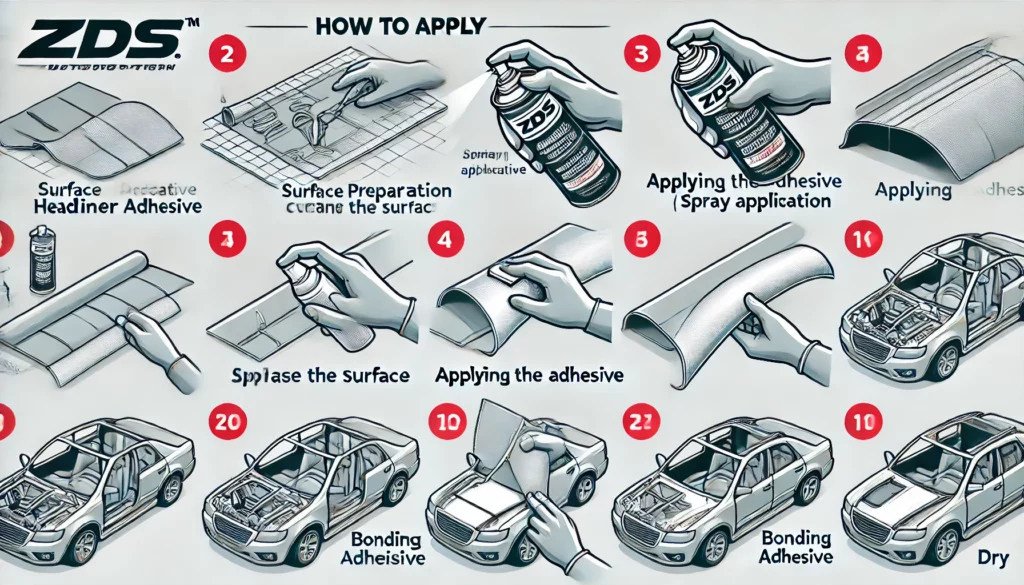

Step-by-Step Guide: How to Apply Automotive Headliner Adhesive

Applying headliner adhesive is key for DIY fans or repair shops. Follow these steps for the best results:

Step-by-Step Application Process

- Clean the Surface: Remove old adhesive, dust, and debris. This helps the adhesive stick well.

- Prepare the Headliner: Cut the headliner to fit and align it with the car’s roof.

- Apply ZDS™ Adhesive Evenly: Use a spray adhesive for even coverage.

- Bond and Press Firmly: Press the headliner onto the car roof and smooth it out to remove air pockets.

- Allow Drying Time: Let the adhesive dry before using the car.

Pro Tips for a Strong Bond

- Work in a well-ventilated area to avoid inhaling fumes.

- Wear gloves to protect your skin from adhesive.

ZDS™ Panel Bonding Adhesives for Professional Repairs

Panel bonding adhesives are vital in collision repairs and vehicle manufacturing. They ensure structural integrity in high-stress areas, like exterior panels.

Why Use ZDS™ Panel Bonding Adhesives?

ZDS™ adhesives offer a strong, durable bond that withstands impacts. This keeps repaired panels structurally sound. It’s key for crash safety and long-term durability

3M.

Why Flexibility Matters: Choosing the Right Adhesive for Car Interiors

In cars, flexibility in adhesives is key. Rigid adhesives can cause cracks and bond failures in moving parts.

Flexible Adhesives: The Key to Long-Lasting Repairs

Flexible adhesives let bonded parts move with the car, preventing damage. This is vital for interior parts, such as door trim and dashboards

Best ZDS™ Products for Flexible Bonding

ZDS™ has flexible adhesives perfect for bonding plastic and fabric components inside cars.

ZDS™: Eco-Friendly Adhesive Solutions for the Automotive Industry

ZDS™ is dedicated to eco-friendly adhesives for the automotive world. They reduce VOC emissions and are non-toxic.

Why Eco-Friendly Adhesives Matter

Eco-friendly adhesives cut environmental impact and improve air quality in cars. This is important for passengers, mainly in confined car interiors

3M.

Common Adhesive Problems and How to Solve Them

Working with automotive adhesives can lead to common issues. Here are some typical problems and how to fix them:

- Sagging Headliners: This issue often comes from using the wrong adhesive or applying it wrong. To fix it, remove the headliner, clean the surface, and use a high-quality headliner adhesive like ZDS™.

- Weak Bonds on Plastic Parts: If plastic parts aren’t sticking right, try an adhesive made for flexibility and plastic bonding.

- Peeling Panels: Make sure to use a panel bonding adhesive that offers strong support.

Quick Tips for Common Adhesive Issues

- Check compatibility with the materials you’re bonding.

- Clean surfaces thoroughly before applying adhesives.

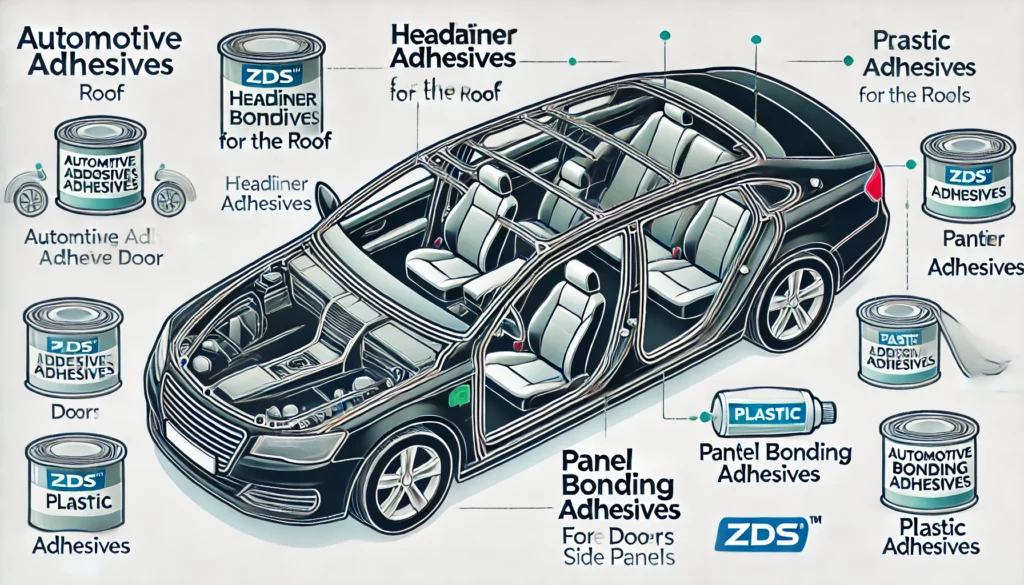

Visual Guide: Where to Use Automotive Adhesives in Your Vehicle

Here’s a quick guide on where to use different adhesives in your vehicle:

Infographic: Automotive Adhesive Applications

- Interior: Use headliner adhesives and trim adhesives here.

- Exterior: Panel bonding adhesives and mirror adhesives work well here.

- Engine: High-temperature adhesives are best for under-hood use.

The Future of Automotive Adhesive Technology

The automotive industry is always changing, and so are adhesives. New trends include smart adhesives that check structural integrity and eco-friendly formulations that are better for the environment.

ZDS™’s Role in Next-Gen Adhesives

ZDS™ is leading the way in creating adhesives that are strong, flexible, and good for the environment.

Conclusion

Automotive adhesives are key in making and fixing vehicles. They ensure safety, durability, and look. By picking the right adhesive and following the right techniques, you can get professional results.

ZDS™ offers a wide range of automotive adhesives that meet industry standards and solve common problems. From heat-resistant headliner adhesives to flexible plastic adhesives, ZDS™ is dedicated to providing innovative and eco-friendly solutions for lasting performance.