Introduction

In the competitive world of electronics manufacturing and assembly, using precise and industry-specific keywords is essential for businesses to reach their target audience effectively. One such critical material in the industry is electronic grade silicone, widely utilized for its superior performance in various applications. This article delves into the importance of electronic grade silicone, its properties, applications, and how it benefits the electronics sector.

What is Electronic Grade Silicone?

Properties of Electronic Grade Silicone

Electronic grade silicone is a highly refined silicone compound designed for electrical and electronic applications. It offers excellent thermal stability, dielectric properties, and resistance to environmental factors. Key characteristics include:

- High thermal resistance – Can withstand extreme temperatures without degradation.

- Excellent dielectric properties – Provides superior electrical insulation.

- Moisture and chemical resistance – Prevents damage from humidity and corrosive agents.

- Flexibility and adhesion – Ensures strong bonding and long-term durability.

Differences Between Electronic Grade Silicone and Standard Silicone

Unlike standard silicone, electronic grade silicone undergoes additional refining processes to remove impurities that could impact electronic performance. This makes it more reliable for sensitive electronic components.

Applications of Electronic Grade Silicone in the Electronics Industry

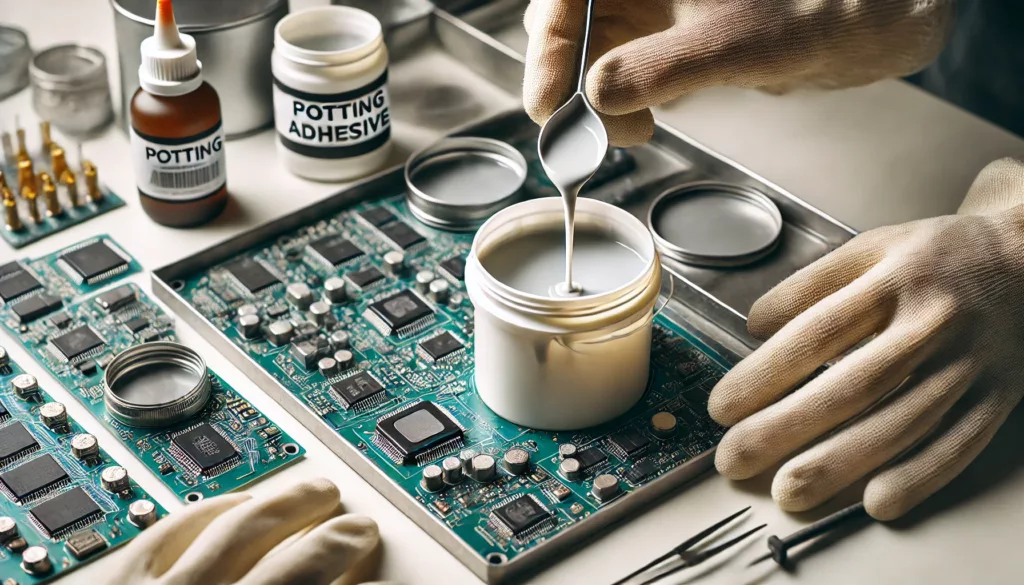

Silicone Adhesive for Electronics

One of the most common applications is as a silicone adhesive for electronics. This adhesive ensures secure bonding of components while allowing for flexibility and vibration resistance. It is widely used in:

- PCB manufacturing – Adhering components to circuit boards.

- LED assemblies – Providing thermal stability and electrical insulation.

- Automotive electronics – Ensuring durable adhesion in harsh environments.

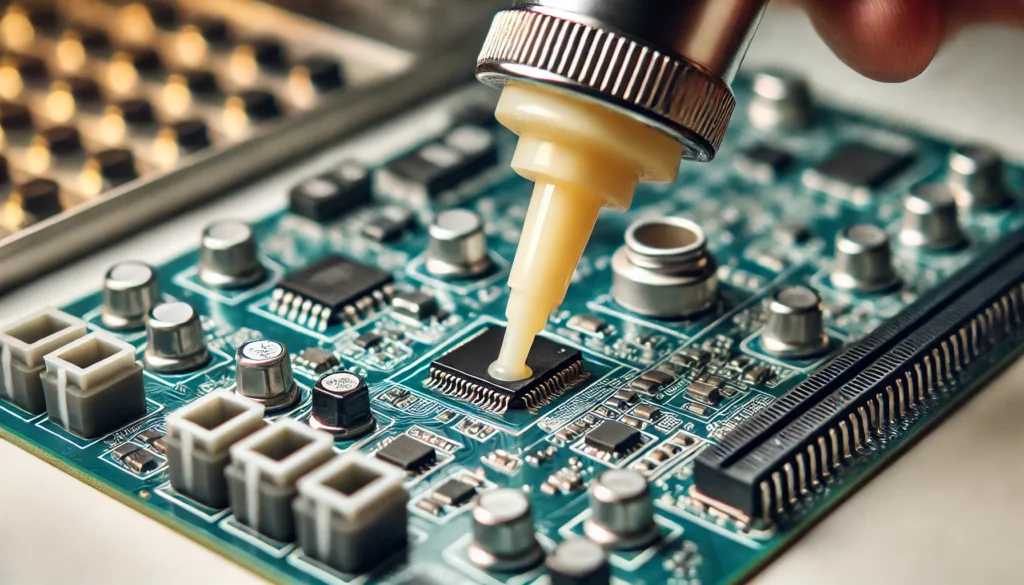

RTV Silicone for Electronics

RTV silicone for electronics (Room Temperature Vulcanizing silicone) is a type of electronic grade silicone that cures at room temperature. It is used for:

- Encapsulation – Protecting circuits from dust, moisture, and thermal damage.

- Coating applications – Providing a protective layer over sensitive components.

- Sealing gaps and joints – Ensuring air-tight protection.

Electrical Sealant for Protection and Insulation

An electrical sealant made from electronic grade silicone is essential for safeguarding electronic components. It prevents:

- Moisture ingress – Protecting circuits from humidity and condensation.

- Short circuits – Providing excellent insulation against unintended electrical contact.

- Thermal expansion issues – Accommodating temperature fluctuations without cracking.

Electronic Silicone Glue for High-Durability Bonding

Electronic silicone glue is used for applications requiring strong yet flexible adhesion. It offers:

- Shock absorption – Reducing mechanical stress on components.

- Chemical resistance – Preventing damage from solvents and oils.

- UV resistance – Ensuring longevity in outdoor and high-exposure environments.

Benefits of Using Electronic Grade Silicone in Electronics Manufacturing

Enhanced Component Protection

By using electronics silicone, manufacturers can ensure better protection of their products against environmental and mechanical stresses.

Improved Performance and Longevity

Electrical silicone materials extend the operational lifespan of electronic devices by offering superior insulation and thermal management.

Compliance with Industry Standards

Using high-quality electrical silicone sealant ensures compliance with industry regulations, including RoHS and REACH, promoting safe and sustainable manufacturing practices.

Choosing the Right Electronic Grade Silicone for Your Needs

When selecting an electronic grade silicone, consider the following factors:

- Curing Method – Choose between RTV, heat-cured, or UV-cured silicone depending on application requirements.

- Thermal Conductivity – Ensure the silicone can handle the required heat dissipation.

- Dielectric Strength – Verify the insulation properties for high-voltage applications.

- Environmental Resistance – Select a formulation that withstands moisture, chemicals, and UV exposure.

Conclusion

The use of electronic grade silicone in the electronics industry is vital for ensuring durability, performance, and safety. Whether it is silicone adhesive for electronics, RTV silicone for electronics, or electrical silicone sealant, these materials play a crucial role in manufacturing and maintenance processes. By understanding their properties and applications, businesses can make informed choices to enhance their products and optimize production efficiency.

For high-quality electronic grade silicone solutions, contact ZDS™—a trusted adhesive manufacturer specializing in customized formulations for industrial, automotive, and electronic applications.