Electronic potting adhesive is a specialized material designed to encapsulate and protect delicate electronic components from environmental and mechanical stress. With its ability to insulate, waterproof, and stabilize components, potting adhesive is widely used in industries like automotive, aerospace, medical devices, and consumer electronics. In this guide, we’ll explore the benefits, applications, and best practices for using electronic potting adhesives.

What is Electronic Potting Adhesive?

Electronic potting adhesive is a resin-based material used to encase electronic components within a protective shell. It provides insulation, protects against dust and moisture, and improves the mechanical durability of components. Potting adhesive can be applied as a liquid, which cures to form a solid or semi-solid encapsulant.

Benefits of Electronic Potting Adhesive

- Environmental Protection: Shields components from moisture, dust, and chemical exposure.

- Electrical Insulation: Prevents short circuits and ensures proper function.

- Mechanical Stability: Reduces vibration and impact damage to fragile parts.

- Thermal Management: Dissipates heat effectively to prevent overheating.

- Long-Term Reliability: Extends the lifespan of devices, even in harsh environments.

Applications of Electronic Potting Adhesive

1. Automotive Electronics

Protects sensors, control units, and battery components in vehicles exposed to extreme temperatures and vibrations.

2. Consumer Electronics

Encapsulates components in smartphones, chargers, and wearables for waterproofing and impact resistance.

3. LED Lighting

Seals and protects LEDs to improve longevity and ensure consistent performance.

4. Medical Devices

Potting adhesives are used in implantable and wearable devices for insulation and safety.

5. Industrial and Aerospace Electronics

Provides robust protection for equipment in harsh industrial or high-altitude environments.

Types of Electronic Potting Adhesives

-

Epoxy Potting Adhesives

- Known for high strength and chemical resistance.

- Suitable for applications requiring strong mechanical protection.

-

Silicone Potting Adhesives

- Highly flexible and heat resistant.

- Ideal for applications where thermal expansion or flexibility is critical.

-

Polyurethane Potting Adhesives

- Excellent moisture resistance and flexibility.

- Commonly used in consumer electronics and outdoor applications.

-

UV-Curable Potting Adhesives

- Cures quickly under UV light, reducing production time.

- Suitable for small components in high-speed manufacturing.

How to Use Electronic Potting Adhesive Effectively

1. Prepare the Components

- Clean surfaces to remove dirt, grease, or debris.

- Ensure all parts are dry before application.

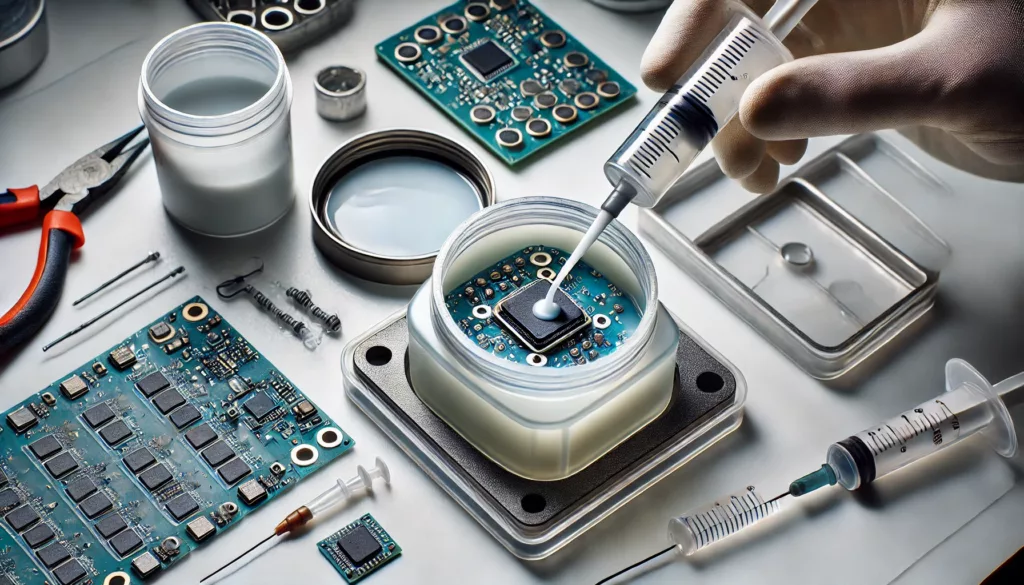

2. Mix the Adhesive

- For two-component adhesives, mix the resin and hardener in the recommended ratio.

- Stir thoroughly to ensure a consistent mixture.

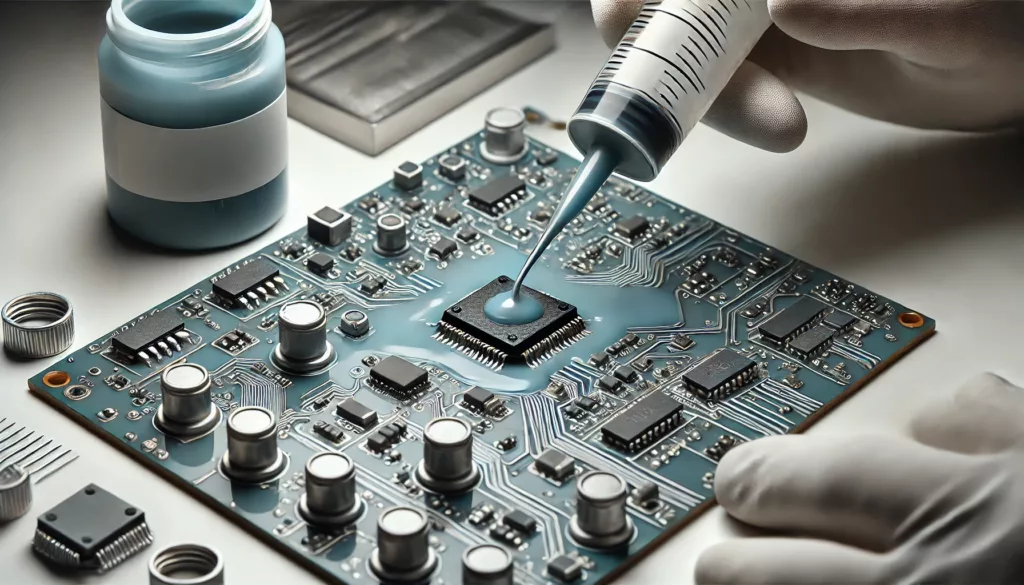

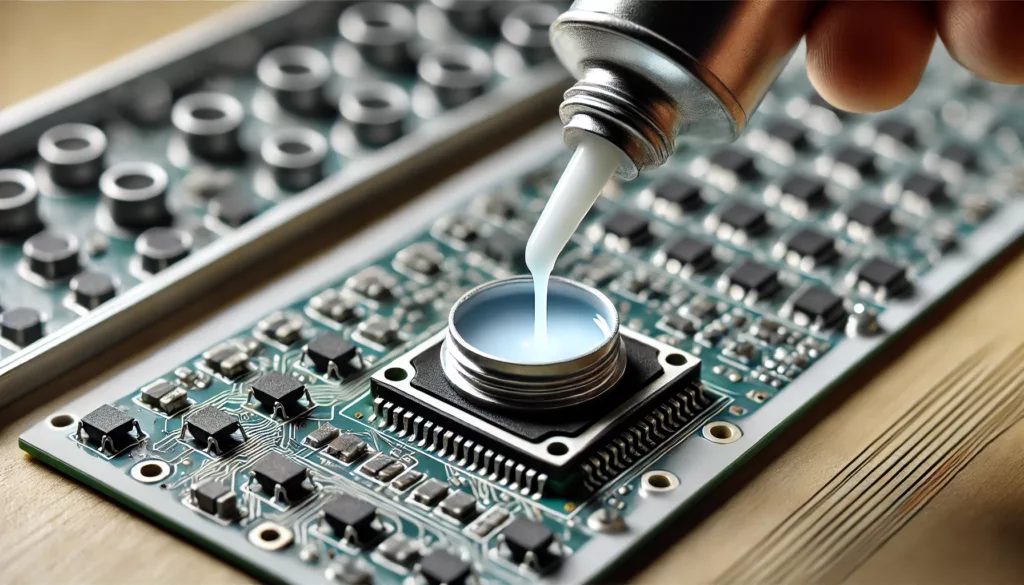

3. Apply the Potting Adhesive

- Pour the adhesive over the components to fully encapsulate them.

- Use a syringe or nozzle for precise application in small areas.

4. Allow Curing

- Follow the manufacturer’s instructions for curing time and temperature.

- Ensure the adhesive is fully cured before handling or testing the components.

Tips for Choosing the Best Potting Adhesive

- Thermal Management: Choose thermally conductive adhesives for heat-sensitive applications.

- Flexibility: Opt for silicone or polyurethane adhesives for applications requiring flexibility.

- Chemical Resistance: Select epoxy adhesives for environments with exposure to chemicals or solvents.

- Cure Time: Match the adhesive’s curing time with your production schedule.

- Volume Requirements: Ensure the adhesive can cover all components adequately without gaps.

Safety Precautions When Using Potting Adhesive

- Ventilation: Work in a well-ventilated area to avoid inhaling fumes.

- Protective Gear: Wear gloves, goggles, and a mask to prevent skin or eye irritation.

- Storage: Store unused adhesive in a cool, dry place to maintain its shelf life.

- Follow Instructions: Adhere to the manufacturer’s guidelines for safe application and curing.

FAQs

What is electronic potting adhesive used for?

Potting adhesive is used to encapsulate and protect electronic components from environmental and mechanical damage.

Which type of potting adhesive is best for heat dissipation?

Thermally conductive adhesives, often made from silicone or epoxy, are ideal for managing heat.

Can potting adhesive be removed after curing?

While difficult, cured potting adhesive can sometimes be removed using mechanical or chemical methods, depending on the type of adhesive.

How long does potting adhesive take to cure?

Curing times vary from minutes to hours, depending on the adhesive type and environmental conditions.

Is potting adhesive waterproof?

Yes, most potting adhesives provide excellent waterproofing and moisture resistance.

Can potting adhesive handle high temperatures?

Silicone and certain epoxy adhesives are designed to withstand high temperatures, making them suitable for demanding applications.

Conclusion

Electronic potting adhesive is an essential tool for protecting and enhancing the performance of sensitive electronic components. By providing insulation, thermal management, and mechanical stability, these adhesives extend the lifespan of devices and ensure reliable operation in various industries. Whether you’re working on automotive sensors, LEDs, or wearable devices, choosing the right potting adhesive can make all the difference in durability and performance.