In the automobile manufacturing industry, selecting the appropriate adhesive is crucial for ensuring vehicle durability, safety, and performance. Two commonly used adhesives are epoxy and super glue (cyanoacrylate). This article delves into their properties, applications, and suitability within automotive contexts.

Understanding Epoxy and Super Glue

Epoxy Adhesives: Epoxy consists of two components—a resin and a hardener—that, when mixed, undergo a chemical reaction to form a strong, durable bond. This adhesive is renowned for its exceptional strength, chemical resistance, and versatility, making it suitable for bonding metals, plastics, and composites.

Super Glue (Cyanoacrylate Adhesives): Super glue is a single-component adhesive known for its rapid bonding capabilities. It cures almost instantly upon contact with moisture, forming a rigid bond. While convenient for quick fixes, it may lack the durability required for structural applications.

Applications in Automobile Manufacturing

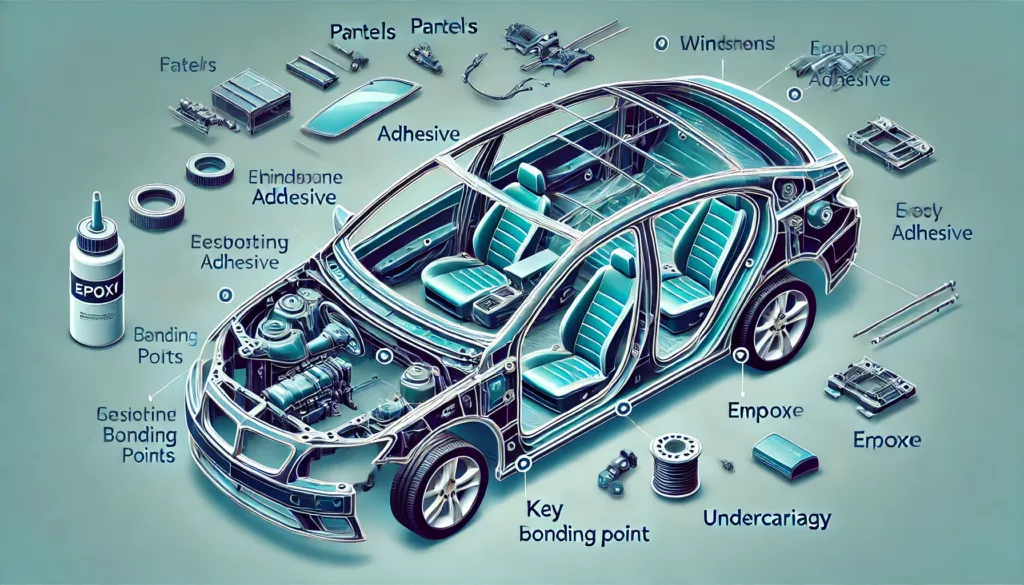

Epoxy in Automotive Applications: Epoxy adhesives are extensively used in the automotive industry for structural bonding, such as attaching body panels, reinforcing joints, and bonding dissimilar materials. Their ability to withstand high stress, temperature variations, and exposure to chemicals makes them ideal for critical components.

Super Glue in Automotive Applications: Super glue is typically reserved for minor, non-structural repairs within the automotive sector. Its rapid curing time is advantageous for quick fixes, but its brittleness and limited gap-filling capabilities restrict its use in areas subjected to significant stress or vibration.

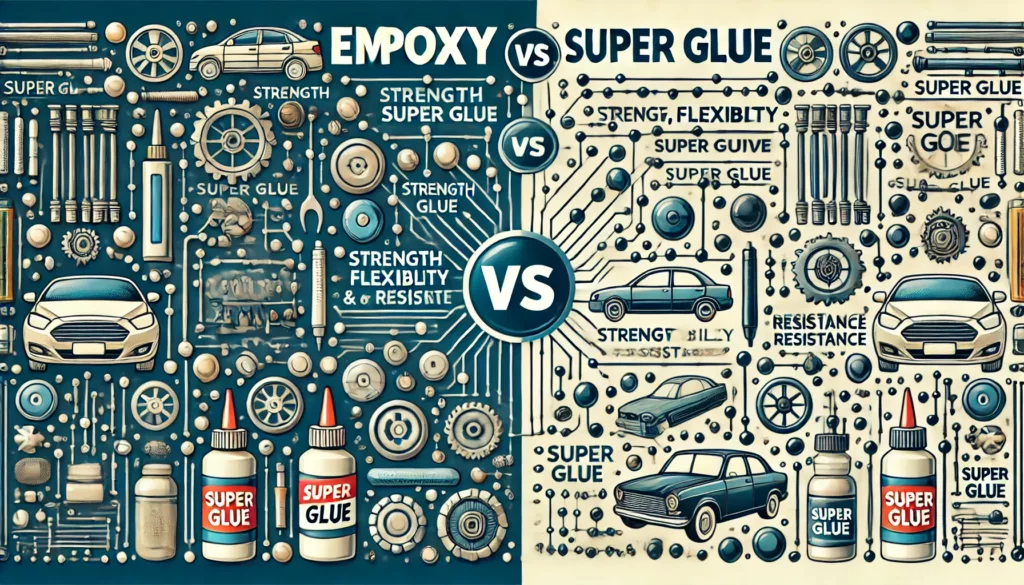

Comparative Analysis

Strength and Durability: Epoxy adhesives provide superior strength and durability, essential for structural components in vehicles. They can withstand shear and peel stresses, making them reliable for long-term performance. In contrast, super glue offers less strength and may become brittle over time, limiting its use to minor repairs.

Curing Time: Super glue’s rapid curing is beneficial for quick repairs but offers limited repositioning time. Epoxy adhesives require longer curing periods, which can be accelerated with heat, allowing for adjustments during assembly.

Material Compatibility: Epoxy exhibits excellent adhesion to a wide range of substrates, including metals, plastics, and composites, making it versatile for various automotive applications. Super glue bonds effectively with certain materials but may not perform well with others, especially those that are porous or flexible.

Conclusion

In automobile manufacturing, the choice between Epoxy vs. Super Glue hinges on the specific requirements of the application. Epoxy adhesives are preferred for structural bonding due to their superior strength, durability, and versatility. Super glue serves as a convenient option for quick, minor repairs but lacks the robustness needed for critical components.

Call to Action

For manufacturers seeking reliable adhesive solutions tailored to the automotive industry, ZDS™ offers a comprehensive range of epoxy adhesives designed to meet stringent performance standards. Contact us today to learn more about our products and how they can enhance your manufacturing processes.