UV adhesives have revolutionized industries with their rapid curing times, precision application, and robust bonding capabilities. However, the future holds even greater promise for this technology. Emerging trends, innovations, and applications are set to redefine how UV adhesives contribute to industries ranging from healthcare to aerospace. This article delves into the exciting advancements and potential of UV adhesives, offering a glimpse into their transformative future of UV adhesives.

Understanding the Evolution of UV Adhesives

UV adhesives have come a long way since their inception. Initially used in niche applications, they are now integral to numerous industries due to their versatility and efficiency. The next phase of this evolution involves tackling challenges like material compatibility, curing limitations, and environmental impact.

From Basic Bonding to Advanced Solutions

In the past, UV adhesives primarily served as a fast-curing alternative to traditional bonding methods. Today, they are tailored to specific needs, offering properties such as optical clarity, flexibility, and resistance to extreme conditions. Future formulations will likely incorporate smart features, such as self-healing and enhanced durability.

The Shift Toward Sustainability

Environmental concerns are driving the development of eco-friendly UV adhesives. Solvent-free formulations and biodegradable adhesives are becoming priorities, ensuring that the technology aligns with global sustainability goals.

Emerging Innovations in UV Adhesives

Hybrid Adhesive Technologies

The future will see a rise in hybrid adhesives that combine UV curing with other curing methods, such as thermal or moisture curing. This fusion enhances flexibility and broadens the scope of applications.

Advanced Photoinitiators

Next-generation photoinitiators are being developed to enable faster curing at lower UV intensities. These advancements will reduce energy consumption and allow for safer, more efficient processes.

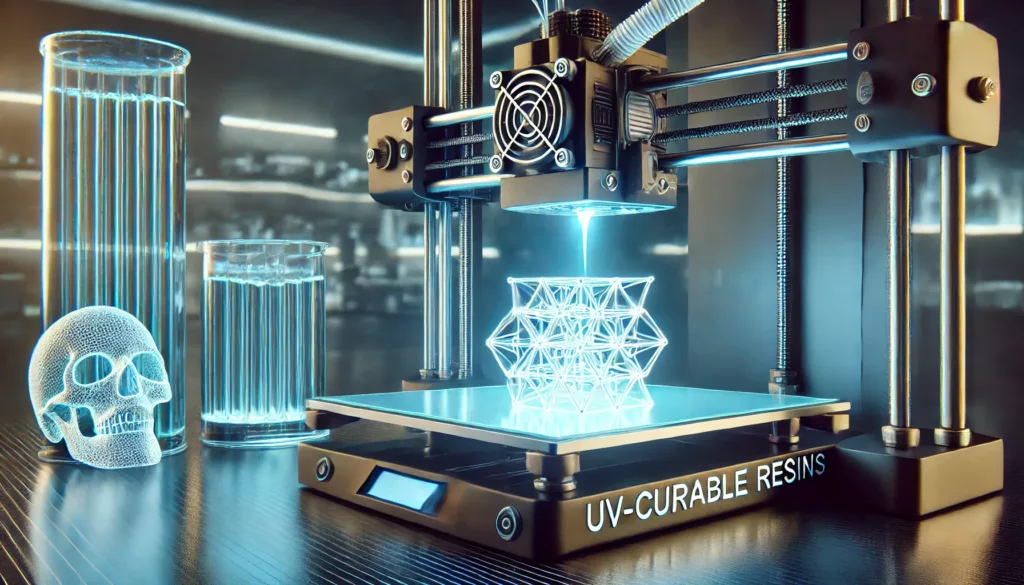

3D Printing with UV Adhesives

The integration of UV adhesives in 3D printing is a game-changer. UV-curable resins enable intricate designs and rapid prototyping, making them indispensable for industries like healthcare, automotive, and consumer goods.

Smart Adhesives

Imagine adhesives that can self-heal or adapt to changes in temperature and pressure. Research in smart materials is paving the way for UV adhesives with built-in intelligence, enhancing their functionality in dynamic environments.

Future Applications of UV Adhesives

Aerospace and Defense

UV adhesives are set to play a crucial role in aerospace manufacturing, offering lightweight and durable solutions for bonding materials in aircraft and spacecraft.

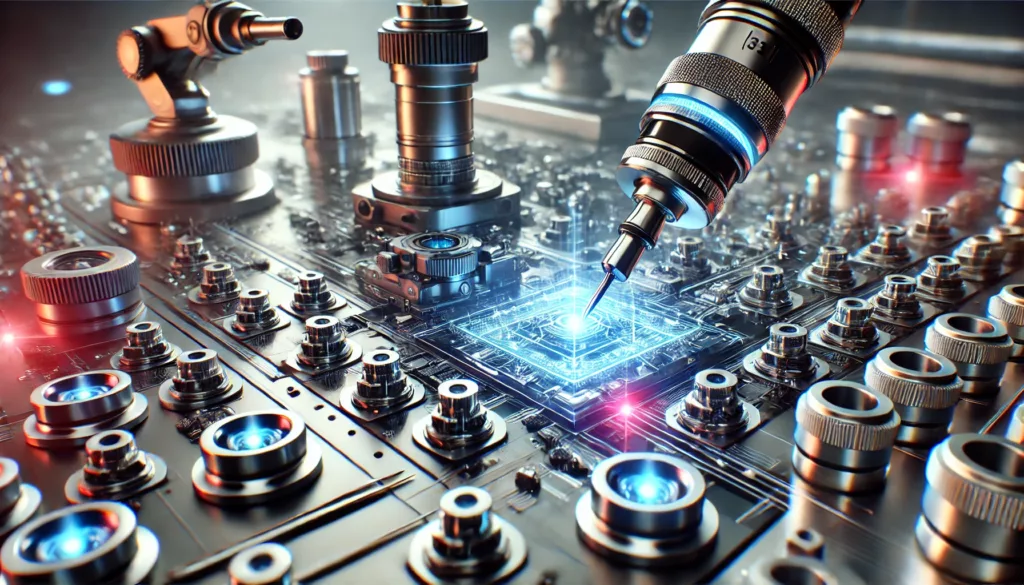

Electronics of Tomorrow

As electronics become smaller and more complex, UV adhesives will provide the precision and strength needed for assembling micro-components in devices like wearables, smartphones, and sensors.

Sustainable Construction

In construction, UV adhesives can reduce material waste and offer energy-efficient solutions for assembling prefabricated components, paving the way for greener building practices.

Medical Innovations

Biocompatible UV adhesives will be instrumental in creating advanced medical devices, such as implants, wearable health monitors, and diagnostic tools.

Challenges and Opportunities Ahead

Overcoming Material Limitations

One of the biggest hurdles for UV adhesives is bonding materials that block or scatter UV light. Future of UV Adhesives developments will focus on formulations that can cure effectively in opaque or shaded areas.

Cost-Effectiveness

Widespread adoption of UV adhesives requires cost-effective solutions. Innovations in manufacturing and materials will bring down costs, making the technology more accessible.

Expanding the UV Spectrum

By expanding the range of UV wavelengths used in curing, manufacturers can achieve greater compatibility with diverse materials and complex designs.

The Role of AI and Automation

Artificial intelligence and automation are poised to revolutionize how UV adhesives are used. Automated systems will enable precise application and curing, while AI-driven algorithms can optimize adhesive formulations and processes for specific needs.

FAQs

What industries will benefit most from future UV adhesives?

Industries like aerospace, electronics, medical devices, and construction stand to gain significantly from advancements in UV adhesive technology.

How are UV adhesives becoming more sustainable?

Eco-friendly formulations, such as solvent-free and biodegradable adhesives, are making UV adhesives more environmentally sustainable.

Will UV adhesives replace traditional bonding methods?

While UV adhesives offer unique advantages, they will complement rather than completely replace traditional methods due to varying application needs.

What role does 3D printing play in the future of UV adhesives?

UV-curable resins are integral to 3D printing, enabling rapid prototyping and intricate designs for diverse industries.

Are UV adhesives safe for medical applications?

Yes, biocompatible UV adhesives are already used in medical devices, and future advancements will enhance their safety and effectiveness.

Can UV adhesives work with opaque materials?

Current limitations exist, but future formulations aim to improve curing in shaded or opaque areas.

Conclusion

The future of UV adhesives is bright, with advancements in technology, sustainability, and applications driving their evolution. From smart materials to hybrid curing methods, the innovations on the horizon promise to redefine how we bond and build. As industries continue to embrace this cutting-edge technology, UV adhesives will undoubtedly play a pivotal role in shaping a smarter, more efficient, and sustainable world.