At ZDS™, we’re all about creating top-notch glass to glass glue items. Our smart adhesive technology makes this possible. We offer a wide range of glues that are perfect for joining glass to glass. They promise a bond that’s strong, see-through, and lasts a long time.

We’re known for being leaders when it comes to glue. We make sure our products are the best, whether it’s for a fun home project or a big industry job. ZDS™ glass glue manufacturer are all about quality and superior performance, making us a go-to for adhesive solutions.

Key Takeaways

- Advanced adhesive technology developed by ZDS™.

- Comprehensive range of glass-to-glass glue solutions.

- High standards tailored for both DIY and industrial use.

- Strong, clear, and durable bonding solutions.

- Leader in adhesive manufacturing and technology.

Understanding Glass to Glass Adhesives

Understanding the various types of glass adhesives is key to successful glass projects. Each type possesses certain features that suit different needs. Knowing what each adhesive can do helps us choose the right one for our task.

Types of Glass Adhesives

Different adhesives for glass come with their own special traits:

- UV-Cured Adhesives: Fast bonding is their highlight due to UV light exposure, perfect for quick jobs.

- Silicone Adhesives: Their flexibility and temperature resistance make them ideal for outdoor and car uses.

- Epoxy Adhesives: With high strength and durability, these are best for jobs needing a sturdy bond.

- Polyurethane Adhesives: They resist moisture well, making them suitable for water-exposed areas.

Advantages of Using Glass Adhesives

Choosing the right glass adhesive brings many benefits:

- Clean Aesthetic Finish: They offer a clear bond that makes projects look better.

- High Tensile Strength: These adhesives create strong bonds that hold up under pressure.

- Environmental Resistance: Some adhesives withstand weather and moisture, adding to the project’s lifespan.

By knowing the different glass adhesives and their pros, we can pick the best one for our needs. This decision makes our glass projects more successful.

Why Choose ZDS™ for Glass to Glass Glue?

At ZDS™, we focus on creating cutting-edge adhesive solutions for our customers’ evolving needs. We aim for excellence with our ZDS™ adhesives. They provide superior quality and reliability for glass bonding. Here are the main reasons ZDS™ is a top choice in the market.

Innovative Adhesive Solutions

We stand out because of our innovation. Our research team works tirelessly. They explore new technologies and materials for top-notch adhesives. Whether it’s for delicate designs or strong structural needs, ZDS™ adhesives are up for the challenge. They meet the high demands of modern industries.

Industry Certifications & Quality Assurance

Quality drives us at ZDS™. We make sure our adhesives are the best. They undergo tough tests and are certified to top standards. Our glass to glass glue gives you confidence. Every product is checked rigorously before it gets to you.

Our quest for excellence includes getting third-party certifications. It’s how we prove our commitment to quality and innovation. Our thorough quality assurance means every batch of ZDS™ adhesives is dependable. Our clients expect the best, and we deliver.

- Innovative product design

- Consistent quality control

- Industry certifications

Best Practices for Applying Glass to Glass Glue

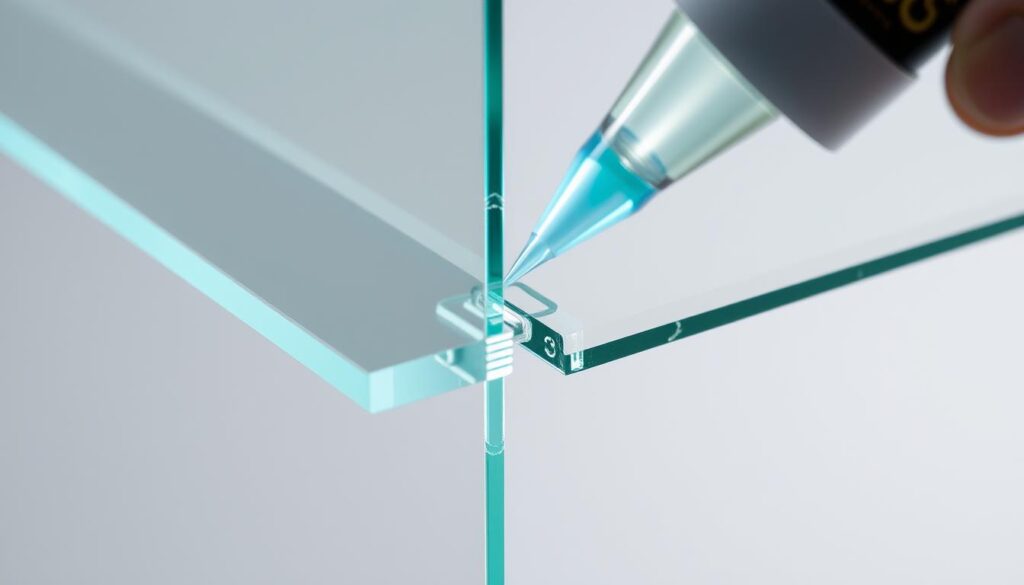

For a successful applying glass adhesive job, preparation and how you apply it are key. We are going to share important tips for securing a strong, crystal-clear bond with glass-to-glass glue.

- Clean Surfaces: Before you start, ensure the glass is clean, dry, and free from anything that could weaken the bond. An alcohol-based cleaner can remove grease, dirt, or oil effectively.

- Dry Surfaces: Make sure the glass is fully dry before you apply glue. Any water can harm the bond’s strength and how clear it looks.

- Uniform Application: Spread the glue evenly on the glass surfaces. This makes the bond stronger and helps prevent air bubbles from forming.

Using these adhesive application tips will lead to the best outcomes. By making sure everything’s clean, dry, and the glue is spread evenly, you’ll create a strong bond between the glass parts. This lets you make the most of the ZDS™ solutions.

Common Applications for Glass to Glass Adhesives

Glass adhesive applications have transformed various industries. They provide seamless solutions for bonding needs. ZDS™ excels in both residential and commercial glass bonding. This ensures top performance and durability. Let’s look at the main uses for glass to glass adhesives.

Residential Applications

In homes, glass adhesives serve many purposes. They bond tabletops, fix glass decor, and boost the look of interiors. These techniques give a clear, strong bond. This keeps home items visually appealing and durable.

Commercial and Industrial Uses

In the commercial world, glass adhesive plays a key role. It meets structural and visual needs in different fields. From building designs and shop fronts to car glass, ZDS™ offers strong adhesive solutions. In industries like electronics and aerospace, precision in glass bonding is key. It ensures things work well and look right.

| Application | Sector | Key Benefits |

|---|---|---|

| Tabletops and Decor | Residential | Durability and Aesthetic Appeal |

| Architectural Projects | Commercial | Structural Integrity and Clear Bonding |

| Storefronts | Commercial | Enhanced Durability and Visual Appeal |

| Automotive Glass | Commercial | Robust and Durable Bonds |

| Electronics | Industrial | Precision and Functionality |

| Aerospace | Industrial | Strength and Reliability |

| Manufacturing | Industrial | Efficiency and Performance |

How to Ensure a Strong and Clear Bond

To get a strong glass bond with clear glue, make sure to follow key steps closely. The steps to prepare and cure are essential for a good bond.

Surface Preparation Techniques

Start by cleaning the glass surface preparation for glue. Use isopropyl alcohol or acetone to clean off any dirt, grease, or contaminants. Adding primers can also improve how well the adhesive sticks, especially on hard surfaces. Always use the guidelines given by the manufacturer for the best outcomes.

Optimal Curing Conditions

The curing part is just as important for bonding. Things like UV light, temperature, and moisture level can affect curing. Make sure to follow ZDS™’s curing time and conditions to keep the glue clear and the bond firm.

Choosing the Right Clear Glass Adhesive

Choosing the right clear glass adhesive is important. You need to know several key points to get a good bond that lasts. The specific qualities of the adhesive affect how strong and durable the glass connection will be.

Evaluating Shear and Tensile Strength

It’s vital to look at both shear and tensile strength when picking an adhesive. Shear strength is about the glue’s ability to handle sideways forces. This keeps the adhesive strong under pressure and keeps the bond secure.

Tensile strength is about resisting forces that pull the bonded areas apart. Understanding these strengths helps us pick the right glue for our projects. This ensures a strong and lasting glass glue solution. ZDS™ has many adhesives with different strengths for various needs.

UV Resistance and Durability

UV resistance and durability are also key for clear glass adhesive, especially if the glue will face sunlight and changing temperatures. UV resistance means the glue won’t weaken over time with sun exposure. A good glass glue also needs to handle humidity, temperature shifts, and physical stress.

ZDS™ adhesives are made to be very resistant to UV and are durable. This makes them great for both inside and outside use. Choosing a ZDS™ adhesive with these features ensures a bond that’s clear, stable, and lasts a long time.

Case Studies: Success Stories with ZDS™ Glass Adhesives

ZDS™ has many ZDS™ success stories that show the quality of our products. These stories, across various industries, demonstrate how we solve tough bonding problems. Our glass adhesive case studies reveal our commitment to innovative solutions.

A top architectural firm needed a strong, clear adhesive for a big project. They picked ZDS™ adhesives. The result was a durable and beautiful bond that met all their needs.

In another case, a global electronics maker had trouble bonding glass parts in a new product. Our special adhesive offered them clarity and strength beyond the usual standards. This made their product more reliable and attractive in the market.

We also worked with big names in the car industry, showing our adhesives’ superior performance. Our collaborations show our drive for innovation and quality in glass bonding tech.

Our ZDS™ success stories prove our dedication to leading adhesive solutions. Through our glass adhesive case studies, we keep pushing for the best.

Comparison of Different Glass Adhesives in the Market

Choosing the right glass adhesive is important. You must look at bond strength, cure time, and how flexible it is. Brands like TroySys Nano470 and La Tim’s B7000 Glue stand out for different reasons. Knowing these details helps pick the best glue for your needs.

Evaluating Performance Metrics

It’s vital to understand what makes a good glass glue. Bond strength measures how tightly the glue holds pieces together. Cure time is about how quickly you can use the glued item. Adhesive comparison articles show that products like UV Glue Kit and Liquid Glass Clear Epoxy are tested for these qualities.

Cost vs. Quality Considerations

Finding the right balance between cost and quality is key. High-quality glues, like ZDS™ products, might cost more but they pay off. Looking for a glue that’s both affordable and strong ensures you get the most for your money. Super Glue for Glass and Durvol Auto Glass Urethane are good options.

For more details on these products, check out the full overview.

Future Trends in Glass to Glass Adhesive Technology

The future of adhesive technology is changing fast. New eco-friendly formulas, faster curing, and stronger bonds are key. These innovations are shaping the industry.

ZDS™ leads in these advances. We’re doing lots of research to bring new ideas into adhesives. Our goal is to make products that go beyond what’s current, matching the market’s growing demands.

Also, there’s a big move towards greener production. Better bonding and less harm to the environment are becoming important. ZDS™ is keen on adopting these changes, advancing what adhesive technology can do.

Our focus is on making adhesives that work better, are green, and meet top quality standards. These steps will change how we use adhesives in glass, making ZDS™ a leading name in the industry.

Conclusion

ZDS™ Adhesives Manufacturer is committed to delivering top-notch bonding solutions. Our expertise in ZDS™ glass to glass glue sets us apart. We ensure that every product meets high standards of quality and performance, thanks to our industry certifications.

In this article, we discussed the different glass adhesives and how to use them. We also looked at their benefits. Our case studies show how ZDS™ glass glue has helped our clients succeed. Our goal is to keep improving our adhesives to meet your needs in both home and business settings.

Looking ahead, ZDS™ aims to keep leading with innovative adhesives. We encourage you to check out our products and see how we can help you. Let’s work together to create lasting, clear bonds.

FAQ

What types of glass adhesives are available?

You can find several kinds of glass adhesives. They include UV-cured, silicone, epoxy, and polyurethane types. Each one is made for specific needs. This ensures they fit different tasks well.

Why should I use a glass adhesive for glass-to-glass bonding?

Using glass adhesives offers big benefits. They give a neat finish and strong hold. Also, they stand up well to weather and moisture. That’s why they’re great for many uses.

What makes ZDS™ adhesives different from other glass adhesives?

ZDS™ aims at bringing new and effective adhesive solutions to the table. Our products pass the test for top quality and performance. They’re made to meet tough standards in testing and quality.

What are the best practices for applying glass to glass glue?

For the best bond, start with clean, dry glass. Make sure there’s no dust or grease. Next, apply the glue evenly. Also, avoid trapped air to ensure a solid connection.

What are common applications for glass to glass adhesives?

These adhesives are often used at home for fixing tables and decorations. In business, they help in building projects and car glass work. They’re also key in making electronics and aerospace items.

How do I ensure a strong and clear bond between glass surfaces?

A good bond needs proper prep. Clean the surfaces with alcohol or acetone. Using a primer might help too. The cure process matters a lot. UV light, the right temperature, and moisture affect the final bond.

How do I choose the right clear glass adhesive?

Picking the right adhesive means looking at its strength. It must be strong enough for the load. Also, check if it can handle UV light well. This ensures it lasts, especially in sunny spots.

Are there any success stories involving ZDS™ glass adhesives?

Yes. We’ve got many stories where ZDS™ adhesive met tough demands in various fields. These stories show our product’s excellent performance. Our clients are very happy with the results.

How do ZDS™ glass adhesives compare to other products in the market?

Consider things like how strong the bond is, how quickly it cures, and its flexibility. ZDS™ might be pricier at first. But it often gives a more durable and trustworthy bond. That means better value.

What are the future trends in glass to glass adhesive technology?

The future looks bright with focus on eco-friendly, quick-curing, and stronger adhesives. ZDS™ leads in adding these advances to our adhesives. We want to offer cutting-edge solutions that keep up with industry changes.