The global UV adhesives market is experiencing unprecedented growth, driven by rising demand for fast-curing and efficient bonding solutions across industries. From electronics and healthcare to automotive and consumer goods, UV adhesives are revolutionizing manufacturing processes. This article delves into the latest market trends, key growth drivers, regional dynamics, and the competitive positioning of leading brands like ZDS™.

Market Overview: The Growth Trajectory of UV Adhesives

The UV adhesives market is projected to achieve a compound annual growth rate (CAGR) of approximately 8-10% from 2023 to 2030, with a market valuation expected to surpass $4 billion by 2030.

Key Factors Driving Growth

- Technological Advancements: Innovations in photoinitiators and curing technology.

- Industrial Demand: Rising adoption in electronics, optics, and automotive sectors.

- Sustainability Trends: Reduced VOC emissions and eco-friendly formulations.

- Healthcare Applications: Biocompatible adhesives for medical devices.

Industry Trends Shaping the Market

1. Rising Adoption in Electronics Manufacturing

The electronics industry has emerged as the largest consumer of UV adhesives, driven by:

- Miniaturization of electronic devices.

- High precision requirements for bonding sensors and circuits.

- Demand for fast-curing adhesives to enhance production efficiency.

2. Expansion in the Medical Device Sector

Medical-grade UV adhesives are transforming device assembly due to their biocompatibility and sterilization resistance. Examples include:

- Catheters

- Syringes

- Diagnostic equipment

3. Sustainable Adhesive Solutions

As industries prioritize sustainability, UV adhesives gain traction for their low environmental impact:

- Minimal VOC emissions.

- Reduced waste due to precise application and minimal overspray.

4. Advancements in Optical Bonding

UV adhesives are increasingly used in the optical industry for their ability to create strong, transparent bonds in lenses, displays, and glass components.

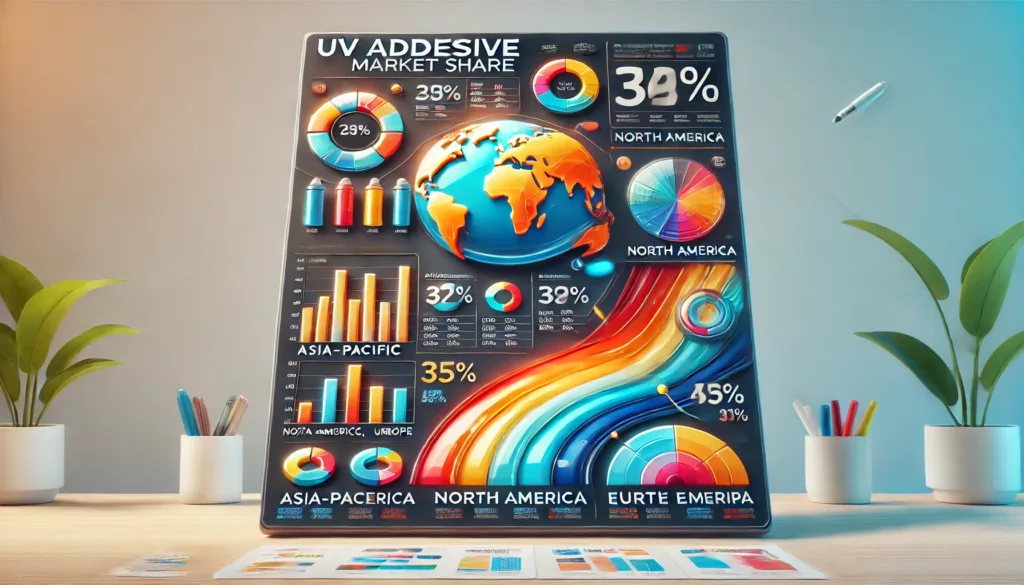

Regional Analysis: Market Dynamics Across the Globe

North America

- Strong presence of electronics and automotive manufacturing hubs.

- Innovations in UV curing technology, particularly in the U.S.

Europe

- Growth driven by strict environmental regulations promoting low-VOC adhesives.

- Germany and the U.K. lead in automotive and optical applications.

Asia-Pacific

- Rapid industrialization in China, Japan, and South Korea.

- Dominance in electronics and consumer goods manufacturing.

Middle East and Africa

- Emerging markets with growing adoption in infrastructure and healthcare.

Competitive Landscape: Spotlight on ZDS™

ZDS™ has emerged as a key player in the UV adhesives market, leveraging innovation, sustainability, and precision engineering to secure its position.

ZDS™’s Market Position

- Focus on R&D: Continuous investment in developing advanced formulations and curing technologies.

- Industry Leadership: Expertise in high-precision adhesives for electronics, optics, and medical devices.

- Sustainability Commitments: Pioneering low-VOC adhesives with minimal environmental impact.

Case Study: ZDS™’s Success in Electronics

A leading electronics manufacturer partnered with ZDS™ to develop a custom UV adhesive solution for bonding microcomponents. The adhesive delivered:

- Faster curing times by 30%.

- Enhanced bond strength, meeting rigorous durability standards.

- Zero defects during thermal cycling tests.

Future Outlook: What Lies Ahead for UV Adhesives?

The UV adhesives market is poised for further growth as industries continue to innovate and streamline production processes. Key future trends include:

- Increased Use of Automation: Robotic application of UV adhesives in high-speed production lines.

- Emergence of New Formulations: Development of adhesives for challenging substrates like composites and low-surface-energy plastics.

- Rising Adoption in Emerging Markets: Expansion in regions with growing industrialization and infrastructure development.

FAQs

What is driving the growth of the UV adhesives market?

The growth is fueled by demand for fast-curing solutions in electronics, optics, and medical devices, along with eco-friendly trends.

Which regions are leading the UV adhesives market?

Asia-Pacific leads in manufacturing, followed by North America and Europe with strong R&D and adoption in automotive and electronics.

How is ZDS™ positioned in the market?

ZDS™ is a leader in innovation, offering advanced, sustainable adhesive solutions for precision industries like electronics and medical devices.

What are the advantages of UV adhesives?

UV adhesives cure quickly, reduce VOC emissions, and provide strong, durable bonds across various substrates.

What industries are driving demand for UV adhesives?

Electronics, medical devices, optics, automotive, and consumer goods are the primary industries driving demand.

How sustainable are UV adhesives?

UV adhesives produce minimal VOC emissions and reduce waste, making them an eco-friendly option compared to traditional adhesives.

Conclusion

The global UV adhesives market is experiencing transformative growth, driven by technological advancements, sustainability trends, and increasing adoption in key industries. Companies like ZDS™ are at the forefront, offering innovative solutions that meet the demands of a rapidly evolving marketplace. As industries embrace fast-curing and eco-friendly bonding technologies, the future of UV adhesives looks brighter than ever.