Industrial glue is a powerful adhesive used in construction, manufacturing, and heavy-duty repairs. Its setting time depends on the type of glue, environmental factors, and the materials being bonded. While some glues stick in seconds, others may require hours to achieve full strength. This article explores the timelines, factors, and tips to optimize the sticking process for industrial glues.

Understanding Industrial Glue Setting Times

The time it takes for industrial glue to stick varies based on its composition and intended use. Setting time can be broken into two key phases:

- Initial Bonding Time: The time it takes for the adhesive to create a temporary hold.

- Full Cure Time: The period required for the glue to achieve maximum strength and durability.

Types of Industrial Glue and Their Sticking Times

Epoxy Adhesives

- Initial Bonding Time: 5 to 30 minutes

- Full Cure Time: 24 to 72 hours

- Usage: Ideal for bonding metals, plastics, and ceramics in heavy-duty applications.

Polyurethane Adhesives

- Initial Bonding Time: 10 to 20 minutes

- Full Cure Time: 12 to 24 hours

- Usage: Commonly used in construction for wood, concrete, and porous materials.

Cyanoacrylate (Super Glue)

- Initial Bonding Time: 10 to 60 seconds

- Full Cure Time: 24 hours

- Usage: Suited for fast repairs on small, non-porous surfaces like plastic and metal.

Silicone Adhesives

- Initial Bonding Time: 5 to 10 minutes

- Full Cure Time: 24 to 48 hours

- Usage: Preferred for sealing and bonding glass, ceramics, and waterproof applications.

Hot Melt Adhesives

- Initial Bonding Time: 5 to 15 seconds

- Full Cure Time: Almost immediate upon cooling

- Usage: Used in packaging, woodworking, and quick assembly tasks.

Factors Affecting the Sticking Time of Industrial Glue

1. Environmental Conditions

- Temperature: Higher temperatures speed up curing, while colder environments slow the process.

- Humidity: Some glues, like cyanoacrylate, require moisture to cure faster.

2. Material Properties

- Porous Materials: Absorb adhesives, which can extend drying time.

- Non-Porous Surfaces: Provide a quicker bond due to the lack of absorption.

3. Glue Thickness

- Thin Layers: Cure faster due to greater exposure to air and moisture.

- Thick Layers: Take longer to set and may compromise bonding strength if improperly applied.

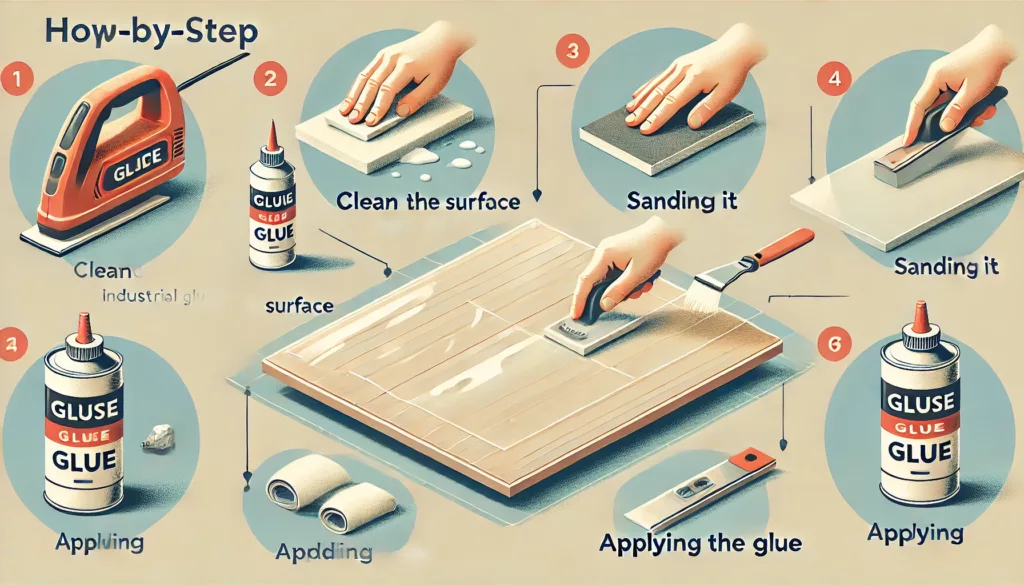

4. Surface Preparation

- Clean, dry, and sanded surfaces ensure better adhesion and faster curing. Contaminants like grease or dust can hinder the sticking process.

Tips to Ensure Proper Bonding with Industrial Glue

- Follow Manufacturer Guidelines: Always adhere to recommended application instructions for optimal performance.

- Use Clamps or Weights: Secure materials during curing to prevent movement and ensure a strong bond.

- Monitor Environmental Conditions: Apply glue in controlled environments with suitable temperature and humidity levels.

- Apply Evenly: Use a consistent layer of glue to avoid weak spots or uneven curing.

- Allow Full Curing Time: Avoid using bonded materials before the adhesive has reached its maximum strength.

FAQs

How can I speed up the drying time of industrial glue?

You can use heat guns, fans, or apply in warm environments to accelerate curing. However, ensure this aligns with the glue’s manufacturer recommendations.

Why is my industrial glue not sticking properly?

This may occur due to improper surface preparation, using the wrong type of glue, or applying it in unfavorable environmental conditions.

Can industrial glue be used on wet surfaces?

Certain adhesives, like polyurethane, can bond to damp surfaces, but most industrial glues require dry conditions for optimal results.

What happens if I move the materials before the glue cures?

Moving the materials can weaken the bond, resulting in poor adhesion. Always let the glue cure fully before handling.

Is full curing necessary for strong bonds?

Yes, while initial bonding may hold materials together, full curing ensures the adhesive reaches its maximum strength and durability.

What is the difference between curing time and drying time?

Drying time refers to when the surface of the glue becomes dry to the touch, while curing time is the total period needed for the adhesive to achieve full strength.

Conclusion

The time it takes for industrial glue to stick properly depends on the type of adhesive, materials, and environmental conditions. While initial bonding can occur in seconds to minutes, full curing may take up to 72 hours. By understanding the properties of different glues and following best practices, you can ensure strong and reliable bonds for your industrial projects.