In today’s world, manufacturers of industrial adhesives play a key role in the energy sector. They meet the growing need for industrial bonding solutions that are reliable and long-lasting. This is especially true for both traditional and renewable energy projects. It’s important to choose manufacturers wisely. The ones who provide energy sector adhesives that meet strict industry standards. High-performance adhesives boost the strength and efficiency of various energy applications. Learn more about these crucial adhesives at ZDS™.

Key Takeaways

- High-quality adhesives are critical for energy sector applications.

- Choosing the right manufacturer affects project success.

- Energy sector adhesives enhance structural integrity.

- Performance and durability are essential in industrial bonding solutions.

- Innovative adhesives support advancements in energy technologies.

Overview of Industrial Adhesives in the Energy Sector

Industrial adhesives are crucial in the energy sector. They enhance operational safety and efficiency. These adhesive products for energy industry applications help keep energy production and distribution components intact. It’s important to understand their role to choose the right adhesives for energy operations.

Importance of Adhesives in Energy Applications

Adhesives are key for bonding materials in the energy sector. They withstand extreme pressures and temperatures. This reliability is vital for the durability of wind turbines, solar panels, and machinery in oil and gas sectors. Their use leads to:

- Enhanced structural integrity

- Reduced weight of components

- Increased operational efficiency

- Improved resistance to environmental factors

Key Properties Required for Energy Adhesives

Choosing the right adhesive means looking at several important properties. Essential properties include:

- Temperature resistance: Must perform under different temperature changes.

- Chemical stability: Should resist solvents and hazardous substances.

- Environmental compatibility: Needs to meet eco-friendly standards.

- Bonding strength: Has to offer lasting material adhesion.

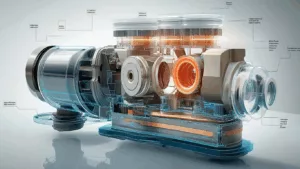

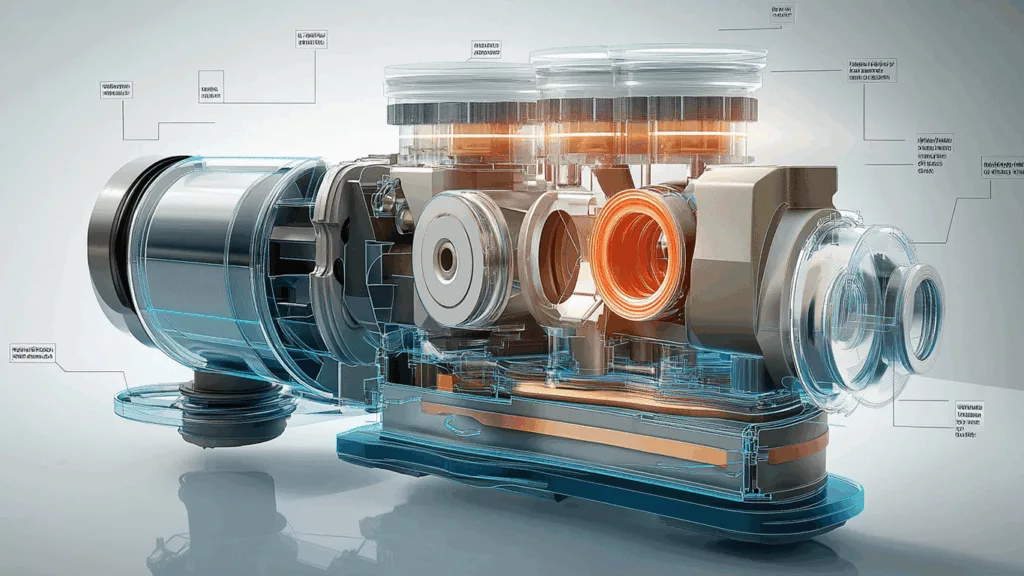

Types of Industrial Adhesives Used in Energy Projects

Understanding different industrial adhesives is key for energy projects. Each adhesive has a role, offering unique benefits. They help in ensuring structural strength and preventing leaks, boosting the success of power plants.

Structural Adhesives

Structural adhesives form strong, permanent connections. They are tough against stress and chemicals. These are used in wind turbines and solar panels to join metals, composites, and glass.

Sealants

Sealants stop leaks and protect from moisture. They are crucial for keeping parts like pipelines safe. By blocking water and dirt, they extend the life of energy systems.

Specialty Adhesives

Specialty adhesives meet specific energy project needs. Some resist high temperatures, perfect for oil and gas work. Others cure fast. This flexibility makes them invaluable in energy projects.

Top Manufacturers of Industrial Adhesives for Energy Sectors

In the energy sector, the role of top adhesive manufacturers is critical. They make innovative adhesive products for the energy industry. These are crucial for the reliability and efficiency of projects. We will look at some well-known brands and analyze their products and market strategies.

Leading Brands in the Adhesives Market

- 3M – Known for diverse industrial bonding solutions, 3M has adhesives for the energy sector’s tough demands.

- Henkel – A leader globally, Henkel offers advanced adhesive tech for energy applications, focusing on sustainability.

- Sika – Focused on structural integrity, Sika provides bonding solutions perfect for wind and solar projects.

- BASF – BASF creates innovative adhesives that enhance energy efficiency and longevity in installations.

Comparisons of Market Leaders

| Brand | Primary Product Lines | Market Presence | Innovations |

|---|---|---|---|

| 3M | Industrial tapes, structural adhesives | Strong in North America | Smart adhesive technologies |

| Henkel | Hybrid adhesives, sealants | Global presence | Eco-friendly formulations |

| Sika | Construction adhesives, sealants | Widely used in renewable energies | Advanced bond and seal technology |

| BASF | Polyurethane and epoxy adhesives | Global leader | Sustainability initiatives |

Applications of Industrial Adhesives in Energy Sectors

Industrial adhesives play a big role in energy sectors. They are used in wind, solar, and oil and gas energies. These materials help with assembly, upkeep, and making things last longer.

Wind Energy

Industrial adhesives are key in putting together turbine parts for wind energy. They keep things sturdy and handle tough weather. Highlights of their benefits include:

- Stronger bonds for rotor blades and nacelles

- Fighting off moisture and UV rays

- They make things lighter than old-school fastening

Solar Energy

Industrial adhesives are crucial for solar panels in the solar energy field. They help with quick setup and lasting durability. Key features include:

- Speeding up assembly and boosting efficiency

- Sealing tech that guards against weather damage

- Durable use with less upkeep needed

Oil and Gas

The oil and gas industry faces tough challenges, like extreme conditions. Specialty adhesives are designed for high-performance needs amid pressure and temperature changes. Important aspects include:

- Great resistance to chemicals and solvents

- Strong bonds that resist mechanical stress

- Perfect for joining different materials like metals and composites

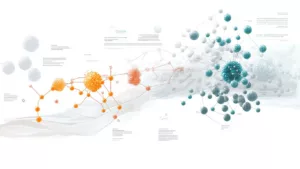

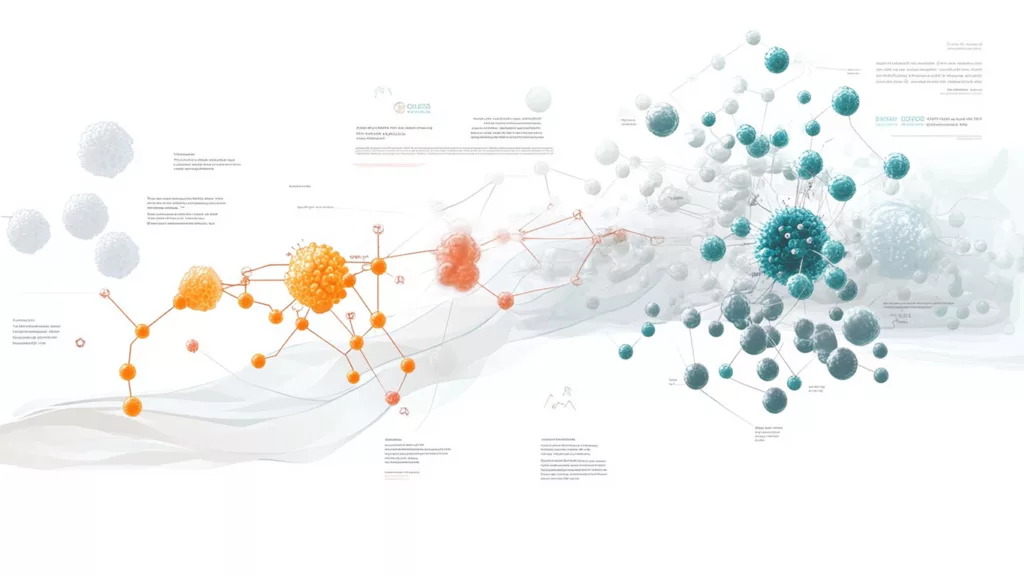

Innovations in Adhesives Technology for Energy

The energy sector is seeing fast growth in adhesive tech. Innovations focus on performance and making things more sustainable. These changes are key, especially for projects needing strong adhesion and quick curing times.

These advancements make things more efficient and reliable. That’s important for different energy projects.

Advances in Adhesive Materials

There have been big leaps in adhesive materials lately. These new developments are improving how things are bonded together for energy needs. Thanks to new recipes, adhesives can now resist environmental challenges better.

This means their bonds stay strong, even in tough situations. Advanced polymers and additives help these adhesives work well in many energy tasks. They also improve how energy systems like batteries manage heat and transfer energy.

Eco-Friendly Adhesive Solutions

As industries aim to be more green, there’s a push for eco-friendly adhesives. These products are both good for the Earth and meet high-performance standards. They’re part of a movement towards more sustainable manufacturing.

Using greener adhesives helps companies cut down on carbon emissions without sacrificing quality. ZDS™ is at the forefront, offering solutions that are good for both the planet and energy storage. Learn more about these innovative adhesives at this resource.

Standards and Regulations for Adhesives in Energy

In the energy field, sticking to standards and rules is key for safe glue use. These rules help with following laws and making green practices in the industry. It’s crucial for companies to get how important these rules are to do well today.

Industry Compliance Requirements

The energy industry has specific standards for glues. Meeting these standards ensures that operations run smoothly and safely. They focus on:

- Following ISO and ASTM details

- Being compatible with materials used in energy

- Passing durability tests under harsh conditions

- Being certified as non-polluting

Environmental Regulations

Energy product makers face strict environmental rules. Following these helps protect nature and promotes eco-friendly practices. Key points include:

- Limits on harmful substances in glues

- Requirement for checking environmental effects

- Rewards for creating greener glue options

- Rules for disposing and recycling glues

Working with these standards boosts product quality. It also makes companies stand out while they take care of the planet and safety issues.

Challenges Faced by Adhesive Manufacturers

The energy sector brings big challenges in making adhesive. These problems greatly impact the success and workability of projects. It’s key for makers to know these issues to provide top-notch adhesive solutions.

Performance Under Extreme Conditions

Adhesive makers face tough demands for performance under extreme conditions. In energy settings, things like:

- High temperatures

- Corrosive environments

- Vibrations and dynamic loads

can mess with how well the adhesive sticks and how long it lasts. To beat these challenges, they need advanced materials and lots of tests. This ensures the adhesive works well everywhere.

Cost-Sensitivity in Energy Projects

Cutting costs is a big challenge too. In energy projects that need to save money, makers feel the push to lower expenses but still keep quality high. This situation leads to challenges in adhesive manufacturing that need:

- Efficient sourcing of raw materials

- Streamlined production processes

- Innovative formulation techniques

Finding a balance between keeping costs down and meeting high standards is tough. It’s crucial for makers to come up with cost-effective methods that don’t hurt the quality of their products.

Future Trends in Adhesives for the Energy Sector

The energy sector’s adhesive landscape is changing fast. New technologies and market changes are shaping the future of adhesive solutions. This leads to an increase in demand for better bonding materials.

This trend points to exciting growth in the adhesive market. Knowing these trends helps industry members stay ahead.

Predictions for Market Growth

Experts foresee strong growth in the adhesive sector. This growth is fueled by new technologies and the demand for effective energy solutions. The key factors pushing this growth include:

- Growing investment in renewable energy projects.

- Increased focus on sustainable manufacturing practices.

- Technological advancements leading to more adaptable adhesive products.

These developments will likely spur adhesive market growth. The shift towards eco-friendly solutions will attract more users. This opens up new market chances.

Emerging Technologies in Adhesives

New advancements are changing the energy sector’s adhesives. Exciting trends are emerging:

- Smart adhesives: They have sensors for timely monitoring.

- Bio-based adhesives: Made from natural resources to lessen environmental harm.

- High-performance adhesives: These provide strong bonds under harsh conditions.

Getting on board with these new trends will put manufacturers in a good spot. They’ll be ready for future advancements in this important market.

| Technology | Description | Impact on Industry |

|---|---|---|

| Smart Adhesives | Adhesives that can communicate environmental changes | Increased safety and performance monitoring |

| Bio-based Adhesives | Adhesives made from renewable resources | Reduction in carbon footprint |

| High-performance Adhesives | Adhesives designed for extreme conditions | Enhanced application in rugged environments |

How to Choose the Right Adhesive for Energy Applications

Finding the right adhesive for energy projects is vital. Optimal performance and longevity depend on it. Consider the environment, how well the adhesive works with your materials, and how you’ll apply it. We’re here to guide you and provide expert advice on picking adhesives.

Factors to Consider

- Substrate Compatibility: Make sure the adhesive sticks well with the surfaces you’re joining.

- Environmental Conditions: Think about how heat, water, and chemicals might affect it.

- Cure Time: Pick adhesives that harden in the time you have.

- Strength Requirements: Assess how much stress the bond will face.

- Application Method: Choose the right formula depending on if you’re applying it by hand or machine.

Expert Recommendations

Industry experts advise testing adhesives under actual conditions before making a choice. Brands like 3M and Loctite offer a wide selection for energy projects. When selecting, keep the following in mind:

- Pick adhesives that meet specific standards for the energy sector.

- Choose options known for their durability and strong bond.

- Look for adhesives that have proven successful in similar projects.

Case Studies: Successful Adhesive Solutions in Energy

This section dives into key examples showcasing successful adhesive applications in energy. We explore how advanced adhesive technologies are vital. They improve efficiency and durability in various projects.

Wind Turbine Assembly

In assembling wind turbines, structural adhesives play a key role. They ensure the components are firmly joined. An Iowa project used a top-notch epoxy adhesive. It outperformed traditional methods in load support and fighting environmental wear. This led to a more robust assembly with fewer parts. Thus, it cut down the installation time and costs.

Solar Panel Installation

Solar panel setups greatly benefit from specialized sealants. They shield the systems from the weather. A project in California chose a polyurethane sealant for its flexibility and toughness. It made the application smoother and boosted the solar panels’ defense against dampness and temperature changes.

| Application | Adhesive Type | Key Benefits | Location |

|---|---|---|---|

| Wind Turbine Assembly | Epoxy Adhesive | High load-bearing, reduced components, cost-effective | Iowa |

| Solar Panel Installation | Polyurethane Sealant | Moisture resistance, temperature flexibility, easy application | California |

Conclusion: The Role of Adhesives in Energy Sector Advancements

Adhesives play a huge role in the energy sector. They make energy infrastructure perform better and last longer. From wind turbines to solar panels, adhesives help in various energy applications.

Our goal is to create special adhesives for specific needs. For energy storage battery packs, we make adhesives that handle heat well and resist chemicals. These adhesives improve safety and life span in energy solutions.

Looking forward, advanced adhesive technologies are key for a greener energy future. We commit to high-quality products that meet our clients’ needs while being eco-friendly. For more info on our innovative adhesives, please visit this page.

FAQ

What types of industrial adhesives are commonly used in the energy sector?

The energy sector uses many industrial adhesives. These include structural adhesives for strong bonds, sealants to stop leaks, and special adhesives for certain uses. Each type meets the specific needs of energy projects.

Why are high-strength adhesives essential for energy applications?

High-strength adhesives are crucial in the energy field. They ensure structures are strong and last long, even in tough conditions. They can handle changes in temperature, chemical exposure, and physical stress. This is vital for keeping energy systems working well.

What should I consider when choosing adhesives for energy applications?

Choosing adhesives for energy uses requires careful thought. Look at factors like how well they stick to different materials, how they handle temperature changes, how quickly they set, and the surrounding environment. Getting advice from experts for your specific project is also smart.

How do innovations in adhesive technology impact the energy sector?

Advances in adhesive tech bring positive changes to the energy sector. New eco-friendly options and better material performance increase efficiency, cut down on harmful effects to the planet, and help meet strict industry rules.

What are the challenges faced by adhesive manufacturers in the energy sector?

Manufacturers of adhesives for energy face tough challenges. They must ensure their products work well under extreme conditions like high heat and corrosive environments while also watching costs. It’s a delicate balance, but necessary for creating reliable adhesives.

Can you provide examples of successful adhesive applications in the energy sector?

Certain successful uses of adhesives in energy are noteworthy. For instance, building wind turbines uses structural adhesives to deal with heavy loads. Putting up solar panels often needs special sealants. These sealants make the panels more durable and protect them from weather and other environmental threats.

What regulations must adhesive products comply with in the energy industry?

Adhesives in the energy field must follow strict rules to ensure safety and effectiveness. This includes laws about the safety of materials and limits on dangerous chemicals. All this is to make adhesive production more environmentally friendly.