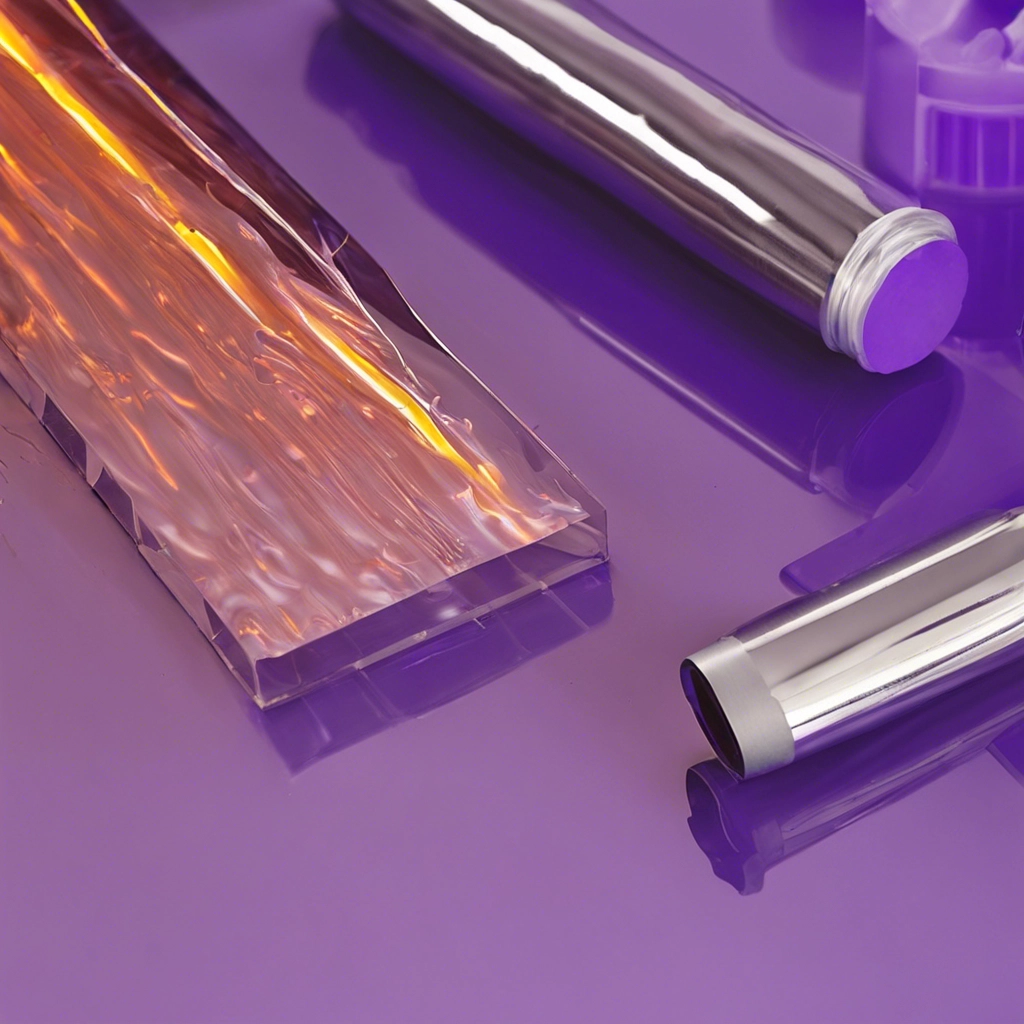

Ultraviolet light is changing how structural acrylic adhesives work in industrial adhesion. This innovation is changing how professionals approach complex bonding challenges across various industries. ZDS™ is a leader in the revolution, making advanced UV light adhesive that meets tough requirements. In this article, we will explore the benefits, uses, and recommended methods for UV curing acrylic adhesives.

What Are UV Light Curing Acrylic Adhesives?

What Are UV Light Curing Acrylic Adhesives?

The Unseen Power of UV Cure

Advantages of UV Light Curing Adhesive Systems

- Rapid Processing: UV curing systems drastically reduce waiting times with cure speeds that enable immediate handling and further processing.

- High Shear and Peel Strength: Structural acrylic adhesives, once cured, offer exceptional shear and peel strength, creating durable bonds fit for heavy-duty applications.

- Superior Temperature Range: These adhesives retain their properties across a wide temperature range, ensuring reliability under various environmental conditions.

- Versatility in Substrate Compatibility: From glass and metals to plastics and rubbers, UV light curing acrylic adhesives form strong bonds with an array of materials.

- Ease of Automation: Their nature allows for easy integration into automated lines, enhancing productivity and consistency.

- Improved Aesthetics: The clear cure of many UV adhesives means that they can be used in visible areas without affecting the design integrity of the product.

Finding the Best UV Light Curing Acrylic Adhesive

- Cure Speed: Assess how quickly the adhesive cures to ensure it aligns with production timelines.

- Viscosity: Evaluate whether a lower-viscosity adhesive for tight fits or a higher-viscosity adhesive for filling larger gaps is needed.

- Bond Strength: Determine the required strength of the adhesive bond to endure the stresses of the application.

- Temperature Resistance: Consider the operating temperature range the adhesive must withstand.

- Substrate Compatibility: Confirm that the adhesive works effectively with the specific types of materials involved.

- UV Wavelength and Intensity Requirements: Ensure that the UV light source matches the adhesive’s specifications for proper curing.

Not All UV Lights Are Created Equal: Best UV Light for Curing Glue

Applications Where UV Light Curing Acrylic Adhesives Shine

The versatility of UV light curing acrylic adhesives makes them suitable for numerous applications, such as:

- Electronics Manufacturing: For bonding components in devices where rapid assembly is key.

- Glass and Acrylic Fabrication: Creating invisible joints in items like aquariums, display cases, and architectural features.

- Automotive Assembly: In areas requiring strong, rapid bonds capable of withstanding vibration and thermal cycling.

- Medical Device Manufacturing: When bio-compatibility and sterilization resistance are paramount.

- Jewelry and Art Crafting: Allowing for precision bonding of delicate parts with minimal visibility of the adhesive.

UV Glue for Acrylic: A Match Made in Transparency

Getting the Most out of Your UV Light Activated Glue

- Always clean and prepare surfaces before applying the adhesive to remove any contaminants that could impede bond strength.

- Use the manufacturer-recommended intensity and wavelength of UV light to ensure complete curing.

- Apply the adhesive in the recommended thickness—too little or too much can affect curing and bond strength.

- Employ fixtures or jigs to hold components in place during the curing process for accurate alignment.

- Store UV adhesives according to guidelines to maintain their shelf life and effectiveness.

Navigating the Market: UV Glue for Glass Prices

Conclusion: The Strategic Choice in Adhesive Technology

Advances in UV light curing acrylic adhesives are causing changes in many industries. These adhesives are fast, strong, and versatile. Choosing the right adhesive is important. It can improve product quality, efficiency, and customer satisfaction.

Businesses are using UV curing technologies to innovate and compete in new ways. UV light curing adhesives will keep growing, offering a bright future for precise and reliable material bonding.