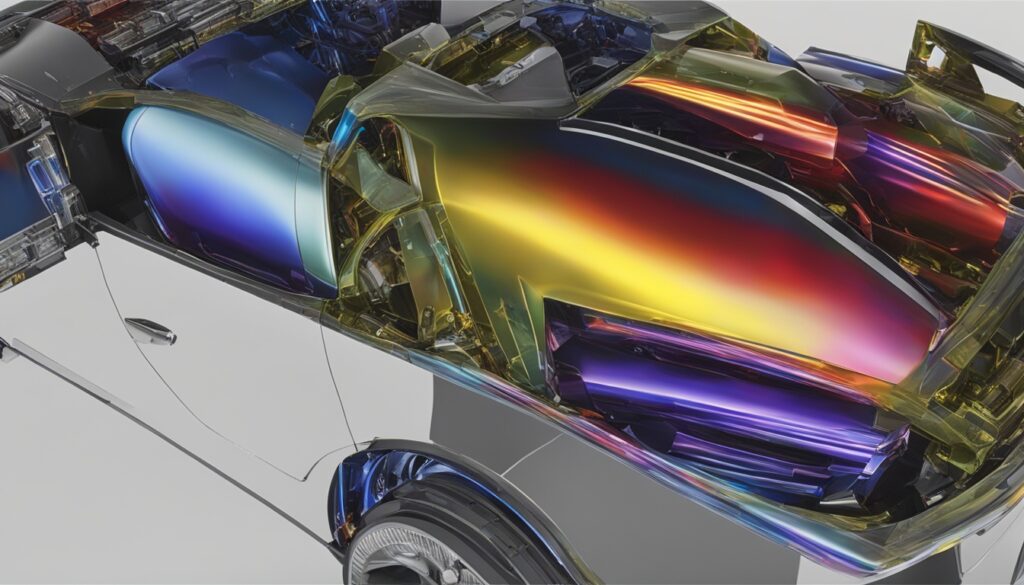

New energy vehicles (NEVs) are changing fast. They need advanced adhesives for motor magnetic tile bonding. This is key in making electric motors. Motor magnetic tile bonding means attaching magnetic tiles to the motor’s rotor or stator. The right adhesives must handle electric motors’ working conditions. They need to be strong against heat, chemicals, and physical forces.

At ZDS™, we create top-notch adhesives for NEVs. They boost performance and trustworthiness. Our special motor magnet glue makes the bonding better. This helps electric motors in these vehicles work better and last longer.

Key Takeaways

- Motor magnetic tile bonding is essential for the performance of electric motors in new energy vehicles.

- Advanced adhesive solutions are required to withstand the operating conditions of electric motors.

- Thermal stability, chemical resistance, and mechanical strength are key properties of effective adhesives.

- ZDS™ offers specialized adhesives designed for the unique requirements of NEVs.

- Proper bonding enhances the performance and reliability of electric motors in new energy vehicles.

Introduction to Motor Magnetic Tile Bonding

Fastening magnets in electric motors is crucial. We use special glues, called tile bonding agents, for this job. The magnets are placed perfectly to make motors run well and last long.

What is Motor Magnetic Tile Bonding?

This process sticks permanent magnets to motor parts securely. It’s key for electric motors to work well for a long time. By bonding magnets properly, vehicles perform better.

Importance in New Energy Vehicles

Electric motors are vital for eco-friendly cars. Motor magnetic tile bonding boosts a motor’s power, making cars run more efficiently. It is essential for high-performance electric cars.

Proper bonding improves how well motors turn electricity into motion. The right binding material takes car performance up. This helps the push for cleaner, smarter car technology.

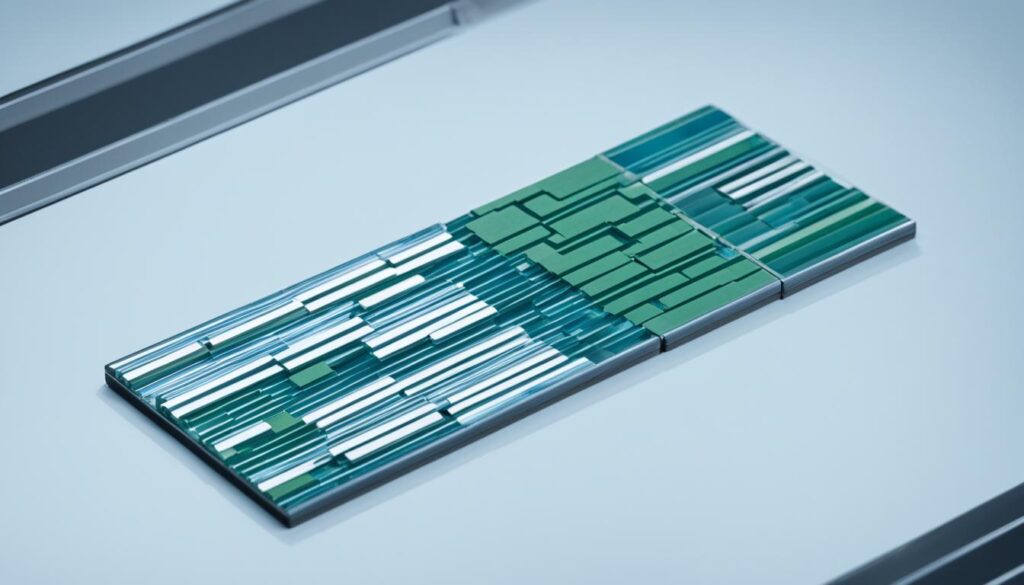

Types of Magnetic Tile Adhesives

Choosing the right magnetic tile adhesive is very important. It affects how motor magnetic tiles stick in new energy vehicles. You have three main kinds: epoxy-based adhesives, silicone-based adhesives, and polyurethane adhesives. Each type offers different advantages for various working conditions.

Epoxy-Based Adhesives

Epoxy adhesives are known for their strong bond and resistance to chemicals. They work well in situations that need handling high stress and staying stable at high temperatures. These adhesives are perfect for the tough conditions electric vehicles face.

Silicone-Based Adhesives

Silicone adhesives stand out for their flexibility and ability to resist heat. They are great for materials that expand or shrink with temperature changes. This makes them a solid option for new energy vehicle parts, ensuring the bond stays strong through temperature shifts.

Polyurethane Adhesives

Polyurethane adhesives are adaptable, showcasing strength and resistance to environmental factors like moisture and vibrations. These qualities make them fit for the dynamic needs of electric vehicles. They also offer some flexibility, helping to lessen stress where the materials are joined.

To pick the best adhesive, manufacturers must understand each type’s unique traits. Whether it’s the bond strength of epoxy, the flexibility of silicone, or the toughness of polyurethane, the right adhesive improves new energy vehicles’ performance and durability.

For more details on strong adhesives, check out our detailed guide on adhesive solutions for new energy vehicles. Here, we cover the latest in adhesive technology and its uses.

Benefits of Using Motor Magnetic Tile Bonding

Motor magnet bonding boosts the durability and efficiency of electric motors in new energy vehicles. This is done using advanced adhesive solutions. These solutions help motors perform better and last longer.

Enhanced Durability

High-quality adhesives increase the durability of magnetic tiles. They can handle tough environments. This means less wear and tear on motor parts.

Companies like ZDS™ offer products that stand up to extreme conditions. They keep magnetic tiles strong over time. For example, ZDS-169AB and ZDS-14167 help secure battery cells and manage heat. They resist shaking and ensure the motor lasts long.

Improved Efficiency

Choosing the right adhesive makes motors more efficient. It reduces energy loss and increases output. This helps new energy vehicles perform better.

The motor faces less mechanical stress with a strong bond. It runs more smoothly, using energy better. Products from ZDS™ play a big role in enhancing performance. They help meet the high standards of modern transport.

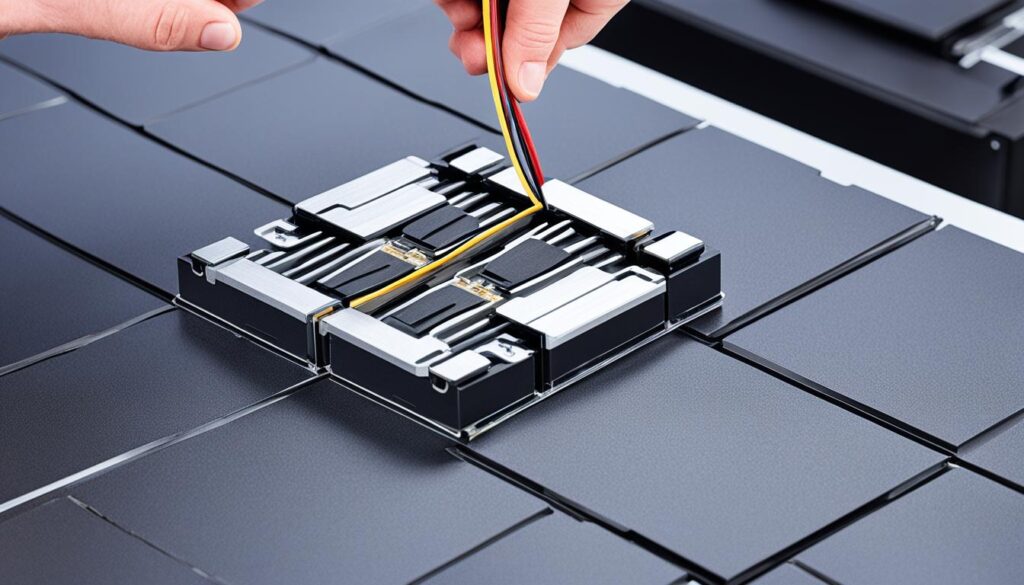

Application Methods for Motor Magnetic Tile Bonding

Motor magnet bonding has several key steps for the best results. It starts with good surface preparation.

Surface Preparation

Surface preparation is key for a strong bond. It makes sure the adhesive sticks well and lasts. Important steps include:

- Cleaning: It’s vital to remove dirt, grease, and oil. Clean surfaces ensure a stronger bond.

- Abrading: Creating a rough surface by sanding helps the adhesive hold better.

- Priming: A primer can boost adhesion, especially on tough surfaces.

Adhesive Application Techniques

After preparing the surfaces well, we focus on adhesive application. There are different bonding techniques:

- Manual Dispensing: This method uses hand tools like syringes for precision in small spots. It’s not the quickest for bigger tasks.

- Automated Systems: These systems ensure even adhesive spread, perfect for lots of products. They’re fast and make fewer mistakes.

- Spray Application: Good for covering large, flat areas evenly.

Choosing the right technique improves the bond’s strength, look, and durability. It makes sure the bond lasts and performs well.

For tougher bonding jobs, ZDS™ adhesives are top-notch. They’re made for different automotive needs, offering dependable and long-lasting results.

Choosing the Right Motor Magnet Bonding Adhesive

When picking motor magnet adhesive, it’s vital to know the core factors. The choice of adhesive impacts motor performance and life. It’s key to look at important features.

Factors to Consider

Choosing the right motor magnet bonding adhesive means looking at several things:

- Operating Temperature: The adhesive must handle the motor’s temperature range well.

- Environmental Stress: It should stand up to moisture, chemicals, and shakes.

- Curing Time: A fast cure time helps in making motors quickly but must keep the bond strong.

- Material Compatibility: It’s important the adhesive works with the motor’s materials, like the magnet and frame.

Common Mistakes to Avoid

Steering clear of usual errors saves time and effort. Some common blunders are:

- Improper Surface Preparation: Not cleaning surfaces well can cause weak bonds.

- Overuse of Adhesive: Using too much adhesive might mess with motor parts.

- Ignoring Manufacturer Recommendations: It’s best to follow the guidelines given by the adhesive maker.

Thinking about these key points and avoiding mistakes helps in picking the right adhesive for motor magnets.

Ceramic Magnet Bonding Solutions

Bonding ceramic magnets in motors is both a challenge and an opportunity. This is because these magnets are cost-effective and resist demagnetization well. As we explore special glues for ceramic magnets, it’s crucial to use formulas that fit their unique needs. Our motor magnet adhesive guarantees strong and long-lasting performance under tough conditions.

ZDS™ offers high-tech glues specifically made for ceramic magnets. These glues are strong yet flexible. This means magnets stay put and can handle the stress and shaking motors might cause.

Let’s now compare some key features of these glues:

| Adhesive Type | Bond Strength | Flexibility | Cost Efficiency |

|---|---|---|---|

| Epoxy-Based | High | Moderate | Medium |

| Silicone-Based | Moderate | High | High |

| Polyurethane | Medium | Medium | High |

Knowing about different glues helps us improve motor durability. We aim to offer glues that meet the special needs of bonding ceramic magnets. This way, motors work better and last longer.

Magnet Assembly Adhesive for New Energy Vehicles

In the world of new energy vehicles, magnet assembly adhesives are very important. They make sure parts stick together well, making electric motors better and last longer. Let’s look into why this adhesive is a top choice and how to use it the best way.

Why Choose Magnet Assembly Adhesive

Selecting a magnet assembly adhesive comes down to its strong bonding power. These adhesives can handle the tough conditions of new energy vehicles. They stand up to heat changes and force without breaking down, helping the vehicle work well for longer.

They also make motor assemblies more efficient. This helps manufacturers make cars faster. The strong bonds reduce the need for repairs, keeping the vehicles running smoothly for a longer time.

Adhesive Best Practices

To get the best bonds, it’s key to use adhesive best practices. Here are some important tips:

- Surface Preparation: Clean all surfaces before applying the adhesive. This makes sure the adhesive sticks better, creating stronger bonds.

- Correct Adhesive Application: Apply the adhesive exactly as recommended. This usually means a even layer on all parts to be joined.

- Curing Process: Follow the right curing time and conditions. The right curing makes the adhesive as strong and lasting as possible.

Using these adhesive best practices helps magnet assembly adhesives work their best. This leads to reliable and efficient new energy vehicles.

Innovations in Permanent Magnet Bonding

The need for new energy vehicles is rising. So, the spotlight is on permanent magnet bonding. This process is key to making electric motors better and more efficient. We work with top names and research spots, like Ames Laboratory, to create innovative adhesive solutions. These solutions fit the tough demands of top-notch electric vehicles.

With cutting-edge technology, our adhesives are now stronger and can handle heat better. These steps forward help make electric motors more reliable. They also cut costs by depending less on rare earth elements. The U.S. Department of notes these innovations as key for future cars.

We’re also checking out magnets that don’t rely on rare earth materials. This move comes as those materials get pricier. Our new mixes make magnets stronger without using those costly materials. This achievement is big news for permanent magnet bonding. It means better efficiency and lower materials cost.

| Advancements | Benefits |

|---|---|

| Enhanced Adhesive Formulations | Increased motor efficiency and reliability |

| Thermal Stability | Longer lifespan of components |

| Non-Rare Earth Magnet Systems | Cost reduction and resource sustainability |

Our ongoing research and development are making waves in the auto industry. The advances in permanent magnet bonding show how cutting-edge technology will drive the future of eco-friendly vehicles.

How ZDS™ Adhesives Stand Out

In the world of motor magnetic tile bonding, ZDS™ adhesives lead the pack. They shine in several important areas, making them stand out. They are the go-to choice for new energy vehicles because of their unique qualities.

One top benefit of ZDS™ adhesives is their amazing bond strength. They are made to keep magnetic tiles in place, even under tough conditions. This makes motors in new energy vehicles more durable and reliable.

Another big plus is how well ZDS™ adhesives handle heat. They stay strong even when it gets really hot. This is key for modern electric motors to work well. It means there’s less chance the bond will weaken over time.

Also, ZDS™ adhesives are easy to use. They can be applied smoothly and quickly, saving time and money. This is especially good for making lots of products efficiently and consistently.

Here’s a comparative table showcasing the standout features of ZDS™ adhesives:

| Feature | ZDS™ Adhesives | Standard Adhesives |

|---|---|---|

| Bond Strength | High | Medium |

| Thermal Resistance | Excellent | Good |

| Ease of Application | User-Friendly | Moderate |

ZDS™ adhesives top the charts by solving major issues like durability, efficiency, and ease of use in motor bonding. Their outstanding performance means they meet magnet joining adhesive needs perfectly. This cements ZDS™’s leadership in the adhesive technology field.

Expert Tips on Magnet Joining Adhesive

We explore expert advice on using magnet adhesive well. Learning the right steps from industry pros is key for top adhesive results. This covers everything from getting ready to putting it on. These tips lead to better results.

Dos and Don’ts

- Do: Clean and prep surfaces well before applying the adhesive. Good preparation means stronger, lasting bonds.

- Don’t: Avoid applying adhesive to surfaces that aren’t ready or are dirty. Doing so can cause weak bonds and failures.

- Do: Stick to the maker’s instructions for mixing and applying the adhesive. This ensures the best results.

- Don’t: Never speed up the curing process. Give the adhesive enough time to cure, ensuring peak performance.

Tips from Professionals

Experts share their best tips for using magnet joining adhesive:

- Make sure parts line up right before the adhesive sets. If they don’t, the bond might not hold well.

- Use the right clamps to keep surfaces together while the adhesive cures. This helps form a strong bond.

- Check the bond often for any signs of trouble. Fixing issues early can stop bigger problems later.

Following these pro tips and advice helps makers create strong, lasting bonds with magnet adhesives. The focus on doing things right ensures great adhesive performance. This makes motors more efficient and durable.

Conclusion

We’ve looked into motor magnetic tile bonding deeply. It’s clear these top-notch adhesives are key for better electric motors in new energy vehicles. Choices range from epoxy to silicone-based adhesives, and cutting-edge options like those from ZDS™.

The benefits are huge: improved strength and performance. In the changing world of cars, these advanced glues help push electric motors forward. Brands like ZDS™ lead the way with special adhesives that meet tough demands. This shines a light on a promising future for this field.

To wrap up, always innovating in motor magnetic tile bonding is crucial for electric motors that last longer and work better. We urge experts to keep up with these technologies and use them in their work. For more info on these top adhesives, check out the ZDS™ website.

FAQ

What is Motor Magnetic Tile Bonding?

Motor magnetic tile bonding attaches magnetic tiles to a motor’s parts with special glues. It’s key for electric motors in new cars, giving them strength and resistance against heat and chemicals.

Why is Motor Magnetic Tile Bonding important in New Energy Vehicles?

It’s vital for making electric motors efficient and long-lasting. Advanced glues increase power conversion and support better car performance. They’re part of the shift towards greener cars.

What types of adhesives are used for Motor Magnetic Tile Bonding?

We use epoxy, silicone, and polyurethane glues for bonding. Each is chosen for its special qualities. They fit different needs and conditions in electric cars.

What are the benefits of using motor magnetic tile bonding?

This method boosts motor strength and effectiveness. Good glues lower damage risk, fight tough conditions, and keep magnetic tiles intact. It means less energy waste and more power.

How are motor magnetic tiles bonded to surfaces?

First, we make the surfaces clean and ready. Then, we apply glue either by hand or with machines. This ensures a solid, even bond.

What factors should be considered when choosing a motor magnet bonding adhesive?

Think about temperatures, environmental stress, cure time, and materials. The right glue choice is key for the best motor performance and durability.

How does ZDS™ adhesive differ for ceramic magnet bonding?

ZDS™ offers glues made for ceramic magnets. They’re focused on being cost-effective and resistant to losing magnetism. These glues keep motors working well in specific uses.

Why is magnet assembly adhesive crucial for new energy vehicles?

It’s key for assembling motor parts securely in new cars. The adhesive handles tough conditions, keeping cars reliable and effective.

How are innovations in permanent magnet bonding advancing new energy vehicles?

New glue formulas and ways to use them are helping electric motors. These changes lead to better and more dependable green cars.

What sets ZDS™ adhesives apart in motor magnetic tile bonding?

ZDS™ glues excel in bonding strength, heat resistance, and ease of use. They make ZDS™ a top choice in the green car market.

What are some expert tips for using magnet joining adhesives?

Tips include preparing surfaces right, following instructions, and choosing suitable glues. Experts say these steps help achieve the best glue performance and motor building.