Keeping your circuit boards in top shape is key. A solid PCB protection coating is vital for this. It defends against hazards like moisture, dust, and chemicals. This defense helps your devices last longer and work better. ZDS™ offers top-notch PCB adhesive sealants for various needs. So, your electronics are safe, no matter where they are.

Key Takeaways

- PCB coating adhesives enhance the durability and functionality of circuit boards.

- They prevent corrosion, electrical malfunctions, and environmental damage.

- ZDS™ offers customized pcb protection coatings for different applications.

- Proper selection of PCB adhesives ensures longevity and reliability.

- Utilizing ZDS™ solutions helps maintain electronic integrity.

Introduction to PCB Coating Adhesives

Printed circuit board adhesives are key in keeping electronic devices safe. They create a protective layer against moisture, dirt, and other harmful substances. This helps the devices last longer and work better.

What is a PCB Coating Adhesive?

A PCB coating adhesive is a special material used on printed circuit boards. It protects them from bad environmental effects. This kind of adhesive prevents short circuits and electrical issues by insulating well.

The Importance of PCB Coating Adhesives in Electronics

Printed circuit board adhesives are very important in electronics. They safeguard the circuit boards, improving device performance and lifespan. This means less maintenance and fewer replacements are needed. Such adhesives make sure devices run smoothly, even in tough conditions.

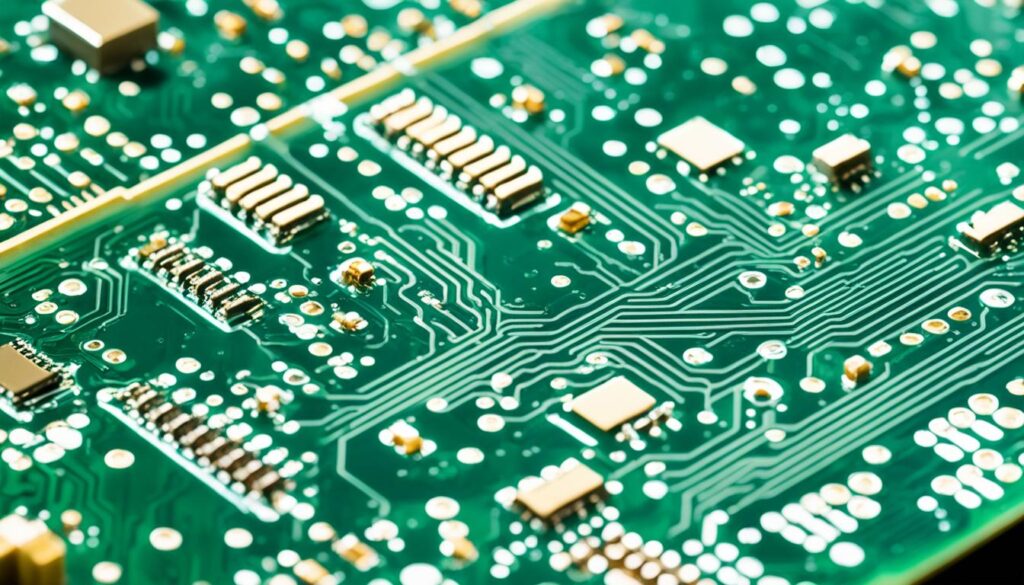

Types of PCB Coating Adhesives

Printed circuit boards (PCBs) need protection against various conditions. Different PCB coating materials help ensure they work well and last long. These materials are different in how they’re used and what they do.

Acrylic coatings are great for keeping out moisture and fungus. They’re also easy to put on and fix if you need to. They’re perfect for many uses because of this.

Silicone coatings are best for places with big temperature changes. That’s because they can handle heat well and are flexible. You’ll find them in cars and planes, thanks to their great performance in extreme conditions.

Urethane coatings stand out because they resist chemicals like solvents. They protect very well but are harder to fix or replace than acrylic ones.

Epoxy coatings are very strong and protect against electrical issues. They create a sturdy layer, making them ideal for heavy-duty industrial uses. This is due to their toughness and ability to insulate well.

| Type | Key Properties | Applications |

|---|---|---|

| Acrylic | Moisture and fungus resistance; easy rework | General-purpose |

| Silicone | Thermal stability; flexibility | Aerospace, automotive |

| Urethane | Chemical resistance | Industrial |

| Epoxy | Mechanical strength; dielectric properties | Industrial |

Choosing the right pcb coating is crucial. You must think about the PCB’s environment and stresses. ZDS™ offers a wide selection of PCB coatings for different needs, including for space and home gadgets. It’s all about understanding each coating’s special traits and uses to protect your PCB the best way.

Benefits of Using Printed Circuit Board Adhesives

Printed circuit board adhesives are great for many uses in electronics. They help improve how circuit boards perform and last. This is important for making your electronics better.

Enhanced Durability and Reliability

Using circuit board adhesive makes things more durable and reliable. It creates a strong bond. This bond keeps electronic parts safe and working well for a long time. As electronics get smaller and more complex, we need strong adhesives to keep everything together.

Protection Against Environmental Factors

Conformal coating adhesive also protects against bad environmental factors. Things like humidity, salt spray, and changes in temperature can harm PCBs. But this type of adhesive keeps your circuit boards safe. It makes sure they work well, even in tough conditions. This is very important for electronics used in cars and planes.

At ZDS™, we focus on making your products last longer and work better. With top-notch circuit board and conformal coating adhesives, you save time and money. You won’t have as many problems later on.

Choosing the Right PCB Coating Material

When picking the right pcb coating adhesive, think about a few key things. These are how well it conducts heat, its insulating power, flexibility, and how easy it is to apply. Each aspect is vital for the product’s performance and life span, making your choice important.

Factors to Consider for Adhesive Selection

To pick the best adhesive for pcb coating, keep these points in mind:

- Thermal Conductivity: This is about how the adhesive handles heat.

- Dielectric Strength: This tells us how good it is at insulating.

- Flexibility: This shows if the adhesive can handle different conditions well.

- Ease of Application: This affects how quick and easy it is to use.

Comparing Different Adhesive Materials

It’s key to compare to find a good mix of cost and function for an adhesive for pcb coating. Below is a table to help you see your choices:

| Material | Thermal Conductivity | Dielectric Strength | Flexibility | Ease of Application |

|---|---|---|---|---|

| Epoxy Resin | Medium | High | Low | Medium |

| Silicone | High | Medium | High | High |

| Polyurethane | Low | High | Medium | Medium |

Our team at ZDS™ is here to help you find the perfect pcb coating adhesive. Whether you’re looking at heat management, insulating power, or flexibility, we offer tailored solutions. We’re ready to meet your specific needs.

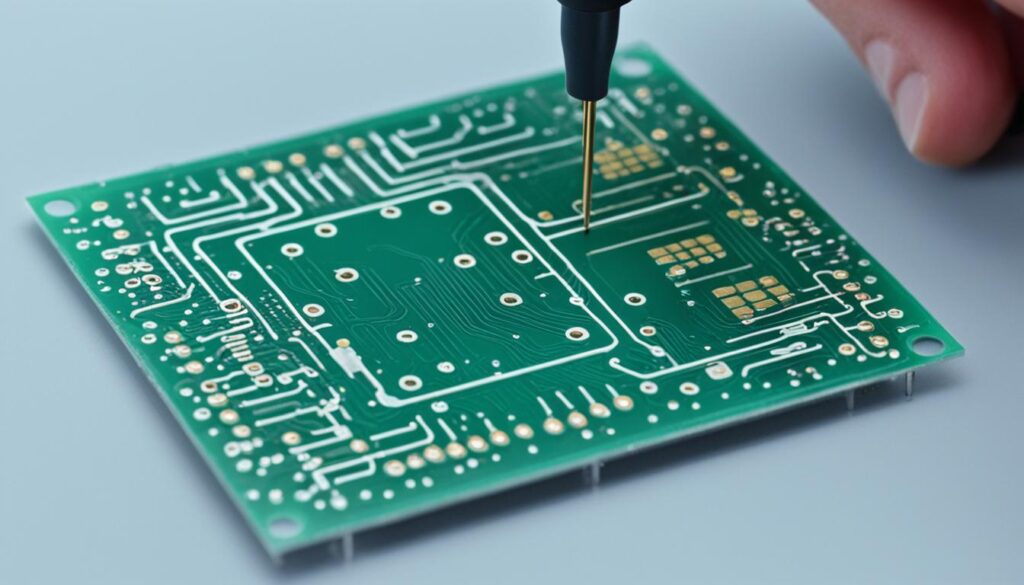

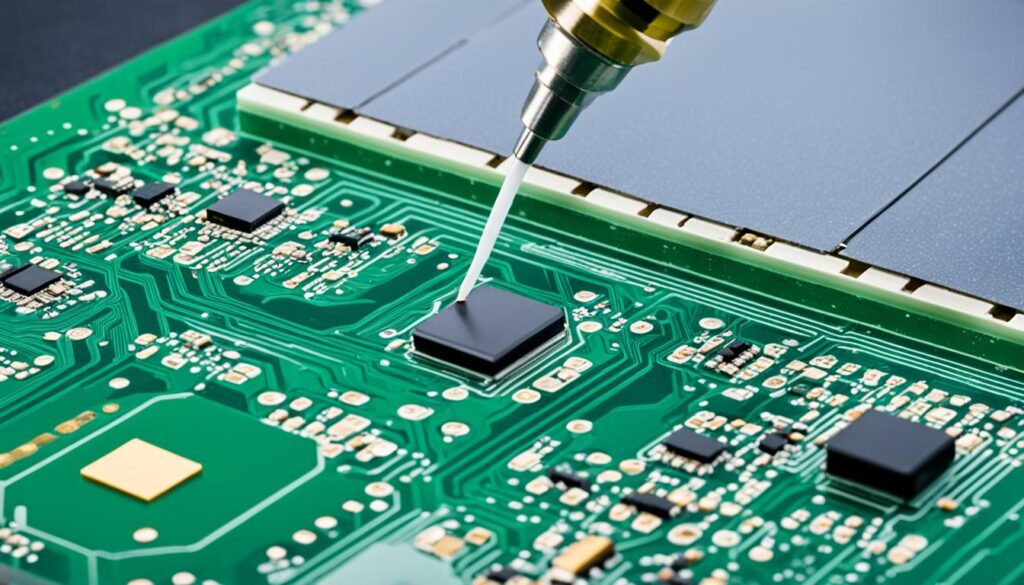

Applying Adhesive for PCB Coating: Best Practices

Using the right pcb coating adhesive application techniques is key for the best protection of electronic devices. It is essential to follow certain practices while applying pcb coatings. This ensures their effectiveness.

Clean all surfaces first. This means getting rid of oils, dust, and moisture that can affect the adhesive. Choosing the right way to apply the adhesive is also crucial. Options include manual spraying, automated spraying, selective coating, dipping, and brushing. The essential guide to conformal coating offers more insights into these methods. It helps in picking the best one for your project.

Following pcb adhesive best practices includes giving enough time for curing. This step makes the adhesive set properly and creates a strong protective layer. The manufacturer’s advice on curing times and conditions can greatly impact coating success.

ZDS™ provides detailed guidance and quality products to ensure your pcb coating adhesive application meets the mark. By adopting these practices, we boost the durability and reliability of electronic components. This protects them from different environmental issues.

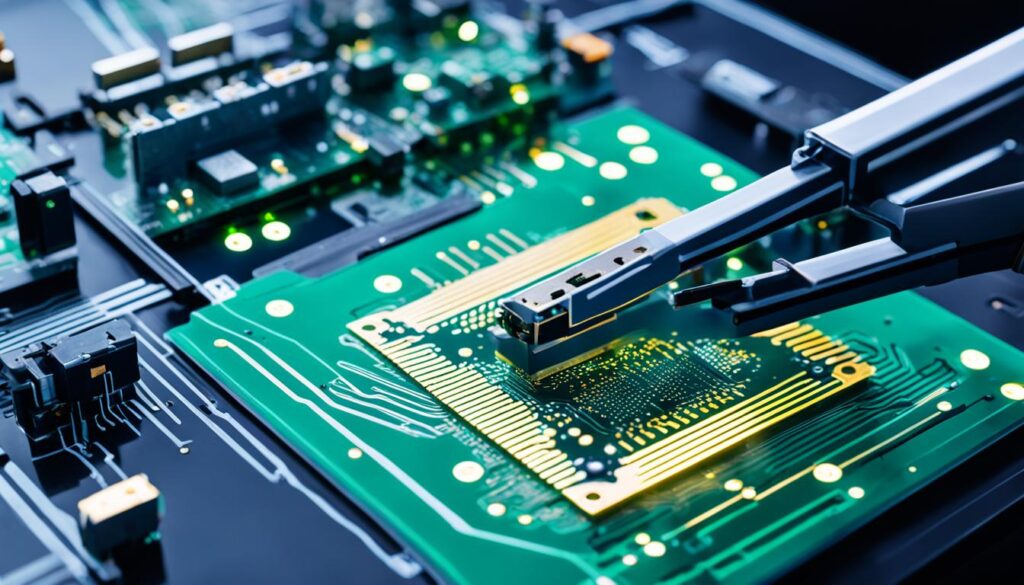

Electronic Component Adhesives: Features and Applications

Electronic component adhesives are key for circuit board protection and performance. They provide high electrical insulation and temperature resistance. These qualities are vital for top-notch results in many applications.

Key Features of Electronic Component Adhesives

These adhesives meet modern electronics needs with important features:

- High Electrical Insulation: They offer top-notch insulation, preventing electrical failures or short circuits.

- Temperature Resistance: Crafted to endure extreme temperatures, they’re ideal for tough environments.

- Mechanical Strength: Their strong mechanical properties boost circuit board durability and reliability.

Common Applications in Various Industries

Electronic component adhesives are crucial in many industries:

- Automotive: They’re used in control units, sensors, and entertainment systems for reliability.

- Medical Devices: They protect and ensure functionality in medical diagnostics and portable devices.

- Aerospace: Essential for avionics systems’ durability and reliability in harsh conditions.

- Consumer Electronics: They keep gadgets like smartphones and laptops safe and working.

Our electronic component adhesives, including ZDS™ advanced solutions, meet various application needs. Using the right pcb coating material boosts device performance and life. This is key in today’s electronics manufacturing.

Understanding Conformal Coating Adhesives

Conformal coating adhesives are key for long-lasting and reliable printed circuit boards (PCBs). They fit the complex shapes of PCBs, making a smooth protective layer. This layer keeps the circuits safe from moisture, dust, and chemicals.

These adhesives keep the PCB parts working right, while making them last longer and work better. The special coatings from ZDS meet tough standards. They provide top-notch PCB protection.

Adding a PCB protection coating to your projects raises protection and helps electronics last longer and be more reliable. At ZDS, we tailor solutions for our customers. We focus on quality, durability, and performance.

How to Use Circuit Board Adhesives for Maximum Protection

To protect your circuit boards to the fullest, start with knowing how to apply pcb coating adhesive correctly. Following a step-by-step method is key for the best outcome. We’ve prepared a guide to help you apply printed circuit board adhesive the right way.

Step-by-Step Application Guide

- Prepare the Equipment: Ensure all necessary tools and materials are available, including precision dispensing systems and personal protective equipment.

- Clean the PCB Surface: Remove any contaminants or residues from the PCB surface. This step is crucial for the adhesive to bond properly.

- Apply the Adhesive: Use a precision dispensing system to apply the printed circuit board adhesive accurately. Ensure uniform coverage to avoid gaps.

- Cure the Adhesive: Depending on the adhesive type, follow the recommended curing process which may include air drying, oven curing, or UV light exposure.

- Inspect the Coating: Post-application inspection is essential. Utilize tools such as UV light to check for even coverage and adherence.

Tips for Optimal Results

- Keep Environment Clean: Ensure the application area is free of dust and other contaminants to prevent defects in the coating.

- Use Precision Tools: Employ precision dispensing systems to control the amount and placement of the adhesive.

- Follow Manufacturer’s Instructions: Adhere to the manufacturer’s guidelines for the pcb coating adhesive application to ensure the best performance.

- Regular Inspection: Implement routine inspections using specialized tools to maintain the integrity of the adhesive coating.

When we stick to the best practices for pcb coating adhesive application, we ensure our circuit boards are well-protected against environmental and mechanical damages. ZDS™ offers top-notch products aimed at making the application process smoother and more dependable, offering strong solutions to protect our electronics.

The Role of Top Coat Adhesives in PCB Protection

Top coat adhesives are key in making printed circuit boards (PCBs) more durable and reliable. They add a protective layer. This helps PCBs withstand different environmental challenges. With top coat adhesives, electronic parts keep working well, even under tough conditions.

Advantages of Using Top Coat Adhesives

Using top coat adhesive for PCB protection has many benefits:

- Improved Surface Finish: A top coat makes the PCB look and work better.

- Added Insulation: It offers excellent insulation, protecting against short circuits.

- Greater Resilience: These adhesives make PCBs stronger against chemicals and physical stress. Studies show they can significantly make PCBs last longer.

Examples of Top Coat Adhesive Applications

Top coat adhesives are crucial for high-performance electronics needing maximum protection:

- Automotive Electronics: They ensure cars’ systems work well despite extreme conditions.

- Aerospace Instruments: They provide strong protection for aerospace gear under tough conditions or against harmful substances.

- Medical Devices: They keep medical electronics safe from water and chemicals. This is important for devices used in diagnosing and treating patients.

It’s important to choose the right top coat adhesive for places where performance and protection matter most.

Choosing ZDS™ for Your PCB Adhesive Needs

ZDS™ proudly offers a wide range of top-notch PCB coating adhesives. Our adhesives are made to fulfill different industry needs. We are experts in PCB adhesive technology. Our products deliver unmatched performance and reliability.

We are committed to high quality. Our electronic component adhesives are highly durable and consistent. We know the challenges our clients face. We aim to boost the life and efficiency of their electronic components.

Customers who choose ZDS™ get personalized expert advice. Our team works hard to help clients find the ideal adhesive solutions. This includes both our standard products and custom options.

| ZDS™ Features | Advantages |

|---|---|

| Comprehensive Selection | Caters to a variety of industry needs |

| Quality & Reliability | Ensures long-lasting performance of electronic components |

| Expert Advice | Customized solutions and supporting guidance |

By choosing ZDS™ for PCB adhesives, clients are guaranteed the best quality. Our electronic component adhesives come with strong customer satisfaction promises. ZDS™’s solutions are crafted for precision and efficiency, making us the top choice for PCB adhesive needs.

Conclusion

In electronics, pcb protection coating adhesives are crucial. They make sure printed circuit boards (PCBs) are durable and reliable. We’ve looked at various types, benefits, and how to apply them. It’s important to choose the right pcb adhesive sealant. Proper use and upkeep are key to protect electronic devices from damage and stress.

At ZDS™, our goal is to offer the best solutions for PCB protection. Our automotive body adhesives are made to meet the high standards of today’s electronics industry. Products like ZDS464, ZDS469, and ZDS181AB-P are not only for cars. They also protect electronic circuits well. Check out our innovative solutions for more info.

Choosing a top-quality pcb adhesive sealant is an investment in your electronics’ future. With ZDS™, you choose adhesives that offer top bonding, safety, and are eco-friendly. Let us help protect your PCBs. This way, your electronic components stay in good shape, working smoothly and efficiently.

FAQ

What is a PCB Coating Adhesive?

A PCB coating adhesive is a protective film for printed circuit boards. It shields against moisture, dirt, and other harmful substances. This barrier is key in preventing short circuits and electrical issues. Thus, it helps in making electronic devices more reliable and long-lasting.

Why are PCB Coating Adhesives Important in Electronics?

PCB coating adhesives are vital in electronics for several reasons. They stop corrosion, electrical problems, and damage from the environment. This means electronic devices work well longer, saving on repair costs.

What Types of PCB Coating Adhesives are Available?

There are many PCB coating adhesives, including acrylic, silicone, urethane, and epoxy. Each type serves different conditions and stresses the PCB might face. ZDS™ offers a broad selection to cater to various needs.

How Do Printed Circuit Board Adhesives Enhance Durability and Reliability?

Using printed circuit board adhesives boosts device stamina and dependability. These adhesives combat wear and tear. They offer strong protection against humidity, salt spray, and temperature changes.

What Should We Consider When Choosing the Right PCB Coating Material?

Choosing a PCB coating adhesive involves several factors. Think about thermal conductivity, flexibility, and how easy it is to apply. By comparing adhesives, you can find the right mix of cost and performance. ZDS™ helps pick the best adhesive for your needs.

What are the Best Practices for Applying PCB Coating Adhesives?

For the best use of PCB coating adhesives, prepare the surface properly. Choose the right way to apply it and let it cure well. Doing it right enhances the adhesive’s benefits. ZDS™ guides to meet high standards.

What are the Key Features of Electronic Component Adhesives?

Electronic component adhesives have excellent insulation, withstand high temperatures, and are strong mechanically. They are made to protect well in many fields like automotive, medical, aerospace, and consumer electronics.

How Do Conformal Coating Adhesives Work?

Conformal coating adhesives fit the PCB’s complex shapes, providing even coverage. They protect circuits from the environment without hindering function. ZDS™ delivers advanced coatings that adhere to strict standards.

How Can We Use Circuit Board Adhesives for Maximum Protection?

For top protection, follow a precise guide, use accurate dispensing, keep the area clean, and check after applying. ZDS™ has the tools and know-how for a great application.

What are the Advantages of Using Top Coat Adhesives?

Top coat adhesives add extra security to PCBs, fighting off chemical and physical stress. Benefits include a better finish, more insulation, and resilience to tough conditions. ZDS™ provides excellent top coat adhesives for high-demand electronics.

Why Should We Choose ZDS™ for PCB Adhesive Needs?

ZDS™ has a wide array of quality PCB coating adhesives for many uses. Our focus on quality and service shows in dependable products and thorough support. Working with ZDS™ means access to expert advice, customized options, and cutting-edge adhesives.