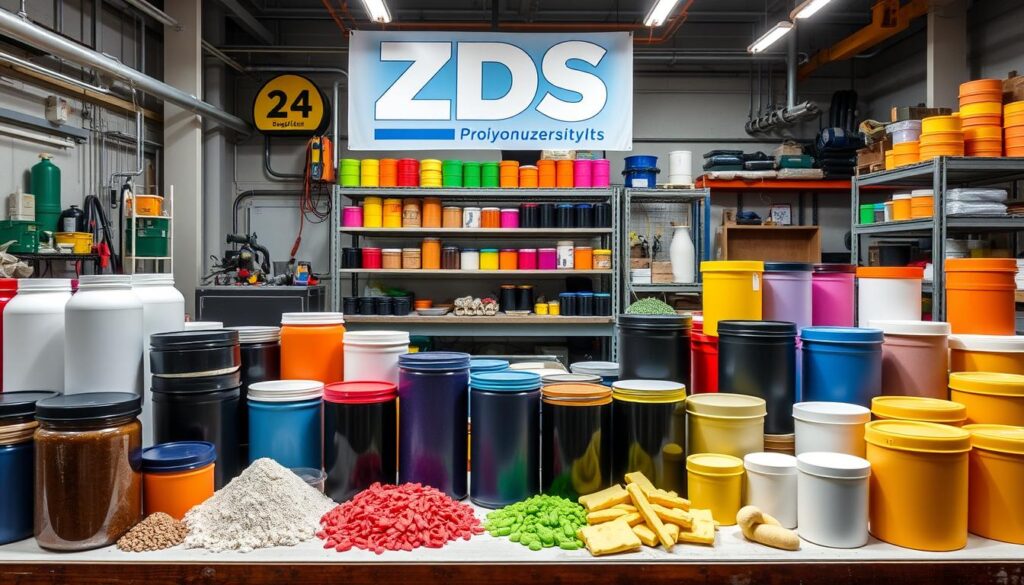

At ZDS™, we’re proud to be a top supplier of Flexible Polyurethane Potting Materials. We’re all about innovation and quality. Our products are made to meet many industry needs.

We aim to provide the best polyurethane encapsulation solutions. This ensures your applications are safe and reliable. Whether it’s a small project or a big industrial need, we lead in excellence.

We have a lot of knowledge and experience. This makes us a trusted polyurethane resin supplier. We’re here to help our clients succeed with our solutions.

Check out our offerings and see how our innovative solutions can boost your project’s performance. They also ensure long-lasting durability.

Discover more about our premiumpotting today!

Key Takeaways

- ZDS™ is a leading Supplier of Flexible Polyurethane Potting Materials.

- Our products provide reliable protection against environmental factors.

- We deliver premium potting compounds suitable for diverse industries.

- Our commitment to quality craftsmanship sets us apart.

- We focus on innovation to enhance project performance.

- ZDS™ offers a wide range of solutions for different applications.

What is Flexible Polyurethane Potting?

Flexible polyurethane potting is a method that uses special compounds to protect electronic parts. These compounds offer strong protection and insulation. This is key for making devices more reliable and efficient.

Definition and Characteristics

Flexible polyurethane potting materials are made of thermoset polymers. When they cure, they turn into a solid that covers the parts. They have important features like:

- High flexibility, allowing for movement and vibrations without cracking.

- Excellent adhesion to many surfaces, creating a strong bond.

- Resistance to moisture and corrosion, keeping components safe from the environment.

Applications in Various Industries

Flexible polyurethane potting is used in many fields. It’s found in:

- Electronics: Protects circuits from damage and ensures they last longer.

- Automotive: Shields against tough conditions and isolates electronic parts.

- Medical devices: Guarantees safe and reliable use in delicate settings.

- Aerospace: Essential for components needing strong protection in harsh conditions.

Benefits of Using Polyurethane Potting Compounds

Using polyurethane potting compounds has many benefits for protecting and improving electronic parts. They are great for both industrial use and DIY projects. These materials perform well and last long.

Enhanced Protection Against Environmental Factors

Polyurethane potting compounds protect electronic parts well against the environment. They are strong and keep out dust, moisture, and chemicals. This helps parts last longer and work better in different places.

Improved Thermal and Electrical Insulation

Flexible potting materials help electrical circuits work better. They manage heat well, preventing overheating. They also keep electrical parts safe from short circuits.

Durability and Long-lasting Solutions

Polyurethane potting compounds are flexible and last a long time. They stay strong even in tough conditions. This makes them a top choice for industries looking for reliable solutions.

For more information on high-quality polyurethane potting compounds, visit this link. Choosing the right materials can greatly improve product life and performance.

Why Choose ZDS™ as Your Polyurethane Resin Supplier

Choosing ZDS™ as your polyurethane resin supplier offers many benefits. These include our expertise, high-quality products, and excellent customer service. We are dedicated to providing top-notch products that meet your specific needs.

Experience and Expertise in the Industry

We have a lot of experience in the industry. This experience lets us offer precise solutions for different needs. Our team is always up-to-date with the latest trends and innovations, helping our customers.

High-Quality and Reliable Products

Quality is our main focus. Our polyurethane resins are tested thoroughly to ensure they meet high standards. This means you get reliable products for various uses.

Customer-Centric Approach and Support

We put our customers first. We listen to your needs and offer custom solutions and support. Building strong relationships with you is important to us, ensuring you’re happy with your project.

| Feature | ZDS™ Advantage |

|---|---|

| Industry Experience | Extensive knowledge and expertise |

| Product Quality | Rigorous testing for reliability |

| Customer Service | Tailored solutions and ongoing support |

Supplier of Flexible Polyurethane Potting Materials

ZDS™ is a top supplier of flexible polyurethane potting materials. We know how important it is to meet different project needs. Our wide range of products shows our dedication to quality and performance in many areas.

Comprehensive Range of Products

We have a variety of encapsulating materials for different needs in many industries. Our products include:

- High-performance potting compounds for electronics.

- Durable encapsulating solutions for automotive applications.

- Advanced materials for medical device manufacturing.

Competitive Pricing and Availability

ZDS™ aims to offer prices that are fair and products that are easy to get. We keep our stock levels high and deliver quickly. This helps our customers get the materials they need on time, making their projects run smoothly.

Understanding Polyurethane Encapsulation Solutions

Polyurethane encapsulation solutions are key in protecting products. They use new polymer chemistry to offer big benefits in many fields. We focus on quality, making protective coatings that fit specific needs.

Innovative Technologies in Encapsulation

Encapsulation has grown with new tech. This tech makes materials more flexible, sticky, and resistant. Now, products can handle tough conditions better. The main improvements are:

- Improved flexibility that adapts to temperature changes.

- Enhanced adhesion for better bonding.

- Increased resistance to chemicals and moisture.

How Encapsulation Enhances Product Performance

Good encapsulation makes products last longer and work better. Using polyurethane solutions, makers can keep their products running well in different situations. The benefits are:

- Components last longer, thanks to protection.

- Electrical insulation gets better, cutting down failure risks.

- Thermal management improves, boosting efficiency.

Flexible Potting Materials: Key Features

Flexible potting materials are key in many industries. They have features that boost their use and results. Knowing these traits helps pick the right materials for certain jobs.

Versatility in Application

Flexible potting materials stand out for their versatility. They fit into many uses, from small gadgets to big aerospace parts. This flexibility lets makers use them in many fields, ensuring top-notch protection and performance.

Adaptability to Different Environments

These materials are made to work well in many settings. They keep their quality whether indoors or outdoors. This makes them perfect for projects needing a strong, lasting solution.

| Feature | Description |

|---|---|

| Versatility | Applicable in electronics, automotive, and aerospace industries. |

| Adaptability | Functions well in both indoor and outdoor environments. |

| Durability | Resistant to moisture, chemicals, and environmental stressors. |

| Ease of Application | Simple to apply, reducing manufacturing time and costs. |

Applications of Polyurethane Potting Compounds

Polyurethane potting compounds are key in many industries. They protect and are versatile. They are used in electronics, automotive, and medical fields.

Electronics and Electrical Components

In electronics, these compounds shield against moisture, dust, and shock. They protect circuit boards, keeping them reliable and working well. This makes devices last longer and safer to use.

Automotive and Aerospace Industries

For cars, polyurethane compounds make parts last under tough conditions. They cover sensors, keeping them safe from vibrations and heat. In space, they protect instruments, making systems more reliable.

Medical Devices and Applications

In medicine, safety is a top priority. Polyurethane compounds keep devices safe from harmful stuff. They help keep medical gear working right and safe for patients.

Choosing the Right Potting Compound for Your Project

Choosing the right potting compound is important. You need to think about several things to get the best results. Knowing these factors will help you pick the perfect compound for your project.

Factors to Consider

- Application Environment: Think about where the compound will be used. Consider the temperature, moisture, and any harmful substances it might face.

- Component Sensitivity: Check how much protection your components need. Think about if they need to be insulated from heat or electricity.

Consultation Services Offered by ZDS™

At ZDS™, we offer consultation services to help you make the right choice. Our experts will guide you through the selection process. They ensure the potting compound fits your project’s needs perfectly.

Trends in Flexible Encapsulation Materials

The world of flexible encapsulation materials is changing fast. New tech is making products better, which is key in many fields. People want things that are good for the planet, leading to a shift in what we buy.

Emerging Technologies and Innovations

New tech is making these materials last longer and work better. This means we can make products that meet our needs and are kind to the Earth. Thanks to advanced tech, we can make things that protect and also help our planet.

Market Demand and Consumer Preferences

Today’s shoppers care a lot about the environment. This is pushing the demand for top-notch materials. Fields like green energy, cars, and gadgets need stuff that’s strong and reliable. So, companies must keep up by making better materials that match what people want.

If you’re looking for the best flexible encapsulation materials, it’s important to know what’s new. Keeping up with trends helps everyone, from big companies to hobbyists, make better choices.

Case Studies: Successful Applications of Potting Compounds

Looking into how potting compounds work in different fields shows their real value. These examples highlight how different areas use potting solutions to make products last longer and work better.

Examples from Various Industries

Fields like telecommunications and renewable energy use new potting compounds to improve their work. In telecom, these materials protect important electronics from moisture and damage. For renewable energy, they shield solar panels and wind turbines from shakes and temperature changes.

Using the right potting solutions makes these key systems run smoothly and last longer.

Lessons Learned and Best Practices

What we learn from these fields is very important. Here are some key points:

- Make sure to pick a potting compound that can handle the product’s environment.

- Always choose materials that meet safety standards.

- Keep trying new things and testing to keep performance high.

If you’re looking for top-notch solutions, check out the marine epoxy resin from ZDS. It’s a great example of advanced materials for many uses.

Conclusion

ZDS™ is a top supplier of flexible polyurethane potting materials. We are dedicated to quality and innovation. Our products meet the needs of many industries.

Whether you make things or like to DIY, we have what you need. Our range helps improve your project’s performance and reliability.

We aim to build strong partnerships and provide top-notch solutions. Our goal is to help you succeed and grow sustainably. We stay ahead by improving and using the latest technology.

Choosing ZDS™ means you get a partner who cares about your success. We offer unmatched support and expertise in flexible polyurethane solutions. Together, we can overcome any challenge and achieve excellence in every project.

FAQ

What are flexible polyurethane potting materials?

Flexible polyurethane potting materials are special kinds of plastics. They protect electronic parts by keeping them safe and insulated. These materials are very flexible, stick well, and keep out moisture.

What applications utilize polyurethane encapsulation solutions?

Polyurethane solutions are used in many fields. This includes electronics, cars, medical tools, and space technology. They help protect against bad weather and other dangers.

What are the benefits of using polyurethane potting compounds?

Polyurethane compounds offer many advantages. They keep dust and water away, improve heat and electrical safety, and last a long time even in tough conditions.

Why should I choose ZDS™ as my polyurethane resin supplier?

Choosing ZDS™ means getting top-notch products and expert advice. We focus on quality and care about our customers’ needs.

What types of encapsulating materials do you supply?

We provide a wide range of flexible polyurethane materials. They meet the needs of many different uses.

How do innovative technologies enhance polyurethane encapsulation solutions?

New technologies have made polyurethane better. They’ve improved its flexibility, sticking power, and resistance. This means components last longer and work better.

What key features define your flexible potting materials?

Our materials are versatile and work well in many places. They can handle different weather conditions, making them great for both inside and outside use.

In which sectors are polyurethane potting compounds commonly used?

Polyurethane compounds are key in many areas. They protect circuits in electronics, sensors in cars, and sensitive parts in medical devices.

What should I consider when choosing a potting compound for my project?

Think about where the compound will be used, how sensitive the parts are, and how much protection you need. This helps choose the right one for your project.

What trends are emerging in flexible encapsulation materials?

The market is moving towards greener and better materials. There’s a big demand for products that meet new standards and preferences.

Can you provide examples of successful applications of potting compounds?

Yes, they’re used in fields like telecom and green energy. These examples show how well our solutions work and offer tips for future projects.