High-Performance Polyurethane Potting Compound - Durable & Versatile

Polyurethane Potting Compound Solutions

At ZDS™, we specialize in offering high-quality polyurethane potting compounds tailored to meet the diverse needs of our clients. With a commitment to innovation and reliability, we provide solutions that protect and enhance your electronic components. Discover how our products can secure your applications with their superior properties and benefits.

Understanding Polyurethane Potting Compounds

Polyurethane potting compounds are versatile materials used for encapsulating and protecting sensitive electronic components. These compounds offer excellent insulation, thermal management, and mechanical protection. ZDS™ polyurethane solutions are formulated to deliver exceptional performance in industrial and commercial applications. Whether you require flexibility, high-temperature resistance, or waterproofing, our portfolio caters to every need.

- Key Features:

- Superior chemical resistance

- Outstanding dielectric strength

- Long-lasting UV stability

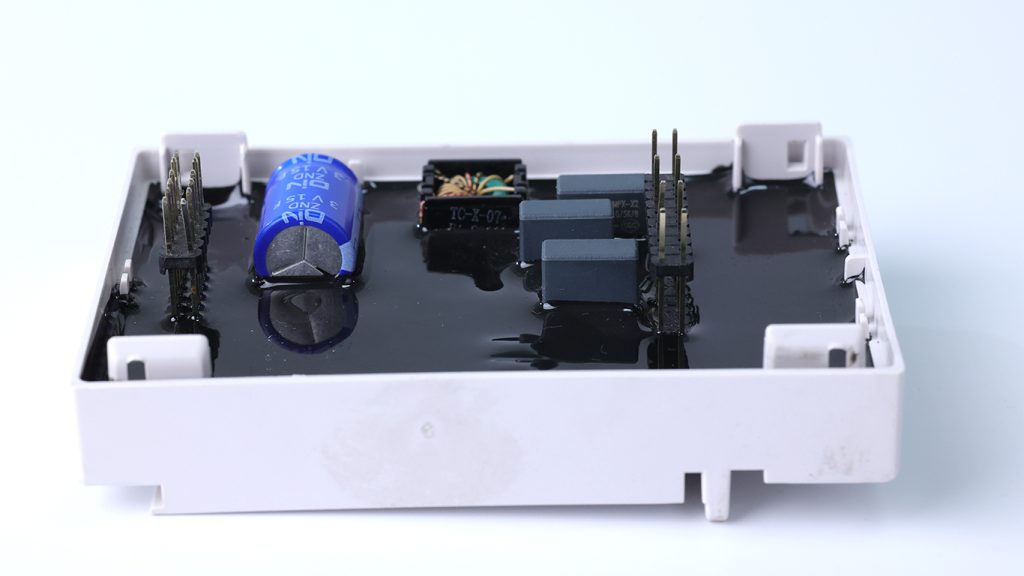

What is Polyurethane Potting?

Polyurethane potting is used to keep electronic components safe. It guards against moisture, chemicals, and wear and tear. This process fills a mold with a polyurethane mixture that then hardens. Once cured, it forms a shield that keeps electronics safe and reliable.

Potting for Sensor

Potting for Rotor Winding

Potting for IGBT Module

Potting for New Energy Vehicles

ZDS™ Polyurethane potting glue

ZDS-217-2-3

| Attribute | Details |

|---|---|

| Model | ZDS-217-2-3 |

| Product Series | Water treatment PU adhesive |

| Application Products | Layered Hollow Fiber Membrane Surface Soft Adhesive |

| Ratio | 1:2 |

| A Viscosity | 30-70 |

| B Viscosity | 500-700 |

| Mixing Viscosity | 350-550 |

| A color | Light yellow transparent |

| B Color | Creamy white |

| Pot life | 45-75min |

| Stagnant time | / |

| Surface curing time | 2-4h |

| Full Curing time | 24h |

| Hardness | 55-65A |

| Product Features | Aging-resistant, no cracking, high bonding |

ZDS-217-57

| Attribute | Details |

|---|---|

| Model | ZDS-217-57 |

| Product Series | Water treatment PU adhesive |

| Application Products | Layered Hollow Fiber Membrane Bottom Rigid Adhesive |

| Ratio | 42:100 |

| A Viscosity | 20±10 |

| B Viscosity | 400±100 |

| Mixing Viscosity | 200-300 |

| A color | Dark brown |

| B Color | Creamy white |

| Pot life | 20±10min |

| Stagnant time | / |

| Surface curing time | 45±10min |

| Full Curing time | 6-7 Days |

| Hardness | 70±5D |

| Product Features | Strong permeability, strong adhesion, low glue creeping, good fluidity |

ZDS-5113-13

| Attribute | Details |

|---|---|

| Model | ZDS-5113-13 |

| Product Series | Filter |

| Application Products | High efficiency filter potting |

| Ratio | 1:3 |

| A Viscosity | 530±100 |

| B Viscosity | 4500±1500 |

| Mixing Viscosity | / |

| A color | Transparent |

| B Color | Creamy white |

| Pot life | 4±1min |

| Stagnant time | 9±2min |

| Surface curing time | 18±5min |

| Full Curing time | 20±4h |

| Hardness | 60±5A |

| Product Features | Good fluidity, no oiling, adjustable speed, low precipitation, affordable |

ZDS-5113-14

| Attribute | Details |

|---|---|

| Model | ZDS-5113-14 |

| Product Series | Filter |

| Application Products | Filter cartridge cover potting |

| Ratio | 1:4 |

| A Viscosity | 175±20 |

| B Viscosity | 4000±1500 |

| Mixing Viscosity | / |

| A color | Dark brown |

| B Color | Off-white |

| Pot life | 3±1min |

| Stagnant time | 3.5±1min |

| Surface curing time | 4±1min |

| Full Curing time | 20±4h |

| Hardness | 75±5D |

| Product Features | Strong adhesion, good fluidity, no oiling, adjustable speed |

ZDS-5113-15

| Attribute | Details |

|---|---|

| Model | ZDS-5113-15 |

| Product Series | Filter |

| Application Products | Filter cartridge cover potting |

| Ratio | 1:5 |

| A Viscosity | 170±50 |

| B Viscosity | 5000±1000 |

| Mixing Viscosity | 2000±500 |

| A color | Brown transparent |

| B Color | Beige |

| Pot life | 5±2 |

| Stagnant time | 10±2 |

| Surface curing time | 20±5min |

| Full Curing time | 24h |

| Hardness | 60-70D |

| Product Features | High adhesion, good fluidity, suitable for a variety of painting processes |

ZDS-206-2-7(Flexible)

| Attribute | Details |

|---|---|

| Model | ZDS-206-2-7(Flexible) |

| Product Series | Filter |

| Application Products | Polyurethane Foam Adhesive |

| Ratio | 1:1 |

| A Viscosity | 750±150 |

| B Viscosity | 450±150 |

| Mixing Viscosity | / |

| A color | Transparent |

| B Color | Creamy white |

| Pot life | 2±1min |

| Stagnant time | / |

| Surface curing time | 25±10min |

| Full Curing time | 20±4h |

| Hardness | 30±5A |

| Product Features | The operation time is controllable and the specific gravity is low |

ZDS-206-11(Hard)

| Attribute | Details |

|---|---|

| Model | ZDS-206-11(Hard) |

| Product Series | Filter |

| Application Products | Polyurethane Foam Adhesive |

| Ratio | 1:1 |

| A Viscosity | 90±30 |

| B Viscosity | 400±150 |

| Mixing Viscosity | / |

| A color | Transparent |

| B Color | Creamy white |

| Pot life | 2±1min |

| Stagnant time | / |

| Surface curing time | 20±10min |

| Full Curing time | 20±4h |

| Hardness | 50±5D |

| Product Features | The operation time is controllable and the specific gravity is low |

ZDS-301A/B

| Attribute | Details |

|---|---|

| Model | ZDS-301A/B |

| Product Series | Potting |

| Application Products | Underwater lights, line lights |

| Ratio | 1:1 |

| A Viscosity | 500±100 |

| B Viscosity | 600±150 |

| Mixing Viscosity | 500±150 |

| A color | Transparent |

| B Color | Yellowish transparent |

| Pot life | 30±10min |

| Stagnant time | / |

| Surface curing time | 3±1h |

| Full Curing time | 24h |

| Hardness | 45±5A |

| Product Features | Yellowing resistance time is 3 years, suitable for transparent potting of all kinds |

ZDS-5112-7-3A/B(yellow)

| Attribute | Details |

|---|---|

| Model | ZDS-5112-7-3A/B(yellow) |

| Product Series | Potting |

| Application Products | Point light sources, line lights, electronic components |

| Ratio | 3:10 |

| A Viscosity | 140±20 |

| B Viscosity | 1600±200 |

| Mixing Viscosity | 750±100 |

| A color | Brown |

| B Color | Yellow |

| Pot life | 25±5min |

| Stagnant time | / |

| Surface curing time | 80±30min |

| Full Curing time | 24h |

| Hardness | 85±5A |

| Product Features | It has strong adhesion with plastic parts such as PC and ABS, and the glue has strong structural properties. |

ZDS-5112-5(white)

| Attribute | Details |

|---|---|

| Model | ZDS-5112-5(white) |

| Product Series | Potting |

| Application Products | Point light sources, line lights, electronic components |

| Ratio | 3:10 |

| A Viscosity | 140±20 |

| B Viscosity | 1600±200 |

| Mixing Viscosity | 750±100 |

| A color | Brown |

| B Color | White |

| Pot life | 25±5min |

| Stagnant time | / |

| Surface curing time | 80±30min |

| Full Curing time | 24h |

| Hardness | 85±5A |

| Product Features | It has strong adhesion with plastic parts such as PC and ABS, and the glue has strong structural properties. Strong waterproofness |

ZDS-205-17R

| Attribute | Details |

|---|---|

| Model | ZDS-205-17R |

| Product Series | Potting |

| Application Products | Inductor protective glue |

| Ratio | 1:1 |

| A Viscosity | 500±100 |

| B Viscosity | 500±100 |

| Mixing Viscosity | 500±100 |

| A color | Transparent |

| B Color | Black/transparent |

| Pot life | 25±10min |

| Stagnant time | / |

| Surface curing time | 3±1h |

| Full Curing time | 24h |

| Hardness | 45±5A |

| Product Features | Good adhesion to substrate, flame retardant V0, waterproof, good elasticity |

ZDS-5118-16R

| Attribute | Details |

|---|---|

| Model | ZDS-5118-16R |

| Product Series | Potting |

| Application Products | Inductor protective glue |

| Ratio | 16:100 |

| A Viscosity | 120±20 |

| B Viscosity | 6000±1000 |

| Mixing Viscosity | 3000±1000 |

| A color | Dark brown |

| B Color | Black |

| Pot life | 30±5min |

| Stagnant time | / |

| Surface curing time | 70±20min |

| Full Curing time | 24h |

| Hardness | 85±10A |

| Product Features | Thermal conductivity 0.8, flame retardant V0, waterproof, good adhesion to substrate |

ZDS-201-10R

| Attribute | Details |

|---|---|

| Model | ZDS-201-10R |

| Product Series | Potting |

| Application Products | Circuit board protective glue |

| Ratio | 1:1 |

| A Viscosity | 20±10 |

| B Viscosity | 400±100 |

| Mixing Viscosity | 200±100 |

| A color | Light yellow |

| B Color | Light yellow |

| Pot life | 30±10min |

| Stagnant time | / |

| Surface curing time | 3-5h |

| Full Curing time | 24h |

| Hardness | 40±10A |

| Product Features | Hardness, speed adjustable, flame retardant V0 waterproof, reworkable, good transparency |

Applications in Various Industries

Polyurethane potting compounds are essential in many fields. They show how versatile and important they are. Here are some of their key uses:

Automotive

They keep sensors and control units safe from harsh conditions.

Aerospace

They protect vital parts from extreme conditions and shaking.

Renewable Energy

They help solar panels and wind turbines work well by protecting electrical connections.

Consumer Electronics

They make everyday gadgets last longer by protecting their delicate parts.

Benefits of Using Polyurethane Potting for Electronics

The integration of polyurethane potting compounds into electronic designs brings several advantages:

- Electrical Insulation: Enhances safety by preventing electrical shorts.

- Moisture Protection: Guards against environmental influences like water and humidity.

- Thermal Management: Efficiently dissipates heat to maintain optimal device temperatures.

ZDS™ polyurethane potting ensures that your electronic devices operate reliably under challenging conditions, extending their lifespan and reducing maintenance costs.

Choosing the Right Potting Solution: Polyurethane vs. Epoxy

Selecting between polyurethane and epoxy potting compounds depends on specific application requirements. While both materials offer robust protection, key differences include:

- Flexibility: Polyurethane provides greater flexibility, making it ideal for applications subjected to vibration and thermal cycling.

- Curing Time: Epoxy tends to cure slower but offers higher rigidity upon completion.

- Temperature Resistance: Polyurethane performs better in moderate temperature ranges, whereas epoxy excels at higher temperatures.

At ZDS™, our experts can guide you through selecting the right material for your unique needs.

How to Apply Polyurethane Potting Compound Effectively

Proper application of polyurethane potting compound is critical for achieving optimal results. Follow these steps to ensure effective encapsulation:

- Surface Preparation: Clean components thoroughly to remove dust and oils.

- Mixing: Accurately mix the two-part compound according to the manufacturer’s instructions.

- Application: Pour the mixture evenly over the components, ensuring complete coverage.

- Curing: Allow adequate time for curing, avoiding any movement of the components during this phase.

Adhering to these guidelines will maximize the protective benefits of your polyurethane potting compound.

Custom Formulated Potting Solutions for Unique Applications

Every project has unique requirements, and at ZDS™, we offer custom-formulated polyurethane potting solutions to address these specific challenges. Whether you need enhanced chemical resistance, reduced viscosity, or faster curing times, our team collaborates with you to develop compounds that precisely match your specifications.

Customization Options:

- Viscosity Adjustments: Tailored flow characteristics for complex geometries

- Color Matching: Pigmented formulations to suit aesthetic needs

- Enhanced Properties: Additives for improved thermal conductivity or flame retardancy

Partner with ZDS™ to create a solution that meets your exact application demands.

Eco-Friendly Potting Compounds for Sustainable Manufacturing

As sustainability becomes increasingly important, ZDS™ is committed to providing eco-friendly potting compounds. Our formulations prioritize low VOC emissions and incorporate renewable resources without sacrificing performance.

Advantages of Eco-Friendly Compounds:

- Reduced Environmental Impact: Lower emissions contribute to cleaner air.

- Compliance with Regulations: Meet global environmental standards.

- Safe Handling: Minimized health risks for workers during application.

By choosing our environmentally conscious products, you support sustainable practices while maintaining the quality and reliability required for your projects.

Tips for Selecting the Right Potting Compound for Outdoor Use

Outdoor applications demand potting compounds that can withstand harsh environmental conditions. When selecting a compound for such uses, consider these factors:

- UV Stability: Ensures long-term durability under sunlight exposure.

- Water Resistance: Protects electronics from rain and moisture ingress.

- Temperature Fluctuations: Materials should accommodate expansion and contraction due to temperature changes.

ZDS™ offers specialized outdoor-grade polyurethane potting compounds that provide robust protection against the elements.

Understanding the Thermal Properties of Polyurethane Potting Compounds

Effective thermal management is crucial in preventing overheating and extending the life of electronic components. Polyurethane potting compounds excel in distributing heat away from sensitive parts, thanks to their inherent thermal properties.

Thermal Management Benefits:

- Heat Dissipation: Reduces hotspots and prevents component failure.

- Low Thermal Conductivity: Maintains stable internal temperatures.

- Improved Efficiency: Supports consistent operation in thermally demanding environments.

Explore how ZDS™ can help optimize your device’s thermal performance with our advanced potting solutions.

Best Practices for Applying Potting Compounds in Electronics

For successful potting application in electronics, following best practices is essential:

- Material Choice: Select the appropriate compound based on environmental and operational conditions.

- Thorough Mixing: Ensure even distribution of resin and hardener for consistency.

- Controlled Environment: Maintain steady temperature and humidity levels during application.

By adhering to these best practices, you ensure maximum efficiency and protection of your electronic assemblies.

Where to Buy Bulk Polyurethane Potting Compound Online

For manufacturers and large-scale operations, purchasing polyurethane potting compound in bulk is both cost-effective and convenient. ZDS™ offers competitive pricing and reliable supply chains, ensuring that you receive top-quality materials when needed.

Why Choose ZDS™ for Bulk Orders?

- Bulk Discount Pricing: Economical options for large orders

- Timely Delivery: Efficient logistics for uninterrupted production

- Expert Support: Dedicated account managers to assist with your requirements

Trust ZDS™ for your bulk polyurethane potting compound needs and experience unmatched quality and service.

Conclusion

Polyurethane potting glue is a leading choice for many industrial needs. It’s known for its strength and durability. Industries like electronics, automotive, and aerospace benefit greatly from it.

This kind of glue outshines others in protecting components. It handles severe conditions well and sticks better than many. That’s why it’s seen as the top option for keeping parts safe and working long.

ZDS™ offers the best in polyurethane potting solutions, tailored for your specific projects. We focus on quality, ensuring our products provide the best protection. Thinking about boosting your component’s life? We’re here with expert advice, excellent products, and the advantages of partnering with ZDS™.

Polyurethane Potting Compound FAQ

What is polyurethane potting?

Polyurethane potting involves a resin and a hardener. When they mix, they harden into a strong shell. This shell shields electronic parts from moisture, dust, and changes in temperature.

What are the benefits of polyurethane potting glue?

This glue is great at conducting heat and insulating electricity, plus it’s flexible. It sticks well and keeps electronic parts safe, helping them last longer and work better.

What are the common applications of polyurethane potting compound in various industries?

Polyurethane potting is used in many fields like automotive, aerospace, energy, and electronics. It’s chosen for its ability to perform in various conditions and meet lots of different manufacturing needs.

Why is polyurethane potting resin considered the best choice for sealing?

It’s especially flexible, which means it can handle expansion and contraction well. It’s also resistant to chemicals and has a strong bond. These features make it the top option for sealant jobs requiring lasting durability and dependability.

How does polyurethane potting resin compare to other potting materials like silicone and epoxy?

While silicone and epoxy are good for some jobs, polyurethane is often better due to its flexibility, chemical resistance, and strong adhesion. It’s best for needs that include maintaining performance through temperature changes and environmental stress.

Why should we choose ZDS™ for our polyurethane potting needs?

ZDS™ stands out for our dedication to quality, innovation, and making customers happy. We customize our products for various industrial uses. With us, you get superior protection and component performance.