ZDS™ leads the way in creating adhesive solutions for battery packs in new energy vehicles. Our products are made to last, making sure cars perform well and stay durable. With the latest technology, we meet the high standards of the electric vehicle industry. ZDS™ is your trusted source for battery pack adhesives that last a long time.

Proud of several adhesives for battery packs [ ZDS-169AB,ZDS-14167 ]

Function: Secures the base of the battery cell at both ends, effectively mitigating vibration pressure to maintain stable battery operation; Epoxy Adhesive ZDS-169AB: Medium to high viscosity, extended working time, offering high strength and good hardness; Acrylic Structural Adhesive ZDS-14167: Medium viscosity, with impact resistance that exceeds that of epoxy resins, and features excellent heat and moisture resistance.

We are known for innovation and quality in the EV market. Our adhesives help battery packs last longer and withstand the wear and tear of driving. When you need solutions that keep up with new energy vehicle technology, ZDS™ is the name to remember. We promise reliability and high performance.

Key Takeaways

- Leadership in battery packs adhesive solutions focused on new energy vehicles.

- Guarantee of durability and efficiency in battery pack performance.

- Advanced technology integration for meeting stringent EV industry standards.

- ZDS™ adhesive solutions enhance the lifespan and reliability of EV battery packs.

- Commitment to innovation, ensuring our solutions meet future demands.

- Dependable partner for evolving new energy vehicle battery packs needs.

The Importance of Quality Adhesive in Battery Pack Assembly

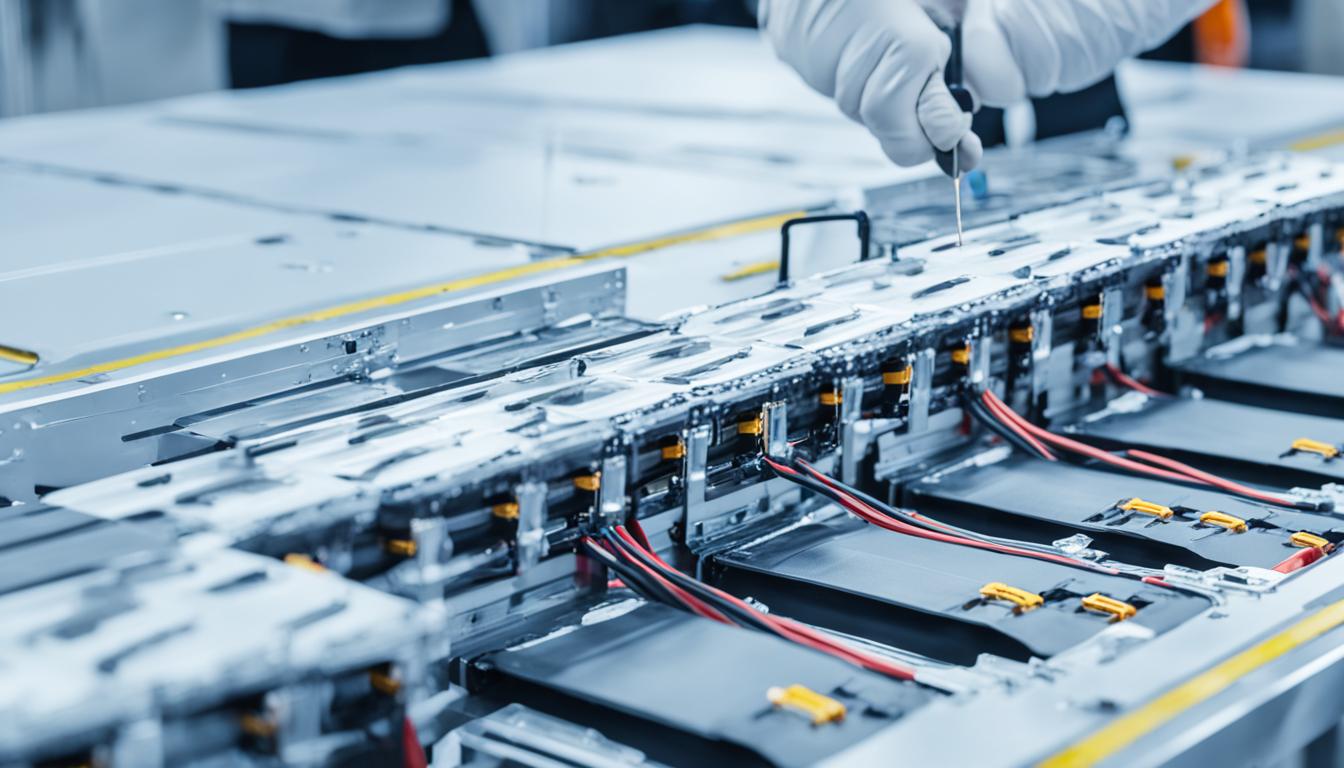

In electric vehicles (EVs), putting together battery packs is a vital step. Quality adhesive plays a key role in this process. It’s crucial for the durability and reliable working of the batteries. ZDS™ offers top-notch adhesive products that boost the longevity and performance of EV battery packs. We stress the importance of excellence in battery pack assembly.

Ensuring Longevity and Performance of EV Battery Packs

The lasting performance of EVs depends much on their battery packs’ endurance. At ZDS™, we provide adhesives that greatly add to the longevity of these packs. Our adhesive technology is made to meet the special needs of these applications. It tackles both the mechanical and thermal challenges battery packs encounter over time.

Building Robust Battery Systems with the Right Adhesive Technology

Making durable battery systems for EVs begins with solid assembly practices. Here, quality adhesives are essential. Our adhesives are created to create strong bonds, manage heat well, and ensure dependable electrical conductivity. These factors are crucial for systems that must meet the demands of new energy vehicles.

Let’s look at how quality adhesives can impact battery system assemblies:

| Feature | Without Quality Adhesive | With ZDS™ Quality Adhesive |

|---|---|---|

| Bond Strength | Poor, leading to early detachment | Strong, durable bonds |

| Thermal Management | Inefficient heat dissipation | Optimized for excellent heat management |

| Electrical Safety | Higher risk of failures | Enhanced safety and reliability |

| System Longevity | Reduced life cycle | Extended durability and performance |

The value of high-quality adhesive in improving the assembly and function of robust battery systems is clear. Trust in ZDS™ for advanced solutions that will elevate the performance and life of your EV battery packs.

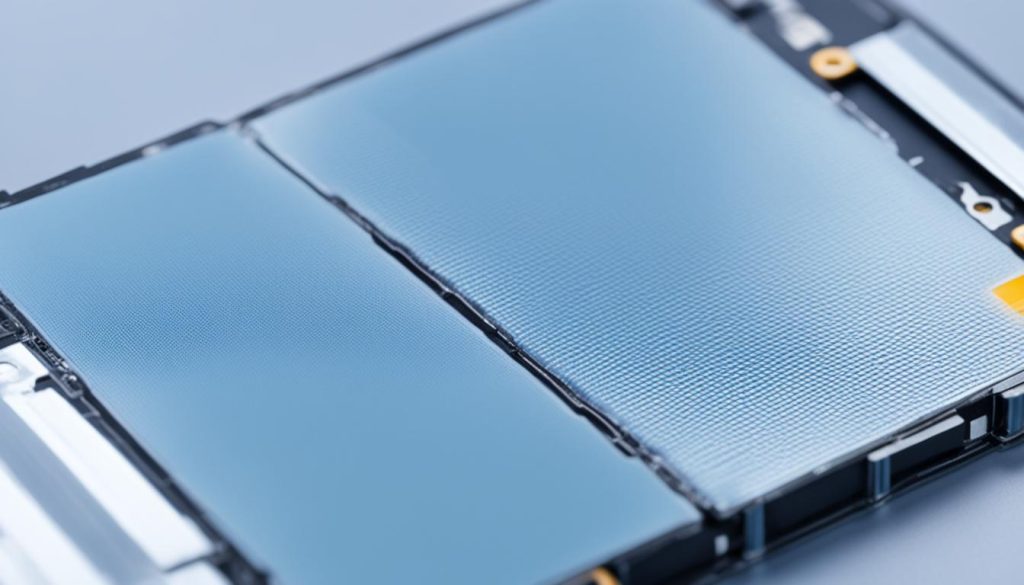

Exploring Adhesive Solutions for Lithium Ion Battery Packs

In the world of new energy cars, lithium ion battery packs are key. They hold a lot of energy and last long. At ZDS™, we create adhesive solutions that bond well and handle heat, making batteries safer and perform better. We aim to improve your product’s life and safety with our adhesives.

Adhesives are important in putting together lithium ion battery packs. They perform many functions that are essential for the battery to work safely and efficiently. For example, our adhesives spread out heat to keep performance high and prevent heat build-up.

It’s important to know the different ways to apply adhesives, like gasketing, potting, and edge bonding. These methods meet the design requirements of lithium ion batteries. They help batteries handle pressure and environmental conditions.

- Structural Adhesives: These give mechanical support and handle loads.

- Thermally Conductive Adhesives: They deal with the heat from the battery’s use.

- Solder Point Protection Adhesives: These protect delicate solder points from damage due to stress or heat.

- Sealants: Keep out moisture and other environmental threats.

Adhesive solutions do more than just stick parts together; they’re a key part of the battery’s build. They greatly affect the battery’s ability to manage temperature, stay safe, and remain solid. Choosing ZDS™ for your adhesive solutions does more than just put a battery pack together. It boosts its value and function, preparing it for today’s energy demands.

Innovative Adhesive for Battery Packs by ZDS™

ZDS™ is all about pushing the limits in adhesive technology, especially for battery packs. We’ve created a special adhesive that makes battery packs better and more efficient. It’s made by watching the market closely and understanding new tech trends.

Customization Options for Battery Pack Adhesive Solutions

We know every battery pack is different. So, our adhesive is made to fit each one’s needs. It works well with all sorts of battery pack designs and uses. This means it can stick to tough standards, improving how they perform.

How ZDS™ is Pioneering Battery Pack Adhesive Tape Technology

ZDS™ is leading the way with our special battery pack adhesive tape. This tape makes putting battery packs together easier and more efficient. It cuts down the time and cost of assembly. This is great news for battery makers everywhere.

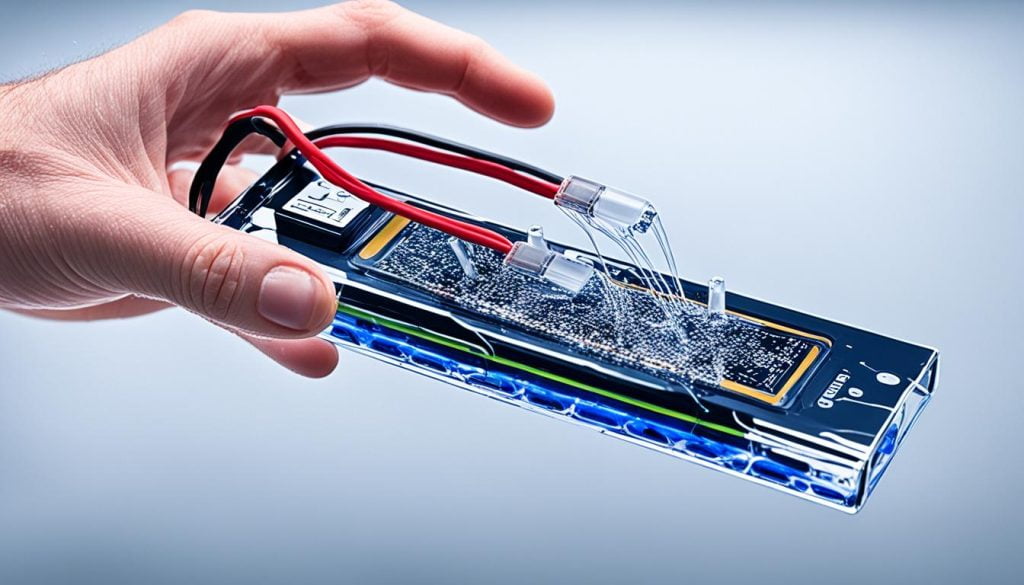

Maximizing Thermal Management with Thermally Conductive Adhesives

At ZDS™, we know how important efficient thermal management is. It keeps battery packs safe and running well in high-power uses. That’s why we have thermally conductive adhesives that help get rid of heat. This keeps temperatures just right and makes battery packs last longer.

Our thermally conductive adhesives keep thermal conductivity steady in tough conditions. They’re great for new energy vehicles where you can’t afford to take risks.

Here’s a detailed look at how our adhesives are better than regular ones for managing heat:

| Adhesive Type | Thermal Conductivity (W/mK) | Heat Dissipation Efficiency | Application Suitability |

|---|---|---|---|

| ZDS™ Thermally Conductive Adhesive | 1.5 | High | New Energy Vehicles |

| Standard Adhesive | 0.2 | Low | General Electronics |

Picking our thermally conductive adhesives means you pick top-notch thermal management. It’s key for keeping battery packs running well in tough spots. Let our advanced solutions boost the reliability and performance of what you’re working on.

Extreme Durability with Battery Pack Adhesive Tape from ZDS™

At ZDS™, we know how vital extreme durability is for battery packs. Our battery pack adhesive tape is key for those who need trust and efficiency, even in tough conditions. It’s made to handle intense heat, moisture, and shaking. This keeps each battery part together firmly, despite environmental challenges.

High-performance technology adoption is crucial. Our ZDS™ adhesive tape shows our commitment to it. With a special formula, it stops parts from coming apart or peeling off. This ensures long-term stability and safety for battery pack uses. Our tape doesn’t just meet industry standards; it exceeds them, creating new high points in adhesive tech.

Check out the top benefits of our ZDS™ adhesive:

- Fights off the worst weather and keeps working through temperature changes.

- Stays strong against the environment, helping your battery packs work their best all the time.

- Keeps vital battery pack parts together, important for keeping the power source working right.

Let’s compare our battery pack adhesive tape to see its strength and efficiency:

| Feature | ZDS™ Adhesive Tape | Standard Adhesive Tape |

|---|---|---|

| Peel Strength | High | Medium |

| Heat Resistance | Up to 150°C | Up to 100°C |

| Vibration Resistance | Excellent | Good |

| Moisture Resistance | Excellent | Good |

We’re dedicated at ZDS™ to boost your battery solutions with adhesives that deliver safety, extreme durability, and reliability. We invite you to see the ZDS™ adhesive tape difference, crafted for tomorrow’s battery tech.

Ensuring Safety with High-Performance Battery Pack Adhesives

Keeping safety and performance in mind, we focus on developing top-notch battery pack adhesives. These adhesives keep battery packs safe and strong in new energy vehicles. Our ZDS™ products go beyond the usual safety standards for adhesives, reducing the risk of failures and making vehicles more reliable.

The Role of Adhesives in Preventing Battery Pack Failures

Our battery pack adhesives are crafted to tackle the main reasons battery packs fail. By firmly holding internal parts in place, they stop any shifts that could cause trouble or danger. They also protect against damage from water or dirt, keeping key parts safe.

ZDS™ Solutions for Adhesive Safety Standards

ZDS™ leads the way in setting high adhesive safety standards. Each mix is made with safety in mind, ready to face extreme heat and vibrations. This means battery packs work well even in tough conditions, staying safe and efficient. Our work ensures that we keep pushing limits while maintaining trust and reliability.

Battery Packs, Adhesive, and New Energy Vehicle Evolution

As new energy vehicles become more common, the need for better battery packs and adhesive grows. ZDS™ focuses on pushing forward battery pack advancements that keep up with rapid new energy vehicle evolution. We aim to provide top-notch ZDS™ adhesive solutions. These innovations boost battery system performance and increase their lifespan.

Meeting the Challenges of Fast-Paced Battery Pack Developments

Battery technology progress requires components that last and work well across various temperatures. Battery packs are vital for the efficiency and cost-effectiveness of electric vehicles (EVs). Our adhesives help battery parts work best between 15-60°C. This is crucial for plug-in hybrids and EVs to perform well.

ZDS™: Staying Ahead in Adhesive Solutions for New Energy Vehicles

ZDS™ is always looking ahead in creating adhesive solutions for the new energy vehicle market. Our adhesives can make a battery pack up to 30 kg lighter. This boosts the vehicle’s efficiency and performance, showing our lead in automotive adhesive innovation.

Cost reduction is key since EV batteries make up a third of the vehicle’s total cost. Our adhesives support using fewer battery pack components, which saves on design costs and enhances thermal management. This is key to improving a battery’s performance and can extend its life to 15 years, aligning with the vehicle’s lifespan.

| Battery Component Importance | Adhesive Influence |

|---|---|

| Optimal operating temperature | Enhances performance & longevity |

| Weight reduction | Up to 30 kg reduction with adhesive use |

| Cost of battery in EV | Reduces with fewer components used |

| Lifecycle of battery pack | Extends up to 15 years with advanced adhesives |

In the fast-changing world of new energy vehicles, ZDS™ is ready and excited to offer solutions that improve tomorrow’s transport. Trust us to lead the next wave of new energy vehicles with our reliable and cutting-edge adhesive technologies.

Understanding Battery Pack Customization and its Adhesives

The rise in electric vehicles (EVs) calls for customizable battery pack solutions. ZDS™ knows how diverse EV needs can be. We focus on battery pack customization for these different needs. Our adhesives ensure each battery pack matches the vehicle and works well in various conditions.

Personalized Adhesive Solutions for Diverse EV Battery Pack Needs

We excel in offering personalized adhesive solutions for varied EV styles and needs. Our team listens to what clients need, from battery chemistry to thermal needs. This lets us customize our adhesives to boost battery pack performance and safety.

The Significance of Tailored Adhesive Properties in Battery Packs

Tailored adhesive properties are key for mechanical strength, performance, and safety in EV batteries. The right adhesive enhances heat handling, electrical safety, and bonding. These factors keep battery packs working well in tough conditions.

Our commitment to adhesive innovation runs deep. Here’s how tailored adhesive properties improve EV battery efficiency:

| Feature | Benefit | Impact on Battery Pack |

|---|---|---|

| Enhanced thermal conductivity | Improves heat dissipation | Prevents overheating, extends battery life |

| Superior electrical insulation | Prevents short circuits | Increases safety and reliability |

| Strong mechanical bonding | Maintains structural integrity | Enhances durability and performance under stress |

In summary, ZDS™ leads in creating adhesive solutions for battery pack customization. Our innovations meet modern EV demands and push industry standards. Rely on ZDS™ for personalized adhesive solutions that improve your EV battery packs.

ZDS™ Adhesive Technology for Enhanced Battery Pack Performance

At ZDS™, we’re dedicated to innovative adhesive solutions. Our aim is to boost battery packs’ performance for electric vehicles. We’re always ahead, meeting and predicting the needs of modern batteries. Thanks to ZDS adhesive technology, we see big gains in efficiency and product quality.

Developing Next-Generation Adhesive for Battery Systems

Our experts focus on creating next-generation adhesive. These new products tackle problems like higher energy needs, faster charging, and longer battery life. We’re helping make battery systems that are stronger, more efficient, and last longer.

Enhancing Operational Efficiency with Innovative Adhesive Solutions

We want to make battery pack production better. Our innovative adhesive solutions make assembly quicker and battery packs more secure. This means less downtime and steady production, which is great for manufacturers wanting to grow and save money.

Below is a table that shows how our adhesives compare with traditional ones in battery applications:

| Feature | Traditional Adhesive | ZDS™ Next-Generation Adhesive |

|---|---|---|

| Bonding Strength | Good | Excellent |

| Thermal Stability | Adequate | Superior |

| Operational Efficiency | Moderate | High |

| Energy Density Compatibility | Limited | Extensive |

| Manufacturing Speed | Standard | Fast |

This table shows ZDS adhesive technology leading to enhanced battery pack performance. By using these adhesives, manufacturers can streamline their operations. They can make battery packs that are more efficient, reliable, and future-ready.

Emphasizing Sustainability in Battery Pack Manufacturing with ZDS™ Adhesives

We deeply care about making battery pack manufacturing greener. Our ZDS™ adhesives are not just effective; they’re made with the environment in mind.

Using ZDS™ adhesives helps your business cut down its environmental impact significantly. These adhesives are built to work with recyclable materials and lower waste. This makes every production step more eco-friendly.

Our adhesives also help lessen energy use during manufacturing. With ZDS™, you’re choosing an option that’s good for the planet, without sacrificing quality or performance.

- Minimizes manufacturing waste

- Reduces energy consumption

- Promotes the usage of recyclable materials

Adopting our adhesives does more than improve your products. It shows a strong dedication to protecting the environment. Join us in moving towards a sustainable future with ZDS™ adhesives.

Conclusion

ZDS™ is proud to offer top-notch adhesive solutions that boost the performance and safety of battery packs in new energy vehicles. Our advanced adhesive technology addresses the complex needs of battery pack assembly. Choosing ZDS™ means ensuring the longevity and efficiency of your EV battery systems, and investing in the future of transportation.

We are committed to innovation, providing customizable options for various applications. No matter the environmental challenges or unique designs, our adhesives offer strong adherence and support. ZDS™ leads in the adhesive market by evolving our technologies to meet the needs of new energy vehicles.

For securing reliable adhesive solutions for your battery packs, turn to ZDS™. Enjoy our high-quality, innovative adhesives crafted for the future of new energy vehicle technologies. We promise excellence and dependability, making sure your battery systems perform well long into the future.

FAQ

What are the benefits of using ZDS™ adhesive solutions for battery packs in new energy vehicles?

A: ZDS™ adhesive solutions are top-notch. They make sure battery packs are strong and work great. We use the latest tech to create adhesives that the EV industry loves.

Why is quality adhesive important in battery pack assembly?

Good adhesives are key for battery packs to last long and work well. They help build sturdy battery systems for new energy vehicles.

What adhesive solutions does ZDS™ offer for lithium-ion battery packs?

A: ZDS™ has special adhesives just for lithium-ion batteries. They stick things together really well and handle heat, improving how the batteries work and stay safe.

Can ZDS™ provide customized adhesive solutions for battery pack assembly?

Yes, ZDS™ makes custom adhesives for battery packs. This lets us match the specific needs of different batteries. We adjust to suit all sorts of requirements.

What advantages does ZDS™ battery pack adhesive tape technology offer?

Our adhesive tape tech leads the way, making battery making better and easier. It keeps everything from falling apart, even in really tough conditions.

How do thermally conductive adhesives contribute to maximizing thermal management in battery packs?

A: ZDS™’s thermally conductive adhesives are great at moving heat away. This keeps batteries cool and lasts longer. They’re perfect for energy vehicles needing to perform well under pressure.

What makes ZDS™ battery pack adhesive tape durable?

Our adhesive tape is really tough. It sticks tight and can handle all kinds of weather and shaking. It’s made to keep battery parts together, always.

How do adhesives contribute to the safety of battery packs?

Adhesives are vital for keeping battery packs safe. They make sure everything stays in place, reducing the chances of problems. ZDS™ adhesives meet strict safety standards.

How does ZDS™ stay ahead in adhesive solutions for new energy vehicles?

ZDS™ keeps innovating to stay ahead. We’re always updating our adhesives for better battery packs. Our research and development make sure we offer the best solutions.

Why is customization of adhesive solutions important for battery packs?

Custom adhesives mean battery packs can perfectly meet specific needs. ZDS™’s personalized options ensure great performance and safety for all kinds of EVs.

How does ZDS™ adhesive technology enhance battery pack performance?

ZDS™ adhesive technology boosts battery pack efficiency and reliability. We’re always working on new solutions to make battery systems better and more efficient.

What emphasis does ZDS™ place on sustainability in battery pack manufacturing?

ZDS™ focuses on being green in making battery packs. Our adhesives are eco-friendly and help reduce waste and energy use, making EVs better for the planet.

Why should I choose ZDS™ adhesive solutions for my battery pack needs?

Choosing ZDS™ means getting adhesive solutions that are dependable and enhance battery pack life and safety. We meet all your assembly needs with our advanced technology.