Resin for 3D Printer

- Home

- Products

- 3D Printer Resin

- Resin for 3D Printer

Resin for 3D Printer: Explore the Best Resin Solutions for Your Printing Needs

Are you searching for high-quality resin materials for your 3D printer? Look no further! ZDS Chemical is a leading manufacturer specializing in resin production for 3D printers. In this guide, we’ll provide valuable insights into different types of resins, compatible printers, and how to choose the best resin material for your printing requirements.

Performance | Viscosity (cps) | Hardness (Shore D) |

Rigid and washable | 180-260 | 81 |

Washable resin, good strength and hardness | ||

Dedicated to 8K printers | Color | Wavelength (nm ) |

multiple colour | 385-405nm |

Understanding Resin Printing

Resin printing has revolutionized the world of 3D printing, offering unparalleled precision and intricate detailing. By utilizing liquid photopolymer resin, resin-based printers (often referred to as SLA or DLP printers) create objects layer by layer through light-induced solidification.

Types of Resins for 3D Printing

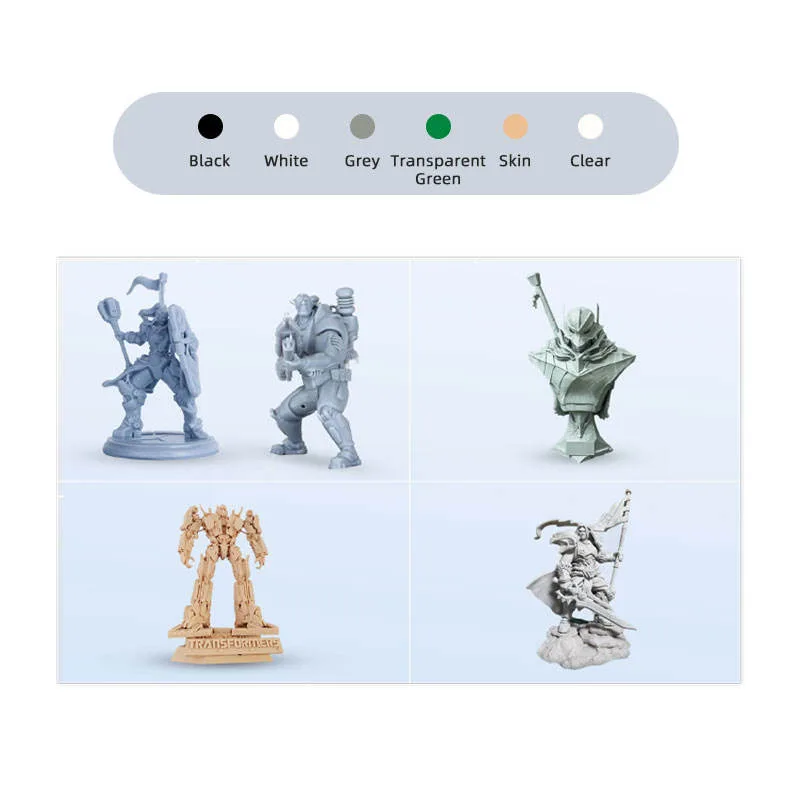

ZDS Chemical offers a wide range of resin options designed to meet diverse printing needs. Some popular resin types include:

- Standard Resin: Our standard resin provides excellent print quality and versatility for various applications.

- Flexible Resin: Ideal for producing parts that require elasticity or impact resistance.

- Durable Resin: Engineered for creating robust prototypes and functional end-use parts.

- Transparent Resin: Produces crystal-clear prints suitable for lenses, light guides, and other transparent objects.

- Castable Resin: Designed specifically for investment casting, perfect for jewelry making or precise metal replicas.

Our extensive product lineup ensures there is a resin type available to cater to the unique requirements of each project.

Compatible Printers and Best Buying Options

To achieve optimal results, it is essential to select a printer compatible with our resins. ZDS Chemical’s resins work seamlessly with various printer brands and models. Here are a few examples:

- Anycubic Photon Series: Renowned for their affordability and reliability, Anycubic Photon printers are an excellent choice for our resins.

- Elegoo Mars Series: Known for their exceptional print quality and user-friendly interface, Elegoo Mars printers deliver outstanding results using our resins.

- Prusa SL1: Prusa Research’s SL1 printer offers superior precision and is compatible with ZDS Chemical’s resins, ensuring top-notch prints.

You can find our resins through different buying options:

- Direct Purchase: Visit our website to browse our product range and make direct purchases conveniently.

- Authorized Resellers: Check our list of authorized resellers who stock our resins to find a local supplier near you.

Selecting the right resin and printer combination ensures optimal print quality and customer satisfaction.

Unlocking the Potential: How to Get Started

If you’re new to resin printing, getting started may seem daunting. However, with our step-by-step guide, you’ll be up and running in no time:

- Material Selection: Determine the type of resin that best suits your project requirements by considering factors like strength, flexibility, or transparency.

- Printer Setup: Ensure your printer is properly calibrated and ready for use with our resin materials. Follow the manufacturer’s instructions for seamless integration.

- Preparation: Prepare your print bed, resin tank, and ensure proper ventilation for a smooth printing process.

- Slicing Software: Utilize slicing software (compatible with your printer) to convert 3D models into printable layers, optimizing settings such as layer thickness and exposure time.

- Printing Process: Load the resin, initiate the printing process, and let our high-quality resin material bring your designs to life.

- Post-Processing: After printing, remove excess resin, rinse the model, and cure it under UV light to achieve its final properties.

By following these steps, you’ll be able to unlock the full potential of resin printing.

Why Choose ZDS Chemical for Your Resin Needs

ZDS Chemical is committed to delivering top-quality resin materials for 3D printers. With our extensive range of resins, compatible with popular printer models like Anycubic, Elegoo Mars, and Prusa SL1, we provide you with the flexibility and versatility required for your projects. Our resins are carefully formulated, ensuring excellent print results and consistent performance.

Contact us today

Contact us today and take your 3D printing projects to new heights with ZDS Chemical’s premium resin solutions!

Frequently Asked Questions about Resin for 3D Printer

3D printer resin is a specialized material used in resin-based 3D printing technologies like SLA (stereolithography) and DLP (digital light processing). The resin used for 3D printing is typically manufactured by chemical companies or resin producers specifically for this purpose. Resin manufacturers formulate and produce the resin using various chemical components and additives to achieve the desired properties such as hardness, flexibility, transparency, or durability.

The manufacturing process of 3D printing resin involves several steps. Here’s a general overview:

- Formulation: Resin manufacturers carefully select and blend different chemical components, monomers, oligomers, polymers, and additives to create the desired resin properties.

- Mixing: The selected components are mixed together under controlled conditions to ensure proper distribution and consistency.

- Reactivity Control: The resin formulation may require photoinitiators or other chemicals to control the reactivity of the resin during the printing process, allowing it to solidify when exposed to specific light wavelengths.

- Quality Assurance: Extensive testing and quality control measures are employed throughout the manufacturing process to ensure the resin meets the desired specifications and performance standards.

Each manufacturer may have specific proprietary methods or variations in their resin production process, but these steps generally outline the overall manufacturing process.

A variety of resins can be used for 3D printing, catering to different applications and requirements. Some common resin types include standard resins, flexible resins, durable resins, transparent resins, and castable resins. Each type has unique properties suited for specific purposes, such as functional prototypes, jewelry making, or producing transparent parts. It is crucial to select a resin that matches your project’s needs and the compatibility requirements of your 3D printer.

The cost of resin for 3D printing can vary depending on several factors, including the brand, resin type, quantity, and supplier. Generally, resins designed for specific applications or with specialized properties may be more expensive than standard resins. Prices typically range from $30 to $150 per liter for consumer-grade resins, while industrial-grade resins can cost significantly higher. It’s advisable to check with different suppliers or retailers to compare prices and find the most suitable option for your budget and project.

The most common resin used for 3D printing depends on the specific application and user preferences. Standard resins are often widely used due to their versatility, affordability, and suitability for a broad range of projects. These resins offer good print quality and are well-suited for general-purpose use. However, it’s important to consider the specific requirements of your project and consult with resin manufacturers or experienced users to determine which resin type will best meet your needs.

The resin you can use in your 3D printer depends on the printer’s compatibility and the recommended resin types provided by the manufacturer. Different printers have specific requirements regarding resin viscosity, curing wavelengths, and other factors. It’s crucial to consult your printer’s documentation or the manufacturer’s website to identify the compatible resin types. Additionally, resin manufacturers or suppliers often provide information about which printers are compatible with their specific resins.

It’s important to note that resin is not an alternative to 3D printing but rather a material used in certain 3D printing technologies. When comparing resin-based 3D printing (such as SLA or DLP) to other 3D printing methods like FDM (Fused Deposition Modeling) that use filament, the cost considerations can vary. The overall cost of resin-based printing includes the price of the printer, the consumables (resin), and post-processing requirements. In some cases, the initial investment and ongoing costs associated with resin-based printing may be higher than those for filament-based printing. However, factors such as print quality, level of detail, and specific project requirements should also be considered when evaluating the suitability and cost-effectiveness of different 3D printing methods.