RTV Silicone Adhesive Solutions for Industrial Applications

RTV Silicone Adhesive

ZDS™ offers high-performance RTV Silicone Adhesives designed to meet the demanding needs of modern industries. Whether you’re sealing electronics, bonding automotive components, or looking for custom formulations, our adhesive technology delivers reliability, flexibility, and strength.

🚀 Why Choose ZDS™ RTV Silicone Adhesives?

One-Component & Two-Component Options

Simplify your application process or tailor to complex assembly lines.

Excellent Temperature Resistance

Withstand extreme conditions from -60°C to 300°C without loss of performance.

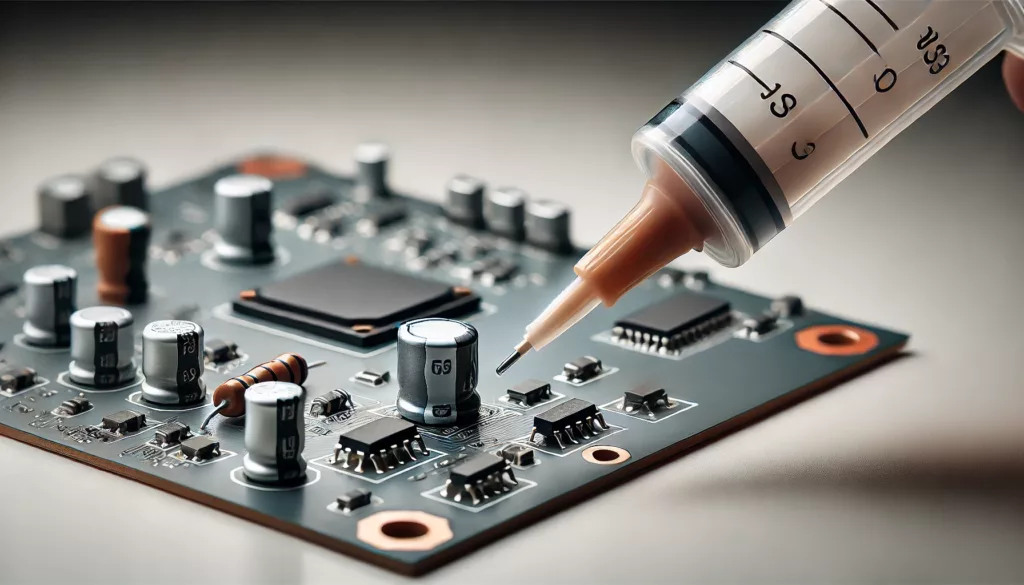

Superior Electrical Insulation

Ideal for electronics, LED modules, PCBs, and sensors.

Waterproof & Weatherproof Sealing

Perfect for both indoor and outdoor bonding solutions.

Custom Formulations Available

Let our R&D team help you develop a silicone adhesive tailored to your specific materials and production requirements.

🛠️ Common Applications

- Automotive Gasket Sealing

- Electronic Component Protection

- LED Light Assembly

- HVAC Systems

- Household Appliances

- Solar Panel Adhesion

- Industrial Equipment Maintenance

⚙️ How Does RTV Silicone Work?

RTV stands for Room Temperature Vulcanizing. These adhesives cure at ambient temperatures, forming a durable, rubber-like silicone seal or bond. They’re especially valuable in industrial settings where heat curing isn’t feasible or where flexible, long-lasting adhesion is critical.

🧪 Need Custom Formulation?

📩 Get a Free Sample or Technical Consultation

Let our team help you select the right RTV adhesive for your project.