Silicone adhesive for electronics is an essential tool in the tech world, offering secure, durable, and versatile bonding for delicate components. Known for its insulation properties, flexibility, and resistance to heat and moisture, silicone adhesive is widely used in applications like circuit board assembly, component protection, and sealing. This guide dives into its benefits, types, and expert tips to ensure you get the most out of this indispensable adhesive.

What is Silicone Adhesive for Electronics?

Silicone adhesive is a specialized bonding agent designed to join and protect electronic components. It is made from silicone polymer, providing excellent thermal stability, electrical insulation, and resistance to environmental factors. This makes it a reliable choice for ensuring the longevity and performance of sensitive electronic devices.

Benefits of Using Silicone Adhesive for Electronics

- Electrical Insulation: Prevents short circuits and electrical failures.

- Heat Resistance: Withstands high temperatures in electronic applications.

- Moisture and Waterproofing: Protects against water, humidity, and corrosion.

- Flexibility: Accommodates expansion and contraction of components.

- Non-Toxic and Safe: Ideal for sensitive environments and applications.

Applications of Silicone Adhesive in Electronics

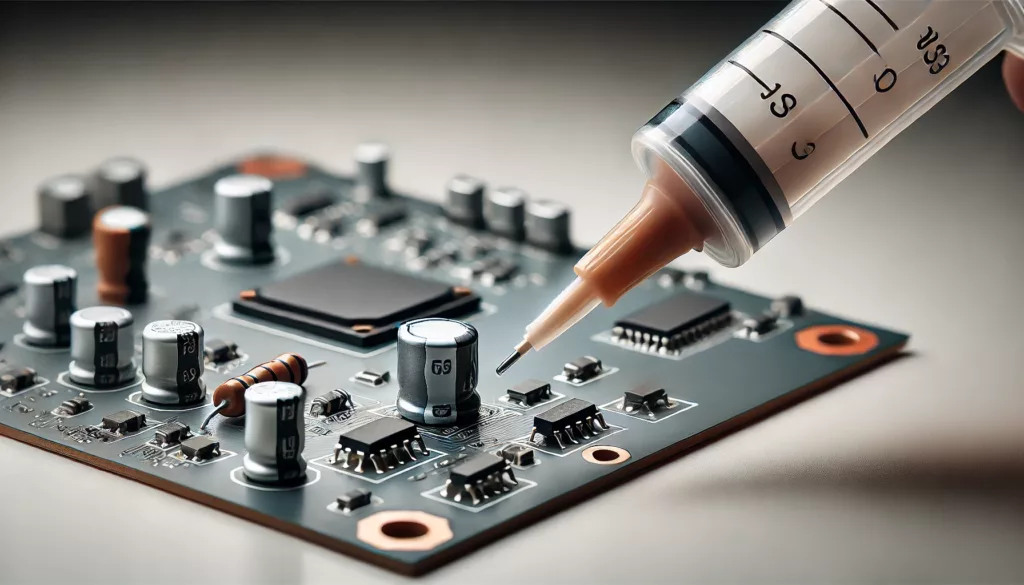

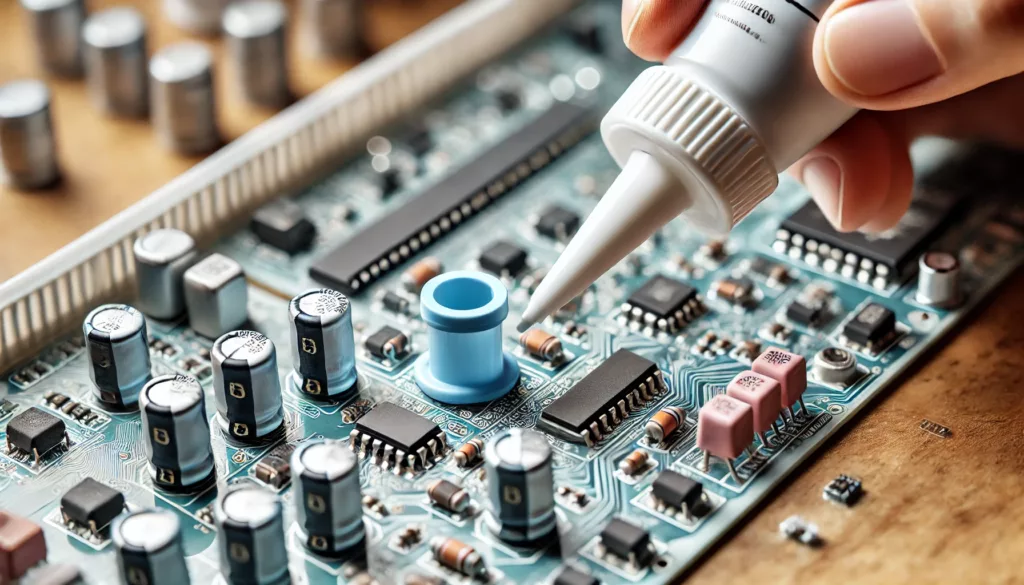

1. Circuit Board Assembly

Used to secure and insulate components like resistors, capacitors, and IC chips.

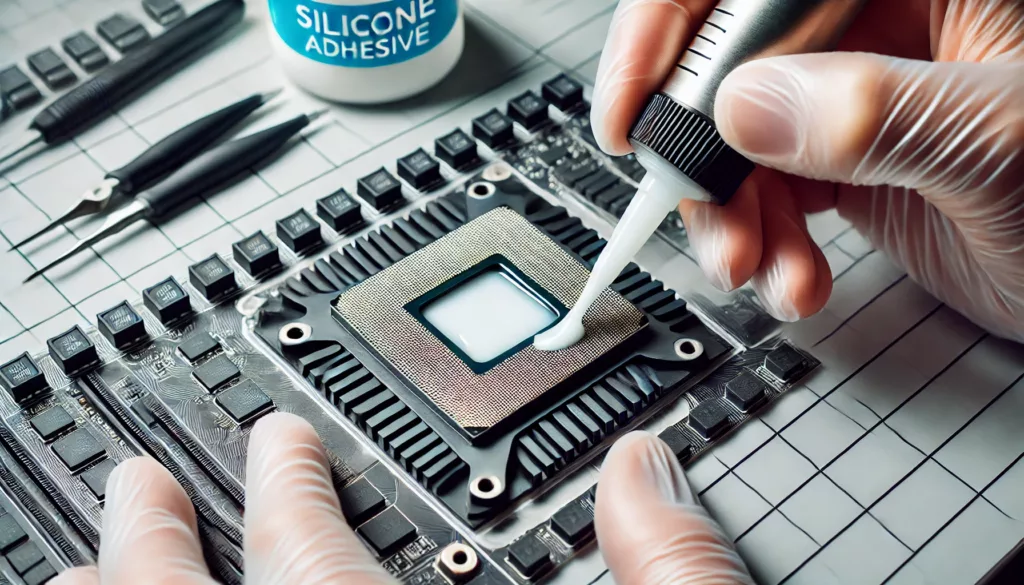

2. Heat Sink Bonding

Effectively attaches heat sinks to CPUs or other heat-generating components.

3. Wire and Cable Sealing

Seals connections, preventing moisture and damage to wiring systems.

4. Device Waterproofing

Essential for protecting gadgets like smartphones, wearables, and other consumer electronics.

5. Vibration Dampening

Reduces the impact of vibrations on delicate parts, prolonging their lifespan.

Types of Silicone Adhesive for Electronics

- Neutral Cure Silicone: Emits minimal by-products during curing, suitable for sensitive electronics.

- High-Temperature Silicone: Ideal for applications requiring thermal stability.

- Transparent Silicone Adhesive: Perfect for applications where aesthetics are important.

- Fast-Curing Silicone: Reduces downtime for quick repairs or assembly.

How to Use Silicone Adhesive for Electronics

1. Clean the Surfaces

- Remove dirt, grease, or moisture from the surfaces to be bonded.

- Use alcohol wipes or a clean cloth for effective cleaning.

2. Apply the Adhesive

- Squeeze the adhesive directly onto the surface or use an applicator for precision.

- Apply a thin, even layer for optimal bonding.

3. Secure the Bond

- Press the components together gently, ensuring proper alignment.

- Use clamps or weights if necessary for larger parts.

4. Allow Curing

- Let the adhesive cure completely according to the manufacturer’s instructions.

- Full curing may take 24-72 hours, depending on the adhesive type.

Tips for Choosing the Best Silicone Adhesive for Electronics

- Consider Thermal Requirements: Choose high-temperature silicone for heat-intensive applications.

- Look for Electrical Insulation: Ensure the adhesive provides effective electrical insulation.

- Check Cure Time: Select an adhesive with a curing time that fits your project schedule.

- Waterproofing Needs: For outdoor or waterproof devices, opt for moisture-resistant silicone.

Safety Precautions When Using Silicone Adhesive for Electronics

- Ventilation: Work in a well-ventilated area to avoid inhaling fumes.

- Protective Gear: Wear gloves and avoid direct skin contact.

- Storage: Keep the adhesive sealed in a cool, dry place when not in use.

- Follow Manufacturer’s Guidelines: Adhere to specific instructions for the adhesive you’re using.

FAQs

Can silicone adhesive be used on all electronic components?

Yes, silicone adhesive is safe for most electronic components, but ensure compatibility with sensitive materials.

Is silicone adhesive heat resistant?

Yes, high-temperature silicone adhesives can withstand temperatures up to 500°F or more.

How long does silicone adhesive take to cure?

Curing time ranges from 24 to 72 hours, depending on the type and application conditions.

Can silicone adhesive waterproof electronics?

Yes, it provides excellent waterproofing, making it ideal for sealing and protecting electronics exposed to moisture.

What tools are needed to apply silicone adhesive?

Basic tools include an applicator nozzle, a small brush for spreading, and alcohol wipes for cleaning surfaces.

How do I remove cured silicone adhesive?

Cured silicone can be removed with a razor blade, scraper, or specialized silicone adhesive remover.

Conclusion

Silicone adhesive for electronics is a must-have for ensuring the durability, safety, and performance of electronic devices. Its insulating properties, flexibility, and resistance to environmental factors make it an invaluable tool for repairs, assembly, and maintenance. By understanding its applications and following proper usage techniques, you can confidently protect and enhance your electronic projects with silicone adhesive.