Ever thought the key to reliable energy storage is in the glue holding your battery together? Currently, the need for strong and effective energy storage solutions is growing fast. However, many overlook the critical part that battery core adhesive solutions play.

ZDS™ focuses on making top-notch adhesives that boost battery performance and ensure they work well. Our unique solutions fit many needs, offering unmatched help and progress in square energy storage technology. Let’s explore the vital role of these adhesives, pushing forward the future of energy storage.

Key Takeaways

- The critical role of battery core adhesives in ensuring reliable energy storage.

- How ZDS™’s expertise leads to innovative adhesive solutions.

- Enhancements in battery performance through tailored adhesive solutions.

- The significance of robust adhesives in the efficiency and longevity of square batteries.

- The forward-looking approach of ZDS™ in energy storage technology.

Introduction to Square Energy Storage Battery Adhesives

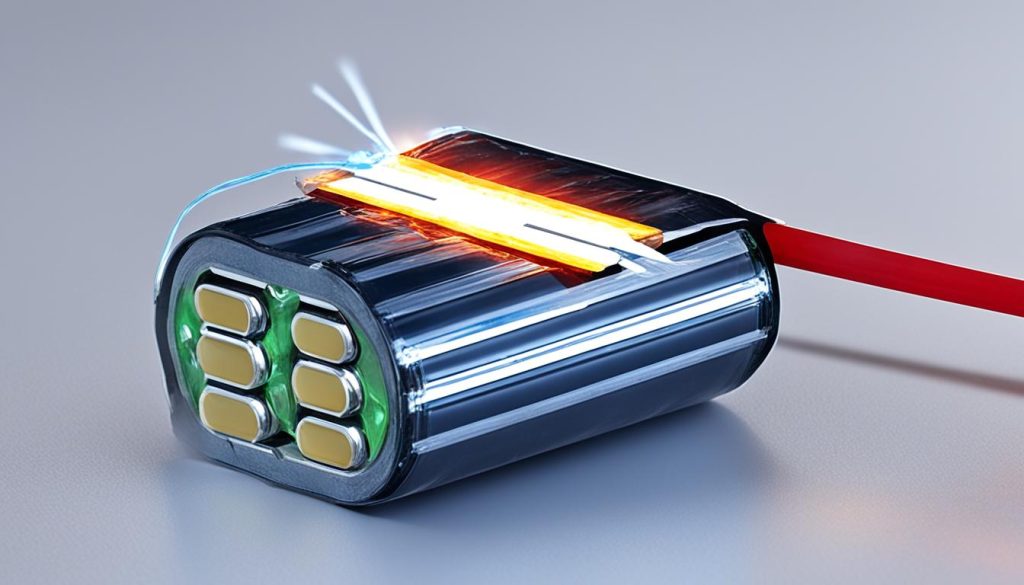

Square battery design is changing how we store energy. Battery adhesive technology is crucial to keep these systems strong and working well.

Battery adhesives are key to making square batteries work. They hold the parts together, making the batteries both efficient and powerful. Using these adhesives makes the batteries last longer, which is great for the environment.

New discoveries in battery adhesives are a big deal. For example, a special kind of glue stops the batteries from forming tree-like structures that can damage them.

Scientists also use computer models to make batteries better. This lets them test new ideas without making an actual battery. It’s a smart way to speed up progress.

Looking into data shows how battery adhesives are boosting energy storage. They’re making not just bigger, but better batteries for a variety of uses.

| Advancements | Impact on Energy Storage |

|---|---|

| 30-50% increase in EV driving range with lithium metal anodes | Significantly boosts the efficiency and practicality of electric vehicles by extending their travel capacity. |

| Suppression of lithium dendrites with soft, solid electrolytes | Enhances battery life and performance by preventing the formation of defects that compromise cell integrity. |

| Molecular dynamics modeling | Enables precise simulation of new materials and chemistries, accelerating the development of optimized battery designs. |

| PIM composite electrolytes | Ensures smooth lithium growth and prevents dendritic growth, contributing to longer battery cycle life. |

In conclusion, adhesives are essential for the future of energy storage. They make systems stronger and more efficient. This helps not just batteries but things like electric cars get even better.

The Role of Battery Core Adhesive in Energy Storage

Battery core adhesives are crucial for the progress of the energy storage field. They ensure cells stick together well. This union boosts the energy storage system’s efficiency.

Without these adhesives, the battery’s life span and performance would decrease. They help cells work in harmony and remain intact.

Why Battery Core Adhesive is Essential

The purpose of battery core adhesives stands key in energy storage. They stop degeneration and protect the battery’s build. This function maintains the battery’s durability, helping it work dependably in any setting.

Key Benefits of Battery Core Adhesives

Special core adhesives offer essential advantages. They manage heat better, cutting overheating risks and using energy efficiently.

These adhesives also offer a stable battery structure. This decreases damage from bumps or constant use, improving overall efficiency. They keep the system free from electrical problems too, ensuring safe performance.

Picking high-grade adhesive brings great value. It elongates the battery’s life and enhances performance. This directly affects how dependable and budget-friendly the system is.

By selecting the right adhesive, we make sure our energy storage setups run well for a long time.

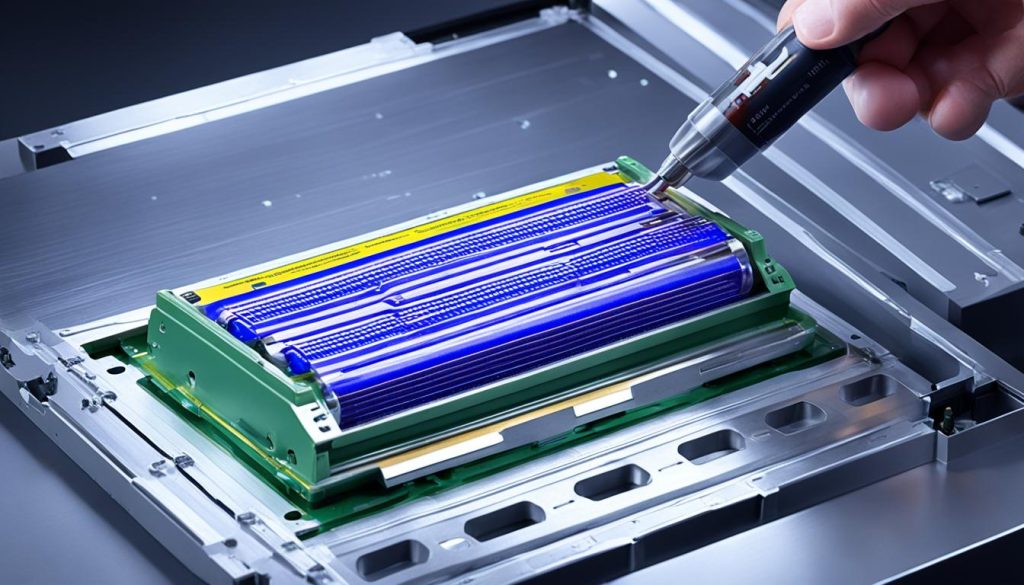

Our Expertise with Battery Assembly Adhesives

At ZDS™, we have deep knowledge and skill in crafting top-notch adhesives for batteries. We take pride in leading the adhesive industry with our innovative solutions. This makes us the go-to choice.

Our advanced R&D helps us lead in adhesive tech. We keep refining our products through tests and research. This means our adhesives are ready to meet the modern battery assembly needs.

We stand out by offering custom solutions. We know every project comes with its own set of obstacles. So, we work closely with our clients to boost their battery’s life and strength. Our adhesives have a track record of success in various scenarios.

Here are a few highlights of our work:

| Project | Solution Provided | Result |

|---|---|---|

| Electric Vehicle Battery Assembly | Advanced ZDS™ adhesive technology | Improved battery stability and performance |

| Portable Electronic Devices | Custom expert adhesive solutions | Enhanced battery longevity and reliability |

| Renewable Energy Storage Systems | Specialized adhesives for superior battery assembly | Increased energy storage efficiency |

We’re known worldwide for trustworthy and innovative adhesive tech. ZDS™ keeps pushing forward, ensuring our adhesive solutions are always top-notch.

Features of High-Performance Battery Adhesives

Today, knowing about high-performance battery adhesives is key. They last long and are dependable. They mix durability and top-notch performance.

Enhanced Durability

Our high-performance battery adhesive is top-notch in lasting long. It helps keep battery parts whole. Its strong adhesive technology can handle different temperatures. This lowers the chance of thermal runaway, which is very important when an electric car battery is so heavy. It also stands up to vibrations and shocks well. This keeps the battery working for a longer time.

Optimized Performance

Our adhesives are all about being the best. They use special materials to manage heat well. This makes the whole battery work better. They keep the right temperature too. Also, they are made for cars, so they can be put on fast. This makes putting together good batteries quick.

Our battery solutions are made to perform. They make new designs work well in real life. For example, they are light enough to use in crash-safe cars. This makes cars safer without losing power or efficiency.

Applications of Battery Encapsulation Adhesives

Battery encapsulation adhesives protect our battery parts from harm. They shield them from the environment and rough use. By using these adhesives, our batteries last longer and work better. This is important for phones, computers, and even huge energy systems.

Battery encapsulation is exciting because it can fit many needs. ZDS™ encapsulation adhesives can be changed to work for different things. So, whether it’s a fast electric car or a small gadget in your home, they both stay safe and reliable.

There is a lot of new thinking in how we use adhesives in energy storage. ZDS™ is leading the way in making better adhesives for batteries. This helps us meet the changing needs in technology without any trouble.

But, these encapsulation processes do more than just protect. They are helping to make better energy solutions. It’s like they are paving the way for the future in how we store energy.

Battery Bonding Agents for Electric Vehicles

Using agents that bond batteries is key in the fast-growing EV industry. They keep electric vehicle batteries both safe and working well. These adhesives are crucial for the strength of battery systems, making sure they work efficiently, even with a lot of power.

Importance in EV Industry

Electric vehicle battery adhesive is vital for creating batteries that last and work well. As more EVs are made, we need better adhesive options. These agents make battery cells work smoothly together, helping with the flow of electricity and the battery’s overall strength. With the right adhesive, EV batteries can stand up to daily demands.

Improving Battery Safety and Efficiency

Enhancing battery safety and efficiency is crucial for electric cars. Our adhesives are crafted to achieve just that. They offer great thermal handling and electrical safety. Besides, these adhesives boost efficiency, which increases energy and makes batteries last longer. This makes electric cars more dependable and saves money over time.

| Aspect | Benefits | ZDS™ Contribution |

|---|---|---|

| Electric Vehicle Battery Adhesive | Improved durability and electrical connectivity | Custom formulations for optimal bonding and performance |

| EV Battery Safety | Enhanced thermal management and mechanical stability | Innovative solutions to ensure safety under various conditions |

| Efficiency Boosting Adhesives | Increased energy output and extended battery life | High-performance adhesives tailored for EV batteries |

Innovations in Lithium-Ion Battery Adhesives

Lithium-ion battery adhesives have seen big changes lately. These changes have led to better batteries. New adhesives make batteries work longer and stronger.

Latest Technological Advances

New adhesives now can handle heat better. This makes batteries last longer and hold more energy. And, they let electricity flow easier, improving energy transfer.

Future Prospects in Lithium-Ion Batteries

Next, we’re looking at adhesives that protect batteries in any weather. They’ll guard against water and stress. These adhesives might even fix themselves if they get a small tear, making batteries safer and longer-lasting.

As we keep improving these adhesives, the way we store energy will change a lot. We’re on the brink of big advancements in how our devices and electric cars are powered.

| Technological Advance | Key Benefit |

|---|---|

| Advanced Thermal Management | Extended Battery Lifecycle |

| Conductive Adhesives | Efficient Energy Transfer |

| Smart Adhesives | Environmental Protection |

| Self-Healing Properties | Long-Term Reliability |

How Battery Manufacturing Adhesives Impact Quality

The connection between adhesive quality and battery performance is crucial. Good adhesives help make batteries strong and safe against defects. ZDS™ is known for making adhesives that lead to reliable batteries.

Adhesives do more than stick parts together in batteries. They also ensure the joints are strong and exact, important for how well the battery works. With the market needing better batteries, the need for strong adhesives is growing too.

ZDS™ aims for the best in making adhesives. Our strong quality checks and new methods help us make top-notch adhesives. Our focus is on every detail to boost battery life and make them safer and more consistent.

Adhesives are key in making batteries better from start to finish. The right adhesive can make batteries more reliable by helping them stay strong, insulating electricity, and managing heat. ZDS™ is trusted for making adhesives that go beyond what’s expected.

The link between adhesive quality and battery trust is vital in improving energy storage. We’re always working to improve, setting the standard higher. This way, every adhesive we make helps build a greener future.

The Importance of Battery Cell Adhesives

In today’s fast-growing battery sector, the role of adhesive importance in batteries is key. Good cell-to-cell adhesion is vital for battery pack stability and life. Companies use various cell types like cylindrical, pouch, and prismatic cells, needing different adhesives for top performance.

Having strong cell-to-cell adhesion helps manage both physical and heat strains. For electric vehicle (EV) batteries, strong adhesives are crucial to withstand movement, ensuring the best power in all conditions. Henkel’s products excel in keeping things together under these challenges.

The link between adhesive importance in batteries and thermal control is crucial. Henkel’s heat conductive materials, with a conductivity of up to 3 W/mK, highlight how top-notch adhesives lead to better temperature control. Improved heat management not only means safer batteries but also longer lasting ones.

Focus is now shifting towards greener and more cost-effective battery materials. Working closely with car makers and battery developers, creating the right adhesives is crucial for easy repair, reuse, and recycling. This is key with the heavy battery packs of today’s electric cars, needing smart and light solutions.

Henkel’s work shows how vital adhesives are for mechanical strength and safety. By paying close attention to adhesive importance in batteries, they help the industry move towards sturdy battery longevity solutions.

Why Choose ZDS™ for Your Battery Adhesive Needs?

ZDS™ is a leader in battery adhesives for good reason. We focus on outstanding innovation and quality. This dedication has earned us deep trust in the industry. Discover what sets our adhesive solutions apart and why customers turn to us for their energy storage demands.

|

Type

|

General Polyurethane Structural Adhesive for Cells

|

High Thermal Conductivity Polyurethane Structural Adhesive

|

Medium-High Thermal Conductivity Polyurethane Structural Adhesive

|

Medium-Low Thermal Conductivity Polyurethane Structural Adhesive

|

|---|---|---|---|---|

|

Model

|

ZDS-PU828

|

ZDS-PU925

|

ZDS-PU926

|

ZDS-PU936

|

|

Mixed Color

|

Green

|

Gray-Black

|

Green

|

Gray-Black

|

|

Volume Ratio A:B

|

1:1

|

1:1

|

1:1

|

1:1

|

|

Working Time (min)

|

30

|

30

|

45

|

35

|

|

Initial Curing Time (min)

|

120

|

180

|

240

|

180

|

|

Shear Strength (Mpa)

|

12

|

7.0

|

9.0

|

9.0

|

|

Operating Temperature (°C)

|

~60~120

|

~60~120

|

~60~120

|

~60~120

|

|

Thermal Conductivity (W/m.k)

|

/

|

2

|

1.2

|

0.8

|

|

Packaging Form

|

400ml Dual Cartridge

|

400ml Dual Cartridge

|

400ml Dual Cartridge |

400ml Dual Cartridge

|

Our Unique Selling Points

The ZDS™ adhesive excellence is rooted in our advanced, in-house technology. We’re always finding new ways to improve our adhesives for customers. This means you get solutions that fit your needs perfectly. Our products are not only reliable but also offer unmatched quality, making them a top choice for discerning buyers.

Customer Testimonials

Our satisfied customers often let us know how we’re doing. They share positive stories about our unique adhesive solutions. They highlight the performance, endurance, and quality of our products. Their happiness reflects our commitment to the best in adhesive solutions.

| Customer | Feedback |

|---|---|

| ABC Energy | “ZDS™ solved our adhesive challenges, significantly improving our battery performance.” |

| PQR Technologies | “The unique adhesive solutions offered by ZDS™ have been transformative for our products.” |

| XYZ Batteries | “We have experienced remarkable consumer satisfaction with ZDS™ adhesive products.” |

Conclusion

Looking back, we see that the right adhesives are key in many industries. They keep battery cores together, with layers of 1-100μm thick. These adhesives are specially made to be 20-80μm thick to work best. Our study also showed the detailed chemistry needed to make batteries run better. Mixing a caking substance and a more volatile chemical perfectly (at ratios 1:9 to 1:19) helps the adhesive stick well and work efficiently.

We’ve highlighted the value of ZDS™ in our journey. ZDS™ offers advanced glue solutions for today’s energy needs. Their products make it easy to wind adhesive around batteries quickly, with layers ready in 2-5 weeks. They use special materials like Kynoar and mix them with solvents such as ethyl acetate and ethyl formate. This shows how ZDS™ leads in making reliable adhesive technology for energy storage.

In short, the [latest in energy storage solutions](https://patents.google.com/patent/CN108242573A/en) are making a big difference in our world. ZDS™ stands out by providing the exact adhesives we need. With their help, we’re ready for the future of energy storage. ZDS™ promises to keep innovating, so we always have the best adhesives for our needs.

FAQ

What is a battery core adhesive, and why is it essential in energy storage solutions?

A battery core adhesive is a glue used in building battery cores. This adhesive makes sure the batteries stay together and work well. It boosts how much energy the battery can hold and keeps the battery safe from losing power over time. Good adhesives, like the ones from ZDS™, are key for top-notch energy storage solutions.

How do our adhesives improve the performance of square energy storage batteries?

Our adhesives make square energy storage batteries stronger and more reliable. They handle heat well, keep the battery parts steady, and make sure electricity flows smoothly. This leads to the batteries lasting longer and working better in any situation.

What are the key benefits of using battery core adhesives in energy storage systems?

Battery core adhesives have many pluses. They help with heat, keep the parts from moving too much, and stop electricity from leaking. These gains mean the batteries last longer, work more dependably, and take a beating from the environment without failing. High-grade adhesives are a must for safe and efficient energy storage.

Why is ZDS™ considered an expert in battery assembly adhesives?

ZDS™ is an authority in making adhesives for batteries because of our deep knowledge and skill. We stand out by tailoring our solutions to meet our customers’ needs. Many success stories showcase how well our tech works for battery assembly.

What makes our high-performance battery adhesives stand out?

Our top-tier battery adhesives are celebrated for being tough and functional. They handle hot and cold temps, shake-ups, and hard knocks, making sure batteries last and perform well. This dedication to performance elevates battery management and efficiency.

Where are battery encapsulation adhesives commonly used?

Battery encapsulation adhesives shield battery parts from the elements and wear and tear. They’re key from gadgets to big energy storages. ZDS™ encapsulation adhesives are fit for all sorts of uses because of their flexibility and quality.

What role do battery bonding agents play in electric vehicles?

Battery bonding agents are vital in making EVs safe and effective. Good adhesives stop batteries from getting too hot and keep them running well. ZDS™ adhesives are a big part of making EV batteries better, ensuring they’re safe and efficient.

What are the latest innovations in lithium-ion battery adhesives?

The newest tech in lithium-ion adhesives focuses on making batteries last longer and hold more energy. These advances are key for energy storage’s future, offering top performance and trust. ZDS™ is always at the head of these advancements, working to meet the industry’s changing needs.

How do manufacturing adhesives impact the quality of batteries?

The adhesives used in making batteries directly affect how well they work and last. By using top-notch adhesives, we ensure the batteries are put together well, making them better. ZDS™ sticks to high standards in making adhesives, aiming for reliable and high-performance batteries.

Why is cell-to-cell adhesion important in battery packs?

Sticking cell-to-cell is key for battery packs to stay strong and do their job. Fine adhesives help with heat and electricity, making sure the pack runs well. ZDS™ offers adhesives made specially to meet tough requirements, adding life and strength to battery packs.

Why should you choose ZDS™ for your battery adhesive needs?

Choosing ZDS™ means picking high-tech solutions, personal care, and deep know-how in battery adhesives. Testimonials from happy clients show the value and edge our products bring. Our passion for innovation and quality means you’ll get the best for your adhesive needs.