Introduction: Why the Strongest Adhesive Matters

In industries where failure is not an option—automotive, aerospace, construction, and electronics—the strongest adhesive can mean the difference between long-lasting performance and catastrophic breakdown. Whether you’re bonding metals, plastics, glass, or composites, understanding which adhesive offers the highest strength is critical.

In this comprehensive guide, we explore the top contenders for the strongest adhesive, breaking down their composition, ideal use cases, and performance benchmarks. Whether you’re a manufacturer, engineer, or procurement manager, this article is your roadmap to high-performance bonding.

What Defines the “Strongest Adhesive”?

Tensile Strength, Shear Strength & Durability

Before choosing the strongest adhesive, it’s essential to understand what “strength” really means. There are three main metrics:

- Tensile Strength: Measures how much force the adhesive can resist when pulled apart.

- Shear Strength: Indicates the adhesive’s resistance to forces sliding across the bond.

- Environmental Durability: The adhesive’s ability to maintain integrity under stress, moisture, and temperature fluctuations.

The strongest adhesive excels in all these areas, providing unmatched performance in demanding environments.

Top 5 Strongest Adhesives in the Industrial Market

1. Epoxy Adhesives

Primary Keyword: Strongest adhesive

Secondary Keywords: high-strength epoxy, industrial adhesive

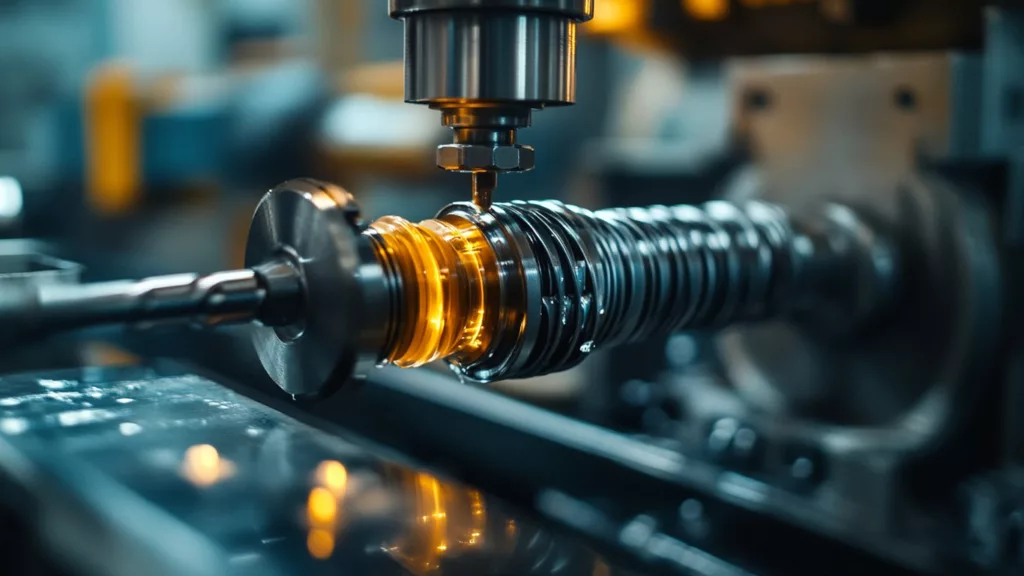

Epoxy adhesives are widely regarded as the strongest adhesive class available today. Formed by mixing a resin with a hardener, epoxies offer high-strength bonding for metals, ceramics, and composites.

Key Features:

- Tensile strength of up to 5000 psi or more

- Excellent gap-filling properties

- High resistance to chemicals and heat

Best Used In: Aerospace components, automotive parts, and heavy machinery assembly.

2. Acrylic Adhesives

Secondary Keyword: structural adhesive

Acrylics are fast-setting, structural adhesives that rival epoxies in strength. They’re also more forgiving on oily or unprepared surfaces.

Key Features:

- Fast curing at room temperature

- Strong adhesion to plastics and metals

- UV and chemical resistant

Best Used In: Electronics, signage, and marine applications.

3. Polyurethane Adhesives

Secondary Keyword: industrial adhesive

Polyurethanes offer strong bonds with flexibility, making them ideal for applications that require movement or impact resistance.

Key Features:

- Good tensile and shear strength

- Resistant to water, oil, and abrasion

- Adapts to vibration and movement

Best Used In: Construction, transportation, and packaging industries.

4. Silicone Adhesives

Silicone adhesives are known for their superior performance under extreme temperatures.

Key Features:

- Temperature tolerance from -100°C to 300°C

- Excellent flexibility and sealing

- Good electrical insulation

Best Used In: Electronics, appliances, and aerospace applications.

5. Cyanoacrylate Adhesives (Super Glue)

Despite being a common household product, cyanoacrylate is also used industrially for rapid bonding of small parts.

Key Features:

- Instant bonding in seconds

- High tensile strength in small areas

- Bonds plastics, rubber, and metal

Best Used In: Electronics and medical device manufacturing.

Comparing Adhesive Strength by Use Case

| Adhesive Type | Tensile Strength (psi) | Best Substrate | Curing Time |

| Epoxy | 3000–5000+ | Metal, Glass | 5 min–24 hr |

| Acrylic | 2000–4000 | Metal, Plastic | 5–20 min |

| Polyurethane | 1000–3000 | Wood, Metal | 30 min–24 hr |

| Silicone | 500–1500 | Glass, Plastic | 30 min–48 hr |

| Cyanoacrylate | 1000–2000 | Plastic, Rubber | <1 min |

Choosing the Right Industrial Adhesive

When selecting the strongest adhesive, consider:

- Substrate Compatibility: Does it bond well to your materials?

- Environmental Conditions: Will it be exposed to moisture, chemicals, or heat?

- Load Requirements: What forces will the bond endure?

- Curing Constraints: Do you have time for a slow cure or need instant bonding?

For heavy-duty, load-bearing applications, a high-strength epoxy or structural adhesive is usually the best choice. For flexibility, polyurethane or silicone adhesives are ideal.

Why ZDS™ is Your Trusted Adhesive Manufacturer

At ZDS™, we specialize in developing the strongest adhesives tailored to your industry’s needs. Whether you’re in electronics, automotive, aerospace, construction, or marine manufacturing, our solutions are engineered to deliver uncompromising strength and durability.

We offer:

- ✔️ Custom adhesive formulation

- ✔️ Bulk and wholesale supply

- ✔️ Rapid R&D and prototyping

- ✔️ Global logistics and technical support

Conclusion: Strength Meets Reliability

The strongest adhesive is more than just holding power—it’s about enduring performance under pressure. By understanding the types of adhesives available and their respective strengths, you can make informed decisions that boost product reliability and safety.

Explore our full range of high-strength adhesives or contact our expert team today to discuss custom solutions for your application.

✅ Ready to Bond with Confidence?

🔗 Contact ZDS™ for Custom Adhesive Solutions

📩 Subscribe to our newsletter for adhesive insights and updates

📘 Learn more about our industrial adhesive technologies