The demand for new energy vehicles is on the rise. This makes the safety and efficiency of these cars vital. ZDS™ battery potting compound is at the front line of ensuring batteries are safe and perform well. It is made to better battery function in new energy cars. It does this by offering protection against heat, fire, water, and bumps.

ZDS™ is about more than just making things work. We aim to lead in battery tech for new energy vehicles, creating industry standards. Our products, like the ZDS-168AB epoxy and ZDS-903 silicone adhesive, fill battery module gaps. They keep the battery at the right temperature and safe from environmental risks. This protection level is crucial for both performance and the safety of electric car operations.

- ZDS™ battery potting compound is crucial for enhancing the performance and safety of new energy vehicles.

- Epoxy Potting Compound ZDS-168AB features high thermal conductivity and robust insulation, making it optimal for battery protection.

- Silicone Adhesive ZDS-903 offers unmatched resistance to moisture, shocks, and temperature fluctuations.

- The comprehensive protection provided by ZDS™ compounds allows vehicles to achieve higher efficiency and longer battery life.

- Adopting ZDS™ technology in new energy vehicles aligns with industry movements toward more sustainable and robust energy solutions.

Introduction to ZDS™ Battery Potting Compounds in the EV Industry

The EV industry is changing fast. New technologies are needed to make cars perform better and be safer. ZDS™ battery potting compounds are leading the way. They provide top-notch material that protects the battery, making vehicles more efficient and durable.

Boosting Performance and Safety with ZDS™

ZDS™ battery potting compounds meet the EV industry’s high demands. These compounds not just support a battery’s structure. They also improve heat control and safety by fully covering and insulating battery cells. This enhances battery life and efficiency, marking them crucial for car makers.

ZDS™ compounds play a big role in wireless power transfer (WPT) too. They work best at 10 kHz for WPT, ensuring power is delivered efficiently with little loss. Also, they help keep the power steady up to 300 kHz. This reliability is key for small devices in electric vehicles that need consistent power.

Setting the Industry Standard

ZDS™ compounds do more than improve battery life. They’re also setting new standards in energy transfer. They’re especially effective in Midfield wireless power transfer (MF-WPT), a new technology in electric cars. These compounds make MF-WPT systems work better, even with very small, loosely connected coils.

Whether comparing two-coil or three-coil systems, ZDS™ compounds show their worth. They enhance energy savings, manage power better, and boost overall performance. ZDS™ is really pushing forward what battery technology can do, setting new records in the EV world.

The Role of Potting Compounds in Battery Safety

Battery safety is crucial during the development and making of energy systems. Potting compounds are key here. They protect batteries against many environmental stress factors. This helps keep batteries safe and reliable.

Potting compounds are made of different resins that form a protective shell. They provide strength, stability, and moisture resistance. These qualities help batteries work right and last longer. They keep batteries at the right temperature and reduce shock.

Choosing the right battery safety compound is important. The best material boosts a battery’s life and makes devices more reliable. Here are the benefits of potting compounds used in battery safety.

| Type of Compound | Properties | Applications |

|---|---|---|

| Epoxy | High mechanical strength, excellent chemical resistance | Industrial batteries, heavy-duty applications |

| Silicone | Flexibility, high temperature resistance | Consumer electronics, automotive batteries |

| Polyurethane | Good flexibility, abrasion resistance | Portable devices, renewable energy systems |

Think about what the battery will be used for. You can then pick the best potting compound. This choice makes a battery safer and work better.

Finding the right potting compounds is just the start to better battery safety. We need to keep improving these materials for better batteries. In our industry, we’re working on next-gen solutions. These new materials will protect and improve batteries for the future.

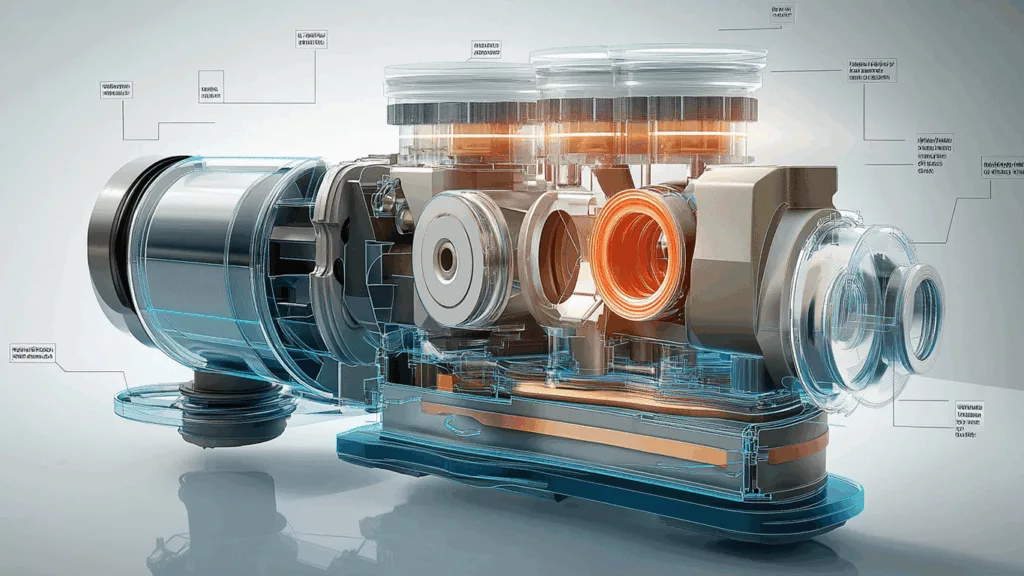

ZDS™ Compounds and Enhanced Thermal Management

ZDS™ compounds are key when it comes to advanced battery technologies. They help with thermal management and extend battery life. As high-density energy storage solutions become more common, controlling heat is critical. This is essential for keeping batteries working well and safely. Let’s see how these unique thermal potting compounds change the game in battery heat control.

Dealing with Heat in High-Density Energy Storage

Modern batteries pack a lot of energy, which makes heat management tough. If a battery can’t get rid of heat, it might overheat. This could lower its performance or even cause it to fail. ZDS™ thermal potting compounds are made to solve this problem. They make sure the heat from the battery cells is managed well.

By improving how well they conduct heat, these compounds keep batteries at the right temperature. This is important for the high-performance standards needed in today’s energy storage uses.

Improving Longevity of Batteries with Thermal Regulation

The life of battery systems depends a lot on how they handle heat over time. ZDS™ thermal potting compounds are crucial for providing excellent thermal stability. This stability means longer life and better durability for battery packs. The compounds are designed to spread heat evenly. This prevents overheating and damage to the battery cells.

| Feature | Benefit | Impact on High-Density Energy Storage |

|---|---|---|

| Enhanced thermal conductivity | Even distribution of heat | Prevents overheating and enhances battery efficiency |

| High thermal stability | Withstands extreme temperatures | Improves battery longevity and reliability under varying operational climates |

| Optimal cure profile | Quick and efficient curing process | Accelerates manufacturing cycles, enhancing productivity |

In the end, using ZDS™ thermal potting compounds boosts thermal management. This leads to longer-lasting and more reliable high-density energy storage systems. These materials are vital for optimizing battery performance in tough settings. They ensure energy efficiency and safety are kept up.

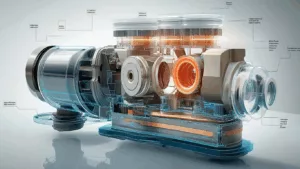

Epoxy vs. Silicone: Choosing the Right ZDS™ Potting Compound

When picking the best potting compound for battery encapsulation, you’re mainly looking at two choices: epoxy potting compound and silicone potting compound. Each serves a different purpose depending on what you need for electronic assemblies and battery packs. It’s key to understand their properties to make a good choice for your project.

Let’s check out the main differences and uses. This will help in choosing either an epoxy potting compound or a silicone potting compound. You want the best performance and reliability for your devices.

| Characteristic | Epoxy Potting Compound | Silicone Potting Compound |

|---|---|---|

| Temperature Resistance | High | Very High |

| Flexibility | Low | High |

| Adhesion | Excellent | Good |

| Chemical Resistance | Good | Excellent |

| Electrical Insulation | Excellent | Good |

If you need strong structural integrity and great adhesion, epoxy potting compounds are the way to go. They protect against chemicals and shocks well because they cure hard and bond strongly.

In contrast, silicone potting compounds are amazing for their flexibility and resistance to high temperatures. Great for parts that experience temperature changes, their flexibility prevents stress on sensitive components.

![]()

This guide aims to help you see why the right choice of ZDS™ potting compound—either epoxy or silicone—matters a lot for the performance and life span of your battery encapsulation material. Each type has unique advantages, so pick based on your specific needs and environmental conditions.

The Importance of Non-Conductive Potting Compounds in EVs

In the fast-growing electric vehicle (EV) market, non-conductive potting compounds are key. They ensure the durability and long life of EVs. More importantly, they keep the electrical components safe and working well.

Isolating Electrical Components for Enhanced Safety

Non-conductive potting compounds provide top-notch insulation. This stops electricity from going where it shouldn’t, preventing short circuits. This is a big deal for battery safety. If physical barriers break, these compounds keep the electrical parts safe and working.

ZDS™ Innovations in Non-Conductivity

ZDS™ brings advanced technology into these potting compounds. This improves the safety of EVs by carefully controlling electrical flow. The creation of new non-conductive potting solutions shows a strong commitment to bettering battery safety in vehicles today.

Through ongoing innovation and thorough testing, the new potting compounds exceed safety and efficiency standards. They protect against common dangers with electric vehicle batteries.

Knowing how important this is, we focus on using non-conductive potting compounds. They handle heat, block water, and absorb shocks well. These advantages make non-conductive potting compounds critical for top performance and safety in EVs.

Custom Solutions: ZDS™ Tailored Potting Compounds for Unique Applications

Our passion is innovating and customizing. We rigorously develop custom potting compounds. They exceed manufacturer specifications for various unique applications. Each solution is a sign of our commitment to quality.

Meeting Manufacturer Specifications

We prioritize understanding and meeting manufacturer specs. Our team works closely with manufacturers. This ensures custom potting compounds fit their design and function, boosting performance and reliability.

Case Studies: Customization in Action

We’ve impacted battery systems with our custom potting compounds. They’re used by startups and big automotive firms. Each compound supports unique applications, meeting strict industry standards.

| Client Type | Application | Outcome |

|---|---|---|

| Automotive | Electric Vehicle Batteries | Enhanced Safety & Performance |

| Technology | Portable Consumer Devices | Increased Durability & Functionality |

| Industrial | Heavy Machinery | Improved Resistance to Extremes |

Our expertise in custom potting compounds shines in each case. We set industry benchmarks. Our work shows our ability to meet and adapt to manufacturer specifications and unique applications.

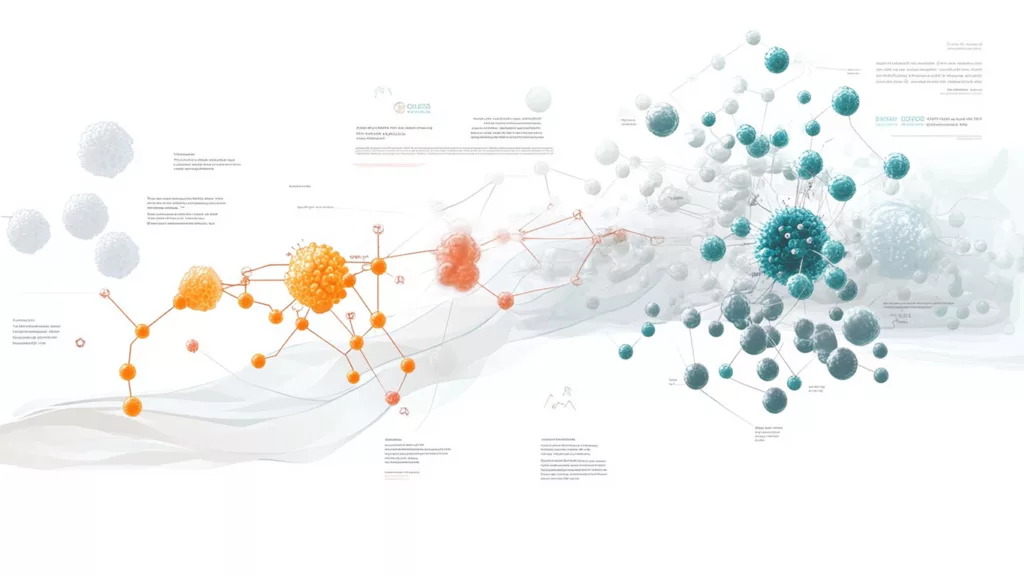

Addressing Vibration and Shock with ZDS™ Encapsulation Compounds

The need for durable and reliable battery systems in electric cars is growing. Materials that protect critical battery parts are very important. ZDS™ encapsulation compounds are made to perform well in extreme situations. They offer vibration and shock protection that is essential for the long life and safety of electric vehicles (EVs).

Protecting Critical Battery Components

In electric vehicle production, it’s vital to protect battery components. ZDS™ encapsulation compounds provide excellent mechanical protection. They keep the battery working safely, even in harsh driving conditions. This is especially important since EVs face many forces that could harm them without good shock absorption.

Long-term Resilience in Harsh Driving Conditions

ZDS™ encapsulation compounds can handle tough environmental and mechanical conditions. This means vehicles can reliably perform in different situations. Whether on rough ground or in stop-start traffic, these compounds keep protecting. This improves the battery system’s durability.

The science behind ZDS™ encapsulation compounds’ success lies in their curing and bonding properties. These are key to their shock and vibration dampening capabilities. Such qualities are invaluable for creating solutions that withstand harsh driving conditions. And they do this without losing vehicle safety or performance.

| Feature | Benefit | Application |

|---|---|---|

| High Elastic Modulus | Enhanced shock absorption | Critical under-hood components |

| Advanced Curing Properties | Strong bond formation | Battery enclosures |

| Thermal Stability | Operational integrity up to 150°C | High-temperature environments |

Through ZDS™ encapsulation compounds, we push forward what’s possible in EV tech. We ensure vehicles are ready for future challenges with today’s innovations.

High Temperature Potting Compounds: Withstanding the Extremes

In our journey, we found that high temperature potting compound is essential. These materials are made to handle extreme temperatures. They keep battery systems safe and working well.

It’s crucial to have extreme temperature resistance. We use these compounds to protect battery systems well. They are the result of advanced chemistry and thorough testing.

Here’s why our high temperature potting compounds are great for batteries:

- They have enhanced thermal stability, which stops them from breaking down at high temps.

- They’re really good at insulating, which prevents thermal runaway and short circuits.

- Their chemical structure is strong, making them last in hot conditions.

- They can be applied in many ways, letting us protect batteries perfectly.

Using high temperature potting compounds in your batteries is a smart move. It’s about safety, efficiency, and lasting performance. Picking the best potting solutions keeps our battery tech top-notch for future challenges.

Environmental Considerations and Sustainability in ZDS™ Compounds

We are leading the way in industrial innovation, always thinking about the environment. Our work with ZDS™ potting compounds improves battery efficiency. We do this with a focus on sustainability and eco-friendly methods.

Eco-friendly Formulations for a Greener Future

Our commitment to the environment is clear in our search for eco-friendly solutions. We choose materials that are good for our earth, helping to cut down on emissions and using renewable resources. This makes sure our products are not just up to par, but they also lead the way in environmental care.

Recyclability and End-of-Life Disposal of Batteries

The importance of a product’s entire life is just as big as how well it performs. That’s why we focus on recycling and the proper disposal of our ZDS™ batteries. Our team is dedicated to processing used products in a way that respects and protects our environment.

We include environmental thinking in how we make and plan the life of our products. This builds our role as a leader in sustainable manufacturing. Our actions not just follow rules but also set an example. We’re encouraging a move towards more eco-friendly industry practices.

Battery Potting Compound

Battery technology is complex, but choosing the right battery potting compound is crucial. These compounds boost battery performance and make them last longer. Let’s look at what makes a compound ideal and the great benefits it brings.

Criteria for Selecting the Right Compound

To pick the right battery potting compound, you need to think about a few key points. The right compound will not just make your battery work better. It also makes it safer and more durable.

- Temperature Resistance: The compound must handle the battery’s working temperature range.

- Chemical Resistance: It should resist chemicals, moisture, and corrosive materials it might meet.

- Electrical Insulation: Good electric insulation is vital to avoid short circuits and keep it safe.

These factors are very important in choosing correctly. They make sure your battery works well and safely in different situations.

Returns on Investment: The Long-term Benefits

Choosing top-quality battery potting compounds pays off. Here’s how they benefit you in the long run:

- Enhanced Performance: A good encapsulation boosts battery efficiency and performance, even in tough conditions.

- Increased Safety: Quality compounds minimize failure risks, making the battery system safer.

- Cost-Effectiveness: They extend battery life, cutting down the need for replacements and saving money.

These advantages highlight why it’s key to carefully pick based on specific criteria. It guarantees your battery performs well and safely.

Conclusion

We explored ZDS™ battery potting compound and saw how it helps new energy vehicles. This material protects advanced batteries in electric vehicles (EVs). It’s key for better performance and safety. ZDS™ compounds are important for managing heat and absorbing shocks. Thus, they help batteries meet today’s challenges.

ZDS™ compound is crucial for electric vehicle batteries to work well and last long. It protects key parts from damage and the environment. We talked about how important it is to pick strong solutions for new car technologies. These solutions help batteries work better and last longer.

In ending, choosing ZDS™ compounds means choosing a strong future for EVs. This choice ensures cars are durable and perform well. As EV technology grows, using advanced materials like ZDS™ will be key. It will help make green transportation more reliable and successful.

FAQ

What is the role of ZDS™ battery potting compound in new energy vehicles?

ZDS™ battery potting compound is crucial for new energy vehicles. It boosts the battery’s performance and safety. This ensures the battery lasts longer and is more reliable.

How do ZDS™ battery potting compounds boost performance and safety in the EV industry?

ZDS™ battery potting compounds enhance EV performance and safety. They insulate, seal, and protect the battery. This keeps the battery safe from moisture, shakes, and heat changes.

How does ZDS™ set the industry standard for battery encapsulation materials?

ZDS™ leads the way with top-grade potting compounds for batteries. These compounds ensure exceptional protection and meet high standards. They enhance performance and manage heat well.

What is the role of potting compounds in ensuring battery safety?

Potting compounds ensure battery safety through insulation and protection. They guard against moisture, shaking, and heat. This boosts the battery’s safety and reliability.

How do ZDS™ compounds contribute to enhanced thermal management?

ZDS™ compounds aid in better thermal management by effectively spreading out heat. They keep the battery’s temperature just right, increasing its life.

What are the key differences between epoxy and silicone potting compounds?

Epoxy offers great stickiness and protects against chemicals. Silicone handles temperature changes well and is flexible. Choosing depends on the battery’s needs.

How do non-conductive potting compounds enhance battery safety in EVs?

Non-conductive potting compounds boost EV battery safety. They keep electrical bits from touching, avoiding shorts. ZDS™’s non-conductive formulas add extra protection to electrical systems.

Does ZDS™ offer custom potting compounds for unique battery applications?

Yes, ZDS™ creates custom potting compounds for special battery needs. They work with manufacturers to meet precise requirements. Their case studies show their success in customization.

How do ZDS™ encapsulation compounds address vibration and shock in battery systems?

ZDS™’s compounds shield batteries from bumps and jolts. This keeps them working well even in tough driving conditions. It makes EV batteries last longer and stay reliable.

What is the significance of high temperature potting compounds in battery applications?

High temperature compounds are vital for batteries. They protect batteries in extreme heat. ZDS™’s high temperature compounds ensure the battery works well and lasts long despite temperature changes.

What are the environmental considerations and sustainability features of ZDS™ compounds?

ZDS™’s compounds are made with the environment in mind. They are eco-friendly, lowering emissions, and use sustainable materials. ZDS™ focuses on recycling and proper disposal of batteries.

What criteria should be considered when selecting a battery potting compound?

When choosing a potting compound, look at temperature and chemical resistance, and how well it insulates. Pick a high-quality compound to ensure the battery’s performance and safety.

What are the long-term benefits of using high-quality battery potting compound?

High-quality potting compounds improve performance and safety, offering good value. They protect the battery system, making it last longer and lowering the risk of problems.