Adhesives are integral to modern manufacturing, but their environmental impact has long been a concern. The rise of eco-friendly adhesives is revolutionizing industries, with UV adhesives leading the charge. Offering low VOC emissions, safer chemical formulations, and energy-efficient curing processes, UV adhesives are helping industries align with global sustainability goals.

Understanding Eco-Friendly Adhesives

Eco-friendly adhesives are formulated to minimize their environmental footprint. These adhesives replace harmful chemicals with safer alternatives, reduce energy consumption, and emit fewer pollutants, making them ideal for industries striving for sustainability.

Key Characteristics of Eco-Friendly Adhesives

- Low VOC Emissions: Reduced volatile organic compounds contribute to cleaner air.

- Energy Efficiency: Require less energy during application and curing.

- Biocompatibility: Safer for humans and wildlife.

- Recyclability: Many are compatible with recycling processes.

The Role of UV Adhesives in Sustainability

UV adhesives are a shining example of eco-friendly innovation, combining precision, durability, and environmental benefits.

1. Low VOC Emissions

Traditional adhesives often release VOCs that contribute to air pollution and health risks. UV adhesives, on the other hand, emit negligible VOCs due to their solvent-free formulations.

2. Energy-Efficient Curing

UV adhesives cure rapidly under UV light, requiring significantly less energy than traditional adhesives that depend on heat curing or lengthy drying times.

- Example: In electronics assembly, UV curing reduces energy usage by up to 40%, enhancing sustainability.

3. Safe Chemical Compositions

UV adhesives are designed with safer chemicals, eliminating toxic components like formaldehyde or solvents. This makes them suitable for:

- Medical devices: Biocompatible adhesives for catheters and implants.

- Food packaging: Non-toxic adhesives for safe food contact.

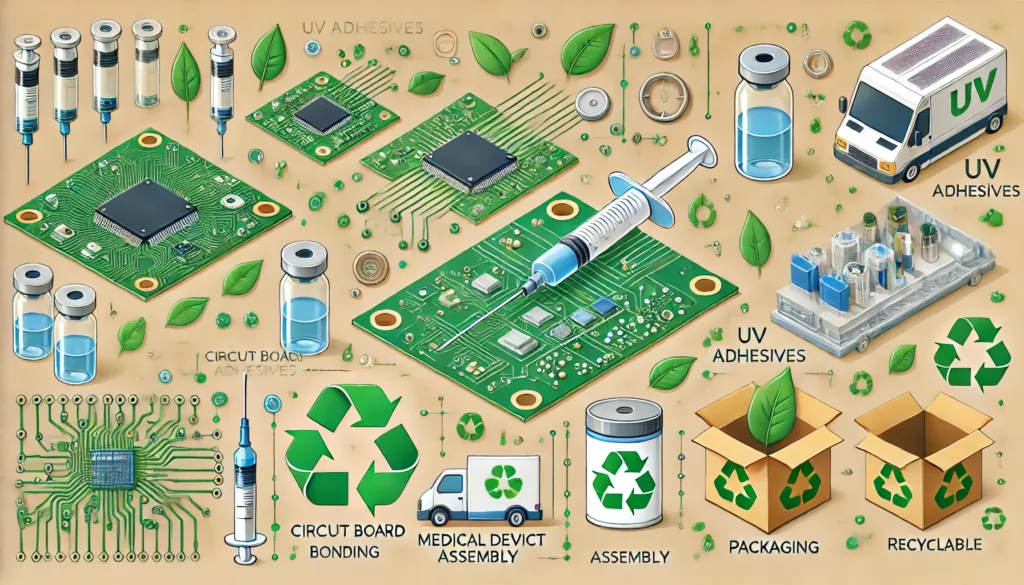

Industries Benefiting from UV Adhesives’ Sustainability

1. Electronics

In electronics manufacturing, UV adhesives provide precise bonding with minimal waste. Their quick curing enhances efficiency while their low-VOC formulations comply with environmental standards.

- Impact: Reduces hazardous waste and energy consumption.

2. Healthcare

Medical devices require adhesives that meet strict safety standards. UV adhesives are non-toxic, sterilizable, and reliable, making them the go-to choice for sustainable healthcare solutions.

- Example: Biocompatible adhesives in syringes and diagnostic equipment.

3. Automotive and Aerospace

Lightweight designs in vehicles and aircraft rely on UV adhesives for their durability and energy-efficient curing. These adhesives contribute to reducing overall emissions in transportation.

4. Packaging

Sustainable packaging demands adhesives that are safe, strong, and compatible with recycling. UV adhesives are increasingly adopted for eco-friendly labeling and carton sealing.

Comparing UV Adhesives to Traditional Adhesives

| Feature | UV Adhesives | Traditional Adhesives |

|---|---|---|

| VOC Emissions | Low to negligible | High |

| Energy Consumption | Low (UV curing) | High (heat or drying needed) |

| Toxicity | Safer chemical formulations | Often contains harmful solvents |

| Recyclability | Compatible with recycling | Often incompatible |

Challenges in Adopting Eco-Friendly Adhesives

While UV adhesives offer numerous sustainability benefits, challenges remain:

- Initial Costs: The equipment for UV curing can be expensive for small-scale manufacturers.

- Material Limitations: Certain UV adhesives may not bond well with low-surface-energy plastics.

- Education: Some industries are still unaware of UV adhesives’ environmental benefits.

Overcoming Challenges

- Cost Offsetting: Energy savings and reduced waste can offset initial equipment costs.

- Innovations: Advancements in UV adhesive formulations are expanding their material compatibility.

- Awareness Campaigns: Promoting the long-term benefits of eco-friendly adhesives encourages adoption.

UV Adhesives: A Key Player in Circular Economy Goals

UV adhesives play a critical role in the circular economy, which focuses on reducing waste and promoting recycling.

- Recyclable Bonds: Many UV adhesives are designed to be compatible with recycling processes, particularly in packaging and consumer goods.

- Resource Efficiency: Precise application reduces adhesive waste.

The Future of Eco-Friendly Adhesives

1. Bio-Based UV Adhesives

The next wave of eco-friendly adhesives includes bio-based formulations derived from renewable resources like plant oils or natural polymers.

2. Wider Industry Adoption

As regulations tighten and consumer demand for sustainable products grows, industries will increasingly adopt UV adhesives for their eco-friendly properties.

3. Enhanced Recycling Compatibility

Future developments will focus on adhesives that not only support recycling but also enhance the recyclability of bonded materials.

FAQs

How do UV adhesives contribute to sustainability?

UV adhesives emit low VOCs, cure quickly with less energy, and use safer chemicals, reducing environmental and health impacts.

Are UV adhesives suitable for food packaging?

Yes, many UV adhesives are non-toxic and safe for direct contact with food, making them ideal for sustainable packaging.

What are VOCs, and why are they harmful?

VOCs (volatile organic compounds) are chemicals that vaporize into the air, contributing to air pollution and health issues like respiratory problems.

Can UV adhesives be used in recycling processes?

Yes, many UV adhesives are compatible with recycling processes, making them ideal for circular economy goals.

Are UV adhesives cost-effective for small businesses?

While UV curing equipment may have high initial costs, long-term savings from reduced energy consumption and waste make them cost-effective.

What industries benefit the most from UV adhesives?

Electronics, healthcare, automotive, aerospace, and packaging industries benefit from UV adhesives’ precision, safety, and eco-friendly features.

Conclusion

The rise of eco-friendly adhesives reflects a broader shift toward sustainable manufacturing. UV adhesives stand out as a transformative solution, meeting environmental goals with low VOCs, safer chemical formulations, and energy-efficient curing. As industries continue to prioritize sustainability, UV adhesives will remain at the forefront, driving innovation and environmental stewardship across sectors. By adopting these eco-friendly solutions, manufacturers not only protect the planet but also gain a competitive edge in an increasingly eco-conscious market.