When it comes to commercial projects that require strong, durable bonds and a professional finish, two-part epoxy resin is often the adhesive of choice. Its superior strength, chemical resistance, and versatility make it ideal for a wide range of industrial applications. However, selecting the right type of epoxy resin for your specific needs can be daunting. This buyer’s guide aims to demystify the process and ensure you choose the perfect product for your project.

Epoxy resins are composed of two parts: the resin itself and a hardener. When mixed together, they undergo a chemical reaction that results in a hardened, sturdy material. But not all 2-part epoxies are created equal; they come in various viscosities, cure times, and with different properties tailored for specific uses.

Viscosity

- Low Viscosity: Ideal for applications requiring deep penetration, such as repairing hairline cracks or laminating.

- High Viscosity: Better suited for filling gaps or bonding uneven surfaces where a thicker adhesive is necessary to hold parts in place.

Cure Time

- Fast Curing: Good for quick repairs or projects on tight schedules but requires swift work to mix and apply before it hardens.

- Slow Curing: Provides more time to work with the material, which might be beneficial for complex assemblies or large-scale applications.

Key Properties

- Chemical Resistance: Necessary for environments exposed to harsh chemicals.

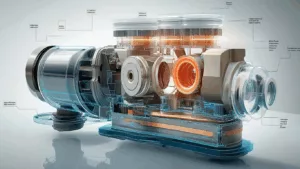

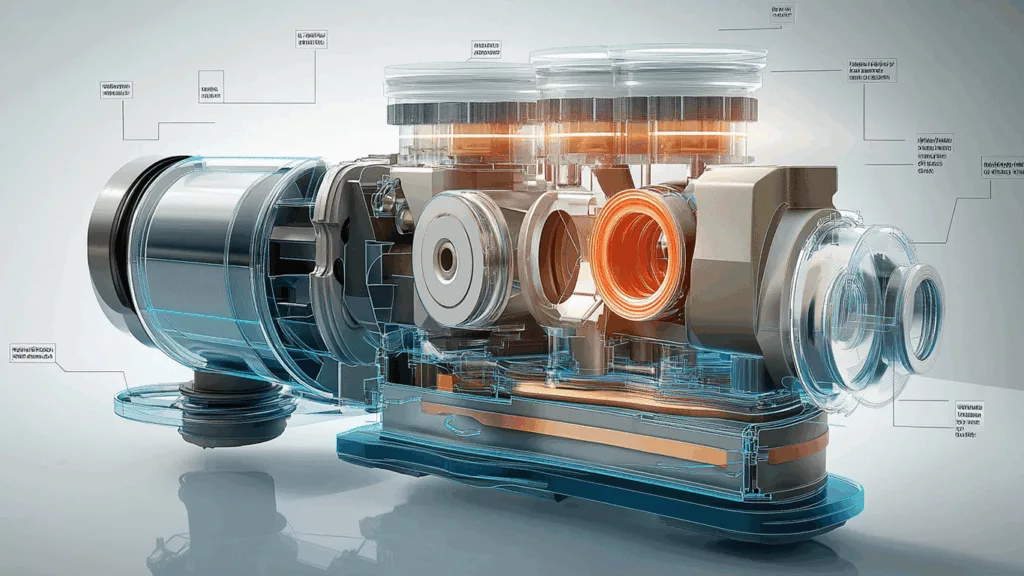

- Temperature Resistance: Important for components that will endure extreme temperatures.

- Electrical Insulation: A must-have for electronic applications.

Choosing the Right Epoxy Resin for Your Project

Before purchasing, consider these factors:

Application Type

Understand the primary use for the epoxy—whether it’s bonding, sealing, coating, or encapsulating—to determine the product features you need.

Material Compatibility

Ensure the epoxy is compatible with the materials you intend to bond. Some formulas are better suited for metals, while others adhere well to plastics or composites.

Environmental Exposure

Consider the environmental conditions the epoxy will face, such as UV exposure, humidity, or temperature extremes.

Purchasing Considerations

Quality and Performance

Always opt for high-quality products from reputable suppliers like ZDS™ to ensure consistent performance and durability.

Quantity and Packaging

Calculate how much material you’ll need for your project and check if the supplier offers the appropriate quantities, which can affect cost efficiency and waste.

Technical Support and Documentation

A supplier that provides excellent technical support and detailed product documentation can be invaluable, especially if you’re working with epoxy resins for the first time.

The right 2-part epoxy resin can make a significant difference in the success of your commercial project. By taking into account the specific requirements of your application and doing thorough research, you’ll be able to select a product that offers the best performance and value. Remember that partnering with a trusted manufacturer like ZDS™ not only gives you access to premium materials but also the expertise and support to ensure your project’s success.

For any commercial venture that demands quality and longevity, understanding the nuances of 2-part epoxy resin is essential. Armed with this guide, buyers can confidently navigate the market and procure the best adhesive solutions for their industrial needs.