Industrial adhesives are key in many fields, like cars, electronics, and construction. They help make products better and manufacturing faster. This guide will cover industrial adhesives, their types, uses, and how they perform. We’ll also look at the latest trends and what to consider when picking industrial glue.

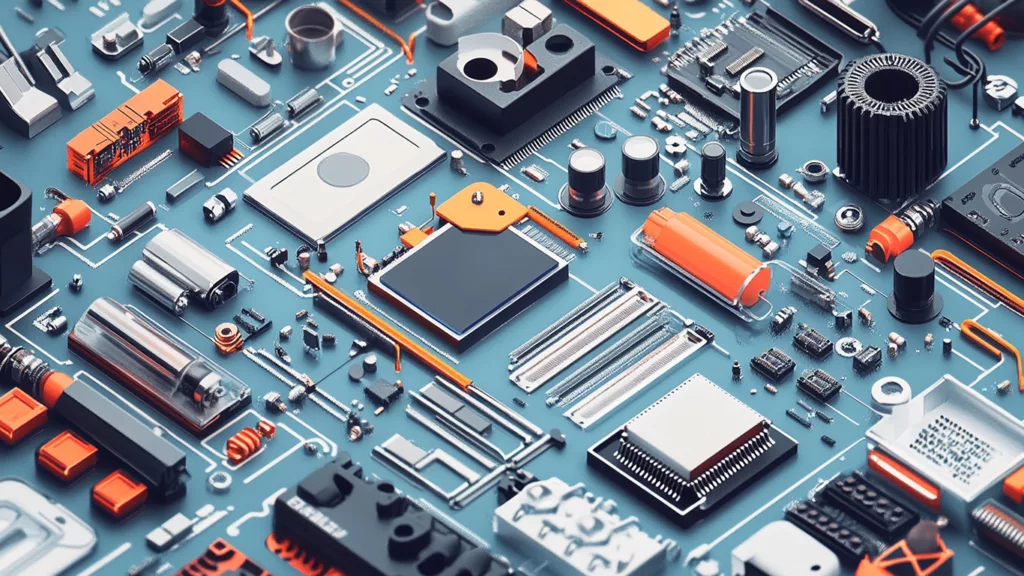

Types of Industrial Glue

Epoxy Adhesives

Epoxy adhesives are very versatile and widely used. They offer exceptional bonding strength and resistance to heat, chemicals, and moisture. They’re great for industries needing strong bonds, such as cars, planes, and electronics. Epoxy can bond materials like metal, plastic, and composites, making it perfect for tough jobs.

Benefits of Epoxy Adhesives:

- High mechanical strength: Epoxy glues can handle a lot of stress and vibrations, perfect for structural jobs.

- Resistance to environmental factors: These adhesives can handle harsh conditions, like high temperatures and chemicals Glue Savior 3M.

- Long-term durability: Epoxy bonds stay strong over time, keeping products safe in tough environments.

Polyurethane Adhesives

Polyurethane adhesives are known for their flexibility and strong adhesion to many surfaces. They’re more flexible than epoxies, making them good for jobs that need movement. They’re used in construction, packaging, and furniture making, bonding materials like wood and foam.

Key Features of Polyurethane Adhesives:

- Flexibility and resilience: These adhesives can absorb vibrations and allow for movement, reducing breakage risk Stacked Industrials Bostik.

- Moisture resistance: Polyurethane adhesives are used outdoors because they resist moisture and weather changes.

- Versatility: They bond with a wide range of materials, including wood, metal, and plastic.

Hot-Melt Adhesives

Hot-melt adhesives are used a lot in packaging and consumer goods. They’re applied when melted and solidify when cooled, creating a strong bond. They’re popular for their quick-setting time and ease of use, perfect for fast production lines.

Benefits of Hot-Melt Adhesives:

- Fast application: Their quick-setting nature boosts production speed.

- Minimal waste: Hot-melt adhesives solidify fast, cutting down on mess and waste Bostik.

- Cost-effective: These adhesives are affordable, making them great for big production runs.

Cyanoacrylate Adhesives (Super Glue)

Cyanoacrylate adhesives, also known as super glue, bond quickly. They are great for small, precise jobs. This makes them perfect for fast assembly in fields like electronics and medicine.

Features of Cyanoacrylate Adhesives:

- Instant bonding: These adhesives create strong bonds fast. They are great for quick assembly lines.

- Versatility: They stick well to many materials, like metal, plastic, rubber, and ceramics 3M Bostik.

- Ease of use: They dry fast, making them easy for repairs and small parts.

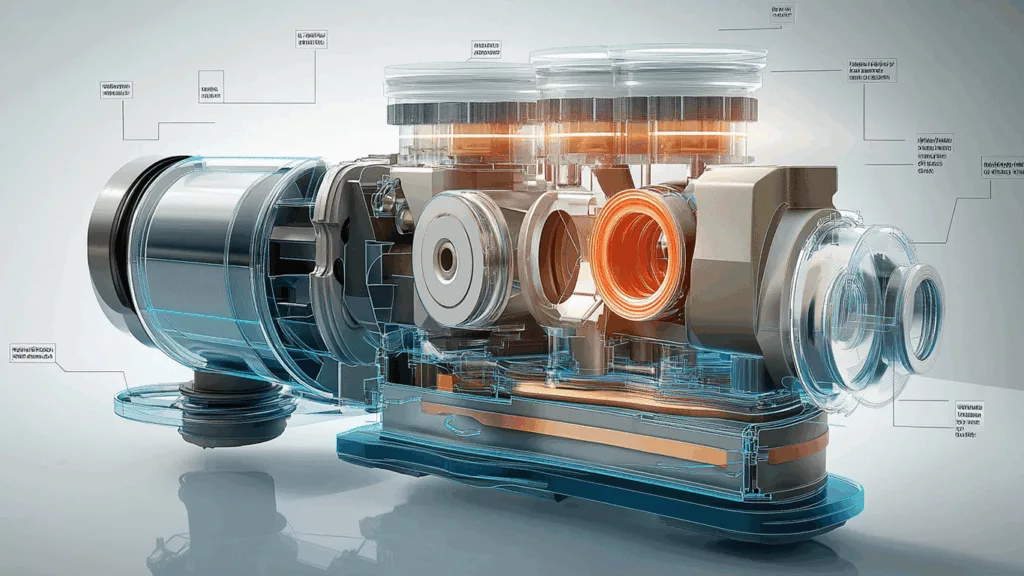

Key Performance Characteristics

Choosing the right industrial glue is key. You need to know what each job needs. Here are the main things to think about:

Strength and Durability

Strength and durability are top priorities. Jobs with lots of stress or movement need strong bonds. Epoxy adhesives, for example, are strong. They’re great for metal bonding in cars and planes Stacked Industrials.

Chemical and Environmental Resistance

Adhesives must stand up to harsh conditions. Polyurethane and epoxy adhesives are tough. They’re good for outdoor use or places with lots of heat and moisture 3M.

Material Compatibility

It’s important to choose adhesives that work with different materials. Not all glues stick to everything. For example, cyanoacrylate glues are good for plastics and ceramics. Epoxy adhesives work best with metals. When sticking different materials together, you need an adhesive that can handle it Glue Savior 3M.

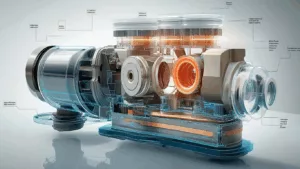

Applications of Industrial Glue

Manufacturing

In the manufacturing sector, glue is key for better production and quality. It’s used in automotive assembly and electronic component manufacturing. For example, epoxy adhesives are used in car making to bond metal. Polyurethane adhesives are better for interior assembly because they’re flexible.

Product Development and R&D

In product development and R&D, adhesives are used to replace mechanical fasteners. They allow for the use of lighter materials. Engineers and designers look for adhesives that bond advanced materials like composites and carbon fiber.

These materials are common in aerospace and sporting goods. Industrial glue also offers increased design flexibility. This allows for more streamlined and aesthetic product designs.

Maintenance and Repairs

Maintenance technicians use industrial adhesives for repairing equipment and machinery. Adhesives like epoxy or cyanoacrylate have high bond strength. They are perfect for quick fixes and structural repairs.

For industries in extreme conditions, like chemical plants or power stations, the right adhesive is key. It ensures long-lasting performance and reduces downtime. Glue Savior.

Safety and Environmental Compliance

Today, choosing adhesives that are environmentally friendly and safe is essential. Many industries, like electronics and automotive sectors, must follow RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) rules. 3M Bostik.

Low VOC Adhesives

Low VOC (volatile organic compound) adhesives are becoming more popular. They emit fewer harmful chemicals, making them safer for workers and the environment.

ZDS™ Solutions for Safety and Sustainability

When picking industrial adhesives, choose products from reputable companies like ZDS™. They focus on safety and sustainability. ZDS™ offers a wide range of adhesives that meet international regulations.

This gives companies peace of mind that their processes are safe and environmentally friendly.

Best Practices for Application and Troubleshooting

Installation and Application Techniques

Proper application techniques are vital for strong and lasting adhesive bonds. Make sure the surface is clean and free of contaminants before applying. Depending on the adhesive, roughening the surface may improve adhesion.

Following the manufacturer’s guidelines for curing times is also key to achieving maximum bond strength. Bostik.

Troubleshooting Common Issues

If an adhesive doesn’t bond correctly, it’s often due to improper surface preparation or incomplete curing. Using the wrong adhesive for the material can also lead to weak bonds. Make sure you’re using the right adhesive and following the recommended curing process to avoid these problems.

Conclusion

Choosing the right industrial glue is key for durability, efficiency, and safety in many areas. It’s important in manufacturing, maintenance, and product development. Knowing the different adhesives and their strengths helps you make better choices.

Whether you’re working with metal in a car factory or fixing equipment in tough conditions, ZDS™ industrial adhesives are up to the task. They offer strong, reliable solutions for the toughest challenges.

By following the best practices shared here, you can make sure your adhesive work lasts long and meets safety and environmental standards.