What is Thread Sealant?

Thread sealant is also known as “pipe thread sealant.” It is a special adhesive used to seal threaded joints. This prevents leaks of gases or liquids. Other sealants are for static uses, like concrete and windshield sealants. In contrast, thread sealant fills the space between threaded metal parts. It hardens into a seal that can bend without cracking. It can handle pressure, temperature changes, and vibrations without loosening.

Chemical Composition of Thread Sealant

Thread sealant’s chemical composition can vary. This depends on the brand and application needs. However, most thread sealants are made from polymers. Examples include polytetrafluoroethylene (PTFE), anaerobic resins, silicone, or a mix of these materials. Anaerobic thread sealants are popular. They stay liquid until they are kept from oxygen when the threads are engaged. Then, they cure to form a solid seal.

Uses of Thread Sealant

The versatility of thread sealant makes it suitable for a broad range of applications:

- Pipe Sealant: Often used in plumbing to ensure watertight seals on pipe threads.

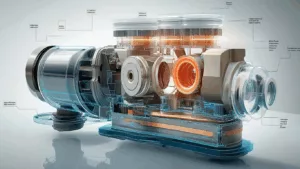

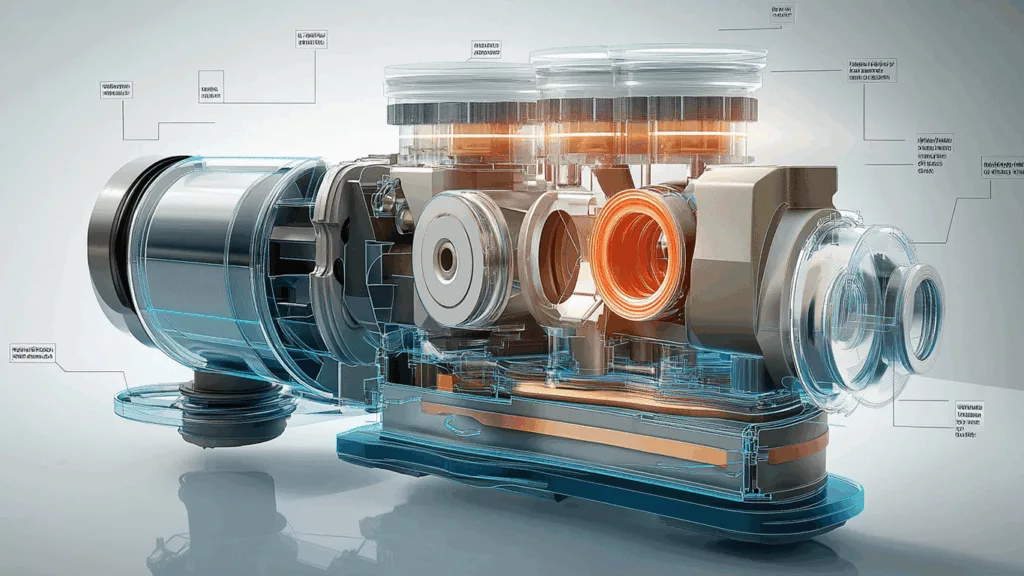

- Automotive Applications: Used to secure and seal threaded connections within engines and other automotive systems.

- Industrial Settings: Helps maintain the integrity of threaded joints under high-pressure conditions.

- HVAC Systems: Acts as a duct sealant to prevent air leaks in ventilation systems.

In essence, whenever there’s a need to prevent leaks in a threaded connection, thread sealant is likely to be an essential product.

Precautions When Using Thread Sealant

To maximize the effectiveness of thread sealant, consider the following precautions:

- Choose the Right Sealant: Ensure the thread sealant is compatible with the materials you’re working with and the environment it will be exposed to (e.g., chemicals, temperature extremes).

- Clean Threads: Before applying the sealant, make sure the threads are clean, dry, and free from grease or oil.

- Correct Application: Apply the correct amount of sealant, following instructions on the packaging. Over-application can lead to excess sealant squeezing out and potentially clogging or contaminating the system.

- Curing Time: Allow adequate time for the sealant to cure before subjecting the connection to pressure.

- Safety: Use thread sealant in a well-ventilated area and wear protective gloves if necessary, as some formulas may contain chemicals that are harmful if inhaled or come into contact with skin.