Use of polyurethane resin

Polyurethane resin is a powerful polymer loved for its strength, flexibility, and wide use in different fields. It’s made by combining polyol with a diisocyanate or a polymeric isocyanate, along with the right catalysts and additives. This process creates a material with customizable properties.

It plays a key role in many areas such as cars, healthcare, electronics, and building. This makes polyurethane essential in lots of products and gadgets.

Key Takeaways

- Polyurethane resin is respected for its robustness and adaptability.

- The polymer is formed by reacting polyol with diisocyanate or polymeric isocyanate.

- It has extensive applications across many industries, from automotive to construction.

- Versatile polyurethane applications are crucial in numerous products and devices.

- Its properties can be fine-tuned to meet specific needs.

Introduction to Polyurethane Resin

Polyurethane resin is both versatile and highly valuable. It plays a crucial role in many industries today. Its structure, made from mixing isocyanates and polyols, offers flexibility and strength.

The story of polyurethane starts in the 1930s with Dr. Otto Bayer. His groundbreaking work has made polyurethane a key material in science. It is used in everything from cars to everyday consumer products thanks to its light weight, durability, and versatility.

Polyurethane resin quickly became popular in various markets since the 1950s. It was first used in the aerospace sector. Now, it’s key in construction, electronics, and medical devices. Its ongoing development ensures it will remain important for future innovations.

Besides its many uses, polyurethane resin’s environmental impact is also considered. Efforts are being made to make it more eco-friendly. This means less pollution and better recycling processes. These efforts show polyurethane can meet high standards of performance while being better for our planet.

Properties of Polyurethane Resin

Polyurethane resin is loved for being so versatile. It’s chosen a lot across different fields. Let’s look at its amazing strength and how flexible it is.

Strength and Durability

One top thing about polyurethane resin is how strong it is. ZDS™ makes a tough kind of polyurethane resin perfect for hard situations. It’s great at fighting off wear, hits, and harmful chemicals, making it super reliable for tough jobs.

Flexibility and Elasticity

Polyurethane resin is also very bendy and stretchy. This flexible polyurethane is great for stuff that gets bent a lot or needs to be a bit bendy. It keeps its shape and bendiness even when it gets used over and over, which is really useful for lots of different work.

| Property | Advantages | Applications |

|---|---|---|

| Strength and Durability | Resistant to abrasions, impacts, and chemicals | High-stress environments |

| Flexibility and Elasticity | Withstands repetitive stress, maintains pliability | Items requiring flexibility and shape retention |

Types of Polyurethane Resin

Polyurethane resin comes in two main kinds—rigid and flexible. Each has unique traits for different uses. Knowing the types of polyurethane resin helps choose the right one for your needs.

Rigid Polyurethane Resin

Rigid polyurethane resins are tough and durable. They work well where strength and durability are needed. These resins are in insulation and electronics. They resist harsh conditions well.

In construction, they help keep buildings warm, saving energy. ZDSpoxy has top-notch rigid polyurethane resins for different industries.

Flexible Polyurethane Resin

Flexible polyurethane resins, however, are known for being soft and flexible. They’re used in furniture and car interiors for comfort. These resins make products that are both strong and cozy. They’re ideal for items we use every day. From soft sofas to car seats, flexible polyurethane adds comfort and durability.

| Type | Characteristics | Common Uses |

|---|---|---|

| Rigid Polyurethane Resin | High structural integrity, durability | Insulation, electronics, industrial components |

| Flexible Polyurethane Resin | Softness, cushioning | Furniture, automotive interiors, consumer goods |

When deciding which kind to use, think about what you need it for. Whether it’s sturdy rigid polyurethane uses in gadgets or the soft flexible polyurethane properties in couches, the right choice will give you the best results.

Manufacturing Process of Polyurethane Resin

Making polyurethane resin involves several careful steps. These steps ensure the resin performs well for different uses. It’s fascinating to see how these steps come together to make polyurethane resin.

It starts with making pre-polymers. In this step, polyols and diisocyanates mix together. This ensures the molecules are set up right for the next parts of the process. Then, pre-polymers meet curatives which begin forming the final resin.

The curing phase is up next. Here, a chemical reaction makes the resin strong and flexible. This reaction is key to getting the resin’s final qualities.

Let’s look at the process stages in the table below:

| Stage | Description |

|---|---|

| Preparation of Pre-Polymers | Mixing of polyols and diisocyanates to form a controlled molecular structure. |

| Mixing with Curatives | Introduction of curatives initiates the polymer network formation. |

| Curing | Chemical reaction that sets the final properties of the polyurethane resin. |

In the end, making polyurethane resin requires both science and technology. This process makes sure we have quality resin for many uses.

Benefits of Polyurethane Resin

Polyurethane resin is not just durable but versatile too. It benefits many industries in different ways.

One key benefit of polyurethane resin is its thermal insulation. It makes buildings more energy-efficient. This saves money for both homeowners and businesses.

It is also great for soundproofing. It cuts down noise, making homes and workplaces quieter. This is especially helpful in busy cities.

The advantages of polyurethane resin also include being eco-friendly. It’s a smart choice in today’s eco-conscious market. It offers durability and sustainability at a good cost.

Its flexibility leads to new ideas in many fields. From cars to medical tools, it helps meet unique needs. This makes it invaluable across different sectors.

For a closer look, check out the various uses of polyurethane resin in all sorts of industries.

| Benefits | Advantages |

|---|---|

| Thermal Insulation | Energy Efficiency |

| Soundproofing | Noise Reduction |

| Sustainability | Eco-Friendly |

| Versatility | Innovative Applications |

Innovative Uses of Polyurethane Resin

Polyurethane resin leads innovation in many areas. It shows its power in different fields by transforming modern applications.

1, In the Automotive Industry

The automotive polyurethane applications are vast, improving both inside and outside of vehicles. They are used in seats, dashboards, and bumpers. This makes driving safer and more comfortable.

2, In the Medical Devices

Polyurethane resin in medical devices is key for its safety and toughness. It’s used in things like catheters and wound dressings. These items help keep patients safe and heal faster.

3, In the Electronics

In electronics, polyurethane resin’s great for insulating. It helps circuit boards last longer and protects them. So, electronic devices work better and longer.

4, In the Construction

Polyurethane resin in construction means better insulation. It’s in panels, sealants, and glues. These help buildings use less energy and be eco-friendly.

5, In the Consumer Goods

Many everyday items come from polyurethane resin. It’s in furniture and shoes because it’s tough yet comfy. This makes these items last longer and feel better.

6, In the Textiles

In textiles, polyurethane resin is used for special fabrics. These fabrics are waterproof but breathe. They make clothes, shoes, and outdoor gear better and longer-lasting.

7, In the Aerospace

The aerospace world uses polyurethane resin for lighter materials. These help planes use less fuel and perform better. It’s in the cabin and parts that make the plane strong.

8, In the Renewable Energy

Renewable energy benefits from polyurethane resin in wind turbines. It makes them stronger and more flexible. This helps them produce energy longer and more efficiently.

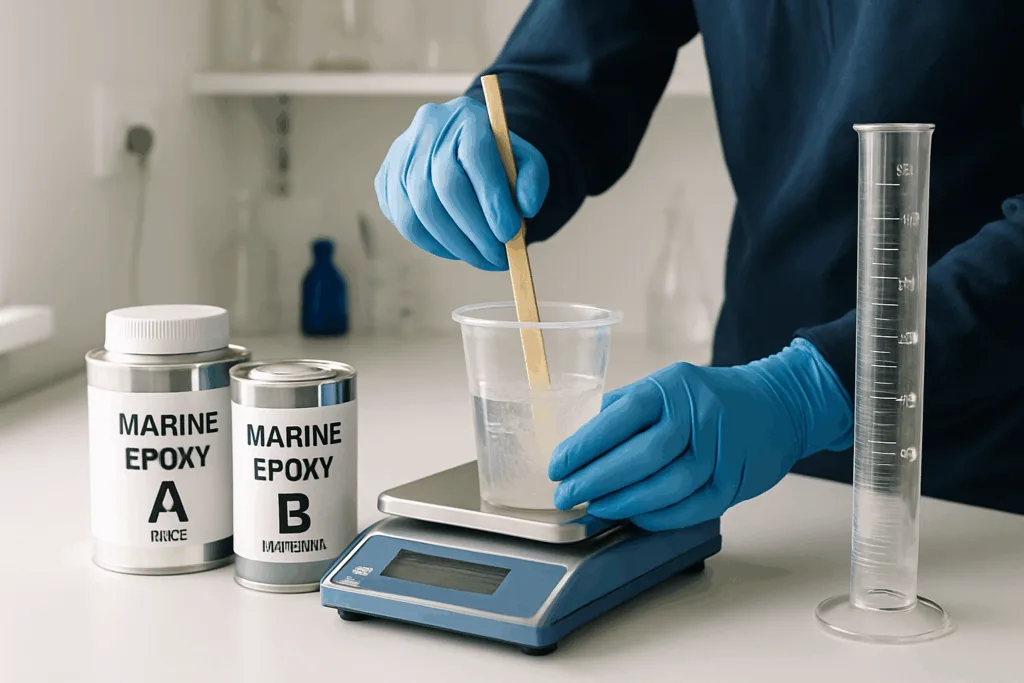

9, In the Marine Applications

Marine uses of polyurethane resin include boats and coatings. These fight off water and rust, making boats last longer and work better.

10, In the Art and Design

Artists and designers love polyurethane resin for its flexibility. They use it for both beautiful sculptures and practical furniture. Its ability to take any shape makes it perfect for creativity.

| Industry | Application Example |

|---|---|

| Automotive | Seats, Dashboards |

| Medical | Catheters, Implants |

| Electronics | Circuit Boards, Coatings |

| Construction | Insulation Panels, Sealants |

| Consumer Goods | Furniture, Footwear |

| Textiles | Waterproof Fabrics |

| Aerospace | Cabin Interiors, Structural Components |

| Renewable Energy | Wind Turbine Blades |

| Marine | Boat Hulls, Coatings |

| Art and Design | Sculptures, Furniture |

Conclusion

Polyurethane resin is vital across many industries. It is used in automotive applications and medical devices. This shows its innovation and performance. Its ability to meet various needs with reliability highlights summary of polyurethane resin benefits.

The resin is sustainable and efficient, making it more appealing. With a push for green solutions, its use in renewable energy is growing. In marine environments, ZDS marine epoxy resin shows its progressive nature. These points help understand concluding thoughts on polyurethane resin applications.

The future of polyurethane resin looks bright. It’s essential for both current and new technologies. As we evolve, its benefits will keep encouraging innovation in many fields. This discussion outlines a promising direction for industries in need of robust and efficient materials.

FAQ

What are the versatile applications of polyurethane resin?

Polyurethane resin is used in many industries, like construction and cars. Its strong and flexible nature makes it key in many products. For instance, it’s used in insulating panels, car seats, and electrical boxes.

Can you provide an overview of polyurethane resin?

Polyurethane resin is a type of plastic made from a special chemical reaction. It’s vital because it can be used in so many ways. This includes making things for construction, cars, and everyday products.

What are the primary properties of polyurethane resin?

Polyurethane resin is strong, durable, and flexible. Its ability to stretch and resist wear makes it perfect for tough conditions. It also stands up well against scratches, hits, and many chemicals.

What are the different types of polyurethane resin?

There are two main kinds: rigid and flexible. Rigid resins are great for things needing to keep their shape, like electronics. Flexible resins are used where a soft touch is needed, as in furniture.

What does the manufacturing process of polyurethane resin involve?

To make polyurethane resin, you start with pre-polymers, add curatives, and then cure it. This tailored process creates specific types of resin for different uses.

What are the benefits of using polyurethane resin?

Polyurethane resin is good for insulating and soundproofing. It’s strong and flexible, which sparks innovation and cost-efficient making.

How is polyurethane resin used in the automotive industry?

Polyurethane resin is in car inside and outsides, like seats and dashboards. It offers comfort and looks good, improving cars overall.

What role does polyurethane resin play in medical devices?

In medical devices, polyurethane resin is chosen for being safe and tough. It is used in items like catheters and surgical drapes, proving reliable in healthcare.

Why is polyurethane resin used in the construction industry?

For construction, polyurethane resin helps save energy. It insulates walls, roofs, and floors well, cutting down on energy use and costs.

What are some innovative uses of polyurethane resin in electronics?

In electronics, polyurethane resin keeps devices safe. It wraps around parts to shield them from moisture and dust.

How is polyurethane resin applied in consumer goods?

Polyurethane resin is in many daily items, like mattresses and sneakers. It’s chosen for its toughness, comfort, and bounce back.

Can you give examples of polyurethane resin’s use in the aerospace industry?

In aerospace, polyurethane resin is for light yet strong parts. It’s used in seats and cabin parts, important for safety and comfort in the air.

What are the benefits of polyurethane resin in renewable energy applications?

Polyurethane resin boosts renewable energy gear, making it last longer. It’s used in things like wind turbine blades and solar panels, enhancing performance.

How is polyurethane resin utilized in marine applications?

For marine uses, polyurethane resin is perfect due to its water resistance. It’s used on boat bodies and buoys, fighting off sea damage.

What role does polyurethane resin play in art and design?

In art and design, polyurethane resin lets creators make unique and lasting works. It’s great for sculptures and molds because it’s so adaptable.